Per un product designer che guarda un prototipo prendere forma, poche cose sono così soddisfacenti come vedere un concetto diventare una componente metallica tangibile. Ma quando quel singolo prototipo deve essere scalato in diecimila o dieci milioni di unità, la domanda “come fondere l'alluminio” smette di riguardare la fusione del metallo e inizia a riguardare la strategia ingegneristica.

L'alluminio industriale fusione è una disciplina definita dalla metallurgia di precisione, dinamica termica, e rigorosa ottimizzazione del ciclo. È la differenza tra una parte che assomiglia semplicemente al design e una che assomiglia esegue sotto stress da anni.

In questa guida, stiamo andando oltre le basi. Analizzeremo l'ecosistema della fusione industriale dell'alluminio da una prospettiva ingegneristica, metodi di confronto, analizzare le leghe, ed esplorare i fattori critici di progettazione che determinano il successo della produzione in grandi volumi.

Comprendere le basi della fusione di alluminio

Al suo livello più semplice, la fusione è il processo di colata del materiale fuso in uno stampo per solidificarsi. Tuttavia, nel contesto della produzione moderna, questa definizione graffia appena la superficie. La fusione industriale dell'alluminio è un atto di equilibrio ad alto rischio tra la fluidodinamica (inserire il metallo nello stampo) e termodinamica (far uscire il calore).

Per ingegneri e responsabili degli acquisti, la distinzione tra metodi fai da te e processi industriali è fondamentale.

- L'approccio fai da te: Spesso si concentra sul riciclaggio dei rottami a basso costo (come le lattine) e stampi di sabbia aperti. L'alluminio risultante è pieno di impurità, gas intrappolato, e ossidi. Le proprietà meccaniche sono imprevedibili, rendendo queste parti inadatte per applicazioni portanti.

- L'approccio industriale: Si concentra sulla ripetibilità e sull'integrità. Qui a Bian Diecast, il processo è controllato fino al millisecondo e al grado. Utilizziamo leghe raffinate, pressioni di iniezione precise, e sistemi di vuoto per garantire che il 10.000esimo pezzo sia chimicamente e dimensionalmente identico al primo.

La fusione industriale non significa solo modellare il metallo; si tratta di creare una catena di fornitura affidabile per componenti critici nel settore automobilistico, telecomunicazioni, e dispositivi medici.

Passaggi chiave nel processo di fusione industriale

La transizione da un file CAD a un pallet di spedizione comporta un flusso di lavoro complesso. Mentre le tecniche specifiche variano, il ciclo di vita industriale generalmente segue queste fasi rigorose:

