The debate over gravity casting vs die casting often determines whether a critical component fails under load or performs reliably for its entire service life, directly impacting warranty claims and field safety. Choosing the wrong process introduces hidden risks that only surface late in production or, worse, after deployment. A part with unchecked internal porosity might pass initial QC but can lead to catastrophic mechanical failure, triggering costly product recalls and exposing your company to significant liability.

This guide provides a technical framework for making an informed decision. We will break down the core mechanics of gravity flow versus high-pressure injection, then establish the economic breakeven point based on tooling and per-unit costs. We’ll also compare production speed, आयामी सटीकता, and the critical issue of mechanical integrity, showing why porosity is often the ultimate dealbreaker in process selection.

Rapid Comparison Table

The choice between gravity and pressure casting is a direct trade-off between upfront tooling investment and the required per-part production speed and geometric complexity.

Manufacturing Process and Cycle Time

The core operational difference is the filling method. Gravity casting uses natural gravitational flow to fill the mold, a slower process with a cycle time of 2-10 minutes. Pressure die casting injects molten metal at high pressure, typically 150 को 1200 bar, completing a cycle in just 10 को 60 seconds. This speed differential dictates the suitable part geometry. Gravity casting is best for simpler shapes with thicker walls (3-10मिमी), while pressure casting excels at producing intricate designs with thin walls (1-5मिमी).

Mechanical Properties and Final Quality

Final part quality and performance diverge significantly. Gravity casting’s slower, controlled fill produces dense parts with very low internal porosity, making them exceptionally well-suited for heat treatment to enhance mechanical properties. Pressure casting, while offering superior dimensional accuracy (±0.1mm) and an excellent surface finish (Ra 0.8-3.2μm), traps gas during its rapid injection cycle. This resulting porosity makes pressure cast parts generally unsuitable for heat treatment, as the process can cause blistering and distortion.

Tooling Costs and Ideal Production Volume

The economic decision depends entirely on production volume. Gravity casting requires a moderate initial tooling investment, making it cost-effective for low-to-medium volume runs. Pressure die casting demands a high initial investment for complex, durable molds but delivers a much lower per-part cost in mass production due to its high efficiency and automation.

- Gravity Casting: Select for low-to-medium volume production, larger parts, or components requiring post-cast heat treatment for maximum strength.

- प्रेशर डाई कास्टिंग: The correct choice for high-volume, mass production of complex, thin-walled components where tight tolerances and a superior surface finish are critical.

Gravity Flow vs. उच्च दबाव इंजेक्शन

This choice is a direct trade-off between mass production speed and the metallurgical integrity required for mission-critical applications.

Mold Filling Method and Production Speed

High-pressure injection forces molten metal into a mold at pressures between 150 और 1200 bar. This method is incredibly fast, filling the mold in milliseconds and achieving cycle times of just 10 को 60 seconds. Such speed makes it the standard for mass production, enabling a single machine to produce over 200 parts per hour. इसके विपरीत, gravity casting uses only natural gravitational force to fill the mold. This slower, more controlled flow leads to significantly longer cycle times of 2 को 10 minutes, limiting output to a range of 30-50 parts per hour and making it suitable for smaller production runs.

Component Integrity and Material Properties

Gravity casting’s slow, laminar filling process minimizes turbulence, resulting in denser parts with very low internal porosity. This superior metallurgical quality makes gravity-cast components highly receptive to heat treatment for enhanced strength and ideal for applications requiring guaranteed airtightness. High-pressure injection delivers an excellent surface finish (Ra 0.8-3.2μm) and tighter dimensional tolerances (±0.1mm), as the force captures every fine detail of the mold. The trade-off is that its rapid filling can trap air, creating internal porosity that compromises heat treatability and sealing performance.

