CNC Machining Service

Custom Online CNC Machining Services

Get instant quotes on custom metal with our Online CNC Machining Service. Make quick turn prototypes and production parts on all orders. ISO 9001:2015, ISO 13485 and AS9100D certified. ITAR registered.

- Mold Design & Design Analysis

- Strong Die Casting Production Capability

- Precision CNC Machining Service

- Multiple Finishing Options

- Online Technical Support

Get Instant Quote

CNC Machining Services Overview

CNC machining, as a vital process within aluminum die casting, allows for precision machining and adjustments to aluminum castings to meet the final product’s requirements and specifications. In the aluminum die casting process, the aluminum castings obtained after aluminum alloy is injected into molds often require secondary machining and finishing to achieve the desired precise dimensions, shapes, and surface quality. This is where CNC machining comes into play.

Reliable & Versatile Die-cast Aluminum for Selection

CNC Milling

CNC milling workshop is equipped with milling machines used for flat milling, contour milling, hole drilling, and other operations. It is commonly employed in the production of parts such as flats, grooves, holes, and continuous threads.

CNC Turning

The CNC turning workshop features lathes used for rotational machining, including external contour machining, end-face machining, and thread machining. It is frequently used for processing components like shafts.

EDM Machining

Wire EDM machining, also known as wire-cut electrical discharge machining, is an electrothermal cutting process. Compared to traditional mechanical cutting methods, Wire EDM machining offers higher precision and surface quality, and it can handle more complex geometric shapes.

CNC Machining Centers

Refine Your Parts Effortlessly

Following is a brief list of our CNC machining centers, capable of precision machining die-cast parts for a portfolio of sectors. Largest machining dimension up to 1000cm.

- 3-axis CNC machine: These machines can move along the X, Y, and Z axes.

- 4-axis CNC machine: These machines have the capability to move along the X, Y, Z axes, plus an additional rotary axis (often referred to as the A-axis).

- 5-axis CNC machine: These advanced machines can move along all three linear axes (X, Y, Z) and has two additional rotary axes (A and B or A and C).

Our Quality Control Measures

Our workshops are equipped with comprehensive sets of facilities from die-casting to final inspection. We will conduct a comprehensive range of quality tests to ensure that the die-cast products meet your specific requirements and standards.

Precise Inspection:

Testing Expertise:

A Full-scale of Meticulous Tests

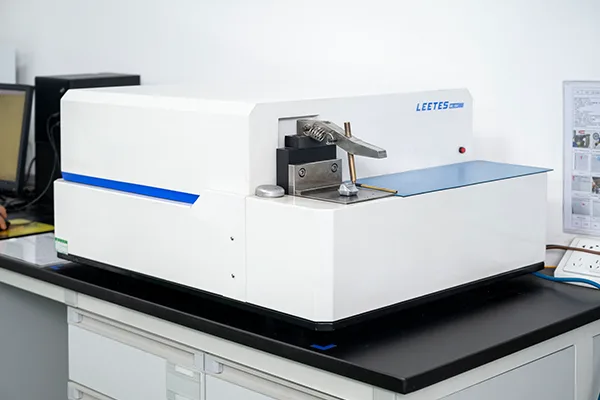

Direct Reading Spectrometer

Material composition analysis.

Coordinate Measuring Machine (CMM)

For precision dimension measurement.

Electronic Density Meter

Measuring the density of materials used in the die-casting process.

X-ray Non-Destructive Testing System

Internal porosity inspection.

Air-Tightness Testing Equipment Vacuum Chamber Helium Leak Detection Device

Product air-tightness inspection.

Cleanliness Scanning Analyzer

A precision instrument used to inspect and assess the cleanliness and quality of surfaces.

Friction and Scratch Tester CS-10F

It's a friction and scratch tester used for evaluating material durability and surface quality.

Maximum Thread Failure Torque Testing

Corrosion resistance testing.

Alcohol & Rubber Friction Testing Machine

Surface coating wear resistance testing.

Colorimeter

Coating color difference detection.

Film Thickness Gauge

Coating thickness measurement.

Paper Strip Abrasion Tester

Designed to assess the wear resistance of materials, particularly paper products.

2.5D Measurement Instrument

Used for precise measurements in manufacturing and quality control, combining 2D data with depth or height information.

CNC Machined Aluminum Alloys Advantages

Bring Your Die-cast Parts to Life with Ease

Flexible Customizations

High Productivity & Fast Delivery

Repeatibility & Excellent Quality Control

Excellent Surface Quality

Resuable & Sustainable

How to Work with Us?

Upload Your Files

To quickly start your die-casting project, pls upload file (2D/3D drawing) to our experts. No worries, your design is safe with us. NDA signing is also acceptable.

Quote & DFM Feedback

With your designs or designs requested by our experts, we will provide you with a Design for Manufacturability (DFM) analysis and a real-time quotation.

Manufacturing

Once you've confirmed the design & quote, we'll start manufacturing process, including die casting, CNC machining and finishing services.

Shipping

You can get custom packaging for die-cast parts, including packaging materials and logo, label printing.

