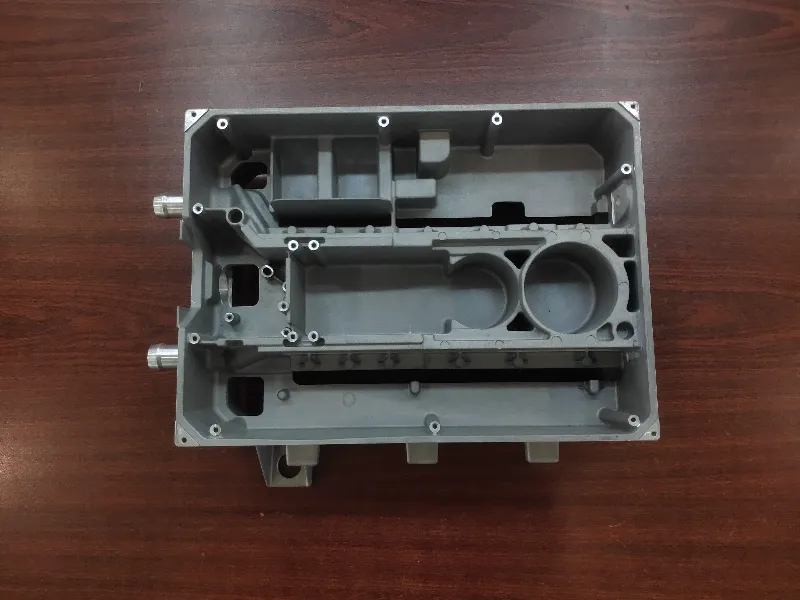

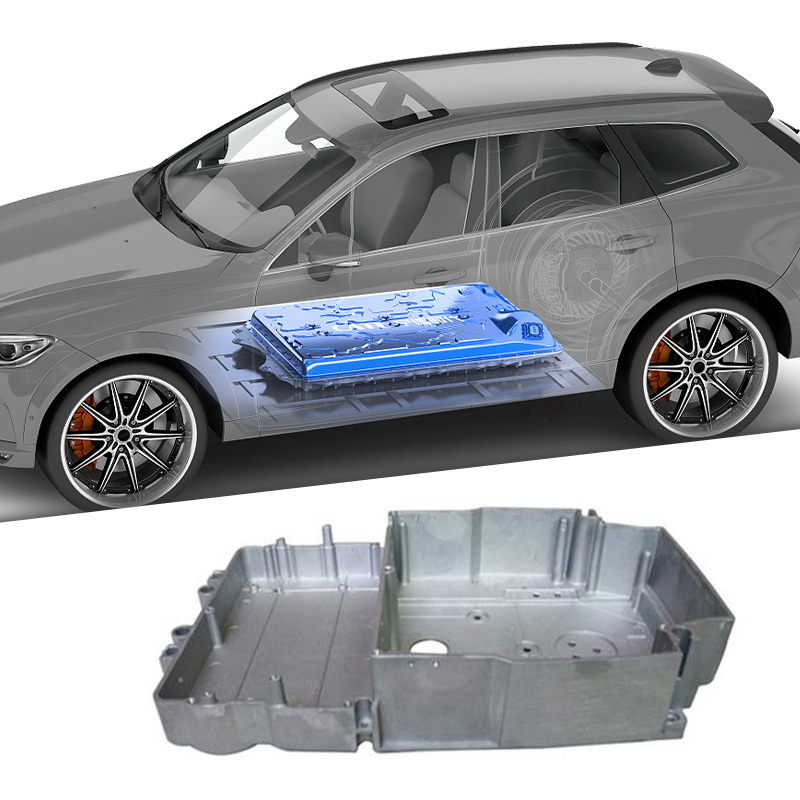

डाई-कास्ट एल्युमीनियम भागों की उत्पादकता निम्न से होती है 2,000 को 3,000 प्रति दिन टुकड़े. मोल्ड की लागत महत्वपूर्ण हो सकती है, और हमारे आर&डी टीमें अनुकूलन सुझावों के साथ आपकी सहायता करने का प्रयास करती हैं, अपने दीर्घकालिक लाभों को प्राथमिकता देना. हमारे सांचे आम तौर पर टिके रहते हैं 3 साल. जब पुराना साँचा अपने जीवनकाल के अंत तक पहुँच जाता है, यदि आप हमारे साथ काम करना जारी रखना चुनते हैं, हम एक नये साँचे को दोहरा सकते हैं, और यह मुफ़्त है.

हम आपसे एक पारदर्शी वादा करते हैं & सुव्यवस्थित मैनुफैट्यूरिंग प्रक्रिया. सभी एल्युमीनियम मिश्रधातुएँ प्रमाणित आपूर्तिकर्ताओं से प्राप्त की जाती हैं, और यह संभावित दोषों से बचाता है. आपका ऑर्डर परिपक्व परियोजना प्रबंधन के अंतर्गत होगा. अलावा, हम लाइव उत्पादन विनिर्माण के लिए डिजिटल औद्योगिक टच स्क्रीन का उपयोग करते हैं. यह सच है, आपको हमेशा लाइव फीडबैक मिलता रहता है.

बियान डायकास्ट कठोर गुणवत्ता नियंत्रण प्रथाओं को बनाए रखता है. हम आईएसओ हैं 45001, आईएसओ 9001, आईएसओ 14001, & आईएटीएफ 16949 प्रमाणित डाई कास्टिंग एल्यूमीनियम निर्माता & कारखाना. प्लस, हमारी डाईकास्ट सामग्री पहुंच योग्य है, RoHS, और विभिन्न बाज़ार आवश्यकताओं को पूरा करने के लिए FDA प्रमाणित. अनुरोध पर, हम पीपीएपी जैसे दस्तावेज़ प्रस्तुत कर सकते हैं, एपीक्यूपी, एफएमईए, एमएसए, छठे वेतन आयोग, और अधिक, गुणवत्ता नियंत्रण और उत्पादन प्रबंधन के प्रति हमारी प्रतिबद्धता का प्रदर्शन.