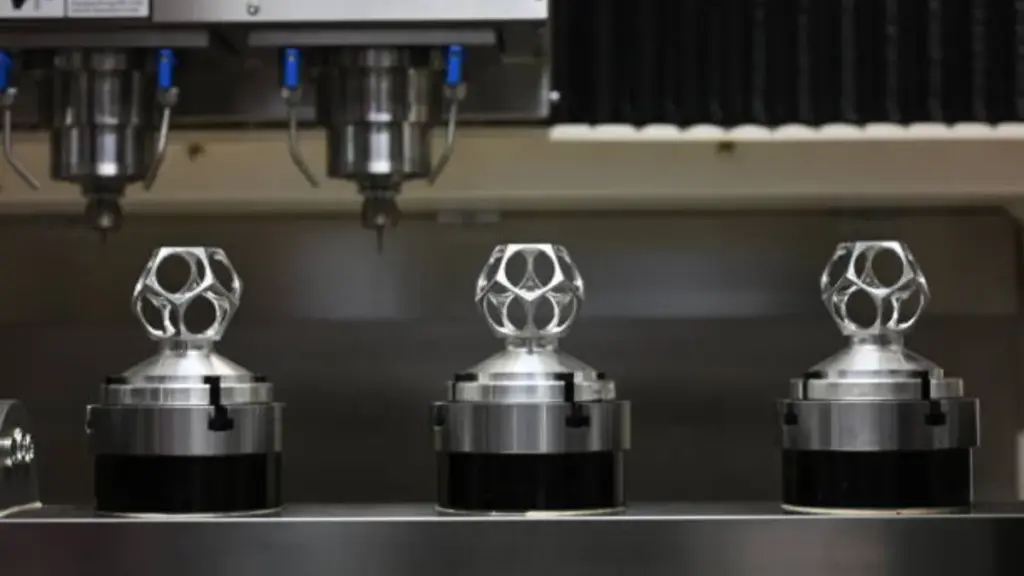

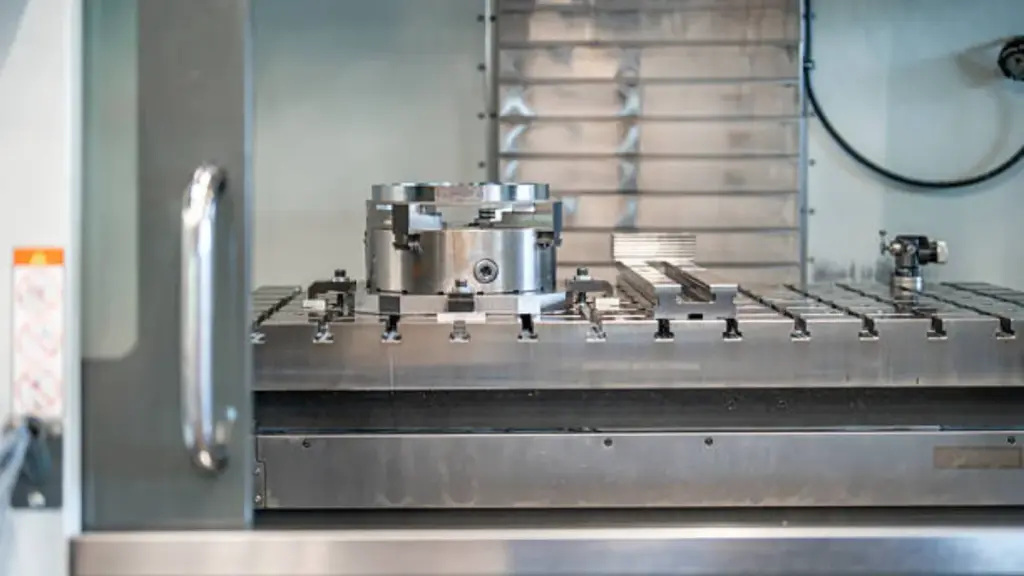

- Realizzazione di modelli e stampi: Tutto inizia con lo strumento. Nella fusione ad alto volume, ciò significa lavorare stampi in acciaio temprato in grado di resistere allo shock termico per centinaia di migliaia di cicli. Questa è la fase più dispendiosa in termini di capitale ma garantisce la precisione dimensionale.

- Fusione e flusso: Lingotti di alluminio (non rottame) vengono fusi in un forno centrale. I flussi vengono aggiunti per rimuovere le impurità (scorie) e prevenire l'ossidazione. La temperatura viene mantenuta rigorosamente, solitamente tra 660°C e 720°C, per garantire una fluidità ottimale senza surriscaldare la lega.

- Versamento o iniezione: È qui che il metodo detta l'azione.

- In colata per gravità, il metallo scorre dolcemente per ridurre al minimo la turbolenza.

- In pressofusione, un pistone idraulico spara il metallo nello stampo in millisecondi.

- Solidificazione e raffreddamento: Lo stampo è a temperatura controllata (spesso tramite linee interne dell'olio o dell'acqua) per gestire la velocità di raffreddamento. Il raffreddamento controllato crea una struttura a grana più fine, che si traduce in una maggiore resistenza.

- Eiezione: Una volta solido, il dado si apre, e i perni di espulsione spingono fuori il componente.

- Rifilatura e pulizia: IL “cancello” (punto di ingresso) e le linguette di overflow vengono tagliate.

- Finitura superficiale: La parte subisce una lavorazione secondaria, come la granigliatura o la lavorazione meccanica, per soddisfare le specifiche di stampa finali.

Spiegazione dei metodi di fusione dell'alluminio

Non tutti i metodi di fusione sono uguali. La scelta tra Sabbia, Gravità, e pressofusione ad alta pressione (HPDC) di solito si riduce a tre variabili: Volume, Costo, e qualità.

Ecco una ripartizione comparativa per aiutarti a decidere quale percorso si adatta al tuo progetto:

| Caratteristica | Colata in sabbia | Pressofusione per gravità | Pressofusione ad alta pressione (HPDC) |

| Volume ideale | Basso (1 – 1,000 unità) | Medio (1,000 – 10,000 unità) | Alto (10,000+ unità) |

| Finitura superficiale | Tessitura ruvida (Ra 12,5-25 µm) | Liscio (Ra 3,2-6,3 µm) | Eccellente (Ra 0,8-1,6 µm) |

| Tolleranza dimensionale | Basso (richiede lavorazione) | Medio | Alta precisione |

| Spessore del muro | Muri spessi (>3mm) | Pareti medie (>3mm) | Pareti sottili (fino a 1-2 mm) |

| Costo degli utensili | Basso | Medio | Alto |

| Velocità di produzione | Lento | Moderare | Molto veloce |

- Colata in sabbia: Il metodo più antico. Utilizza uno stampo usa e getta fatto di sabbia. È eccellente per parti di grandi dimensioni o prototipazione perché gli strumenti sono economici. Tuttavia, le parti sono ruvide, e la precisione dimensionale è allentata.

