The casting vs machining decision is often the single most critical factor determining a project’s profitability, setting a course that can lead to either efficient scaling or crippling budget overruns. An incorrect choice early in the design stage can lock you into expensive, inflexible tooling for a high-volume part, or saddle you with a per-unit cost that makes production unsustainable. This isn’t just a technical comparison; it’s a fundamental analysis of your manufacturing economics and supply chain risk.

This guide provides a standard operating procedure for evaluating both processes. We will break down the cost structures, comparing the upfront investment in tooling against the variable costs of materials and cycle times. We’ll also examine how specific design geometries—like internal cavities and tight tolerances—dictate the ideal manufacturing path, and analyze the performance trade-offs in structural integrity and surface finish.

Subtractive vs. Formative Manufacturing

Selecting the right manufacturing process hinges on the trade-off between precision tooling for low volumes and cost-effective shaping for mass production, a decision that defines a part’s final cost.

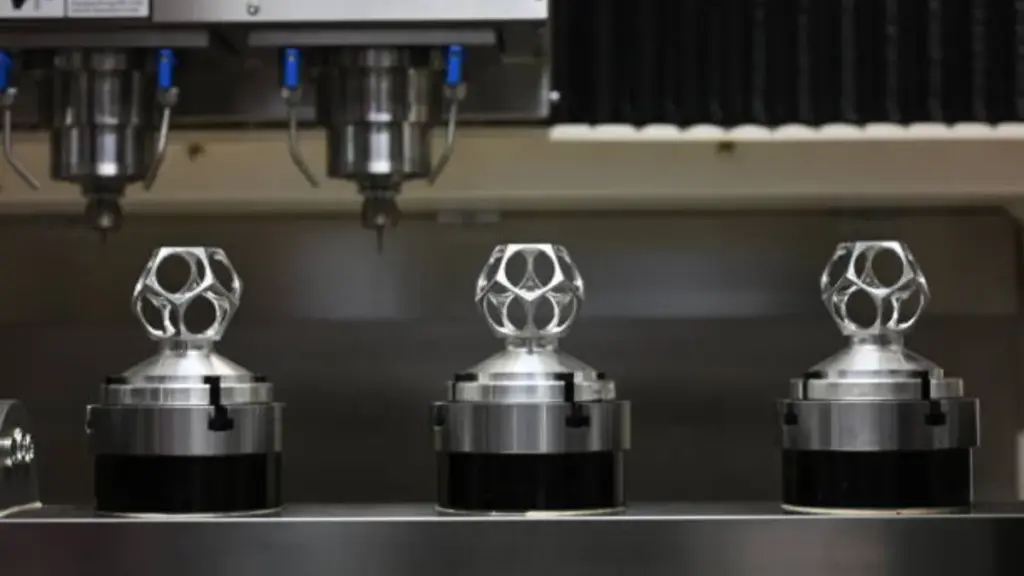

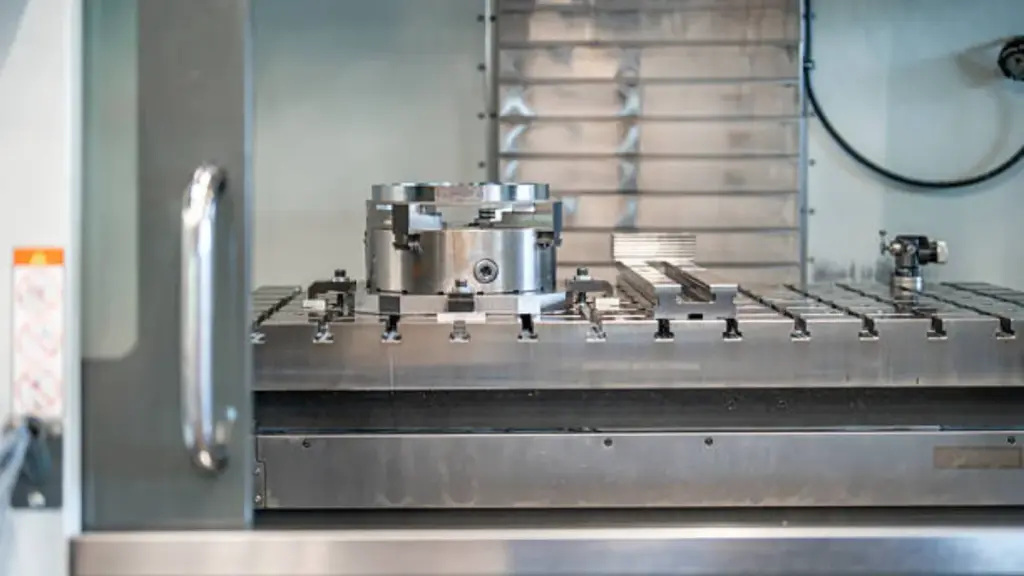

Subtractive Methods for Precision Tooling

Subtractive manufacturing works by systematically removing material from a solid block to achieve a final shape. The most common process, CNC 가공, uses computer-controlled cutting tools to achieve high dimensional accuracy and superior surface finishes. This precision is essential for creating the hardened steel molds and dies required for formative processes like die casting. Subtractive methods are the go-to for prototypes and mid-volume production runs, 일반적으로 범위는 10 에게 10,000 단위, where initial tooling costs must be minimized.

