Quand tu sautent dans ta voiture, Il est facile d'oublier le nombre de pièces spécialisées pour rendre votre balade lisse, sûr, et fiable. Mais derrière chaque véhicule élégant se trouve une gamme de pièces qui sont fabriquées à l'aide de la moulage de mat. Si vous vous êtes déjà demandé comment les plus difficiles, le plus léger, et les composants les plus précis sont fabriqués, Le moulage est l'ingrédient secret. Plongeons-nous dans ce qu'est le casting d'automobiles, les matériaux utilisés, les avantages qu'il apporte, et quelques exemples clés de produits de moulage automobile.

Qu'est-ce que le moulage sous pression?

À la base, moulage sous pression est une méthode utilisée pour produire des pièces métalliques en forçant le métal fondu dans un moule sous haute pression. Imaginez le dentifrice en serrant un tube, Sauf dans ce cas, C'est un métal liquide chaud injecté dans des moules complexes pour former des formes complexes.

Dans l'industrie automobile, Le coulage de la matrice est utilisé pour créer pièces automobiles moulées sous pression qui sont légers, durable, et très détaillé. Ces pièces doivent supporter les conditions les plus difficiles, des blocs moteurs aux boîtiers de transmission, Et le moulage de moules permet de le faire efficacement. C'est comme avoir la recette parfaite pour la précision et la force.

Types communs de matériaux utilisés en automobile Moulage sous pression

Moulage sous pression en aluminium

Les moulages à base d'aluminium dans le secteur automobile sont favorisés pour leur rapport force / poids, Ce qui signifie que vous obtenez une partie robuste qui n'ajoute pas de poids inutile au véhicule. Pensez-y - les voitures de Today doivent être à la fois solides et légères pour améliorer l'efficacité énergétique, et les composants automobiles en aluminium cochent les deux cases. Des blocs moteurs aux roues, Les pièces automobiles de moulage en aluminium font partie intégrante de la conception automobile moderne. Ils sont utilisés dans des composants de moteur critiques, En leur faisant des acteurs clés dans l'amélioration des performances des véhicules tout en réduisant la consommation de carburant.

Avantages des pièces automobiles coulant en aluminium

- Léger: L'aluminium est un métal léger, aider à réduire le poids global du véhicule, qui améliore l'efficacité énergétique et les performances.

- Force et durabilité: Les pièces de coulée de dépérisation en aluminium automobile sont solides et peuvent résister à des températures élevées et à une usure lourde, Les rendre idéaux pour les applications automobiles.

- Résistance à la corrosion: L'aluminium résiste naturellement à la corrosion, qui augmente la longévité et la fiabilité des pièces automobiles, Surtout dans des conditions difficiles.

- Flexibilité de conception: La coulée de matrice permet des formes complexes et complexes, permettant aux fabricants de créer des pièces avec des murs fins et des dimensions précises.

- Production rentable: Le processus de coulée de matrice est très efficace pour la production de masse, Réduire à la fois les déchets de matériaux et les coûts de fabrication globaux.

Moulage sous pression de zinc

Le zinc n'est peut-être pas le premier matériel auquel vous pensez, Mais il est également très populaire dans le secteur des moulages automobiles. Les produits de moulage en zinc sont connus pour leur durabilité et leur polyvalence. Tandis que le zinc est souvent utilisé dans des pièces plus petites comme les mécanismes de verrouillage ou les connecteurs, C'est essentiel pour les constructeurs automobiles qui ont besoin de précision et de force dans leurs composants.

Avantages des pièces automobiles de coulée de zinc die

- Forte résistance: Les pièces de moulage en zinc offrent une excellente force et ténacité, Les rendre idéaux pour les composants automobiles qui doivent résister à la stress et à l'impact.

- Précision et détail: Le zinc permet des tolérances serrées et des conceptions complexes, S'assurer que les pièces s'adaptent avec précision et fonctionnent comme prévu dans les systèmes automobiles complexes.

- Rentable: Le zinc est plus abordable que de nombreux autres métaux, Et le processus de moulage de la matrice est très efficace pour produire de grands volumes, En faire une option rentable pour les constructeurs automobiles.

- Excellente finition de surface: Les pièces moulées en zinc ont un lisse, finition polie, Réduire le besoin de processus de finition supplémentaires et améliorer l'apparence globale des composants.

- Résistance à la corrosion: Le zinc a des propriétés inhérentes à la corrosion, Le rendre bien adapté aux pièces automobiles exposées à l'humidité et aux conditions environnementales dures, Assurer une durée de vie plus longue.

Moulage sous pression de magnésium

Le magnésium pourrait ne pas être aussi communément parlé, Mais c'est l'un des métaux structurels les plus légers disponibles, Le rendre idéal pour les applications automobiles où la réduction du poids est cruciale. Magnésium Die Casting Les pièces automobiles gagnent en popularité, surtout dans les véhicules haute performance et électriques, car la réduction du poids aide à l'efficacité énergétique et à la durée de vie de la batterie.

Avantages des pièces automobiles de coulée de matrice de magnésium

- Léger: Le magnésium est le métal structurel le plus léger, ce qui réduit considérablement le poids global du véhicule, Amélioration de l'efficacité énergétique et des performances.

