Questa guida tecnica fornisce i dati necessari per reperire e produrre correttamente le parti ADC12. Esamineremo la composizione chimica elemento per elemento, spiegando come i livelli di silicio e rame influiscono sulle prestazioni. Tratteremo anche i parametri di processo critici per l'ADC ad alta pressione 12 pressofusione, difetti comuni e come prevenirli, e i controlli di qualità essenziali necessari per garantire che ogni componente soddisfi le specifiche tecniche.

Cos'è la lega di alluminio ADC12?

ADC12 è la lega standard del settore per la pressofusione ad alta pressione, progettato per produrre complessi, componenti a pareti sottili con eccellenti proprietà meccaniche e stabilità dimensionale su scala.

ADC12 è un materiale da lavoro in pressofusione ad alta pressione, apprezzato per il suo equilibrio tra prestazioni e producibilità. È uno standard industriale giapponese (LUI) lega, riconosciuto a livello globale con equivalenti come l'A383 negli Stati Uniti e l'YL113 in Cina. Questa coerenza garantisce proprietà dei materiali affidabili per le catene di fornitura globali. La lega è stata specificatamente formulata per la fusione di parti complesse con pareti sottili, dove il metallo fuso deve fluire rapidamente e in modo uniforme nelle cavità complesse dello stampo con difetti minimi.

Composizione chimica e standard dei materiali

Le prestazioni del materiale ADC12 sono radicate nella sua composizione Al-Si-Cu. I due elementi di lega principali sono il silicio (E), A 9.6-12.0%, che garantisce un'ottima fluidità per il riempimento dello stampo e riduce il ritiro durante la solidificazione. Rame (Cu), A 1.5-3.5%, viene aggiunto per aumentare la resistenza alla trazione, durezza, e lavorabilità, rinforzando la struttura interna del materiale. Altri elementi come il ferro vengono controllati per ridurre l'adesione dello stampo, un fattore critico nella produzione automatizzata di grandi volumi.

Proprietà meccaniche e termiche

ADC12 offre una forte combinazione di proprietà fisiche che lo rendono adatto ad applicazioni impegnative. La sua bassa densità crea parti leggere senza sacrificare la resistenza, mentre le sue prestazioni termiche sono ideali per i componenti che necessitano di gestire il calore. I parametri chiave delle prestazioni sono coerenti e ben documentati per le specifiche tecniche.

- Conducibilità termica: Circa 96 W/m · k, consentendo un'efficace dissipazione del calore per l'elettronica e gli involucri di illuminazione.

- Densità: In giro 2.74 g/cm³, consentendo la produzione di parti resistenti che pesano circa un terzo dell'acciaio.

- Resistenza alla trazione: Varia da 230-280 MPa allo stato grezzo, fornendo prestazioni robuste per componenti strutturali e meccanici.

- Durezza: Una durezza Brinell di 75-100 Hb, indicando una buona resistenza all'usura per le parti funzionali.

Composizione chimica dell'ADC12 & Come ciascun elemento influisce sulle prestazioni

Il preciso equilibrio degli elementi di lega nell'ADC12 determina direttamente la sua fluidità di fusione, resistenza meccanica, e integrità della parte finale per applicazioni di pressofusione ad alta pressione.

Silicio (E): Il fondamento per la fluidità e la riempibilità

Con una composizione di 9.6% A 12.0%, il silicio è l'elemento di lega principale che conferisce all'ADC12 la sua caratteristica elevata fluidità. Questa caratteristica è fondamentale per la pressofusione ad alta pressione, consentendo alla lega fusa di riempire rapidamente stampi complessi con pareti sottili e geometrie complesse. Il silicio riduce inoltre significativamente il ritiro da solidificazione e il rischio di fessurazioni a caldo. Ciò porta a componenti dimensionalmente stabili con difetti di fusione minimi, riducendo la necessità di un'estesa post-lavorazione.

Rame (Cu): Miglioramento della resistenza meccanica e della lavorabilità

Rame, presente a 1.5% A 3.5%, migliora direttamente le proprietà meccaniche delle parti ADC12. Forma l'Al₂Cu (alluminuro) fase intermetallica all’interno della matrice della lega, che rinforza la struttura del materiale. Questo rinforzo aumenta sia la resistenza alla trazione che la durezza, rendendo il componente finale adatto ad applicazioni portanti. Il rame contribuisce inoltre a una migliore lavorabilità durante le operazioni di finitura.

