ऑटोमोटिव लाइटवेटिंग में डाई कास्टिंग की भूमिका

डाई कास्टिंग भारी मल्टी-पीस स्टील असेंबलियों को सिंगल से बदलकर ऑटोमोटिव लाइटवेटिंग को संचालित करती है, हल्के एल्यूमीनियम या मैग्नीशियम घटक.

AZ91D और AM50A जैसे मैग्नीशियम मिश्र धातुओं का घनत्व लगभग 1.77-1.81 ग्राम/सेमी³ है।, पारंपरिक लौह सामग्री की तुलना में बहुत कम. इस बड़े घनत्व अंतर का मतलब है कि वे घटक द्रव्यमान में तक की कटौती कर सकते हैं 75% माइल्ड स्टील की तुलना में, जिसका घनत्व लगभग है 7.8 g/cm g. वे उपकरण पैनल बीम और सीट फ्रेम के लिए आदर्श विकल्प हैं.

A380 और ADC12 जैसे एल्यूमीनियम डाई-कास्टिंग मिश्र धातुओं का घनत्व लगभग होता है 2.7 g/cm g. यदि ये मिश्र धातुएँ स्टील की जगह ले लेती हैं, वे आम तौर पर 30-35% वजन बचत की पेशकश करते हैं. वे बेहतर संक्षारण प्रतिरोध भी प्रदान करते हैं. यही कारण है कि निर्माता भारी लौह इंजन ब्लॉक और ट्रांसमिशन मामलों के बजाय पावरट्रेन हाउसिंग और संरचनात्मक नोड्स में व्यापक रूप से उनका उपयोग करते हैं.

यदि कम घनत्व वाले मिश्र धातुओं को उच्च दबाव कास्टिंग तकनीकों के साथ लागू किया जाता है जो दीवार की मोटाई को कम करने की अनुमति देता है 2.0 मिमी, परिणाम प्रभावशाली हो सकते हैं. निर्माता तक हासिल कर सकते हैं 50% दुर्घटना सुरक्षा मानकों को बनाए रखते हुए संरचनात्मक भागों में वजन में कमी. यह दृष्टिकोण आंतरिक दहन और इलेक्ट्रिक वाहनों दोनों के लिए उद्योग के आक्रामक हल्के लक्ष्यों का समर्थन करता है.

पतली दीवार संरचनात्मक समाधान

हाई-प्रेशर डाई कास्टिंग (एचपीडीसी) संरचनात्मक डिजाइन को बदल रहा है. यह नीचे की दीवार की मोटाई को सक्षम बनाता है 2.0 मिमी और इंजीनियरों को केवल वहीं सामग्री रखने की सुविधा देता है जहां लोड पथों को इसकी आवश्यकता होती है. यदि स्टैम्प्ड स्टील असेंबलियों से तुलना की जाए, अंतर स्पष्ट है. उन पारंपरिक तरीकों में वेल्डिंग के लिए 2-3 मिमी के मोटे गेज और ओवरलैपिंग क्षेत्रों की आवश्यकता होती है. एचपीडीसी एक सटीक और वजन-कुशल विकल्प प्रदान करता है.

प्रमुख इंजीनियरिंग लाभ:

- परिशुद्ध सामग्री प्लेसमेंट: एचपीडीसी गैर-संरचनात्मक अनुभागों में धातु की मात्रा को कम करता है, घटक की कठोरता से समझौता किए बिना प्रभावी ढंग से वजन कम करना.

- क्रैश-क्रिटिकल प्रदर्शन: उन्नत वैक्यूम डाई कास्टिंग सरंध्रता को कम करती है, T7 ताप उपचार को सक्षम करना. यह शॉक टावरों जैसे सुरक्षा-महत्वपूर्ण अनुप्रयोगों के लिए उपज शक्ति को बढ़ाता है, पतले क्रॉस-सेक्शन की अनुमति देता है जो प्रभाव ऊर्जा को प्रभावी ढंग से अवशोषित करता है.