Tooling Investment and Application Suitability

The initial investment for high-pressure injection tooling is high. Dies must be built from robust tool steel to endure extreme, repeated cycles, which is only economically feasible for high-volume production. This makes it the cost-effective choice for manufacturing complex, thin-walled components in large quantities. Gravity casting tooling is less complex and requires a more moderate investment, making it the practical option for small-to-medium volume runs. It is best applied to producing larger, simpler parts where structural integrity and minimal porosity are more critical than intricate design or rapid output.

IATF-Certified Die Casting for Zero-Defect Components

लागत विश्लेषण: Finding the Economic Breakeven Point

Selecting the right casting process depends on a breakeven analysis where high upfront tooling costs are justified by high-volume production and lower per-unit expenses.

Mapping Initial Investment: Tooling and NPI

The primary fixed cost in any casting project is mold development, which we typically execute at our China technology center to leverage cost efficiencies and deep engineering expertise. The investment level varies significantly between processes. Pressure die casting molds require a high initial investment, often exceeding $20,000, as they are built from high-grade tool steel to withstand extreme injection pressures. Gravity casting molds are simpler and represent a more moderate investment. This initial budget must also account for New Product Introduction (एनपीआई) costs, which include rapid prototyping for design validation and the production of initial samples for testing and approval.

Calculating Variable Per-Unit Production Costs

The variable per-unit cost is a composite of three key factors. First is the raw material cost, which we track based on current market rates for alloys like ADC12, ए 380, or Zamak 5, ensuring material consistency across all production bases. Second is the manufacturing overhead, which includes labor and machine time. These costs differ between our China, मेक्सिको, और वियतनाम सुविधाएं, allowing us to align production with specific budget or logistical targets. The third component is the cost of any required secondary operations, such as precision CNC machining, surface finishing like powder coating, or sub-assembly tasks.

Integrating Tariffs and Logistics into Landed Cost

The final cost per part—the landed cost—extends beyond the factory gate. We actively model the impact of import duties, leveraging our global footprint for tariff optimization. उदाहरण के लिए, using our Vietnam facility and its Certificate of Origin (C/O) can significantly reduce duties for clients in certain Western markets. Our models also factor in all logistics variables, including freight, insurance, and customs clearance from each potential shipping origin. Minimum Order Quantities (MOQs) play a crucial role here; for shipments from Vietnam and Mexico, meeting the recommended 3,000-5,000 piece MOQ helps amortize fixed shipping costs across more units, driving down the per-part landed cost.

Determining Volume Thresholds for Process Selection

The breakeven point is where the total cost of one process becomes more economical than another. Pressure die casting, with its high tooling cost but rapid cycle times (as low as 10-60 seconds), is built for high-volume runs where the low per-unit cost quickly offsets the initial investment. Gravity casting, with its lower tooling costs but slower cycle times (2-10 minutes), remains the cost-effective choice for small-to-medium production volumes, typically from a few hundred to 50,000 parts annually. The decision isn’t purely financial; gravity casting is also the technically superior option for parts that require subsequent heat treatment to enhance mechanical properties, as its slower fill process results in a less porous internal structure.

Modeling Total Cost of Ownership Scenarios

We model total cost of ownership using a clear formula: Total Cost = Tooling + (Per-Unit Cost × Volume) + रसद + Tariffs. This allows for direct comparisons between different strategic scenarios. A high-volume project for the US market might show the best TCO when produced in Mexico for nearshoring speed or in Vietnam for tariff advantages. An equivalent project for the EU market may find that direct production from our China base is the most efficient path. Beyond these numbers, we treat supply chain resilience as a real financial factor. हमारा “चीन + 2” global layout provides a backup against regional disruptions, protecting revenue and ensuring supply continuity, which is a critical component of long-term cost modeling.

Production Capabilities: रफ़्तार, Accuracy, and Complexity

High-pressure die casting is engineered for mass production, delivering complex, net-shape parts with high precision and speed, which directly lowers per-unit costs on large volume orders.