Magnesio (Mg): Chiave per la durezza e la risposta al trattamento termico

Sebbene limitato a 0.3% o meno, il magnesio svolge un ruolo cruciale nel rafforzare la lega attraverso il trattamento termico. La sua presenza consente ai getti ADC12 di subire processi di invecchiamento T5, che fa precipitare le fasi di rinforzo e aumenta notevolmente la durezza del materiale e il carico di snervamento. Ciò consente ai produttori di adattare le proprietà meccaniche finali della parte a specifici requisiti prestazionali senza alterare il processo di fusione stesso.

Ferro (Fe): Prevenire l'attaccamento dello stampo durante la fusione

Il ferro è intenzionalmente mantenuto a un livello di 0.9% o meno per svolgere una funzione produttiva vitale: impedisce la saldatura dell'alluminio fuso, o attaccarsi, alla superficie della matrice in acciaio. Ciò riduce l'attrito durante l'espulsione del pezzo, consentendo cicli di produzione più rapidi e coerenti. Riducendo al minimo l'incollamento dello stampo, il ferro aiuta a proteggere gli utensili da eventuali danni e ne prolunga la vita operativa in ambienti di produzione ad alto volume.

Zinco (Zn): Un contributore alla colabilità complessiva

Zinco, limitato a 1.0% o meno, funge da elemento di supporto che affina la colabilità complessiva della lega. Funziona insieme al silicio per migliorare il modo in cui il metallo fuso riempie la cavità dello stampo. Questo contributo aiuta a produrre fusioni sonore esenti da difetti interni come la porosità, garantire una qualità costante delle parti in grandi cicli di produzione nei processi ad alta pressione.

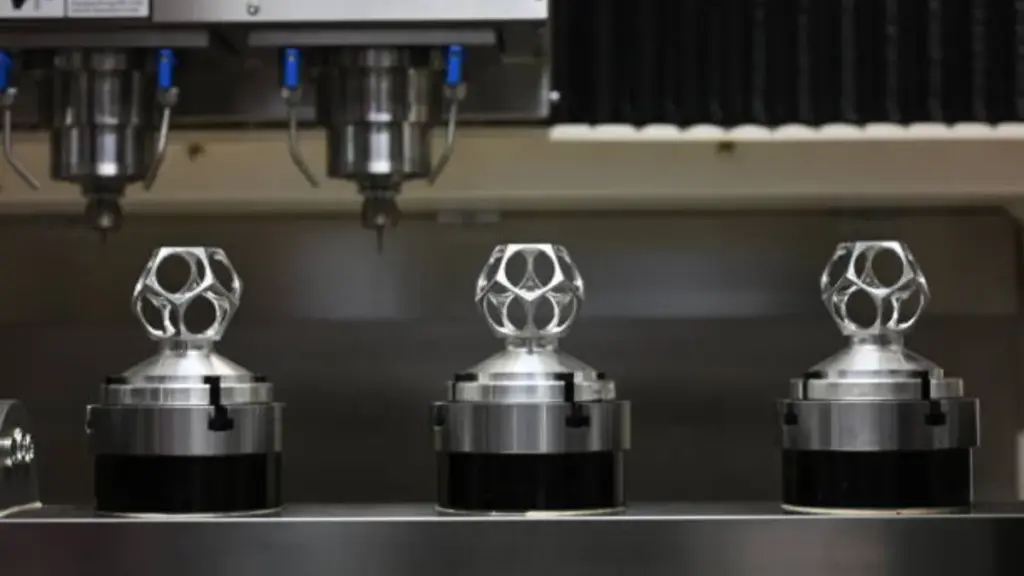

IATF 16949 Pressofusione di precisione certificata

Come ordinare parti di pressofusione ADC12 personalizzate

Un processo di approvvigionamento strutturato garantisce che i componenti personalizzati soddisfino specifiche tecniche precise, sfruttando al tempo stesso un'impronta di produzione globale per l'efficienza dei costi e della catena di fornitura.

Fare un passo 1: Invio di file di progettazione e specifiche tecniche

Il processo inizia con un pacchetto tecnico completo per garantire un preventivo accurato e una verifica di fattibilità. Abbiamo bisogno sia di modelli CAD 3D che di disegni tecnici 2D per catturare l'intera portata del tuo progetto, prestando molta attenzione alle dimensioni e alle tolleranze critiche per la qualità. Prima che i file vengano scambiati, stipuliamo un accordo di non divulgazione (NDA) per proteggere la tua proprietà intellettuale. Tutti i materiali devono soddisfare gli standard internazionali, quindi specifica se i tuoi componenti ADC12 devono essere conformi alla norma ASTM, IN, o standard JIS per garantire la coerenza dei materiali nelle nostre strutture globali.

- 3Modelli CAD D: Fornire file in formato STEP o IGS.

