تعيش أجزاء أمان السيارات ذات الجدران السميكة في أرضية وسطى غير مريحة: إنهم يريدون صلابة واتساق المعدن المطروق, لكنهم يحتاجون أيضًا إلى حرية الشكل وبنية تكلفة الصب. ولهذا السبب يستمر المهندسون في العودة إلى نفس السؤال: متى يكون HPDC منطقيًا, ومتى يتم الضغط على الخطوة الأكثر ذكاءً?

أدناه هو عملي, التفسير الهندسي الأول لكلتا العمليتين, ما الخطأ الذي يحدث بالفعل في الأقسام السميكة, وكيفية اختيار طريق الإنتاج دون الوقوع في شرك "أيديولوجية العملية".

لماذا تمثل قطع غيار السيارات ذات الجدران السميكة تحديًا؟

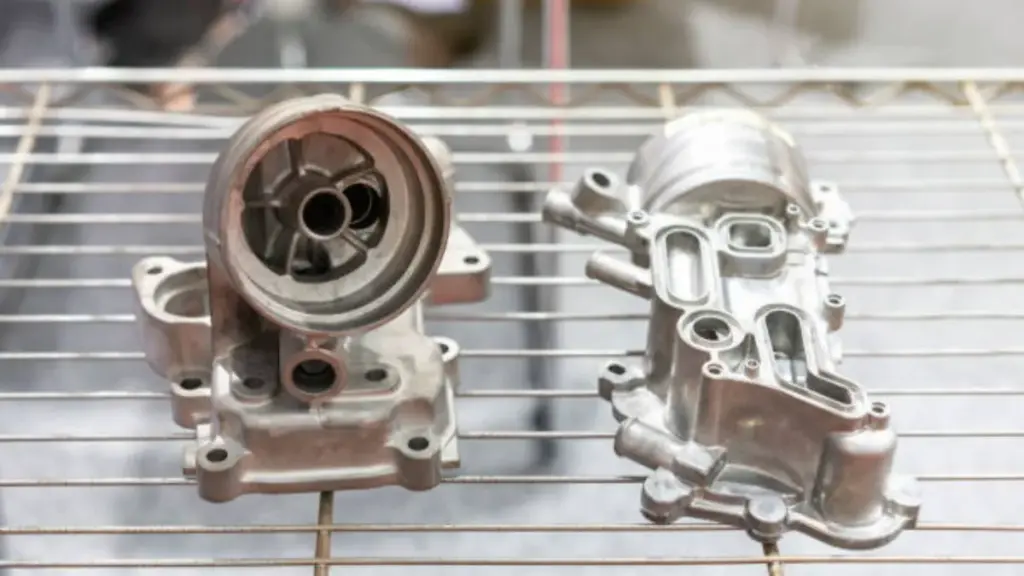

"الجدران السميكة" تبدو بسيطة, لكنه يغير كل شيء: تدفق المعادن, سلوك التبريد, تشكيل الخلل, وحتى أي المعالجات الحرارية واقعية. مكونات مثل مفاصل التوجيه, السيطرة على الأسلحة, ومساميك الفرامل ليست مكتنزة فقط; كما أنها ذات أهمية بالغة للسلامة, محملة بالتعب, وغالبًا ما تكون مليئة بالهندسة التي تجعل إلقاء الصوت أصعب مما يبدو.

إليك ما تتطلبه هذه الأجزاء عادة من عملية التصنيع:

- كثافة عالية ومسامية منخفضة, لأن الفراغات المخفية هي مبتدئات التعب ومسارات التسرب.

- أداء التعب موثوق, لأن مكونات التعليق والفرامل تشهد ملايين دورات التحميل, لا الأحمال الثابتة لمرة واحدة.

- ضيق الضغط (خاصة بالنسبة للأجزاء الهيدروليكية مثل الفرجار, المساكن, وأجسام الصمامات), حيث يمكن أن تصبح المسامية الدقيقة تسربًا حقيقيًا.