- Pressofusione per gravità (Muffa permanente): Utilizza uno stampo in metallo riutilizzabile. Si basa sulla gravità per riempire la cavità. Questo metodo produce parti con eccellente potenziale di trattamento termico e bassa porosità, rendendolo uno dei preferiti per le parti strutturali automobilistiche come nocche o pinze.

- Pressofusione ad alta pressione (HPDC): Questa è la centrale elettrica della produzione di massa. Iniettando metallo ad alta velocità e pressione, possiamo produrre complessi, parti a pareti sottili con finiture superficiali incredibili. Per progetti che richiedono decine di migliaia di unità all'anno, L'HPDC è quasi sempre la soluzione più conveniente per parte.

Settori chiave alimentati dalla pressofusione di alluminio

Settore automobilistico

Nel panorama automobilistico, la pressofusione di alluminio consente una costruzione leggera per una migliore efficienza del carburante e minori emissioni. La fusione di precisione fornisce i blocchi motore, casi di trasmissione, componenti della ruota, e parti strutturali complesse. Il processo consente alle case automobilistiche di soddisfare rigorosi standard di sicurezza riducendo al contempo i costi di produzione e il peso del veicolo.

Aerospaziale

In ingegneria aerospaziale, i vantaggi della pressofusione di alluminio sono fondamentali. Il suo elevato rapporto resistenza/peso e le strette tolleranze dimensionali supportano la produzione di componenti complessi per i telai degli aerei, alloggiamenti per l'avionica, e segmenti di turbina. Queste parti critiche resistono a condizioni estreme contribuendo al contempo a una maggiore sicurezza, volo più efficiente.

Elettronica & Apparecchiature elettriche

L'elettronica moderna e i dispositivi elettrici dipendono dall'alluminio pressofuso per la gestione termica e la durata. Alloggiamenti, dissipatori di calore, e i telai interni beneficiano della conduttività superiore dell’alluminio, proteggere i componenti sensibili dei computer, hardware per le telecomunicazioni, Illuminazione a LED, e alimentatori.

Elettrodomestici

I principali marchi di elettrodomestici si affidano alla pressofusione di alluminio per offrire prestazioni ed estetica. Questo processo produce robustezza, parti antiruggine per frigoriferi, lavatrici, gadget da cucina, e unità di condizionamento dell'aria, garantendo che gli elettrodomestici durino più a lungo e abbiano un aspetto elegante.

Dispositivi medici

La pressofusione dell’alluminio svolge un ruolo fondamentale nella tecnologia medica, dove precisione, igiene, e l’affidabilità strutturale sono fondamentali. Supporta la produzione di custodie per dispositivi, telai di apparecchiature diagnostiche, ausili per la mobilità, e persino componenti chiave di strumenti chirurgici, soddisfare standard rigorosi di sicurezza e pulizia.

Selezione della migliore lega di alluminio per il tuo progetto

Uno degli errori più comuni nel sourcing è semplicemente specificare “Alluminio” su un disegno. L'alluminio è un elemento; quello che lanci è un lega. La composizione chimica specifica determina la lavorabilità del pezzo, forza, e resistenza alla corrosione.

Ecco le tre leghe industriali più comuni:

- A380 (Il tuttofare): È la lega per pressofusione più utilizzata al mondo. Offre un fantastico equilibrio di fluidità (riempire facilmente lo stampo), tenuta alla pressione, e resistenza alla fessurazione a caldo. Se stai realizzando una custodia elettronica, una scatola del cambio, o una staffa, L'A380 è probabilmente il miglior punto di partenza.

- A356 (Lo specialista della forza): Tipicamente utilizzato nella fusione a gravità o nella fusione semisolida specializzata. Ha un'elevata resistenza e un eccellente allungamento (duttilità). È la lega di riferimento per ruote e componenti delle sospensioni dove la sicurezza è fondamentale.

- ADC12 (La scelta della precisione): Una lega standard giapponese simile all'A380 ma con un contenuto di silicio leggermente superiore. Ciò migliora ulteriormente la colabilità, rendendolo ideale per intricati, parti a pareti sottili, sebbene sia leggermente più fragile dell'A356.

Per Suggerimento: Dai priorità alle tue esigenze. Se la parte deve dissipare il calore (come un dissipatore di calore), cercare leghe con livelli di silicio inferiori. Se deve essere leggero ed economico, attenersi ai gradi standard di pressofusione come A380.

Prevenire e risolvere i comuni difetti di fusione

Anche in una struttura all'avanguardia, il metallo fuso è caotico. I difetti accadono, ma un produttore di alta qualità sa come prevedere, rilevare, e mitigarli.