- 2D Disegni tecnici: Dettagliare tutte le tolleranze critiche, discussioni, e didascalie sulla finitura superficiale.

- Finitura e assemblaggio: Definire tutti i requisiti secondari, come la verniciatura a polvere, anodizzazione, o eventuali operazioni di sottoassemblaggio necessarie.

- Standard sui materiali: Confermare la conformità con ASTM, IN, o JIS per la lega ADC12.

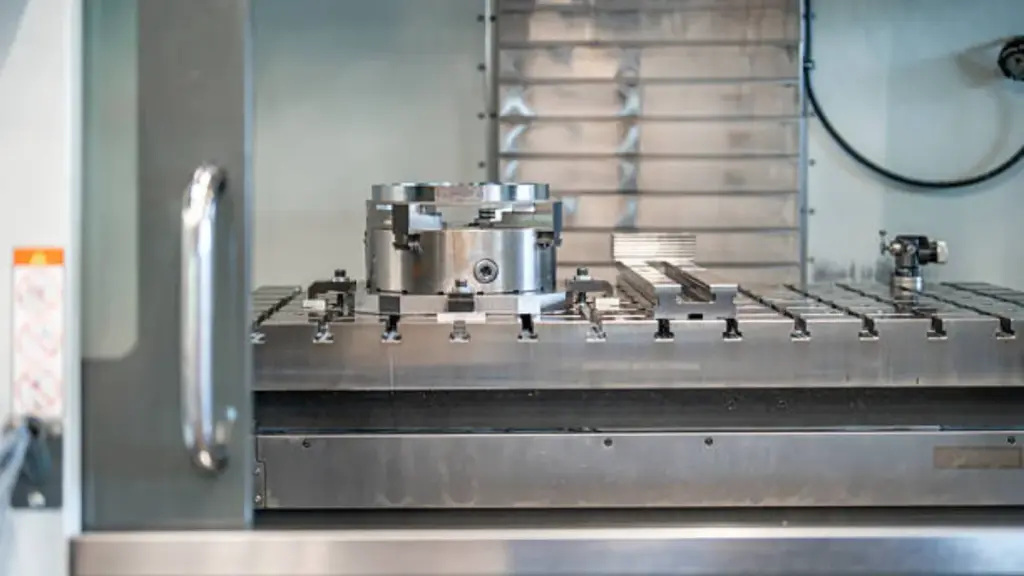

Fare un passo 2: Fabbricazione di attrezzature e approvazione del primo articolo

Una volta finalizzato il progetto, realizziamo lo stampo per pressofusione ad alta pressione presso la nostra sede centrale R&Centro D in Cina, un processo che in genere richiede 25-35 giorni. Una volta completata l'attrezzatura, eseguiamo un ordine di prova di 500 A 1,000 pezzi per la validazione iniziale. Riceverai un'ispezione completa del primo articolo (FAI) rapporto con questi campioni iniziali. Questo rapporto include i dati dimensionali della CMM rispetto ai disegni 2D, certificati dei materiali che confermano la composizione della lega, e risultati di test prestazionali come il rilevamento di difetti a raggi X e i controlli di ermeticità. La produzione in serie inizia solo dopo aver fornito la piena approvazione dei primi articoli.

Fare un passo 3: Selezione della base produttiva e organizzazione della logistica

Il nostro layout di produzione globale ti consente di scegliere una base di produzione che meglio si adatta alla tua strategia di catena di fornitura. Puoi scegliere tra le nostre strutture in Cina, Messico, o il Vietnam per bilanciare le tariffe, costi di spedizione, e velocità di consegna. Per la produzione con tariffe vantaggiose in Vietnam o Messico, una quantità minima d'ordine di 3,000 si raccomanda di unità per ammortizzare in modo efficace i costi operativi transfrontalieri. Dopo l'approvazione del campione, richiede la produzione di massa 4-6 settimane. Tutte le parti vengono quindi imballate in modo industriale, imballaggi resistenti agli urti progettati per resistere al trasporto marittimo a lungo raggio e garantire che i vostri componenti arrivino sani e salvi alla loro destinazione finale.

Perché ADC12 è ideale per la pressofusione ad alta pressione

La composizione della lega di ADC12 offre una fluidità eccezionale per parti complesse e la durata necessaria per la produzione in grandi volumi, rendendolo lo standard industriale per la pressofusione di precisione.

ADC12 non è la scelta predefinita per la pressofusione ad alta pressione per sbaglio. La sua composizione chimica è appositamente progettata per risolvere le sfide principali della produzione complessa, componenti a pareti sottili su scala. La lega fornisce un equilibrio affidabile di colabilità, prestazioni meccaniche, ed efficienza economica che pochi altri materiali possono eguagliare.