High-Speed Production Cycles for Mass Volume

Our automated pressure die casting process executes cycles in as little as 10 को 60 seconds per part, a rate built for high-volume manufacturing. This efficiency makes the process ideal for orders of 3,000 को 5,000 units or more, where the initial investment in tooling is effectively amortized across a large production run. The rapid, consistent output is essential for supplying demanding sectors like automotive manufacturing and 5G telecommunications, where components like powertrain systems and equipment enclosures require both scale and reliability.

Achieving Tight Tolerances and Surface Finish

We consistently hold dimensional tolerances of ±0.1mm for the first 25mm of a feature, minimizing the need for costly secondary machining. This level of precision is paired with a superior as-cast surface finish, typically between Ra 0.8 and 3.2μm, which is suitable for direct use or ready for subsequent treatments like powder coating or anodizing. To guarantee these specifications, all our facilities verify component quality using Coordinate Measuring Machine (सीएमएम) full dimensional inspections and X-Ray flaw detection, ensuring every part meets IATF 16949 मानकों.

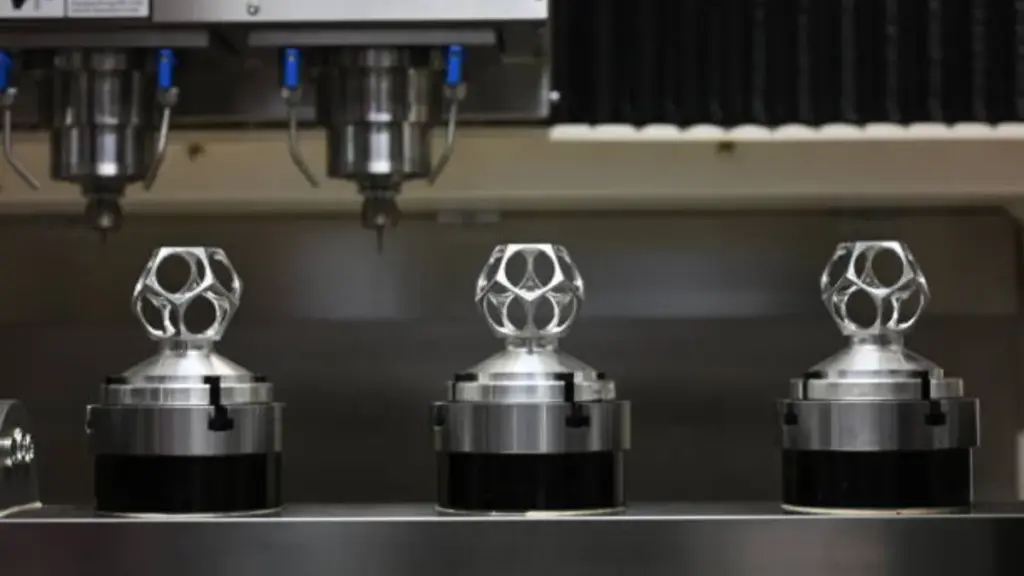

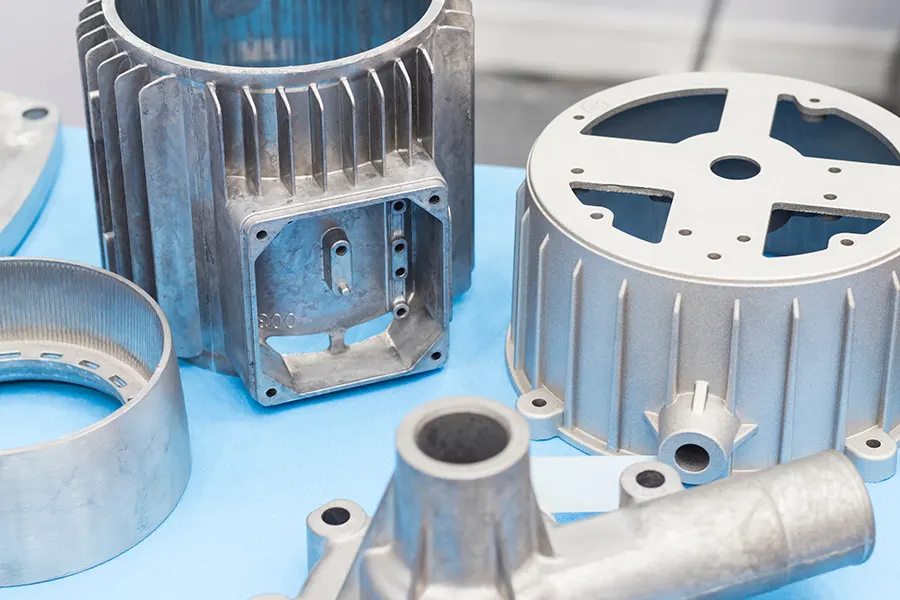

Manufacturing Complex Geometries and Thin-Walled Parts

The high-pressure injection process is uniquely suited for producing intricate parts with thin walls, ranging from 1mm to 5mm. Molten metal is forced into every detail of the mold cavity, allowing us to cast complex features like integrated heat sinks, structural ribs, and mounting bosses directly into the component. This capability is critical for manufacturing lightweight, high-strength parts for New Energy Vehicle (एनईवी) systems, industrial automation sensors, and other applications where design complexity and weight reduction are primary engineering goals.

Mechanical Integrity: क्यों “सरंध्रता” is the Dealbreaker

Porosity creates invisible internal weaknesses that compromise strength and airtightness, making it the primary failure point in load-bearing or sealed die-cast components.

How Trapped Gas Creates Internal Voids

High-pressure die casting forces molten metal into a mold at extreme speed and pressure, a process that inevitably traps ambient air and dissolved gases. This turbulence creates microscopic bubbles that become permanent voids as the metal rapidly solidifies. Gravity casting uses a fundamentally different approach. Its slower, controlled filling process allows molten metal to flow smoothly into the mold, giving gases time to escape before the part solidifies. The result is a denser, more solid internal structure with minimal internal voids.