- التوافق مع المعالجة الحرارية (غالبًا ما يكون هناك شكل من أشكال تقوية المزاج مثل T6), لأن المصممين يريدون أهداف القوة/الليونة التي قد لا تلبيها خصائص "المصبوب"..

ما هو صب الضغط (تزوير السائل)?

ضغط الصب (غالبا ما يسمى المعدن السائل تزوير) من الأفضل وصفه بأنه طريق هجين يجمع بين قدرة شكل الصب والتكثيف الشبيه بالتزوير. يتم إدخال المعدن المنصهر لأول مرة في قالب لتشكيل الشكل الهندسي, ثم يتم الحفاظ على الضغط العالي أثناء التصلب حتى يتمكن المعدن من الاستمرار في التغذية أثناء انكماشه. القيمة الحقيقية ليست "قوة أعلى تلقائية".,"ولكن منظف, بنية داخلية أكثر اتساقًا - خاصة في المقاطع السميكة - لذا فإن متطلبات المصب مثل أداء الكلال, ضيق التسرب, وتصبح المعالجة الحرارية أكثر قابلية للتحقيق وأكثر تكرارًا.

- الوجبات الجاهزة الرئيسية: الحشو المتحكم فيه بالإضافة إلى التصلب المضغوط يمنع الانكماش- والعيوب المتعلقة بالغاز, مما يجعل سلامة الجدران السميكة والاستعداد للمعالجة الحرارية أكثر موثوقية من طرق التعبئة المعرضة للاضطرابات.

ما هو الصب بالضغط العالي؟ (HPDC)?

ارتفاع الضغط يموت الصب (HPDC) هي عملية عالية الإنتاجية يتم فيها حقن المعدن المنصهر في قالب فولاذي بسرعة وضغط عاليين, إنتاج أجزاء ذات شكل قريب من الشبكة مع تكرار أبعاد ممتاز. أكبر ميزة لها هي كفاءة التصنيع: أوقات دورة قصيرة, اتساق قوي بمجرد استقرار نافذة العملية, وتكاليف الوحدة تنافسية للغاية بكميات متوسطة إلى عالية. وتتمثل المقايضة في أن التعبئة عالية السرعة يمكن أن تزيد من مخاطر المشكلات المتعلقة بالاضطرابات - مثل الغاز المحبوس أو أغشية الأكسيد - خاصة في الأقسام أو التصميمات السميكة ذات التهوية الصعبة, والتي يمكن أن تظهر لاحقًا على شكل تعب مبعثر, مسارات التسرب, أو عدم الاستقرار أثناء المعالجة الحرارية للمحلول العدواني.

- الوجبات الجاهزة الرئيسية: HPDC يفوز بالسرعة, قابلية التوسع, والتكرار, لكن المقاطع السميكة تتطلب تصميمًا منضبطًا للقالب, استراتيجية التنفيس/الفراغ, ومراقبة العمليات لمنع العيوب الداخلية التي يمكن أن تحد من التعب, ضيق الضغط, ومتانة المعالجة الحرارية.

| غرض | صب الضغط (تزوير السائل) | صب القالب بالضغط العالي (HPDC) |

|---|---|---|

| فكرة العملية | "إلقاء الشكل, ثم اضغط أثناء التجميد" للتكثيف | "الملء السريع تحت الضغط" لتحقيق إنتاجية عالية |

| الميزة الأساسية | النزاهة الداخلية والاتساق (الكثافة أولاً) | إنتاجية, التكرار, وانخفاض تكلفة الوحدة على نطاق واسع |

| سلوك الجدار السميك | أكثر تسامحًا مع التغذية/المسامية في المناطق السميكة | ممكن, ولكنه يتطلب تهوية/فراغ أقوى + استراتيجية النابضة |

| راحة المعالجة الحرارية | بشكل عام أكثر ملاءمة للمعالجة الحرارية (انخفاض المخاطر المرتبطة بالغاز) | يمكن أن تكون محدودة في حالة وجود انحباس الغاز |

| أفضل ملاءمة نموذجية | السلامة الحرجة / محكم الضغط / أقسام سميكة يحركها التعب | الأجزاء المعقدة كبيرة الحجم حيث تهيمن التكلفة ووقت الدورة |

صب الضغط غير المباشر مقابل. HPDC للأقسام السميكة

لمكونات السلامة ذات الجدران السميكة, نادرا ما يكون القرار فلسفيا; إنه عملي. تعتمد العملية الصحيحة على مدى قربك من حدود تحمل المسامية, احتياجات المعالجة الحرارية, أهداف التعب, ومتطلبات التسرب.