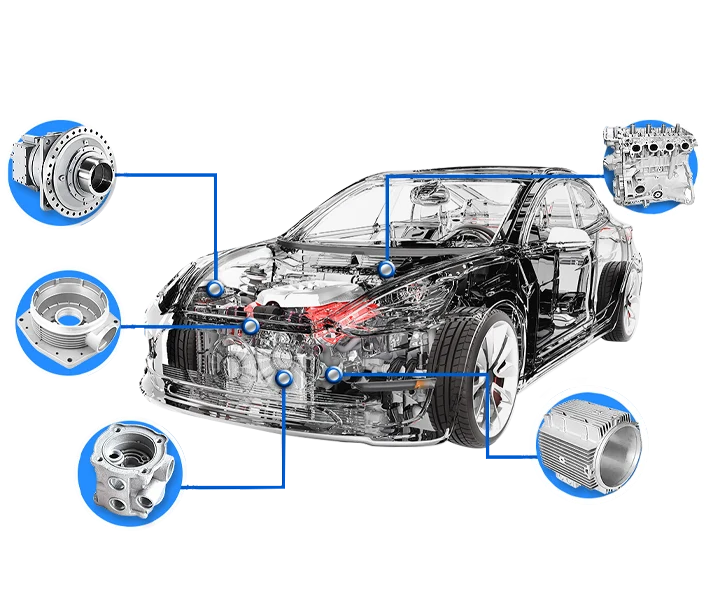

Automotive Parts

Lighting Parts

Custom Die Casting Parts for A Wide Range of Industries

Electronic Parts

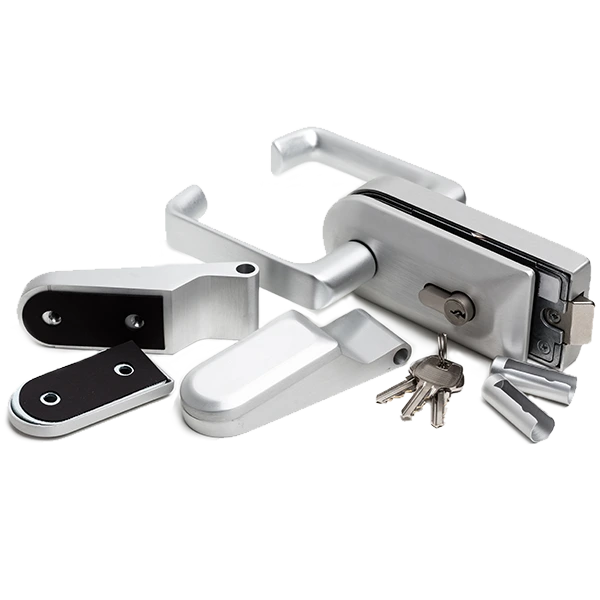

Furniture Parts

Construction Parts

Project Management Excellence You Can Rely On

FAQ

CNC machining stands for Computer Numerical Control machining. It’s a highly precise manufacturing process that complements die casting by allowing for fine-tuning, shaping, and post-casting modifications of die-cast parts. CNC machining ensures parts meet tight tolerances and specified dimensions, enhancing their overall quality and functionality.

Yes, CNC machining is versatile and applicable to both aluminum and zinc die-cast parts. It offers the flexibility to fine-tune and modify parts made from various materials, ensuring they meet specific project requirements.

Absolutely, CNC machining is the go-to solution for achieving tight tolerances in critical die-cast parts. Its computer-controlled precision ensures parts conform to exact dimensional requirements, even for demanding applications in industries like aerospace and automotive. CNC machining enhances the quality, reliability, and performance of these precision components.

CNC machining encompasses various operations, including milling, turning, drilling, and surface finishing. These operations can be tailored to meet specific design and functional requirements for die-cast parts.

CNC machining significantly contributes to shorter lead times by offering rapid setup, efficient tool changes, and high-speed cutting capabilities. This agility allows for quick adjustments in production schedules and accommodating urgent orders, making CNC machining a key factor in meeting tight project timelines.

CNC machining is versatile and compatible with a wide range of materials commonly used in die-casting, including aluminum, zinc, magnesium, and more. Material selection depends on your project’s specific requirements, and CNC machining can accommodate various materials with ease.

Yes, CNC machining is an excellent choice for producing prototypes of die-cast parts. Its ability to quickly and accurately machine parts makes it ideal for testing and validating designs before committing to mass production. This reduces the time and costs associated with creating physical prototypes.

Design factors such as material selection, tolerances, part complexity, and the desired surface finish should be considered when planning CNC machining for die-cast parts. Collaboration with experienced engineers can help optimize designs for efficient CNC machining.

We maintain quality consistency through rigorous process control, employee training, and adherence to industry standards. Our advanced measurement equipment verifies dimensions and shapes, ensuring each machined die-cast part meets specified requirements.

Our Clients

Get A Quote for Die Casting Services Today!

-

.No. 128-129, East Industrial Zone,

Mashe East, Lishui Town, Nanhai District, Foshan, Guangdong, China

- Contact:katherine

- Phone:+86 189 4247 5007

- E-mail:Katherine@mag-cast.com

- WhatsApp:+86-159 1863 4657

- Contact:Reno

- Phone:+86 177 9601 9842

- E-mail:sales3@mag-cast.com

- WhatsApp:+86-186 6688 2487