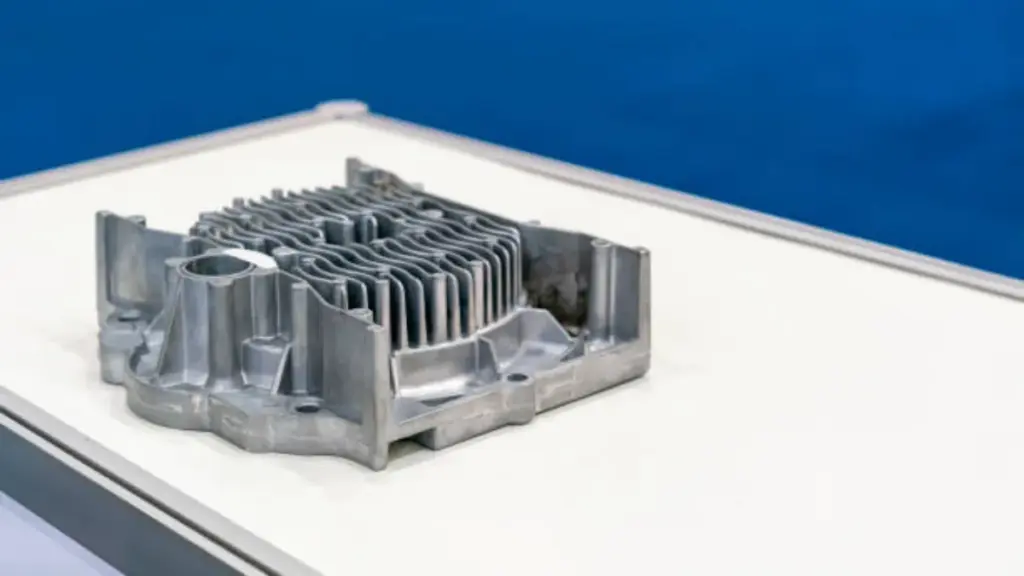

Elevata fluidità per geometrie complesse e pareti sottili

Il vantaggio principale di ADC12 sono le sue eccezionali caratteristiche di flusso allo stato fuso. Ciò è guidato direttamente dal suo alto contenuto di silicio, che consente alla lega di riempire rapidamente ogni dettaglio di uno stampo complesso prima di solidificarsi. Questa proprietà è fondamentale per le parti con spigoli vivi, dettagli raffinati, e pareti sottili come 0.5 mm. Il basso intervallo di fusione del materiale e il ritiro minimo garantiscono che la parte finale sia dimensionalmente accurata e priva di comuni difetti di fusione come crepe o giunzioni fredde.

- Alto contenuto di silicio (9.6-12.0%): Garantisce che la lega fusa riempia facilmente le complesse caratteristiche dello stampo.

- Basso intervallo di fusione (549-577°C): Supporta cicli rapidi di iniezione e solidificazione, aumentando la velocità di produzione.

- Fattore di restringimento minimo (1.005): Riduce il rischio di porosità e migliora la precisione dimensionale finale.