- भाग समेकन: यह प्रक्रिया जटिल ज्यामिति को एक में एकीकृत करती है “गोली मारना,” मल्टी-पीस स्टील असेंबलियों में आवश्यक भारी फ्लैंज और फास्टनरों को खत्म करना. उदाहरण के लिए, समेकित एल्यूमीनियम समाधान कुल स्टैक मोटाई को कम कर सकते हैं 3.6 मिमी (बनाम. 4.4 स्टील/राल समकक्षों के लिए मिमी), वाहन के वजन को सीधे कम करना.

ईवी बैटरी सिस्टम घटकों का विनिर्माण

जबकि लागत दक्षता के लिए बड़े बैटरी फ़्लोर शेल पर अक्सर स्टील की मोहर लगाई जाती है, महत्वपूर्ण आंतरिक वास्तुकला एल्यूमीनियम डाई कास्टिंग पर बहुत अधिक निर्भर करती है. अल ए380 और अल ए390 जैसे एल्यूमीनियम मिश्र धातु जटिल घटकों के निर्माण के लिए आवश्यक हैं जिनके लिए उच्च तापीय चालकता और सटीक ज्यामितीय सहनशीलता की आवश्यकता होती है - ऐसी विशेषताएं जो मुद्रांकित स्टील प्राप्त नहीं कर सकती हैं.

160T–1250T मशीनों से सुसज्जित सुविधाओं के लिए, सबसे अच्छी बात बैटरी मॉड्यूल एंड प्लेट्स के उत्पादन में है, इन्वर्टर आवास, और आंतरिक शीतलन ब्रैकेट. इन घटकों को गर्मी को कुशलतापूर्वक नष्ट करना चाहिए (-5°C और 45°C के बीच तापमान का प्रबंधन) वजन कम करते हुए. स्टील के विपरीत, जिसमें जटिल आकार बनाने के लिए बहु-भाग वेल्डिंग की आवश्यकता होती है, डाई-कास्ट एल्यूमीनियम कूलिंग चैनलों और माउंटिंग पॉइंट्स को एक में एकीकृत करने की अनुमति देता है, हल्का हिस्सा.

सामग्री चयन: जहां एल्युमीनियम जीतता है

एल्यूमीनियम और स्टील के बीच चयन केवल लागत के बारे में नहीं है; यह कार्य के बारे में है. फ्लैट के लिए स्टील को प्राथमिकता दी जाती है, आग प्रतिरोधी सुरक्षात्मक गोले, लेकिन थर्मल प्रबंधन और वजन घटाने के लिए एल्युमीनियम मानक है.

| प्रदर्शन मीट्रिक | एल्युमिनियम डाई कास्टिंग (जैसे, एडीसी12, ए 380) | उच्च शक्ति वाला स्टील (जैसे, स्टाम्प) |

|---|---|---|

| बेसिक कार्यक्रम | गर्मी लंपटता & संरचनात्मक जटिलता | अग्नि सुरक्षा & निचला प्रभाव |

| डिजाइन लचीलापन | उच्च (पसलियों को एकीकृत करता है, मालिकों, चैनल) | कम (साधारण आकृतियों तक सीमित) |

| ऊष्मीय चालकता | उत्कृष्ट (~100 W/m·K) | गरीब (~15-50 डब्लू/एम·के) |

| वजन लाभ | स्टील से ~35% हल्का | भारी (पतले गेज की आवश्यकता होती है) |

| लक्ष्य घटक | इन्वर्टर, अंत प्लेटें, कूलिंग माउंट्स | फर्श के गोले, कवर प्लेटें |

सटीक विनिर्माण प्रक्रियाएं और लीक-प्रूफ असेंबली

ऑटोमोटिव घटकों के उत्पादन के लिए आयामी सटीकता और दबाव की जकड़न सुनिश्चित करने के लिए मजबूत मशीनरी और कठोर दोष नियंत्रण रणनीतियों के संयोजन की आवश्यकता होती है.

हाइब्रिड असेंबली समाधान: हम केवल कच्ची कास्टिंग के अलावा और भी बहुत कुछ प्रदान करते हैं. हमारी असेंबली क्षमताओं में सटीक वेल्डिंग और चिपकने वाली बॉन्डिंग का उपयोग करके एक्सट्रूडेड सेक्शन के साथ डाई-कास्ट एल्यूमीनियम ब्रैकेट को जोड़ना शामिल है, बैटरी मॉड्यूल सिस्टम और इलेक्ट्रॉनिक बाड़ों के लिए टर्नकी समाधान की पेशकश.