Impact on Strength, Sealing, and Heat Treatment

Porosity is a critical structural defect, not a minor cosmetic flaw. Each internal void acts as a stress concentration point, creating a microscopic weak spot that can initiate cracks or fractures under mechanical load or vibration. For applications like hydraulic manifolds or sealed 5G enclosures, these internal voids directly compromise the part’s ability to maintain a pressure seal, leading to component failure. Attempting to heat-treat a porous part is also ineffective. The trapped gas expands when heated, which often results in surface blisters and further damage to the component’s structural integrity.

Process Selection for High-Density Components

The choice between casting methods depends entirely on the part’s functional requirements. Gravity casting is the preferred process for components where mechanical strength and pressure tightness are non-negotiable design criteria. For these critical applications, validating the internal structure is a mandatory quality control step.

- We utilize X-Ray flaw detection to inspect and validate the internal integrity of components for NEV powertrains, sealed enclosures, and other mission-critical applications.

सतही समापन & सामान्य दोष

Controlling surface finish and preventing defects are non-negotiable for ensuring part performance, उपस्थिति, and long-term reliability in demanding applications.

Available Surface Finishing Options

We manage a full spectrum of in-house surface finishing processes to meet diverse functional and aesthetic requirements. This includes robust options like Powder Coating and Wet Painting for durability and color matching, along with various Plating services for conductivity and wear resistance. For specific material needs, we offer specialized treatments such as Anodizing for aluminum alloy parts and Passivation to enhance the natural corrosion resistance of metals. Critically, our finishing standards are unified across all three manufacturing bases in China, मेक्सिको, और वियतनाम. This guarantees that a component produced in any facility will have a consistent appearance, बनावट, और प्रदर्शन, ensuring global product uniformity.

Identifying Common Casting Imperfections

High-pressure die casting is a rapid process, and precise control is essential to prevent common imperfections. Understanding these potential issues is the first step in eliminating them from production. We categorize defects into three main groups:

- Surface Issues: Defects like cold shuts, hot tears, and jetting are typically related to improper metal flow dynamics or temperature gradients within the mold. These manifest as lines, दरारें, or flow marks on the part’s surface.