طريقة مفيدة للتفكير في الأمر:

- HPDC مثالي عند السرعة, يكلف, والهندسة المعقدة هي الأكثر أهمية - ويمكن للجزء أن يتحمل مستوى واقعيًا من عيوب الصب (أو يمكن تصميم التصميم/العملية لإبقاء تلك العيوب تحت عتبة ضيقة).

- يصبح الصب بالضغط غير المباشر جذابًا عندما تحتاج إلى المزايا الهندسية للقالب المغلق بالإضافة إلى التغيير التدريجي في السلامة الداخلية, وخاصة في المقاطع السميكة.

| متري | HPDC | صب الضغط غير المباشر |

|---|---|---|

| سلوك الملء | تعبئة عالية السرعة, خطر الاضطراب | ملء تسيطر عليها, انخفاض الاضطراب |

| ميل المسامية | يجب إدارة انحباس/انكماش الغاز بشكل فعال | يتم قمع المسامية بقوة عن طريق الضغط أثناء التجميد |

| المعالجة الحرارية | غالبًا ما يقتصر على علاجات الحلول العدوانية | عادة ما يكون أكثر ملاءمة للمعالجة الحرارية |

| أفضل أنواع الأجزاء الملائمة | المساكن ذات الحجم الكبير, بين قوسين, يغطي, العديد من الأجزاء الهيكلية (مع الضوابط المناسبة) | السلامة الحرجة, أقسام سميكة, أجزاء محكمة الضغط, المرشحين استبدال مزورة |

| الملف الاقتصادي | أقل تكلفة للوحدة على نطاق واسع | وقت دورة أعلى; مبررة باحتياجات الجودة / العائد |

حيث يكون HPDC غالبًا "كافيًا"

يمكن أن يكون HPDC هو الحل الصحيح حتى بالنسبة للأجزاء السميكة:

- يمكن تحقيق المتطلبات الميكانيكية من خلال المعالجات اللاحقة "المصبوبة" أو الأكثر اعتدالًا,

- متطلبات ضيق الضغط معتدلة ويتم التحقق من صحتها عن طريق الاختبار,

- تسمح هندسة الجزء بإستراتيجية تنفيس/تجاوز قوية,

- والمسبك لديه مراقبة عملية منضبطة (ليس فقط الآلات).

حيث يكسب الضغط على الصب الاحتفاظ به

يميل صب الضغط إلى الفوز عندما:

- أداء التعب له هامش ضئيل,

- عتبات المسامية ضيقة للغاية ويجب أن تكون مستقرة مع مرور الوقت,

- يجب أن يكون إحكام الضغط قويًا بدون عمليات الختم الثانوية,

- ويجب أن يتحمل الجزء بشكل موثوق مسار المعالجة الحرارية المعزز.

يهتم مهندسو السلسلة المنطقية

- المسامية → خطر الإرهاق تعمل المسام مثل الشقوق الدقيقة. تحت التحميل الدوري, الشقوق تبدأ في مركزات الإجهاد, والمسام مرشحة مثالية.

- المسامية → خطر ضيق الضغط حتى لو اجتاز الجزء اختبار التسرب الأولي, يمكن أن تصبح المسامية الدقيقة المتصلة مشكلة ميدانية في ظل التدوير الحراري, اهتزاز, أو ظروف التآكل.