Resistenza meccanica e conducibilità termica bilanciate

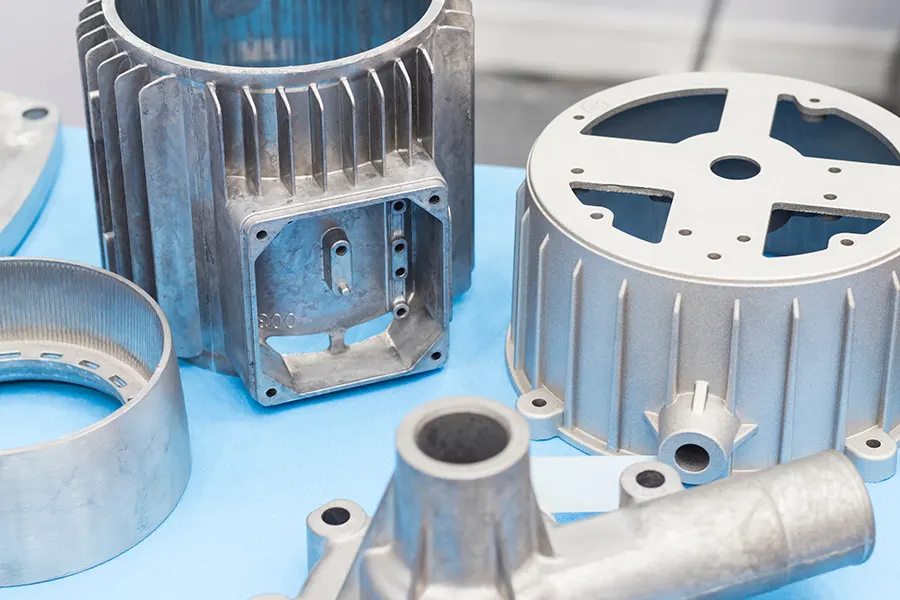

Mentre la lanciabilità è cruciale, il componente finale deve soddisfare anche requisiti funzionali. ADC12 fornisce un elevato rapporto resistenza/peso, rendendolo adatto per parti strutturali leggere in applicazioni automobilistiche e industriali. La sua eccellente conduttività termica è essenziale per i componenti che devono dissipare il calore, come gli involucri elettronici, alloggiamenti del motore, e apparecchi di illuminazione a LED. L’aggiunta di rame migliora sia la durezza del materiale che la sua lavorabilità, semplificando le operazioni secondarie come foratura e maschiatura.

- Conducibilità termica (96 W/m · k): Consente un'efficace dissipazione del calore negli alloggiamenti e nei componenti del gruppo propulsore.

- Contenuto di rame (1.5-3.5%): Rinforza la matrice della lega per migliorare la resistenza, durezza, e lavorabilità.

- Resistenza alla trazione come da colata (230-280 MPa): Fornisce prestazioni robuste per applicazioni portanti direttamente dallo stampo.

Ottimizzato per la produzione di volumi elevati e la durabilità

ADC12 è costruito per le esigenze della produzione di massa. La sua formulazione include elementi come il ferro che riducono l'adesione dello stampo, che prolunga la vita dell'utensile e riduce al minimo i tempi di fermo. La buona lavorabilità della lega e le proprietà di distacco dallo stampo riducono i tempi e i costi associati alla post-lavorazione. Inoltre, la sua intrinseca resistenza alla corrosione e all'ossidazione fa sì che le parti mantengano la loro integrità e il loro aspetto per una lunga durata, anche senza trattamenti superficiali estesi. Questa combinazione di fattori lo rende una scelta altamente conveniente e affidabile per grandi cicli di produzione.

- Eccellente lavorabilità: Riduce i costi e semplifica le operazioni di finitura secondaria.

- Resistenza alla corrosione naturale: L'elevato contenuto di alluminio e silicio prolunga la durata del pezzo finito.

- Materiale conveniente: Fornisce una soluzione affidabile ed economica per la produzione su larga scala.

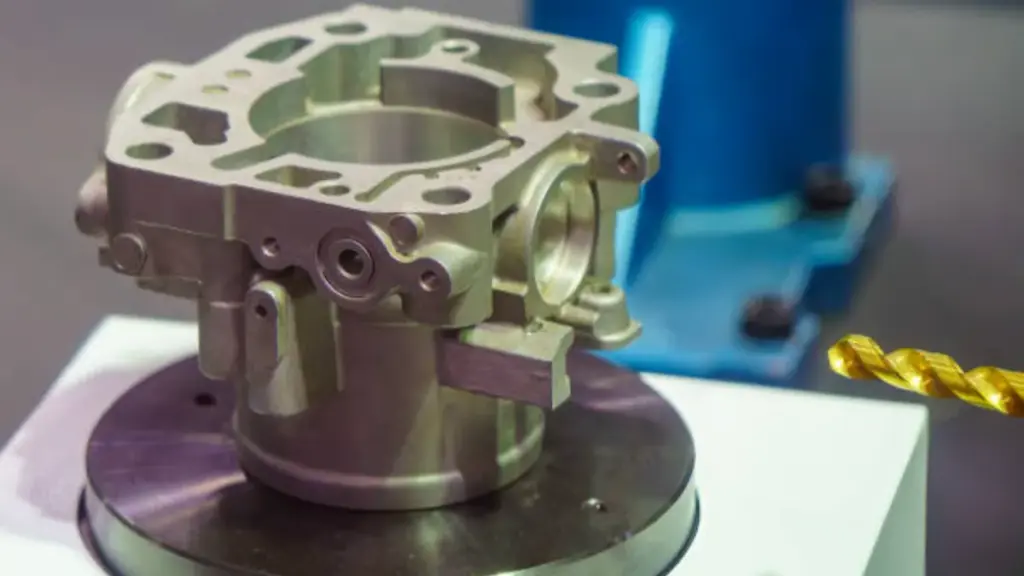

Parametri critici del processo di pressofusione per ADC12

Controllo dell'iniezione, termico, e i parametri di espulsione basati sulle proprietà specifiche del materiale di ADC12 sono l’unico modo per ottenere risultati ripetibili, produzione priva di difetti di componenti complessi.