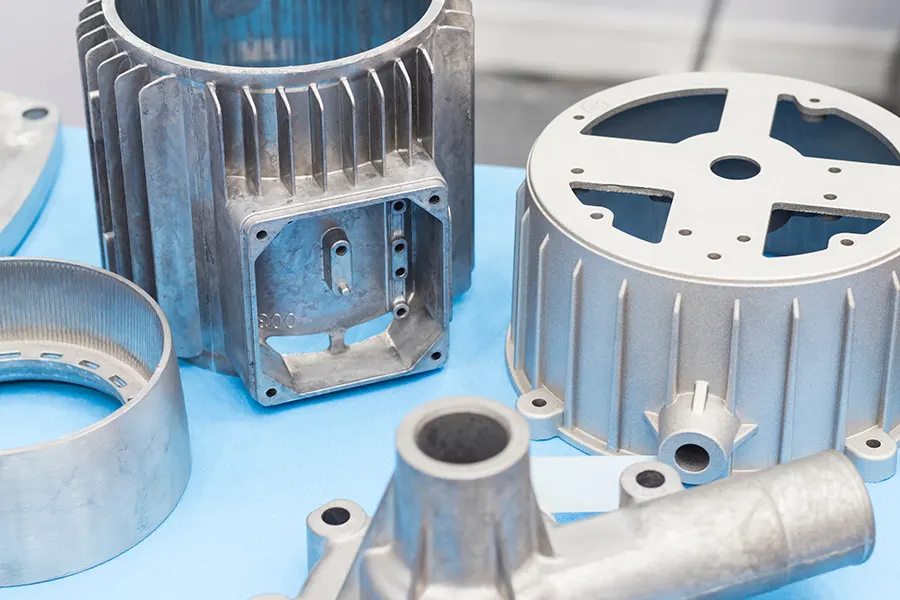

Formative Methods for High-Volume Cost Efficiency

Formative manufacturing shapes materials like molten aluminum or zinc into a desired near-net shape by pouring them into a mold cavity. 이 과정, exemplified by die casting, is engineered for repeatability and minimal material waste. While the initial tooling investment is significant, the per-unit cost drops dramatically once production starts. This makes formative methods the most economical choice for mass production runs that exceed 10,000 단위, delivering high repeatability and the lowest possible unit cost.

Hybrid Approach in Modern Supply Chains

A modern, resilient supply chain rarely relies on a single method. The hybrid approach combines the strengths of both manufacturing types. It uses subtractive manufacturing (CNC 가공) to create highly precise, durable tooling and molds. 그 다음에, it uses those tools in a formative process (다이캐스팅) to mass-produce the final parts efficiently. This strategy, central to our “중국 + 2” model, allows us to develop cost-effective tooling in our China R&D center and then transfer it to Vietnam or Mexico for tariff-advantaged mass production. It optimizes the entire manufacturing lifecycle, from initial precision to final part cost.

비용 분석: Tooling Investment vs. Per-Unit Price

Understanding the balance between a one-time tooling investment and ongoing per-unit price is critical for calculating the true cost-effectiveness of high-volume manufacturing.