- Porosità (Gas e ritiro): Questo è il nemico di un casting forte. Si manifesta come piccoli fori all'interno della parte.

- Causa: Aria intrappolata durante l'iniezione o ritiro di raffreddamento irregolare.

- Ottimizzazione: Le fonderie avanzate utilizzano la tecnologia Vacuum Assist per aspirare l'aria dallo stampo pochi millisecondi prima dell'iniezione, riducendo drasticamente la porosità.

- Chiuse fredde: Una linea o crepa visibile nel punto in cui due flussi di metallo fuso si incontravano ma non riuscivano a fondersi.

- Causa: Raffreddamento del metallo troppo veloce o velocità di iniezione troppo lenta.

- Ottimizzazione: L'aumento della temperatura dello stampo e della velocità di iniezione garantisce che il metallo rimanga liquido finché la cavità non è piena.

- Saldatura: L'alluminio aderisce alla matrice d'acciaio, danneggiando la superficie.

- Causa: Surriscaldamento dell'acciaio dello stampo.

- Ottimizzazione: Applicazione precisa dei distaccanti e gestione computerizzata dei canali di raffreddamento.

Opzioni di finitura superficiale e post-elaborazione

IL “come cast” la superficie raramente è la fine della strada. A seconda dell'applicazione, la parte potrebbe necessitare di protezione o miglioramento estetico.

- Granigliatura: Questo è il metodo di pulizia più conveniente. Bombarda la parte con perle di acciaio o ceramica per rimuovere bave e bave, lasciando una texture opaca uniforme.

- Verniciatura a polvere: Una polvere secca viene applicata elettrostaticamente e polimerizzata a caldo. Crea uno spessore, pelle dura che è altamente resistente ai graffi e alla corrosione. È standard per gli involucri esterni.

- Anodizzazione: Sebbene popolare per l'alluminio estruso (come gli infissi delle finestre), l'anodizzazione dell'alluminio pressofuso è complicata a causa del contenuto di silicio, che può rendere la parte scura o grigia. Tuttavia, fornisce un'eccellente resistenza all'usura.

- Lucidatura: Per parti decorative, la lucidatura meccanica può creare una finitura a specchio, anche se questo è laborioso e costoso.

Progettazione per la producibilità

Il momento più economico per risolvere un problema di fusione è durante la fase di progettazione. Se porti un “lavorazione” mentalità per la progettazione del casting, dovrai affrontare costi elevati e tassi di difetti elevati.

Ecco gli esperti DFM (Progettazione per la producibilità) suggerimenti per ottimizzare le parti per la produzione in serie:

- Mantenere uno spessore della parete uniforme: Questa è la regola d'oro. Le variazioni di spessore causano un raffreddamento non uniforme, portando a deformazioni e porosità da ritiro.

- Aggiungi angoli di sformo: Non è possibile espellere una scatola perfettamente verticale da uno stampo d'acciaio. Aggiungi un angolo di sformo (tipicamente da 1° a 3°) a tutte le pareti verticali per garantire un'espulsione regolare.

- Smussa gli angoli: Gli angoli interni acuti sono concentratori di stress che portano alla fessurazione. Usa sempre i raggi (filetti) per aiutare il metallo a fluire senza intoppi e ridurre l'usura dello stampo.

- Costole per la forza: Non limitarti a rendere il muro più spesso per renderlo più forte; che aumenta il peso e il tempo ciclo. Utilizzare le nervature per aggiungere rigidità senza aggiungere massa eccessiva.

Come Bian Diecast aggiunge valore agli ordini di volume elevato

Bian Diecast aiuta a scalare la tua fusione di alluminio, dall'ideazione alla produzione di massa. Offriamo una produzione one-stop con attività interna progettazione dello stampo, produzione in Cina e Messico, e un rigoroso controllo di qualità. Risparmia tempo e costi collaborando con il nostro team di esperti per consegne rapide e affidabili, parti di alta qualità.

Pronto per essere scalato? Smetti di indovinare con la tua produzione. Venite a trovarci a https://mag-cast.com/ per esplorare le nostre capacità e ottenere un'analisi DFM completa per il tuo prossimo progetto.

- Progettazione interna di stampi & Produzione: Costruiamo i nostri stampi di precisione, garantendo che lo strumento corrisponda perfettamente all'intento progettuale e consentendo una rapida manutenzione.

- Impronta globale: Con strutture sia in Cina che Messico, offriamo flessibilità nella catena di fornitura che mitiga i rischi geopolitici e riduce i tempi di spedizione per i clienti nordamericani.

- Controllo qualità totale: Dall'analisi spettrale delle materie prime al rilevamento della porosità a raggi X in tempo reale, garantiamo che ogni parte soddisfi i rigorosi standard automobilistici e industriali.