The choice between alloy steel vs carbon steel is a critical engineering decision that directly impacts structural integrity, manufacturing costs, and the risk of premature component failure. Selecting the wrong material for a high-stress application can lead to costly product recalls and significant operational downtime. This isn’t just about comparing datasheets; it’s about matching the right material to a specific operational environment to prevent over-engineering and control production expenses.

This guide provides a direct technical comparison of these two materials, focusing on key performance metrics like strength, résistance à la corrosion, and CNC machinability. We will also analyze the critical trade-offs between steel and die-cast aluminum, clarifying the exact scenarios where switching from machined steel to a lightweight aluminum alloy reduces part cost and cycle time without sacrificing performance.

The Fundamental Difference Between Carbon Steel and Alloy Steel

The choice is a direct trade-off: carbon steel’s low cost and weldability versus alloy steel’s superior strength, temperature tolerance, and corrosion resistance for demanding applications.

Compositional and Elemental Makeup

Carbon steel’s composition is straightforward, consisting almost entirely of iron and carbon, where other elements are treated as residual impurities. This simple formula defines its fundamental properties. Alloy steel, par contre, is intentionally engineered for specific outcomes by adding elements like chromium, nickel, molybdenum, or vanadium. These additions are not impurities; they are deliberate modifications to enhance physical and chemical properties far beyond what carbon and iron alone can achieve.

Key Differences in Mechanical Properties

The divergence in composition creates distinct performance profiles. Alloy steel delivers superior tensile strength, typically ranging from 758–1882 MPa, and has excellent corrosion resistance due to elements like chromium forming a protective oxide layer. Carbon steel, while having a lower tensile strength (450–965 MPa), offers higher surface hardness and is significantly easier to weld. This weldability, combined with its lower production cost, makes carbon steel the default for general fabrication and structural work where extreme conditions are not a factor.

Criteria for Material Selection in Applications

Your selection process should be driven entirely by the part’s operational environment and budget. There is no universally “better” material, only the correct material for the job.

- Use carbon steel for structural components, machine frames, and general parts where ease of welding and cost are the primary decision factors. It is the practical choice for high-volume, low-stress applications.

- Select alloy steel for high-performance use cases. This includes gears, engine components, and parts operating in corrosive, high-temperature, or heavy-load environments where failure is not an option and material durability justifies a higher cost.

Key Performance Breakdown: Force, Corrosion, and Cost

Material selection is a direct trade-off between a component’s field performance, required lifespan, and the total cost of manufacturing.

Evaluating Strength, Dureté, and Tensile Properties

The term “force” is often misapplied in material comparisons. Carbon steel typically exhibits greater surface hardness, making it the superior choice for applications that demand high resistance to pressure and deformation. En revanche, alloy steel provides significantly higher tensile strength, with ratings from 758 à 1882 MPa compared to carbon steel’s 450-965 MPa. This specification makes alloy steel better equipped for scenarios involving sustained loads or tension. Its durability can also be enhanced through specific heat treatments, a key advantage for high-performance components.

Assessing Corrosion Resistance and Weldability

Alloy steel holds a clear advantage in corrosion resistance. The inclusion of elements like chromium allows it to form a self-healing passive oxide layer, offering reliable protection in humid or chemical-rich environments. Carbon steel, lacking these elements, is highly susceptible to rust and almost always requires a secondary protective coating like paint or plating. The trade-off comes in fabrication. Carbon steel is straightforward to weld with consistent, reliable results. Alloy steels are more difficult to work with, often requiring specialized techniques like pre-heating to prevent cracking during the welding process.

Analyzing Material Cost and Machining Efficiency

Carbon steel is the more economical raw material due to its simple iron-carbon composition. Alloy steel’s price is significantly higher, driven by the cost of added elements like nickel, chromium, and molybdenum. This cost difference extends to manufacturing. Low-carbon steels offer excellent machinability, enabling faster cycle times and reduced tool wear. Alloy steels are inherently tougher and more resistant to cutting, which demands slower machining speeds, more robust tooling, and more complex processes, increasing the time and cost required to produce a finished part.