Controllo dell'iniezione, termico, e i parametri di espulsione basati sulle proprietà specifiche del materiale di ADC12 sono l’unico modo per ottenere risultati ripetibili, produzione priva di difetti di componenti complessi.

Panoramica dei parametri chiave del processo

| Fase del processo | Parametro | Tipico / intervallo consigliato | Perché è importante (impatto sulla qualità) |

|---|---|---|---|

| Preparazione della fusione | Versare / temperatura di fusione | 600–650°C | Troppo basso: errori di funzionamento/chiusure a freddo; troppo alto: maggiore rischio di accumulo di gas/porosità ed erosione dello stampo. |

| Condizionamento della muffa | Morire (muffa) temperatura di preriscaldamento | 200–250°C | Stabilizza il riempimento e la solidificazione; aiuta a ridurre lo shock termico e la tendenza alla fessurazione. |

| Iniezione | Velocità di iniezione (tiro veloce) | 2–5 m/sec | Una velocità più elevata migliora il riempimento delle pareti sottili; un'eccessiva turbolenza può aumentare l'intrappolamento dell'aria. |

| Iniezione | Pressione di iniezione | 70–100MPa | Supporta il riempimento completo e la definizione delle funzionalità; un livello troppo alto può aumentare il rischio di bave se la configurazione dello stampo/macchina è debole. |

| Solidificazione | Velocità di raffreddamento | 10–20 °C/sec | Controlla la dimensione e la forza dei grani; un raffreddamento eccessivamente aggressivo può aumentare il rischio di stress termico su alcune geometrie. |

| Controllo dimensionale | Fattore di contrazione (riferimento progettuale) | ≈ 1.005 | Aiuta a impostare il ridimensionamento della cavità e la strategia di tolleranza per dimensioni ripetibili. |

Ottimizzazione per la composizione ad alto contenuto di silicio di ADC12

L’alto contenuto di silicio di ADC12 (9.6-12.0%) fornisce una fluidità eccezionale, che richiedono un controllo termico preciso per prevenire la solidificazione prematura. Manteniamo la temperatura di fusione appena al di sopra del punto liquidus della lega di 577°C per garantire un flusso costante senza degrado del materiale. L’elevata conduttività termica della lega 96 W/m·K consente un design efficiente del canale di raffreddamento dello stampo che riduce i tempi di ciclo garantendo al tempo stesso una solidificazione completa.

Punti critici di controllo per la prevenzione dei difetti

Le velocità del gate sono impostate per creare un flusso laminare, riducendo al minimo l'intrappolamento dell'aria e la porosità dei gas che compromettono l'integrità strutturale. Il tempo di raffreddamento è calibrato in base alla sezione più spessa del pezzo per prevenire difetti interni come lo strappo a caldo. Il basso fattore di ritiro di ADC12 e le proprietà intrinseche di rilascio dello stampo consentono una forza di espulsione controllata che previene la distorsione della parte, segni superficiali, o danni.

Applicazioni industriali

La pressofusione di precisione produce componenti essenziali che soddisfano i rigorosi requisiti strutturali, termico, e le esigenze di qualità dell’automotive moderna, telecomunicazioni, e settori dell'automazione industriale.