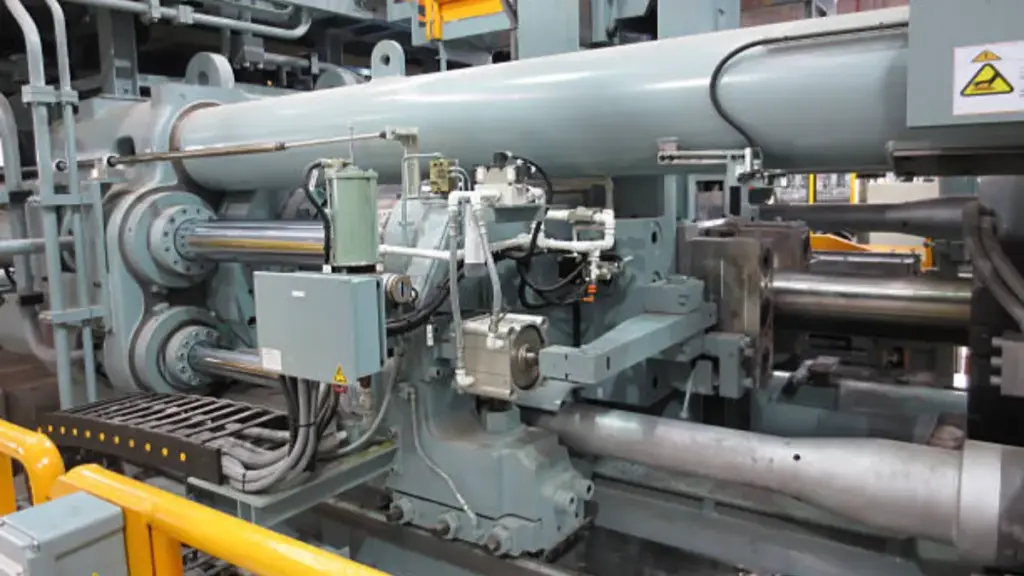

अनुकूलित टनभार क्षमता (160टी-1250टी): हमारी सुविधा 1250T तक की कोल्ड चैम्बर मशीनों से सुसज्जित है. यह क्षमता पावरट्रेन हाउसिंग के उच्च मात्रा में उत्पादन के लिए इंजीनियर की गई है, इलेक्ट्रिक ड्राइव इकाइयाँ (एडू), और संरचनात्मक कोष्ठक. यह फ़्लैश को रोकने और जटिल ज्यामिति में घनत्व सुनिश्चित करने के लिए आवश्यक सटीक लॉकिंग बल प्रदान करता है, बड़ी मशीनरी के अत्यधिक ओवरहेड के बिना.

उन्नत प्रवाह विश्लेषण: मैग्मासॉफ्ट प्रवाह सिमुलेशन और वैक्यूम सहायता प्रौद्योगिकियों का कार्यान्वयन गैस फंसाव को कम करता है. इससे सरंध्रता दोष कम होकर नीचे आ जाता है 0.1%, हाइड्रोलिक वाल्व बॉडी और लिक्विड-कूल्ड इन्वर्टर हाउसिंग के लिए एक महत्वपूर्ण मानक जिसे उच्च आंतरिक दबाव का सामना करना होगा.

लीक-प्रूफ पावरट्रेन & हाइड्रोलिक घटक

पावरट्रेन अनुप्रयोगों के लिए - जैसे ट्रांसमिशन हाउसिंग, हाइड्रोलिक वाल्व निकाय, और तेल पंप कवर- सरंध्रता नियंत्रण केवल एक मीट्रिक नहीं है. यह कार्यात्मक भाग और सिस्टम विफलता के बीच का अंतर है. निर्माता इन दबाव-महत्वपूर्ण घटकों का उत्पादन करने के लिए 160T-1250T डाई कास्टिंग कोशिकाओं का उपयोग करते हैं, जहां उद्योग मानक आम तौर पर कुल सरंध्रता मात्रा को सख्ती से नीचे रखने का आदेश देते हैं 3% हाइड्रोलिक द्रव रिसाव को रोकने के लिए.