Initial Tooling Investment: China-Based Mold Development

We centralize all tooling development at our China facility to capitalize on cost-effective engineering and rapid prototyping capabilities. This is a one-time, 100% prepaid investment with a typical lead time of 25-35 days to produce a production-ready mold. The fixed tooling cost is then amortized over the total production volume, a key factor that directly impacts the project’s break-even point. Once the mold is paid for, it belongs to the client, and the primary cost driver shifts to the per-unit price.

Factors Influencing Per-Unit Production Price

The per-unit price is determined by three main variable costs. First is the raw material, selected based on the component’s mechanical and thermal requirements; common choices include aluminum alloys like ADC12 and A380, zinc alloys Zamak 3/5, or magnesium AZ91D. Second are the costs for any secondary operations, such as precision CNC machining for critical tolerances, surface finishing like powder coating or anodizing, and light sub-assembly. 마지막으로, operational overhead varies between our manufacturing bases in China, Vietnam, 그리고 멕시코, which affects the final unit cost depending on the chosen production location.

Impact of Production Volume on Total Cost

Production volume is the single most important factor in reducing the effective cost per unit. While die casting requires a significant upfront tooling investment, its per-unit cost is substantially lower than CNC machining, making it far more economical for mass production. We recommend volumes of 5,000 units or more when producing in Vietnam or Mexico, as this scale is necessary to properly amortize cross-border operational and logistics costs. These Minimum Order Quantity (MOQ) levels ensure that the total landed cost remains competitive, offsetting the fixed expenses associated with international production and shipping.

Tariff and Logistics Impact on Final Landed Cost

Our tri-base manufacturing model allows for the strategic selection of a production base to mitigate or completely eliminate import tariffs for specific markets. For clients targeting the United States, producing in Vietnam or Mexico provides a clear path to tariff avoidance. The final landed cost includes not just the unit price but also ocean freight, customs clearance, and duties. We actively optimize these costs by utilizing Certificates of Origin (예를 들어, Form E/B from Vietnam) to leverage free trade agreements. 추가적으로, the nearshoring advantage of our Mexico facility reduces transit times and logistics risk for our North American partners.

IATF 16949 Die Casting for Flawless Components

설계 & 복잡성: Geometries That Dictate the Process

A part’s geometry determines the manufacturing path, forcing a choice between the high-volume efficiency of casting and the critical precision of CNC machining.

Formative-First Designs for High-Volume Production

A formative-first approach treats die casting as the primary manufacturing driver from the initial design stage. This method prioritizes features that are inherently efficient to cast, such as uniform thin walls, complex structural ribs, and integrated mounting bosses. The goal is to produce a near-net-shape part directly from the die, which dramatically reduces or eliminates the need for secondary machining. This strategy is the most direct path to lowering unit costs for high-volume orders (일반적으로 10,000+ 단위) and is standard practice for common alloys like Aluminum (ADC12, A380) 아연 (Zamak series) across our global facilities.

Subtractive Finishing for Critical Tolerances

Die casting alone cannot meet the tightest geometric tolerances required for many applications. Subtractive finishing, specifically multi-axis CNC machining, is essential for creating features beyond the limits of the casting process. This includes precision-mating surfaces, threaded holes, and bores requiring tight fits. This post-casting step ensures components meet CMM-verified dimensional accuracy, a mandatory requirement for IATF 16949 certified automotive parts. We apply this process in both the rapid prototyping stage at our China R&D center and for final refinement in mass production across all locations.

Hybrid Approach for Cost-Optimized Precision

The hybrid approach is the standard for modern precision manufacturing, blending the strengths of formative and subtractive methods. We start by creating a cost-effective, near-net-shape die-cast blank that captures the part’s complex geometry. 그 다음에, targeted CNC machining is applied only to the specific surfaces and features that demand high precision. This integrated workflow balances the speed of casting with the accuracy of machining, delivering an optimized balance of cost and performance. This is the ideal method for parts like 5G communication enclosures, which require intricate cast fins for heat dissipation alongside precisely machined interfaces for sealing and assembly.

Performance Battle: Tolerances, 힘, and Surface Finish

A component’s real-world viability is defined by its dimensional accuracy, material strength, and surface integrity—factors determined long before production begins.

