Service d'usinage CNC

Services d'usinage CNC en ligne personnalisés

Obtenez des devis instantanés sur du métal personnalisé avec notre service d'usinage CNC en ligne. Réalisez des prototypes rapides et des pièces de production sur toutes les commandes. OIN 9001:2015, OIN 13485 et certifié AS9100D. ITAR enregistré.

- Conception de moules & Analyse de conception

- Forte capacité de production de moulage sous pression

- Service d'usinage CNC de précision

- Plusieurs options de finition

- Assistance technique en ligne

Obtenez un devis instantané

Présentation des services d'usinage CNC

Usinage CNC, comme un processus vital au sein moulage sous pression en aluminium, permet un usinage de précision et des ajustements aux pièces moulées en aluminium pour répondre aux exigences et spécifications du produit final. Dans le processus de moulage sous pression de l'aluminium, les pièces moulées en aluminium obtenues après injection de l'alliage d'aluminium dans des moules nécessitent souvent un usinage et une finition secondaires pour obtenir les dimensions précises souhaitées, formes, et qualité de surface. C'est là que l'usinage CNC entre en jeu.

Fiable & Aluminium moulé sous pression polyvalent pour la sélection

Fraisage CNC

L'atelier de fraisage CNC est équipé de fraiseuses utilisées pour le fraisage plat, fraisage de contours, perçage de trous, et autres opérations. Il est couramment utilisé dans la production de pièces telles que des appartements., rainures, des trous, et fils continus.

Tournage CNC

L'atelier de tournage CNC comprend des tours utilisés pour l'usinage rotatif, y compris l'usinage des contours externes, usinage des faces d'extrémité, et usinage de filetage. Il est fréquemment utilisé pour traiter des composants tels que des arbres.

Usinage EDM

Usinage par électroérosion à fil, également connu sous le nom d'usinage par électroérosion par fil, est un procédé de découpe électrothermique. Par rapport aux méthodes de découpe mécanique traditionnelles, L'usinage par électro-érosion à fil offre une précision et une qualité de surface supérieures, et il peut gérer des formes géométriques plus complexes.

Centres d'usinage CNC

Affinez vos pièces sans effort

Voici une brève liste de nos centres d'usinage CNC, capable d'usiner avec précision des pièces moulées sous pression pour un portefeuille de secteurs. Plus grande dimension d'usinage jusqu'à 1000cm.

- 3-machine CNC à axes: Ces machines peuvent se déplacer le long du X, Oui, et axes Z.

- 4-machine CNC à axes: Ces machines ont la capacité de se déplacer le long du X, Oui, Axes Z, plus un axe rotatif supplémentaire (souvent appelé l'axe A).

- 5-machine CNC à axes: Ces machines avancées peuvent se déplacer le long des trois axes linéaires (X, Oui, Z) et dispose de deux axes rotatifs supplémentaires (A et B ou A et C).

Nos mesures de contrôle qualité

Notre ateliers sont équipés d'un ensemble complet d'installations allant du moulage sous pression à l'inspection finale. Nous effectuerons une gamme complète de tests de qualité pour garantir que les produits moulés sous pression répondent à vos exigences et normes spécifiques..

Inspection précise:

Expertise en tests:

Une échelle complète de tests minutieux

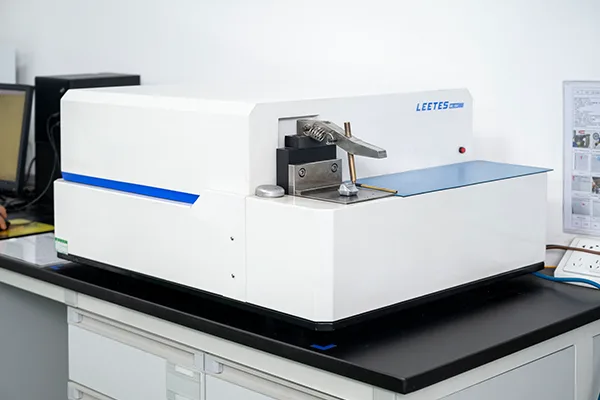

Spectromètre à lecture directe

Analyse de la composition des matériaux.

Machine de mesure de coordonnées (MMT)

Pour une mesure dimensionnelle précise.

Densimètre électronique

Mesurer la densité des matériaux utilisés dans le processus de moulage sous pression.

