Servicio de mecanizado CNC

Servicios de mecanizado CNC en línea personalizados

Obtenga cotizaciones instantáneas sobre metales personalizados con nuestro servicio de mecanizado CNC en línea. Realice prototipos de entrega rápida y piezas de producción en todos los pedidos.. YO ASI 9001:2015, YO ASI 13485 y certificado AS9100D. registrado en ITAR.

- Diseño de molde & Análisis de diseño

- Fuerte capacidad de producción de fundición a presión

- Servicio de mecanizado CNC de precisión

- Múltiples opciones de acabado

- Soporte técnico en línea

Obtenga una cotización instantánea

Descripción general de los servicios de mecanizado CNC

Mecanizado CNC, como un proceso vital dentro fundición a presión de aluminio, permite mecanizado de precisión y ajustes a las piezas fundidas de aluminio para cumplir con los requisitos y especificaciones del producto final. En el proceso de fundición a presión de aluminio., Las piezas fundidas de aluminio obtenidas después de inyectar la aleación de aluminio en moldes a menudo requieren mecanizado y acabado secundarios para lograr las dimensiones precisas deseadas., formas, y calidad de la superficie. Aquí es donde entra en juego el mecanizado CNC.

Confiable & Aluminio fundido a presión versátil para elegir

Fresado CNC

El taller de fresado CNC está equipado con fresadoras utilizadas para fresado plano., fresado de contorno, perforación de agujeros, y otras operaciones. Se emplea comúnmente en la producción de piezas como pisos., surcos, agujeros, y hilos continuos.

Torneado CNC

El taller de torneado CNC cuenta con tornos utilizados para mecanizado rotacional, incluido el mecanizado de contornos exteriores, mecanizado de extremos, y mecanizado de roscas. Se utiliza frecuentemente para procesar componentes como ejes..

Mecanizado por electroerosión

Mecanizado por electroerosión por hilo, También conocido como mecanizado por descarga eléctrica con corte de alambre., es un proceso de corte electrotérmico. En comparación con los métodos de corte mecánico tradicionales, El mecanizado por electroerosión por hilo ofrece mayor precisión y calidad superficial, y puede manejar formas geométricas más complejas.

Centros de mecanizado CNC

Refina tus piezas sin esfuerzo

A continuación se muestra una breve lista de nuestros centros de mecanizado CNC., capaz de mecanizar con precisión piezas de fundición para una cartera de sectores. Mayor dimensión de mecanizado hasta 1000centímetro.

- 3-máquina CNC de eje: Estas máquinas pueden moverse a lo largo de la X, Y, y ejes Z.

- 4-máquina CNC de eje: Estas máquinas tienen la capacidad de moverse a lo largo de la X, Y, ejes Z, más un eje giratorio adicional (a menudo denominado eje A).

- 5-máquina CNC de eje: Estas máquinas avanzadas pueden moverse a lo largo de los tres ejes lineales. (incógnita, Y, z) y tiene dos ejes giratorios adicionales (A y B o A y C).

Nuestras medidas de control de calidad

Nuestro Talleres de trabajo están equipados con conjuntos integrales de instalaciones desde la inspección final hasta la inspección final. Realizaremos una amplia gama de pruebas de calidad para garantizar que los productos de fundición a presión cumplan con sus requisitos y estándares específicos..

Inspección precisa:

Experiencia en prueba:

Una escala completa de pruebas meticulosas

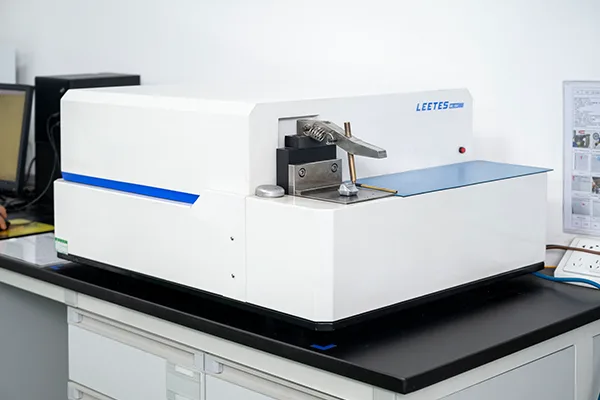

Espectrómetro de lectura directa

Análisis de composición de materiales..