The “एक बंद” गुणवत्ता लूप: कास्टिंग से संसेचन तक

शून्य-रिसाव प्रदर्शन प्राप्त करने के लिए कास्टिंग प्रक्रिया को पोस्ट-प्रोसेसिंग चरणों के साथ एकीकृत करने की आवश्यकता होती है. बियान डायकास्ट में, हम संरचनात्मक अखंडता सुनिश्चित करने के लिए संपूर्ण गुणवत्ता लूप का प्रबंधन करते हैं:

अनुकूलित कास्टिंग भौतिकी: हम गहनता चरण को सटीक रूप से नियंत्रित करके स्रोत पर दोष गठन को कम करते हैं. प्लंजर वेग को अनुकूलित करके और उच्च धातु दबाव लागू करके (60-100 एमपीए) जमने के दौरान, हम घना बनाने के लिए गैस के बुलबुले को संपीड़ित करते हैं, हाइड्रोलिक सर्किट के लिए आवश्यक गैर-छिद्रपूर्ण संरचना.

परिशुद्धता सीएनसी & रिसाव जोखिम: डाई कास्टिंग स्वाभाविक रूप से एक सघनता बनाती है “त्वचा” जो आंतरिक सूक्ष्म छिद्र को सील कर देता है. तथापि, सटीक सीएनसी मशीनिंग - हमारी एक मुख्य सेवा - सीलिंग फेस और वाल्व स्पूल बनाने के लिए इस त्वचा को काटती है. यह आवश्यक कदम सूक्ष्म छिद्रों को उजागर कर सकता है, संभावित रिसाव पथ बनाना.

वैक्यूम संसेचन समाधान: मशीनिंग के बाद दबाव की जकड़न की गारंटी के लिए, हम वैक्यूम संसेचन समाधान प्रदान करते हैं. यह प्रक्रिया खुले छिद्रों से हवा निकालती है और उन्हें एक टिकाऊ बहुलक राल से भर देती है. यह उच्च दबाव वाले संचरण तरल पदार्थों के खिलाफ कास्टिंग को स्थायी रूप से सील कर देता है, यह सुनिश्चित करना कि हमारे द्वारा वितरित मशीनीकृत घटक लीक-प्रूफ हैं और असेंबली के लिए तैयार हैं.

एल्यूमिनियम बनाम. ऑटो पार्ट्स के लिए जिंक

बियान डायकास्ट में, हम दोनों शीत कक्ष संचालित करते हैं (160टी-1250टी) और गर्म कक्ष (88टी-168टी) मशीनों, हमें आपके विशिष्ट ऑटोमोटिव एप्लिकेशन के लिए सही मिश्र धातु का मिलान करने की अनुमति देता है. एल्युमीनियम और जिंक के बीच का चुनाव मूल रूप से घटक के आकार पर निर्भर करता है, तापीय वातावरण, और दीवार की मोटाई की आवश्यकताएं.

अल्युमीनियम (एडीसी12, ए 380)

~2.7 ग्राम/सेमी³ के घनत्व और ~660°C के गलनांक के साथ, हल्के वजन और उच्च ताप वाले क्षेत्रों के लिए एल्युमीनियम निर्विवाद विकल्प है.

- प्रदर्शन: यह हुड के नीचे के तापमान को सहन करता है जो जिंक को नरम कर देगा, इसे इंजन और ई-ड्राइव घटकों के लिए आवश्यक बना दिया गया है.

- आवेदन: हमारे 1250T सेल ECU हाउसिंग के लिए एल्यूमीनियम का उपयोग करते हैं, ट्रांसमिशन कवर, और हीटसिंक जहां वजन में कमी और थर्मल अपव्यय महत्वपूर्ण हैं.

जस्ता (भार 3, 5)

जबकि भारी (~6.6 ग्राम/सेमी³), जिंक बेहतर तरलता प्रदान करता है, पतली दीवारों को सक्षम करना (नीचे तक 0.5 मिमी) और सख्त सहनशीलता (±0.0015 इंच/इंच) द्वितीयक मशीनिंग के बिना.