Système de contrôle non destructif à rayons X

Inspection de porosité interne.

Dispositif de détection de fuite d'hélium de chambre à vide d'équipement de test d'étanchéité à l'air

Contrôle d'étanchéité du produit.

Analyseur de numérisation de propreté

Un instrument de précision utilisé pour inspecter et évaluer la propreté et la qualité des surfaces.

Testeur de friction et de rayures CS-10F

Il s'agit d'un testeur de friction et de rayures utilisé pour évaluer la durabilité des matériaux et la qualité de la surface..

Test de couple de rupture de filetage maximal

Tests de résistance à la corrosion.

Alcool & Machine de test de friction en caoutchouc

Tests de résistance à l'usure des revêtements de surface.

Colorimètre

Détection de différence de couleur de revêtement.

Jauge d'épaisseur de film

Mesure de l'épaisseur du revêtement.

Testeur d'abrasion de bande de papier

Conçu pour évaluer la résistance à l’usure des matériaux, en particulier les produits en papier.

2.5Instrument de mesure D

Utilisé pour des mesures précises dans la fabrication et le contrôle qualité, combiner des données 2D avec des informations de profondeur ou de hauteur.

Avantages des alliages d'aluminium usinés CNC

Donnez vie à vos pièces moulées sous pression en toute simplicité

Personnalisations flexibles

Productivité élevée & Livraison rapide

Répétabilité & Excellent contrôle de qualité

Excellente qualité de surface

Réutilisable & Durable

Comment travailler avec nous?

Téléchargez vos fichiers

Pour démarrer rapidement votre projet de moulage sous pression, s'il vous plaît télécharger le fichier (2Dessin D/3D) à nos experts. Pas de soucis, votre conception est en sécurité avec nous. La signature de NDA est également acceptable.

Citation & Commentaires sur le DFM

Avec vos créations ou créations demandées par nos experts, nous vous fournirons une conception pour la fabricabilité (DFM) analyse et cotation en temps réel.

Fabrication

Une fois que vous avez confirmé la conception & citation, nous allons commencer le processus de fabrication, y compris le moulage sous pression, Services d'usinage et de finition CNC.

Expédition

Vous pouvez obtenir un emballage personnalisé pour les pièces moulées sous pression, y compris les matériaux d'emballage et le logo, impression d'étiquettes.