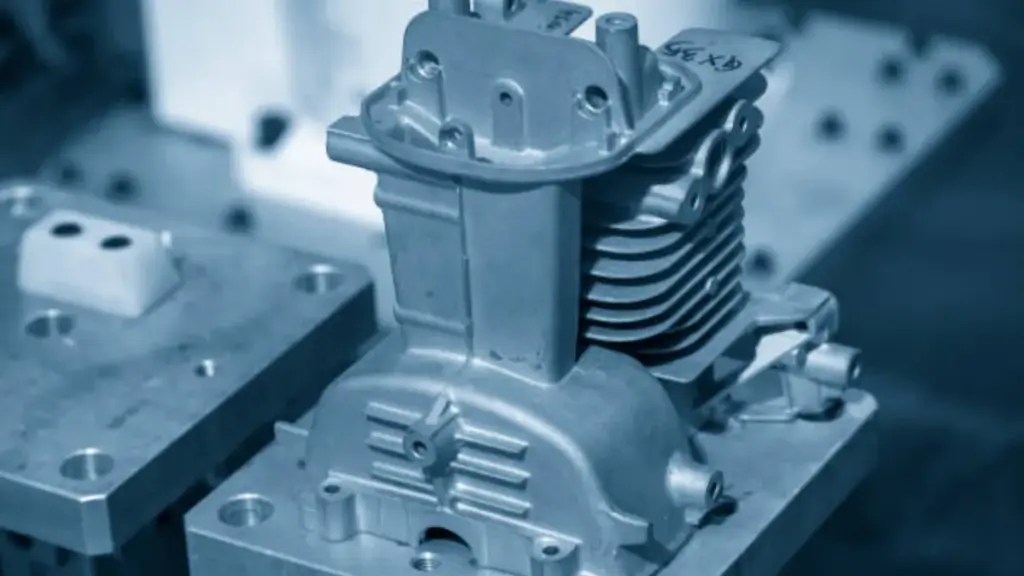

Veicoli automobilistici e di nuova energia (NEV) Componenti

Produciamo alloggiamenti del gruppo propulsore e parti strutturali chiave per veicoli a nuova energia (NEV) sistemi trielettrici. Utilizzando leghe di alluminio leggere come ADC12 e A380, e magnesio AZ91D, aiutiamo a ridurre il peso complessivo del veicolo per migliorare l'autonomia e l'efficienza. Questo approccio offre un elevato rapporto resistenza/peso, fondamentale per la moderna progettazione automobilistica.

La nostra rete di produzione globale, con strutture in Cina, Messico, e Vietnam, opera sotto un'unità unificata IATF 16949 sistema di qualità. Ciò garantisce coerenza, risultati di livello automobilistico indipendentemente dal luogo di produzione. L'integrità di ogni componente viene verificata attraverso test rigorosi, compreso il rilevamento dei difetti a raggi X per la solidità interna e l'ispezione CMM per la massima precisione dimensionale.

5G Armadi per telecomunicazioni e reti

I nostri involucri pressofusi per stazioni base 5G e hardware di rete sono progettati per eseguire molteplici funzioni critiche. Forniscono una schermatura EMI ad alte prestazioni per proteggere i componenti interni sensibili dalle interferenze del segnale. Li progettiamo anche per una gestione termica superiore, sfruttando l'eccellente conduttività termica dell'alluminio ADC12 (96 W/m · k) per dissipare in modo efficiente il calore dall'elettronica ad alta potenza.

Per l'impiego all'aperto a lungo termine, utilizziamo leghe resistenti alla corrosione e verifichiamo la durabilità con test standardizzati in nebbia salina. Il processo di pressofusione ad alta pressione ci consente di produrre le geometrie complesse e a pareti sottili richieste per i prodotti avanzati, hardware 5G con vincoli di spazio, garantendo sia prestazioni che un ingombro compatto.

Opzioni di trattamento superficiale & Controllo qualità per parti ADC12

Un approccio unificato alla finitura superficiale e al controllo qualità garantisce che le parti ADC12 soddisfino rigorosi requisiti funzionali, cosmetico, e standard normativi nelle catene di fornitura globali.

Processi di finitura funzionale ed estetica

I trattamenti superficiali post-fusione sono fondamentali per migliorare le prestazioni e l'aspetto dei componenti ADC12. L'alto contenuto di silicio (9.6-12.0%) di ADC12 presenta sfide uniche, in particolare per l'anodizzazione, che può risultare più scuro, finitura meno uniforme. Per applicazioni che richiedono colori uniformi e protezione superiore, vengono impiegate strategie alternative o a più fasi. Le nostre strutture in Cina, Messico, e il Vietnam forniscono una suite completa di opzioni di finitura per soddisfare i requisiti specifici del progetto.

- Verniciatura a polvere: Fornisce un bene durevole, superficie resistente alla corrosione ideale per componenti utilizzati in ambienti difficili, come sottoscocca automobilistici e involucri di comunicazione 5G esterni.

- Anodizzazione: L'anodizzazione con acido solforico di tipo II migliora la durezza superficiale e la resistenza all'usura. Sebbene efficace, richiede un controllo preciso del processo per gestire gli effetti estetici dell’alto contenuto di silicio di ADC12.

- Pittura bagnata: Offre una precisa corrispondenza dei colori e finiture cosmetiche di alta qualità, essenziale per l'elettronica rivolta al consumatore e le apparecchiature industriali di marca.

- Passivazione: Un trattamento chimico che migliora la resistenza alla corrosione formando uno strato protettivo di ossido, il tutto mantenendo l’aspetto metallico originale del materiale.

Verifica dell'integrità dimensionale e dei materiali

La verifica dell'integrità delle parti va oltre i controlli a livello superficiale. Utilizziamo una combinazione di test non distruttivi e metrologia per garantire che ogni componente sia conforme al modello CAD e alle specifiche prestazionali. Ciò è particolarmente critico per le parti di sicurezza automobilistiche e gli alloggiamenti elettronici sigillati in cui difetti interni o derive dimensionali possono portare a guasti sul campo.