- आवेदन: हम उच्च परिशुद्धता कनेक्टर शेल का उत्पादन करने के लिए अपनी 88T-168T हॉट चैम्बर मशीनों का उपयोग करते हैं, सेंसर आवास, और दरवाज़ा लॉक तंत्र.

- क्षमता: जिंक कास्टिंग चक्र एल्युमीनियम की तुलना में 150-200% तेज है, और सांचे लंबे समय तक टिके रह सकते हैं 1,000,000 फुहार, उच्च मात्रा के लिए महत्वपूर्ण लागत बचत की पेशकश, छोटे प्रारूप वाले हिस्से.

वैक्यूम डाई कास्टिंग

मानक उच्च दबाव वाली डाई कास्टिंग अक्सर हवा को साँचे के भीतर फँसा देती है, आंतरिक सरंध्रता बनाना जो किसी घटक के यांत्रिक प्रदर्शन को सीमित करता है. इस पर काबू पाने के लिए, वैक्यूम-असिस्टेड हाई-प्रेशर डाई कास्टिंग (एचपीडीसी) इंजेक्शन वातावरण को मौलिक रूप से बदल देता है. धातु इंजेक्शन से मिलीसेकंड पहले मोल्ड कैविटी से गैस निकालकर, यह तकनीक एक वायुरोधी वातावरण बनाती है जो हवा को फंसने से रोकती है, सघनता सुनिश्चित करना, उच्च-प्रदर्शन वाले ऑटोमोटिव भागों के लिए आवश्यक गैर-छिद्रपूर्ण भराव.

हीट-ट्रीटेबल भागों के लिए वैक्यूम-असिस्टेड एचपीडीसी

वैक्यूम डाई कास्टिंग का प्राथमिक लाभ केवल सरंध्रता को कम करना नहीं है - यह प्रक्रिया के बाद के ताप उपचारों को अनलॉक करना है. मानक कास्टिंग में, जब हिस्सों को गर्म किया जाता है तो फंसे हुए गैस के बुलबुले फैलते हैं और सतह पर फफोले पैदा करते हैं. वैक्यूम सहायता गैस सामग्री को लगभग शून्य स्तर तक कम कर देती है, एल्यूमीनियम घटकों को सुरक्षित रूप से T6 या T7 ताप उपचार से गुजरने की अनुमति देना.

प्रमुख इंजीनियरिंग लाभ:

- संरचनात्मक अखंडता: हीट-ट्रीटेड वैक्यूम कास्टिंग काफी अधिक उपज शक्ति और बढ़ाव प्राप्त करती है. यह उन्हें सुरक्षा-महत्वपूर्ण के लिए उपयुक्त बनाता है “क्रैश नोड्स” सस्पेंशन टावरों की तरह, सबफ्रेम, और शरीर के खंभे, जहां सामग्री को बिना फ्रैक्चर के प्रभाव ऊर्जा को अवशोषित करना चाहिए.

- जुड़ने की योग्यता: गैस पॉकेट की अनुपस्थिति इन कास्टिंग को अन्य बॉडी-इन-व्हाइट में वेल्ड करने की अनुमति देती है (बेंच) संरचनाएं (जैसे, एल्यूमीनियम एक्सट्रूज़न या स्टील पैनल) झरझरा बनाए बिना, कमजोर वेल्ड जोड़.

- वास्तविक समय में निगरानी: उन्नत वैक्यूम सिस्टम वास्तविक समय में निकासी स्तरों की निगरानी के लिए सीधे डाई के अंदर सेंसर को एकीकृत करते हैं. ये सेंसर कैविटी को तुरंत सील करने के लिए वाल्व ट्रिगर करते हैं, यह सुनिश्चित करना कि प्रत्येक शॉट के लिए लगातार वैक्यूम दबाव बनाए रखा जाए, बड़े पैमाने पर उत्पादन के लिए प्रक्रिया स्थिरता की गारंटी.