- Ratio de force / poids élevé: En dépit d'être léger, Le magnésium offre une forte intégrité structurelle, Le rendre parfait pour les composants automobiles hautes performances.

- Conductivité thermique: Le magnésium a d'excellentes propriétés de dissipation thermique, Ce qui est crucial pour les pièces automobiles comme les composants du moteur qui ont besoin de gérer des températures élevées.

- Sécurité améliorée: Les pièces en magnésium sont fortes mais légères, contribuant à une meilleure maniabilité, freinage, et la sécurité globale du véhicule en abaissant le centre de gravité.

- Recyclabalité: Comme l'aluminium, Le magnésium est recyclable, En faire une option respectueuse de l'environnement pour la fabrication automobile durable.

Autres matériaux utilisés dans le moulage

Alors que l'aluminium, zinc, et le magnésium sont les matériaux de moulage les plus courants, fabricants de moulage sous pression Utilisez occasionnellement du cuivre, plomb, étain, Et même l'acier dans leurs processus de moulage, en fonction des exigences spécifiques de la pièce. Alliages de cuivre, Par exemple, sont souvent utilisés dans les parties qui ont besoin de résister aux températures élevées.

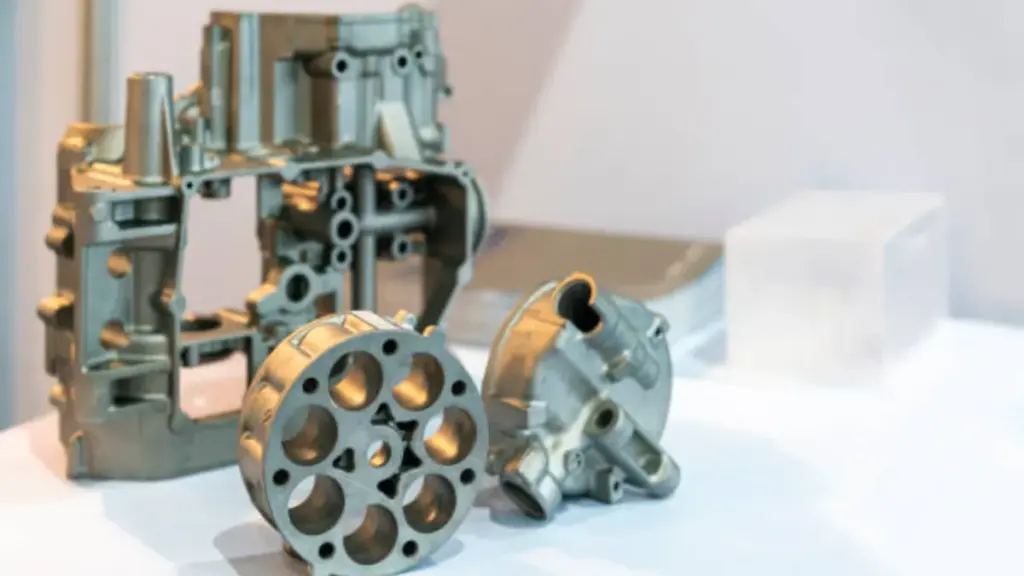

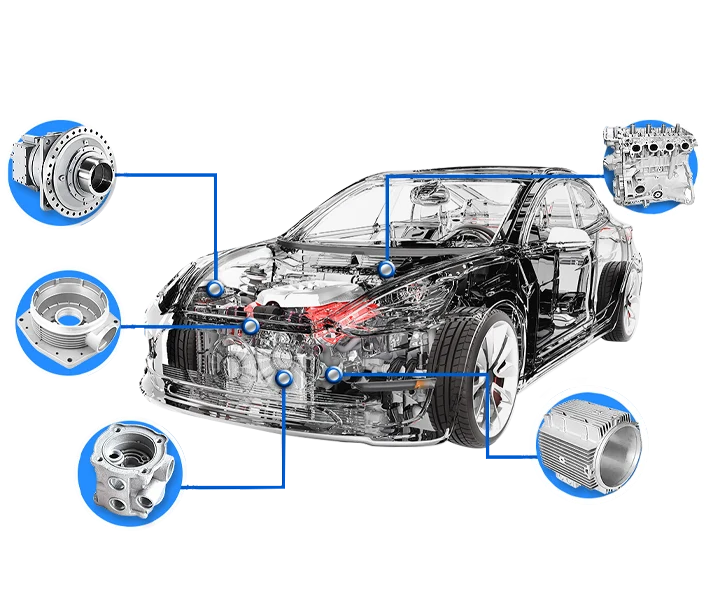

Exemples de pièces automobiles moulées

Le casting est responsable de la création de certaines des pièces les plus importantes de votre voiture. Jetons un coup d'œil à quelques exemples clés de pièces automobiles que la moulage a un coup de main.

Composants du moteur

Le moulage est particulièrement précieux en ce qui concerne les composants du moteur. Pièces automobiles en aluminium moulé sous pression, comme les culasses et les blocs moteurs, sont légers mais incroyablement durables. Ces pièces doivent gérer des températures et des pressions extrêmes, Et le moulage de moule garantit qu'ils font.