IATF-Certified Die Casting for Zero-Defect Production

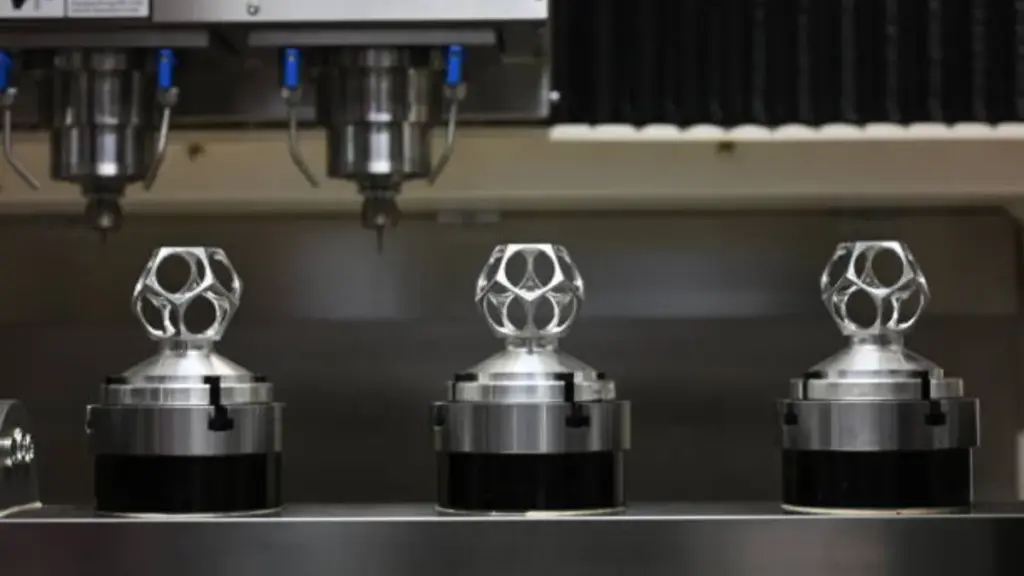

CNC Machinability: Which Steel is Faster to Process?

Carbon steel machines significantly faster, but alloy steel’s properties often justify the longer, more expensive processing required for high-performance parts.

Acier au carbone: The Baseline for High-Speed Machining

Carbon steel’s simple, uniform composition of iron and carbon enables highly predictable cutting behavior. This consistency allows machine shops to run at faster material removal rates without unexpected complications. Low-carbon and free-machining grades, such as 12L14, are the industry benchmark for machinability, offering minimal resistance to cutting tools and excellent chip formation. This directly translates to lower machine power requirements and reduced tool wear, making carbon steel the ideal choice for applications where processing speed and cost-efficiency are the primary design drivers.

How Alloying Elements Reduce Machining Speed

Adding elements like chromium, nickel, and molybdenum fundamentally changes steel’s properties, increasing its toughness, dureté, and heat resistance. While beneficial for the final part’s performance, this creates significant challenges during machining. The increased material toughness requires slower cutting speeds and more robust tooling to manage heat and prevent tool failure. Par exemple, machining alloy steel like 4140 can take twice as long as a standard carbon steel.

En outre, many complex alloys are prone to work hardening, where the material becomes harder as it is cut. This complicates subsequent operations and requires careful process control. To manage these challenges, specialized cutting tools and advanced cooling strategies are often necessary, extending the overall cycle time and increasing the cost per part.

Selecting Steel Based on Total Processing Time

The material selection process involves a direct trade-off between production speed and part performance. Carbon steel provides the shortest path from raw material to a finished component but offers limited mechanical and chemical properties. Alloy steel, d'autre part, requires a longer and more costly machining process, but this investment is often justified by its superior strength, résistance à la corrosion, and durability in harsh environments.

The final decision depends entirely on the part’s end-use requirements. If the component will operate under high stress, in a corrosive environment, or at elevated temperatures, the enhanced properties of alloy steel become non-negotiable, outweighing the need for rapid production.

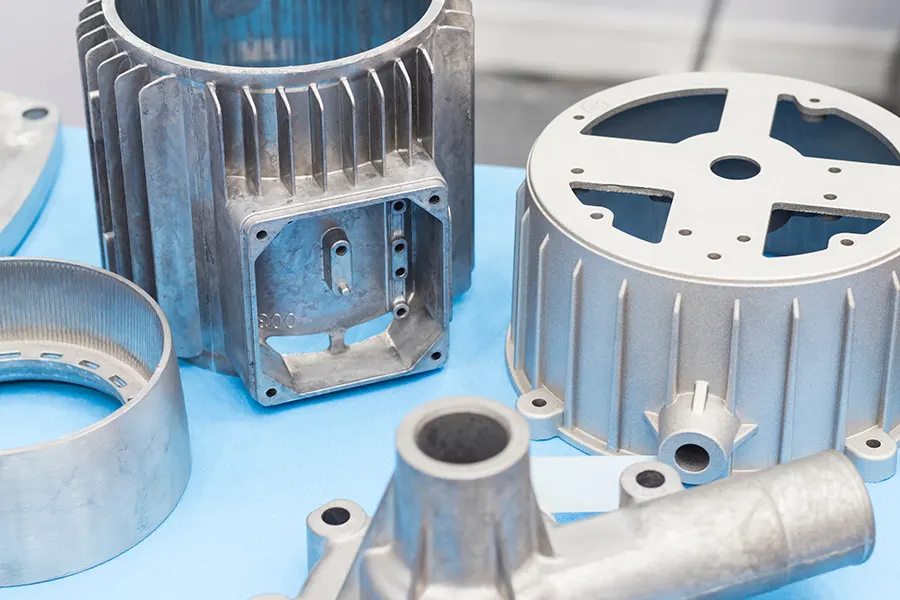

Carbon Steel vs Aluminum Alloy: When to Switch to Die Casting?

Switching from steel fabrication to aluminum die casting is a strategic pivot based on part complexity, volume de production, and total cost, not just material specs.