- Internal Voids: Gas porosity is the most common internal defect, caused by air being trapped as molten metal is injected into the die cavity at extreme speed and pressure. These voids can compromise the part’s structural integrity and airtightness.

- Dimensional Variance: Warping or distortion occurs when a part does not cool evenly or experiences excessive stress during ejection from the mold. This can cause the final part to deviate from its specified geometric tolerances.

Defect Prevention and Inspection Methods

To guarantee that every part meets its design specifications, we employ a multi-layered inspection strategy using advanced metrology and testing equipment. This approach allows us to identify and correct potential issues at every stage of the manufacturing process.

- एक्स-रे दोष का पता लगाना: We use industrial X-ray systems to non-destructively inspect the internal structure of castings. This process reveals hidden defects like gas porosity or shrinkage that are not visible on the surface, ensuring the part’s mechanical soundness.

- CMM Full Dimensional Inspection: A Coordinate Measuring Machine (सीएमएम) is used to perform a complete dimensional analysis. The CMM probe measures the part’s geometry against the original 3D CAD model, verifying that all critical tolerances and features are within specification.

- नमक स्प्रे परीक्षण: To validate the performance of our coatings, we conduct salt spray tests in a controlled chamber. This accelerated corrosion testing method confirms the durability and resistance of finishes like powder coating and plating, ensuring the part will withstand its intended operational environment.

निष्कर्ष

The choice between gravity and die casting depends entirely on your project’s goals for volume, लागत, and component performance. Gravity casting provides a cost-effective solution for lower-volume parts requiring high mechanical integrity and the option for heat treatment. High-pressure die casting excels in mass production, delivering complex, thin-walled parts with high precision and speed that justify the initial tooling investment.

If you are calculating the economic breakeven point for a new component, our engineering team can help you model the costs. We’ll assist in selecting the optimal process and manufacturing base—China, मेक्सिको, or Vietnam—to align with your budget and supply chain strategy.

अक्सर पूछे जाने वाले प्रश्नों

Is gravity casting stronger than die casting?

While pressure die casting often has higher as-cast strength, gravity cast parts possess a denser and less porous internal structure. This quality makes them highly suitable for heat treatment, which can significantly improve their mechanical properties to achieve superior final strength and durability compared to die-cast parts, which are difficult to heat-treat.

What is the cost difference between gravity and die casting?

The primary cost difference lies in tooling and per-unit price. Gravity casting has a moderate initial tooling cost ($5,000 – $50,000), making it more economical for low to medium production volumes. इसके विपरीत, pressure die casting involves high tooling costs ($20,000 – $100,000+), but its rapid cycle times and high efficiency lead to a much lower per-unit cost in high-volume mass production.

Can gravity cast parts be heat treated?

हाँ, gravity cast parts are excellently suited for heat treatment. Their dense, low-porosity internal structure allows them to undergo heat treatment effectively. This process is a key advantage, as it significantly enhances their final mechanical properties, such as strength and durability.

Which process has better surface finish?

Pressure die casting produces a better surface finish. It typically achieves an excellent finish with a surface roughness (आरए) of 0.8-3.2μm, compared to the good finish (Ra 3.2-12.5μm) of gravity casting. The high-pressure injection forces the metal to conform tightly to the smooth mold surface, resulting in a superior finish.

What is the minimum wall thickness for gravity casting?

The typical minimum wall thickness for gravity casting is 3mm. This process is better suited for parts with thicker sections compared to pressure die casting, which can achieve thinner walls down to 1mm.

Why is die casting tooling more expensive?

Die casting tooling is more expensive because the molds must be engineered to withstand the extreme conditions of the process. This includes handling molten metal injected under very high pressures (10,000-50,000 साई) and enduring rapid, repetitive thermal cycles. This requires more complex designs, higher-grade materials, and more robust construction than the simpler molds used for gravity casting.