Pièces de transmission

Pièces de transmission, y compris les boîtes de vitesses et les boîtiers, bénéficier grandement de la précision que le casting Die propose. Les pièces automobiles de coulée de matrice permettent des conceptions complexes qui peuvent résister au décalage constant et à la déformation qu'une transmission subit.

Parties structurelles

Supports, logements, et les composants du cadre sont également généralement produits en utilisant la moulage. Ces pièces doivent supporter beaucoup de stress et d'impact, Et la moulage de matrice permet aux fabricants de créer des pièces à la fois solides et légères - critiques pour les performances globales du véhicule.

Autres pièces automobiles

Des roues aux boîtiers d'éclairage et composants d'embrayage, Le casting de Die joue également un rôle dans la création de nombreuses pièces plus petites mais juste importées qui composent les systèmes d'un véhicule.

Avantages de la moulage dans l'industrie automobile

Donc, Pourquoi l'industrie automobile s'appuie-t-elle si fortement sur le casting de mat? Bien, Les avantages sont difficiles à ignorer.

Précision et détail

L'une des principales raisons pour lesquelles le moulage est utilisé dans la fabrication automobile est sa capacité à créer des pièces avec des tolérances étroites et des conceptions complexes. Cette précision est essentielle dans le monde automobile, où même le plus petit composant doit s'adapter parfaitement et fonctionner correctement.

Durabilité et force

Les produits de moulage de dépérisation sont conçus pour durer. Que ce soit une partie en alliage en aluminium ou un cadre de magnésium, Ces composants doivent gérer une contrainte extrême, fluctuations de température, et porter. Le processus de coulée de déménagement garantit que chaque partie est forte et peut résister aux rigueurs de la route.

Léger et efficacité

Le moulage de pure offre un avantage significatif lorsqu'il s'agit de réduire le poids. À mesure que les voitures deviennent plus légères, Ils consomment moins de carburant et fonctionnent mieux. Castings à base d'aluminium, en particulier, sont excellents pour garder les choses légères sans compromettre la force.

Rentabilité et évolutivité

Le moulage de matrices est très efficace pour la production de masse. Une fois un moule créé, Le processus peut être répété à grande échelle, Réduire le coût par pièce. C'est parfait pour l'industrie automobile, qui doit produire des milliers (ou même des millions) de pièces sur une base cohérente.

Le processus de coulée de matrice dans la fabrication automobile

Étapes du processus de coulée

Le processus de moulage de la matrice implique plusieurs étapes clés: création de moisissure, injection de métaux, refroidissement, et l'éjection. Une fois le moule conçu et créé, métal fondu (Souvent en aluminium) est injecté dans le moule sous haute pression. Après refroidissement, La pièce est éjectée, Et le processus recommence.

Automatisation dans le moulage

L'une des raisons pour lesquelles le casting est devenu si populaire est à cause de son automatisation. L'automatisation dans le moulage de la matrice permet d'assurer la précision, répétabilité, et la vitesse. Ceci est crucial dans la fabrication automobile, où les délais et le contrôle de la qualité sont essentiels.

Défis dans le moulage de la matrice pour les pièces automobiles

Tandis que le casting Die offre de nombreux avantages, Ce n'est pas sans défis. Le processus peut être coûteux, surtout lorsqu'il s'agit de moules complexes ou de matériaux de qualité supérieure. En plus, Le contrôle de la qualité est primordial - l'inscription que chaque partie répond aux spécifications requises peut être délicate, surtout avec des composants de haute précision.

Conclusion

Le moulage de matrices est une partie indispensable de la fabrication automobile. La combinaison de haute précision, force, et l'efficacité qu'il fournit a permis à l'industrie automobile de produire des composants complexes et légers qui sont essentiels aux véhicules modernes. Que ce soit une réduction du poids, Améliorer la durabilité, ou créer des conceptions complexes, Les pièces automobiles moulées continuent de jouer un rôle vital dans l'avenir du monde automobile.

FAQ

- Quel est le matériau le plus courant utilisé dans la coulée de matrice automobile? L'aluminium est le matériau le plus utilisé, grâce à son ratio de force / poids et de rentabilité.

- Pourquoi l'aluminium est-il utilisé pour les pièces automobiles? L'aluminium est léger, durable, et résistant à la corrosion, Le rendre parfait pour les composants automobiles qui doivent fonctionner dans des conditions difficiles.

- Quelles pièces automobiles sont généralement fabriquées à partir de moulage? Blocs de moteur, pièces de transmission, composants structurels, roues, et les boîtiers d'éclairage ne sont que quelques exemples de produits de moulage automobile.

- Comment la coulée de la mort améliore-t-elle l'efficacité énergétique? En produisant des composants légers, Le moulage de dépérisation aide à réduire le poids global du véhicule, ce qui conduit à une meilleure efficacité énergétique.

- Est-ce que le moulage est adapté à la production de masse dans l'industrie automobile? Oui, Le moulage de la matrice est parfait pour la production de masse en raison de sa vitesse élevée, précision, et la rentabilité.