Dimensional Accuracy and Global Consistency

Achieving repeatable precision across a global supply chain is non-negotiable. 우리의 통합 IATF 16949 quality management system ensures that a part cast in China, 멕시코, or Vietnam meets identical tolerance specifications. This eliminates regional variability, providing a consistent assembly experience for your production lines. We verify every part’s integrity against the original tooling CAD data using rigorous inspection protocols. CMM (좌표 측정기) full dimensional inspections confirm geometric accuracy, while X-Ray flaw detection identifies any internal porosity or defects that could compromise structural strength.

Material Selection for Mechanical Properties

The choice of alloy directly dictates a part’s performance characteristics. We work with a core set of high-strength, high-performance alloys to meet specific engineering demands. Our primary selections include Aluminum (ADC12, A380), 아연 (잔뜩 3, 잔뜩 5), and Magnesium (AZ91D), all conforming to ASTM, 안에, and JIS standards for global material consistency. These materials are not chosen arbitrarily; they are engineered for specific functions like the high thermal conductivity needed for heat sinks, the EMI shielding required for 5G communication enclosures, or the lightweight structural strength essential for automotive and aerospace components.

Functional and Cosmetic Surface Finishing

While die casting produces a near-net-shape part, the surface finish provides critical functional and aesthetic properties. A proper finish is the first line of defense against environmental factors and wear. Our in-house capabilities cover the full spectrum of finishing processes, ensuring complete control over quality and lead times. Each finish is selected to meet specific application requirements, from enhancing corrosion resistance for outdoor lighting enclosures to providing a durable, cosmetic surface for consumer electronics. Durability is verified through systematic salt spray testing to confirm long-term performance in harsh conditions.

- 분말 코팅

- 습식 페인팅

- Plating (예를 들어, Chrome, Nickel)

- 아노다이징

- 패시베이션

재료 선택 & Sustainability

Proper alloy selection directly impacts component performance, global market access, and environmental responsibility, making it a foundational element of effective product design and manufacturing strategy.

Core Alloys and International Standards

We standardize our primary alloys across all global facilities to ensure predictable, repeatable results. Our core selection includes Aluminum (ADC12, A380, AlSi12), 아연 (잔뜩 3, 잔뜩 5), and Magnesium (AZ91D). Material consistency is not left to chance; whether a part is produced in China, 멕시코, or Vietnam, it strictly adheres to ASTM, 안에, and JIS standards. This unified material protocol eliminates regional variability and guarantees that components meet precise engineering specifications regardless of their origin.

Functional Properties for Target Applications

Material selection is purpose-driven, aligned with the specific demands of the end-use application. Aluminum alloys are chosen for their exceptional thermal conductivity, a critical property for managing heat in New Energy Vehicle (NEV) powertrain systems and high-output LED lighting enclosures. These materials also provide inherent EMI shielding and high strength-to-weight ratios, making them ideal for protecting sensitive electronics in 5G communication base stations and for building durable, lightweight components for industrial automation.

Environmental and Material Compliance

Operating a global manufacturing footprint requires a rigorous commitment to environmental stewardship and regulatory compliance. All our production bases are managed under the ISO 14001 environmental management system, ensuring responsible operational practices. We also guarantee full material compliance with RoHS and REACH directives. This proactive restriction of hazardous substances is essential for gaining and maintaining access to key international markets, particularly in North America and the European Union.

Lead Times: Instant Start vs. Tooling Wait Times

Lead time analysis separates the one-time tooling delay from the repeatable, faster mass production cycle, which is critical for accurate supply chain planning.

Initial Tooling Development & NPI Phase (25-35 Days)

The New Product Introduction (NPI) process for any new custom component begins with a one-time tooling setup. This critical phase includes the mold creation and first article inspection (FAI), all completed at our central R&중국 D센터. This upfront investment in time, 일반적으로 25 에게 35 날, is required before mass production can begin for any new part design.

Standard Mass Production Cycle (4-6 Weeks)

Once tooling is approved, the standard manufacturing lead time is 4 에게 6 주. This cycle starts upon receipt of a purchase order and runs at your selected global facility in China, Vietnam, or Mexico. The timeframe covers the complete operational flow, from procuring raw materials like ADC12 or A380 aluminum to die casting, 마무리 손질, and final packaging for shipment.