- CMM (Macchina di misura a coordinate) Ispezione: Garantisce la massima precisione dimensionale rispetto ai dati CAD originali, verifica delle tolleranze critiche, GD&Callout T, e posizioni delle caratteristiche.

- Rilevamento dei difetti a raggi X: Identifica e quantifica i difetti interni come porosità e ritiro invisibili a occhio nudo. Questo metodo non distruttivo è una pratica standard per i componenti ad alta affidabilità.

- Test in nebbia salina: Convalida la resistenza alla corrosione delle parti finite simulando l'invecchiamento accelerato in un ambiente salino, garantendo una durabilità a lungo termine.

- Test di tenuta all'aria: Conferma l'integrità della tenuta dei componenti progettati per gli involucri, un test obbligatorio per l'elettronica, Sistemi di batterie NEV, e alloggiamenti per illuminazione esterna.

Sistemi di qualità globali e protocolli di conformità

La coerenza è il fondamento del nostro modello di produzione globale. Un singolo, Il nostro sistema di gestione della qualità unificato governa le nostre operazioni in Cina, Messico, e Vietnam. Ciò garantisce che una parte prodotta in uno qualsiasi dei nostri stabilimenti soddisfi esattamente gli stessi standard per la composizione dei materiali, precisione dimensionale, e prestazioni. Aderiamo rigorosamente agli standard materiali internazionali, compreso ASTM, IN, e JIS, fornendo una consistenza materiale verificabile. Pieno rispetto delle normative ambientali e di sicurezza come RoHS e REACH viene mantenuto per garantire l'accesso al mercato e la responsabilità aziendale. La nostra IATF 16949 la certificazione conferma che i nostri processi soddisfano i severi requisiti della catena di fornitura automobilistica, uno standard di qualità che applichiamo a tutti i progetti.

Conclusione

La lega di alluminio ADC12 fornisce una combinazione equilibrata di eccellente colabilità, resistenza meccanica, e conduttività termica. Ciò lo rende un materiale affidabile ed economico per componenti complessi nel settore automobilistico, elettronica, e settori industriali. Comprenderne le proprietà specifiche e i requisiti di lavorazione è fondamentale per garantire qualità e prestazioni costanti nella produzione di massa.

Se il tuo progetto richiede parti ADC12 di precisione, il nostro team di ingegneri può esaminare la producibilità del tuo progetto e garantire che soddisfi i tuoi obiettivi prestazionali. Contattaci per discutere delle tue esigenze relative ai componenti e scoprire come la nostra produzione globale ha sede in Cina, Messico, e il Vietnam possono ottimizzare la tua catena di fornitura.

Domande frequenti

Qual è l'equivalente di ADC12?

ADC12 è uno standard giapponese per le leghe di pressofusione di alluminio. I suoi equivalenti internazionali diretti sono la lega statunitense A383 e la lega cinese YL113.

ADC12 è adatto per l'anodizzazione?

Grazie al suo alto contenuto di silicio (9.6-12.0%), L'ADC12 non è generalmente considerato ideale per l'anodizzazione decorativa, poiché ciò può comportare una non uniforme, finitura grigia. Tuttavia, la lega possiede naturalmente un'ottima resistenza alla corrosione e all'ossidazione, che può ridurre la necessità di trattamenti superficiali in molte applicazioni.

Quali sono le proprietà meccaniche di ADC12?

Nella sua condizione di fusione, ADC12 presenta una resistenza alla trazione di 230-280 MPa, una resistenza allo snervamento di 140-170 MPa, un allungamento di 1.0-3.0%, e una durezza Brinell di 75-100 Hb. La lega mantiene le sue prestazioni meccaniche alle alte e basse temperature.

È resistente alla corrosione ADC12?

SÌ, ADC12 ha un'elevata resistenza alla corrosione. La sua composizione, in particolare l'alto contenuto di alluminio e silicio, Fornisce un'eccellente protezione sia contro la corrosione che contro l'ossidazione, che aiuta a prolungare la durata del prodotto.

Perché viene aggiunto il silicio all'ADC12?

Il silicio è l'elemento di lega chiave nell'ADC12, aggiunto per migliorarne la colabilità. L'alto contenuto di silicio (9.6-12.0%) migliora significativamente la fluidità della lega, consentendo al metallo fuso di riempire facilmente stampi complessi e a pareti sottili. Serve anche a ridurre il ritiro durante la solidificazione.