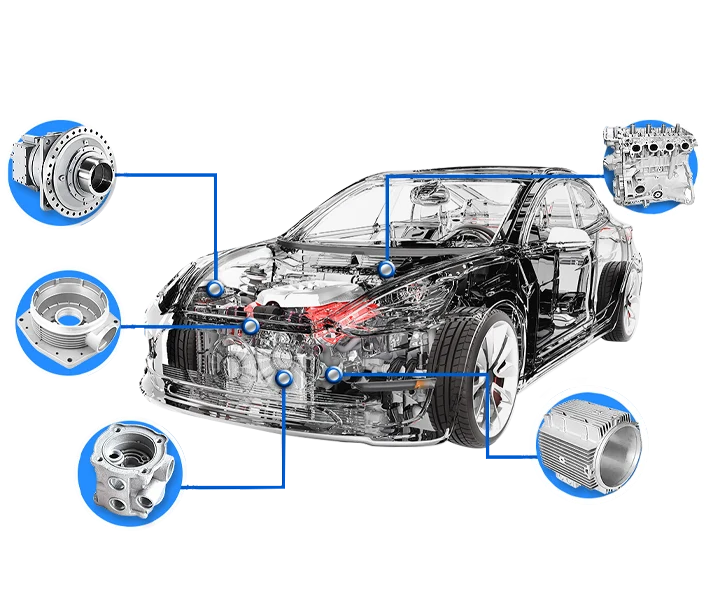

Pièces automobiles

Pièces d'éclairage

Pièces moulées sous pression personnalisées pour un large éventail d’industries

Parties éléctroniques

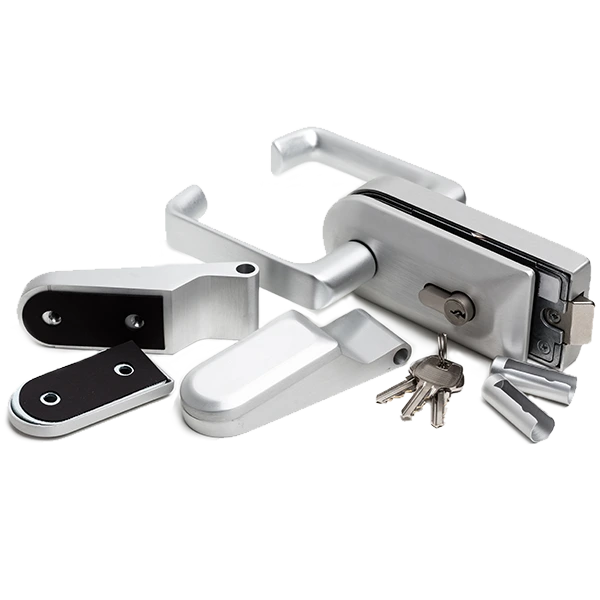

Pièces de meubles

Pièces de construction

Une excellence en gestion de projet sur laquelle vous pouvez compter

FAQ

L'usinage CNC signifie usinage à commande numérique par ordinateur.. Il s'agit d'un processus de fabrication très précis qui complète le moulage sous pression en permettant un réglage fin, façonner, et modifications post-coulée des pièces moulées sous pression. L'usinage CNC garantit que les pièces respectent des tolérances strictes et des dimensions spécifiées, améliorer leur qualité globale et leur fonctionnalité.

Oui, L'usinage CNC est polyvalent et applicable aux pièces moulées sous pression en aluminium et en zinc.. Il offre la flexibilité d'affiner et de modifier des pièces fabriquées à partir de divers matériaux, s'assurer qu'ils répondent aux exigences spécifiques du projet.

Absolument, L'usinage CNC est la solution idéale pour obtenir des tolérances serrées dans les pièces moulées sous pression critiques.. Sa précision contrôlée par ordinateur garantit que les pièces sont conformes aux exigences dimensionnelles exactes, même pour les applications exigeantes dans des secteurs comme l'aérospatiale et l'automobile. L'usinage CNC améliore la qualité, fiabilité, et performances de ces composants de précision.

L'usinage CNC englobe diverses opérations, y compris le fraisage, tournant, forage, et finition de surface. Ces opérations peuvent être adaptées pour répondre aux exigences spécifiques de conception et de fonctionnalité des pièces moulées sous pression..

L'usinage CNC contribue de manière significative à des délais de livraison plus courts en offrant une configuration rapide, changements d'outils efficaces, et capacités de coupe à grande vitesse. Cette agilité permet des ajustements rapides des calendriers de production et de répondre aux commandes urgentes., faire de l'usinage CNC un facteur clé pour respecter les délais serrés des projets.

L'usinage CNC est polyvalent et compatible avec une large gamme de matériaux couramment utilisés dans le moulage sous pression., y compris l'aluminium, zinc, magnésium, et plus. La sélection des matériaux dépend des exigences spécifiques de votre projet, et l'usinage CNC peut facilement s'adapter à divers matériaux.

Oui, L'usinage CNC est un excellent choix pour produire des prototypes de pièces moulées sous pression. Sa capacité à usiner des pièces rapidement et avec précision le rend idéal pour tester et valider les conceptions avant de se lancer dans la production de masse.. Cela réduit le temps et les coûts associés à la création de prototypes physiques.

Facteurs de conception tels que la sélection des matériaux, tolérances, complexité de la pièce, et la finition de surface souhaitée doit être prise en compte lors de la planification de l'usinage CNC pour les pièces moulées sous pression.. La collaboration avec des ingénieurs expérimentés peut aider à optimiser les conceptions pour un usinage CNC efficace.

Nous maintenons la cohérence de la qualité grâce à un contrôle rigoureux des processus, formation des employés, et le respect des normes de l'industrie. Notre équipement de mesure avancé vérifie les dimensions et les formes, s'assurer que chaque pièce usinée moulée sous pression répond aux exigences spécifiées.

Nos clients

Obtenez un devis pour des services de moulage sous pression dès aujourd'hui!

-

.Non. 128-129, Zone industrielle Est,

Mashé Est, bourgade de Lishui, District de Nanhai, Foshan, Guangdong, Chine

- Contact:Catherine

- Téléphone:+86 189 4247 5007

- E-mail:Katherine@mag-cast.com

- WhatsApp:+86-159 1863 4657

- Contact:Réno

- Téléphone:+86 177 9601 9842

- E-mail:sales3@mag-cast.com

- WhatsApp:+86-186 6688 2487