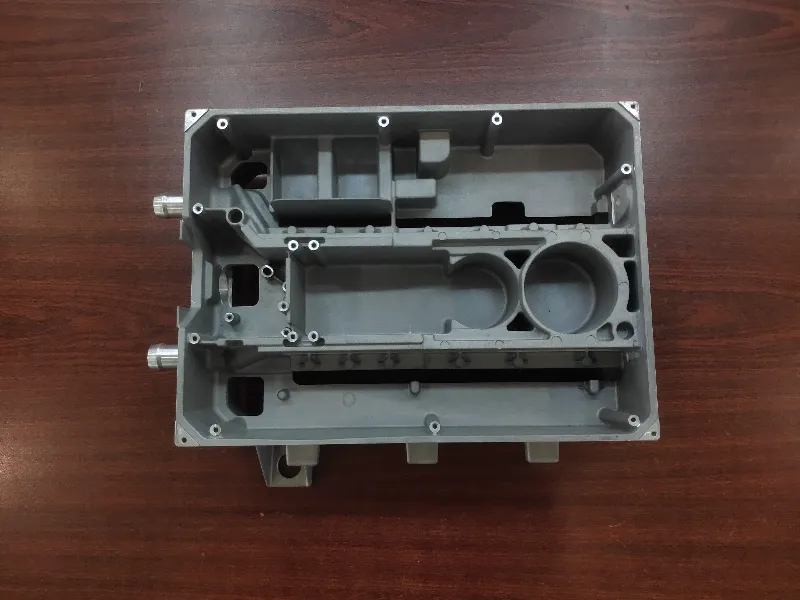

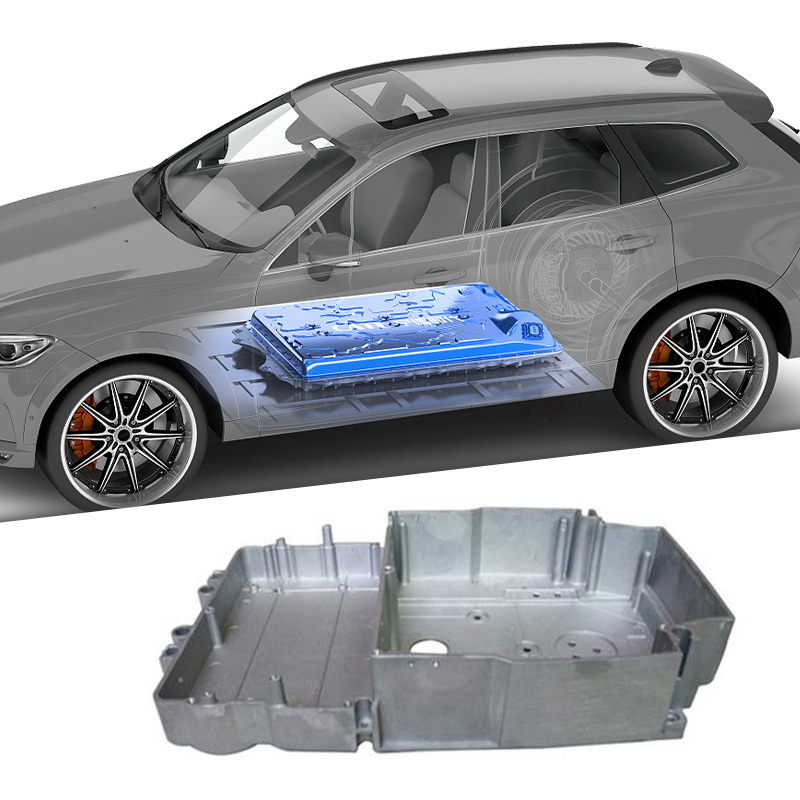

La productividad de las piezas de aluminio fundido a presión varía desde 2,000 a 3,000 piezas por dia. Los costos del molde pueden ser significativos, y nuestro r&Los equipos D se esfuerzan por ayudarlo con sugerencias de optimización, priorizando sus beneficios a largo plazo. Nuestros moldes suelen durar alrededor 3 años. Cuando el viejo molde llega al final de su vida útil, si eliges seguir trabajando con nosotros, Podemos replicar un nuevo molde., y es gratis.

Te prometemos un transparente & proceso de fabricación simplificado. Todas las aleaciones de aluminio provienen de proveedores certificados., y esto evita posibles defectos. Su pedido estará bajo gestión de proyectos maduros.. Además, Empleamos pantalla táctil industrial digital para la fabricación de producción en vivo.. Eso es cierto, siempre recibes comentarios en vivo.

Bian Diecast mantiene rigurosas prácticas de control de calidad. Somos ISO 45001, YO ASI 9001, YO ASI 14001, & IATF 16949 Fabricante de aluminio de fundición certificado & fábrica. Más, Nuestro material fundido a presión es REACH, RoHS, y certificado por la FDA para cumplir con diversos requisitos del mercado. A pedido, Podemos proporcionar documentos como PPAP., APQP, AMEF, MSA, proceso estadístico, y más, mostrando nuestro compromiso con el control de calidad y la gestión de la producción.