Máquina de medición de coordenadas (MMC)

Para medición de dimensiones de precisión.

Medidor de densidad electrónico

Medición de la densidad de los materiales utilizados en el proceso de fundición a presión..

Sistema de pruebas no destructivas de rayos X

Inspección de porosidad interna.

Equipo de prueba de estanqueidad Cámara de vacío Dispositivo de detección de fugas de helio

Inspección de estanqueidad del producto..

Analizador de escaneo de limpieza

Un instrumento de precisión utilizado para inspeccionar y evaluar la limpieza y calidad de las superficies..

Probador de fricción y rayones CS-10F

Es un probador de fricción y rayado que se utiliza para evaluar la durabilidad del material y la calidad de la superficie..

Prueba de par de torsión máxima de falla de rosca

Pruebas de resistencia a la corrosión.

Alcohol & Máquina de prueba de fricción de caucho

Pruebas de resistencia al desgaste del revestimiento de superficies..

Colorímetro

Detección de diferencia de color de recubrimiento.

Medidor de espesor de película

Medición del espesor del recubrimiento.

Probador de abrasión de tiras de papel

Diseñado para evaluar la resistencia al desgaste de los materiales., particularmente productos de papel.

2.5D Instrumento de medición

Se utiliza para mediciones precisas en fabricación y control de calidad., combinar datos 2D con información de profundidad o altura.

Ventajas de las aleaciones de aluminio mecanizadas por CNC

Haga que sus piezas de fundición cobren vida con facilidad

Personalizaciones flexibles

Alta productividad & Entrega rápida

Repetibilidad & Excelente control de calidad

Excelente calidad superficial

Reutilizable & Sostenible

Cómo trabajar con nosotros?

Sube tus archivos

Para comenzar rápidamente su proyecto de fundición a presión, por favor sube el archivo (2Dibujo D/3D) a nuestros expertos. No hay problema, tu diseño está seguro con nosotros. La firma de NDA también es aceptable.

Cita & Comentarios sobre DFM

Con tus diseños o diseños solicitados por nuestros expertos, Le proporcionaremos un diseño para la fabricabilidad. (DFM) análisis y cotización en tiempo real.

Fabricación

Una vez que hayas confirmado el diseño. & cita, comenzaremos el proceso de fabricación, incluyendo fundición a presión, Servicios de mecanizado y acabado CNC..

Envío

Puede obtener embalajes personalizados para piezas de fundición a presión., incluyendo materiales de embalaje y logotipo, impresión de etiquetas.