गुणवत्ता आश्वासन: IATF से परे 16949 प्रमाणन

जबकिआईएटीएफ 16949:2016 प्रमाणीकरण ऑटोमोटिव आपूर्तिकर्ताओं के लिए आधार रेखा है, सच्चा गुणवत्ता आश्वासन अनुपालन ऑडिट से परे है. इसके लिए एक सक्रिय व्यक्ति की आवश्यकता है, असेंबली लाइन तक पहुंचने से पहले दोषों को रोकने के लिए जोखिम-आधारित दृष्टिकोण. हमारी सुविधा पर, हम यह सुनिश्चित करने के लिए उन्नत मेट्रोलॉजी के साथ कठोर प्रक्रिया नियंत्रण को एकीकृत करते हैं कि प्रत्येक घटक ओईएम की सख्त सुरक्षा और आयामी मानकों को पूरा करता है.

The 3 दोष निवारण के स्तम्भ

केवल अंतिम निरीक्षण पर निर्भर रहने के बजाय, हम पूरे उत्पादन चक्र में एक स्तरित गुणवत्ता रक्षा प्रणाली लागू करते हैं:

- सामग्री अखंडता & पता लगाने की क्षमता: गुणवत्ता पिघलने से शुरू होती है. हम प्रत्येक मिश्र धातु बैच की रासायनिक संरचना को सत्यापित करने के लिए ऑप्टिकल उत्सर्जन स्पेक्ट्रोमीटर का उपयोग करते हैं (एडीसी12, ए 380) कास्टिंग से पहले. आगे, प्रत्येक घटक पर लेजर मार्किंग तकनीक लागू की जाती है, एक स्थायी विशिष्ट पहचानकर्ता बनाना जो उस हिस्से को उसकी विशिष्ट उत्पादन तिथि तक ले जाता है, मशीन पैरामीटर, और कच्चा माल बहुत.

- प्रक्रियाधीन निगरानी & खोज: आंतरिक दोषों को पकड़ने के लिए जो नग्न आंखों से अदृश्य हैं, हम वास्तविक समय एक्स-रे निरीक्षण का उपयोग करते हैं. यह गैर-विनाशकारी परीक्षण (एनडीटी) ब्रेक घटकों और ब्रैकेट जैसे सुरक्षा भागों के घनत्व को मान्य करने के लिए महत्वपूर्ण है, यह सुनिश्चित करना कि कोई छुपी हुई सरंध्रता संरचनात्मक मजबूती से समझौता न करे.

- आयामी परिशुद्धता: जटिल मशीनीकृत भागों के लिए, हम पूरी तरह से स्वचालित समन्वय मापने वाली मशीनों का उपयोग करते हैं (सीएमएम). ये सिस्टम ज्यामितीय सहनशीलता को सत्यापित करते हैं (गोलों का अंतर&टी) माइक्रोन स्तर तक नीचे, यह सुनिश्चित करना कि महत्वपूर्ण विशेषताएं-जैसे कि बेयरिंग बोर और माउंटिंग सतहें-सीएडी मॉडल से पूरी तरह मेल खाती हैं.

वैश्विक विनिर्माण आपूर्ति श्रृंखला लचीलापन

हमारी सटीक इंजीनियरिंग से परे, बियान डाइकास्ट डुअल-शोर मैन्युफैक्चरिंग के माध्यम से रणनीतिक आपूर्ति श्रृंखला सुरक्षा प्रदान करता है. दोनों में स्थापित संचालन के साथ चीन और मेक्सिको, हम लचीले उत्पादन विकल्प प्रदान करते हैं जो लागत दक्षता को निकटवर्ती लाभों के साथ संतुलित करते हैं. यह वैश्विक पदचिह्न उत्तरी अमेरिकी ग्राहकों को टैरिफ जोखिमों को कम करने और लीड समय को कम करने की अनुमति देता है, यह सुनिश्चित करना कि आपके ऑटोमोटिव घटकों की डिलीवरी समय पर हो, वैश्विक व्यापार में उतार-चढ़ाव की परवाह किए बिना.

अक्सर पूछे जाने वाले प्रश्नों

ऑटोमोटिव डाई कास्ट भागों के लिए मानक सरंध्रता स्तर क्या है??