Material Properties: Poids, Force, and Corrosion Resistance

The most significant difference is the strength-to-weight ratio. Aluminum alloys like A380 offer high strength at a density of roughly 2.7 g / cm³, a fraction of carbon steel’s 7.85 g / cm³. This lightweighting is critical for automotive NEV powertrain systems and portable electronics. When evaluating environmental exposure, aluminum naturally forms a protective oxide layer, resisting corrosion without secondary treatments. Acier, in contrast, rusts readily and almost always requires painting, placage, or another surface finish to prevent degradation, adding cost and a process step. For thermal management, aluminum provides far superior heat dissipation, a necessary property for high-performance applications like LED lighting housings and 5G communication enclosures.

Total Cost Analysis: Tooling Investment vs. Per-Unit Price

A total cost analysis reveals a clear breakeven point. Aluminum die casting requires a significant initial investment in a steel mold. This upfront cost is amortized over a large production run, resulting in a much lower per-unit price. Steel fabrication, like CNC machining or welding, avoids high initial tooling costs but carries a consistently higher piece price. This makes steel fabrication suitable for prototypes and low-volume projects. Moulage sous pression, cependant, drastically reduces or eliminates secondary machining costs by producing complex, near-net-shape parts directly from the mold. Features that would require extensive milling or welding in steel are cast in place with aluminum, lowering the final cost per part.

Geometric Complexity and Feature Integration

The decision to switch becomes clear when a part requires intricate designs. Die casting excels at producing thin walls, complex internal ribbing, and integrated features like mounting bosses, heat sink fins, or threaded inserts in a single operation. Fabricating a comparable steel part would involve multiple steps—stamping, bending, soudage, and assembly. Each additional process increases labor costs, extends lead times, and introduces the risk of tolerance stack-up, where small dimensional variations accumulate across different components. A unified IATF 16949 quality system ensures that complex die-cast parts maintain consistent dimensional accuracy, whether produced in China, Mexique, or Vietnam.

Performance Triggers for Demanding Applications

Specific performance requirements often force the switch to aluminum die casting. For sensitive electronics, the inherent conductivity of aluminum alloys provides natural EMI shielding without needing costly secondary coatings. When a component requires an airtight or watertight seal for ingress protection, the dimensional stability of a die-cast part is superior. These seals can be verified with pressure decay testing to guarantee performance. In the automotive sector, lightweighting is a primary driver. Die-cast aluminum components are essential for reducing the overall mass of New Energy Vehicle (NEV) systems, which directly improves range and efficiency.

Production Volume and Global Supply Chain Factors

Die casting is fundamentally a mass-production process. It becomes the most cost-effective option once production volumes exceed a threshold of 3,000–5,000 units, as this scale justifies the tooling investment. In today’s trade environment, supply chain strategy also plays a role. For US market access, shifting production to a facility in Mexico or Vietnam can optimize tariff exposure. High-speed, automated die casting cycles also enable rapid fulfillment for high-volume orders, shortening overall lead times compared to labor-intensive steel fabrication processes. This allows for a more responsive and resilient global supply chain.

Conclusion

Choosing the right material involves a trade-off between strength, poids, and total cost. While carbon and alloy steels provide exceptional strength, aluminum die casting is a superior alternative for complex, lightweight parts where extensive machining of steel is not cost-effective.

If your project demands intricate geometries or weight reduction, our team can help evaluate your steel components for a transition to aluminum. Contact us to see how our global manufacturing capabilities in China, Mexique, and Vietnam can optimize your product design and supply chain.

Foire aux questions

Is alloy steel stronger than carbon steel?

Oui, alloy steel generally exhibits higher tensile strength (758–1882 MPa) than carbon steel (450–965 MPa), making it better for applications with sustained loads. Cependant, carbon steel often has greater hardness, which provides superior resistance to pressure in different contexts.

Does carbon steel rust faster than alloy steel?

Oui, carbon steel has poor corrosion resistance and is highly susceptible to rust. En revanche, alloy steels, especially those with chromium, demonstrate excellent corrosion resistance by forming a protective oxide layer on the surface.

Can I replace steel parts with aluminum?

The provided research focuses exclusively on the differences between carbon steel and alloy steel. It does not contain information regarding the replacement of steel parts with aluminum, as this would involve comparing different material properties not covered in the text.

Is machining steel more expensive than aluminum?

The supplied research material details the properties and costs of carbon steel versus alloy steel but does not include data on aluminum. Donc, a cost comparison for machining steel versus aluminum cannot be derived from the provided content.

What is the weight difference between steel and aluminum?

Information comparing the weight or density of steel and aluminum is not available in the provided research content. The text is focused on the characteristics and distinctions between carbon steel and alloy steel.

Which material is better for high-temperature use?

Based on the research, alloy steel is the superior choice for high-temperature applications. The inclusion of specific alloying elements gives it a higher melting point and makes it ideal for high-performance scenarios in demanding, high-temperature environments.

Référencement

Titre: Acier allié vs acier au carbone: Différences & L'alternative légère

Description: Acier allié vs acier au carbone: A technical guide for OEM parts. Evaluate strength, coût & when to switch to IATF 16949 moulage sous pression.

URL: alloy-steel-vs-carbon-steel

Mots-clés: Acier allié vs acier au carbone