Production Readiness for Repeat Orders

For all subsequent production batches of an existing part, the initial 25-35 day tooling wait is completely eliminated. With the validated mold ready for use, manufacturing can be scheduled immediately against a new purchase order. This creates a direct-to-production workflow, ensuring faster and more predictable delivery timelines for repeat business.

The Hybrid Strategy: Precision Machined Castings

This hybrid model merges the speed of high-volume casting with the tight tolerances of CNC machining, creating complex, cost-effective parts without sacrificing precision.

Combining Formative and Subtractive Processes

The most effective manufacturing strategies combine formative and subtractive methods. We use high-pressure die casting (a formative process) to produce the initial near-net-shape part. This approach is optimized for speed and material efficiency, especially for complex geometries in high-volume runs of aluminum, 아연, or magnesium alloys. After casting, we employ multi-axis CNC machining (a subtractive process) for secondary operations. This step is critical for adding features and achieving tolerances that casting alone cannot deliver. This integrated process balances the unit cost savings of casting with the high dimensional accuracy of precision machining, delivering a superior final component.

Achieving Critical Tolerances on Cast Components

Secondary CNC machining is not an afterthought; it is a planned step to meet strict functional requirements. We machine critical mounting points, mating surfaces, and bores to satisfy demanding geometric dimensioning and tolerancing (GD&티) specifications. This ensures absolute precision for features like airtight sealing surfaces on 5G communication enclosures or bearing interfaces in automotive powertrain systems. While casting typically produces wider tolerances (IT12 or higher), our machining centers consistently achieve tighter grades required for precision fits. To guarantee conformity, every machined casting undergoes a full dimensional inspection using Coordinate-Measuring Machine (CMM) protocols and X-Ray flaw detection before shipment.

Integrated Workflow from Casting to Final Part

A fragmented supply chain introduces risk and delay. Our one-stop model streamlines production by managing tooling design, 다이캐스팅, and CNC machining within a single, unified quality management system certified to IATF 16949. This vertical integration eliminates the logistical handoffs and quality discrepancies that occur between separate casting foundries and machine shops. The result is shorter lead times and improved process control. This consistent standard is enforced across all our manufacturing bases in China, 멕시코, 그리고 베트남, guaranteeing that a part produced in any facility will meet the exact same specifications and quality benchmarks.

결론

Choosing between casting and machining is a strategic decision driven by production volume, 부품 복잡성, and long-term cost targets. While CNC machining offers speed and precision for prototypes and low-volume runs, casting provides significant cost-efficiency and geometric freedom at scale. A hybrid strategy, where cast parts are precision machined, often delivers the ideal balance of both worlds.

When evaluating your next project, our engineering team can analyze your design for manufacturability and recommend the most effective production path. Contact us to find the right balance between tooling investment, per-unit price, and a global supply chain strategy tailored to your needs.

자주 묻는 질문

Is casting cheaper than machining?

Casting is generally cheaper than machining for high-volume production, specifically for quantities over 10,000 단위. The formative nature of casting allows for reduced unit costs at scale, making it the cost-leader in that range, while machining is more economical for mid-volume production.

At what quantity should I switch from machining to casting?

According to market data, the typical switch-over point from machining to casting occurs when production volume exceeds 10,000 단위. Machining is the dominant process for mid-volume runs (10-10,000 단위), after which casting becomes the more cost-effective solution.

Is machined aluminum stronger than cast aluminum?

The provided research content focuses on manufacturing volumes, cost-effectiveness, and process trends. It does not contain specific data on material properties like the relative strength of machined versus cast aluminum.

Can you machine die cast parts?

예, 전적으로. Machining cast parts is a key component of modern hybrid manufacturing. This approach combines the formative efficiency of casting with the subtractive precision of machining to achieve high dimensional accuracy and add complex features to a part.

Which process has better surface finish?

Machining generally provides a better surface finish. The research highlights that subtractive manufacturing is valued for its “dimensional accuracy.” This precision allows for finer surface finishes than a raw casting, which often requires secondary machining for critical surfaces.

What are the disadvantages of casting?

The primary disadvantage of casting is its lack of cost-effectiveness for low-to-mid volume production (under 10,000 단위). 추가적으로, while it offers excellent repeatability, it may lack the inherent dimensional accuracy of machining, often necessitating secondary processes for high-precision features.