महत्वपूर्ण तनाव सहने वाली और सीलिंग सतहों के लिए, एएसटीएम ई505 जैसे उद्योग मानक आमतौर पर सरंध्रता को ≤ 0.5-1.0 मिमी व्यास तक सीमित करते हैं, श्रृंखला के आकार के छिद्रों के साथ सख्त वर्जित है. सामान्य कार्यात्मक क्षेत्र तक छिद्रों को स्वीकार कर सकते हैं 1.5 मिमी (एएसटीएम ई446 स्तर 2+), लेकिन पावरट्रेन घटकों को अक्सर यह सुनिश्चित करने के लिए वैक्यूम कास्टिंग की आवश्यकता होती है कि घनत्व इन कड़े विनिर्देशों को पूरा करता है.

ईवी बैटरी हाउसिंग के लिए एल्यूमीनियम पसंदीदा सामग्री क्यों है??

एल्युमीनियम प्रदान करता है 40% स्टील की तुलना में वजन में कमी, जो सीधे तौर पर इलेक्ट्रिक वाहन रेंज का विस्तार करता है. हल्के वजन से परे, इसकी उच्च तापीय चालकता तेज चार्जिंग के दौरान गर्मी का प्रबंधन करती है, और उन्नत 6xxx श्रृंखला मिश्र धातु (300-360 एमपीए उपज शक्ति) बैटरी पैक के लिए आवश्यक संरचनात्मक क्रैश सुरक्षा प्रदान करें.

A380 और ADC12 मिश्रधातुओं के बीच मुख्य अंतर क्या है??

ए 380 (अमेरिकी मानक) इसे इंजन ब्रैकेट जैसे उच्च-लोड भागों के लिए चुना जाता है क्योंकि इसमें तांबे की मात्रा अधिक होती है (3-4%) बेहतर कठोरता और ताकत प्रदान करता है. एडीसी12 (जापानी मानक) उच्च सिलिकॉन सामग्री की विशेषता है (तक 12%), बेहतर तरलता और संक्षारण प्रतिरोध प्रदान करना, इसे कॉम्प्लेक्स के लिए आदर्श बनाना, पतली दीवार वाले इलेक्ट्रॉनिक आवास.

वैक्यूम डाई कास्टिंग ऑटोमोटिव घटकों को कैसे बेहतर बनाती है?

वैक्यूम डाई कास्टिंग इंजेक्शन से पहले मोल्ड से हवा निकाल देता है, गैस सरंध्रता को लगभग शून्य स्तर तक कम करना. यह संरचनात्मक अखंडता भागों को बिना ब्लिस्टरिंग के टी 6 ताप उपचार और वेल्डिंग से गुजरने की अनुमति देती है, जो सस्पेंशन टावरों और ट्रांसमिशन मामलों जैसे सुरक्षा-महत्वपूर्ण घटकों के लिए आवश्यक है.

ऑटोमोटिव डाई कास्टिंग मोल्ड आमतौर पर कितने समय तक चलते हैं?

एल्युमीनियम डाई कास्टिंग मोल्ड का जीवनकाल आम तौर पर होता है 80,000 को 150,000 फुहार, साथ 100,000 बड़े पैमाने पर उत्पादन के लिए साइकिलें मानक डिज़ाइन लक्ष्य हैं. इसके विपरीत, जिंक मोल्ड कम तापमान पर काम करते हैं और अक्सर इससे अधिक भी हो सकते हैं 500,000 को 1,000,000 चक्र.

ऑटोमोटिव डाई कास्टिंग के लिए सबसे बड़ा लागत चालक क्या है??

टूलींग परिशोधन एक प्राथमिक लागत चालक है, अक्सर चारों ओर जोड़ते रहते हैं $1.50 प्रति किग्रा (मोटे तौर पर 15-20% कुल भाग लागत का) 200,000-शॉट से अधिक मोल्ड जीवन. जटिल भाग ज्यामिति टूलींग की लागत में काफी वृद्धि करती है, प्रारंभिक निवेश के परिशोधन में उत्पादन की मात्रा को एक महत्वपूर्ण कारक बनाना.