- المسامية ← قيود المعالجة الحرارية في حالة وجود غاز داخلي, العلاج بمحلول درجة الحرارة العالية يمكن أن يوسعه. هذا التوسع يمكن أن يسبب تقرحات, تشويه, أو ببساطة تقلب غير مقبول.

- القدرة على المعالجة الحرارية → سقف الخاصية الميكانيكية إذا لم تتمكن من تشغيل مزاج تقوية بشكل موثوق, قد تكون عالقًا بمجموعات أقل قوة / ليونة ويتعين عليك التعويض بالسمك (مما يجعل عملية الإرسال أكثر صعوبة، وهي حلقة مزعجة).

ماذا يعني هذا في الممارسة العملية

- أكبر ميزة ميكانيكية للصب بالضغط ليست "قوة أعلى بشكل افتراضي". إنه الاتساق – البنية المجهرية الكثيفة, عدد أقل من العيوب الكبيرة, وأداء أكثر قابلية للتنبؤ به بعد المعالجة الحرارية.

- لا يزال بإمكان HPDC تقديم نتائج قوية عندما يتم التحكم في تكوين الخلل بشكل فعال, لكن العملية تتطلب نظامًا هندسيًا أكثر صرامة: تصميم يموت, التنفيس, فارغ, جودة الذوبان, ومراقبة عملية مستقرة.

متى يجب الشراكة مع مورد قوالب الصب بالضغط العالي مثل Bian Diecast

عندما تنتقل المقالة من "ما هي العمليات" إلى "ما يجب فعله بعد ذلك".,"الشيء الأكثر فائدة للمهندسين والمشترين هو إطار القرار. إليك طريقة نظيفة لتوجيه هذا القرار دون المبالغة في الترويج لأي طريقة واحدة.

إطار اختيار بسيط

- اختر HPDC أولاً عندما:

- أنت بحاجة إلى حجم كبير وكفاءة في التكلفة,

- التعقيد الهندسي مرتفع,

- المعالجة الحرارية ليست عدوانية (أو غير مطلوب),

- ويمكن للمورد إثبات التحكم المستقر في سلامة الأجزاء المماثلة.

- التحقق من جدوى HPDC لأجزاء السلامة ذات الجدران السميكة عندما:

- أهداف التعب متطلبة ولكنها ليست متطرفة,

- يسمح التصميم بالتغذية/التهوية/التدفق المناسب,

- يمكنك الالتزام بتكرارات سوق دبي المالي المبكرة والتحقق من صحة النموذج الأولي.

- التحرك نحو الضغط الصب / تزوير عندما:

- يعتبر تحمل المسامية صارمًا للغاية ويجب أن يظل صارمًا خلال فترات الإنتاج الطويلة,

- المعالجة الحرارية مطلب صعب (وخاصة معالجة المحلول بحدود تشويه مشددة),

- أو أن مخاطر البرنامج مرتفعة ويكون "هامش العملية" أكثر أهمية من وقت الدورة.

ما الذي يجب إرساله إلى المورد للحصول على إجابة حقيقية

- 3نموذج د + ملاحظات الرسم ثنائية الأبعاد الهامة (جي دي&ت, التاريخ, أسطح الختم).

- الهدف سبيكة وتوقعات المزاج (أو أهداف الملكية إذا لم يتم إصلاح السبائك).

- الحجم السنوي والخطة المنحدرة.

- متطلبات الجودة: اختبار التسرب, الأشعة السينية/التصوير المقطعي, الاختبار الميكانيكي, توقعات التتبع.

- حيث فشل الجزء اليوم (أسباب الخردة, نقاط التسرب, مكان التعب, مناطق التشويه).

للفرق التي تبحث عن شريك HPDC مع دعم متكامل, تقوم Bian Diecast بتسويق نفسها حول تطوير الأدوات, يموت الصب, التصنيع باستخدام الحاسب الآلي, والتشطيب في سير عمل شامل - يكون مفيدًا عندما تتطلب الأجزاء ذات الجدران السميكة أكثر من "صب جيد" لتصبح مكونًا جيدًا.