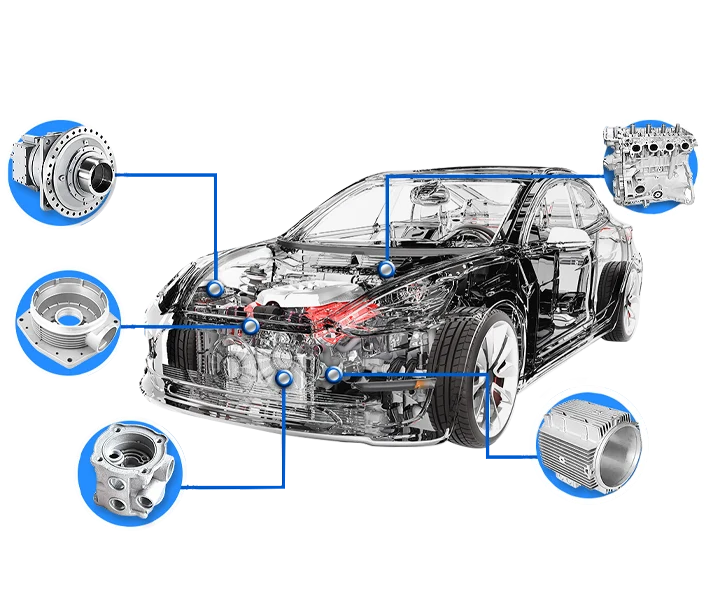

Piezas de automóviles

Piezas de iluminación

Piezas de fundición a dieds personalizadas para una amplia gama de industrias

Partes electronicas

Piezas de muebles

Piezas de construcción

Excelencia en la gestión de proyectos en la que puede confiar

Preguntas más frecuentes

El mecanizado CNC significa mecanizado por control numérico por computadora.. Es un proceso de fabricación de alta precisión que complementa la fundición a presión al permitir ajustes, organización, y modificaciones posteriores a la fundición de piezas fundidas a presión. El mecanizado CNC garantiza que las piezas cumplan con tolerancias estrictas y dimensiones específicas, mejorando su calidad y funcionalidad generales.

Sí, El mecanizado CNC es versátil y aplicable tanto a piezas de fundición a presión de aluminio como de zinc.. Ofrece la flexibilidad de ajustar y modificar piezas fabricadas con diversos materiales., garantizar que cumplan con los requisitos específicos del proyecto.

Absolutamente, El mecanizado CNC es la solución ideal para lograr tolerancias estrictas en piezas críticas de fundición a presión. Su precisión controlada por computadora garantiza que las piezas cumplan con los requisitos dimensionales exactos., incluso para aplicaciones exigentes en industrias como la aeroespacial y la automotriz. El mecanizado CNC mejora la calidad, fiabilidad, y rendimiento de estos componentes de precisión.

El mecanizado CNC abarca diversas operaciones., incluyendo fresado, torneado, perforación, y acabado de superficies. Estas operaciones se pueden adaptar para cumplir con requisitos funcionales y de diseño específicos para piezas fundidas a presión..

El mecanizado CNC contribuye significativamente a reducir los plazos de entrega al ofrecer una configuración rápida, cambios de herramientas eficientes, y capacidades de corte de alta velocidad. Esta agilidad permite realizar ajustes rápidos en los cronogramas de producción y atender pedidos urgentes., hacer del mecanizado CNC un factor clave para cumplir con los plazos ajustados de los proyectos.

El mecanizado CNC es versátil y compatible con una amplia gama de materiales comúnmente utilizados en la fundición a presión., incluyendo aluminio, zinc, magnesio, y más. La selección de materiales depende de los requisitos específicos de su proyecto., y el mecanizado CNC puede acomodar varios materiales con facilidad.

Sí, El mecanizado CNC es una excelente opción para producir prototipos de piezas fundidas a presión.. Su capacidad para mecanizar piezas de forma rápida y precisa lo hace ideal para probar y validar diseños antes de comprometerse con la producción en masa.. Esto reduce el tiempo y los costos asociados con la creación de prototipos físicos..

Factores de diseño como la selección de materiales., tolerancias, complejidad de la pieza, y se debe considerar el acabado superficial deseado al planificar el mecanizado CNC para piezas fundidas a presión.. La colaboración con ingenieros experimentados puede ayudar a optimizar los diseños para un mecanizado CNC eficiente.

Mantenemos la consistencia de la calidad a través de un riguroso control de procesos., formación de empleados, y cumplimiento de los estándares de la industria. Nuestro equipo de medición avanzado verifica dimensiones y formas., garantizar que cada pieza mecanizada de fundición cumpla con los requisitos especificados.

Nuestros clientes

Obtenga una cotización para servicios de fundición a presión hoy!

-

.No. 128-129, Zona Industrial Este,

Mashe Este, ciudad de lishui, Distrito de Nanhai, Foshán, Cantón, Porcelana

- Contacto:katherine

- Teléfono:+86 189 4247 5007

- Correo electrónico:katherine@mag-cast.com

- WhatsApp:+86-159 1863 4657

- Contacto:reno

- Teléfono:+86 177 9601 9842

- Correo electrónico:ventas3@mag-cast.com

- WhatsApp:+86-186 6688 2487