Source des images: pixels

En casting de dé, La sélection des matériaux est la pierre angulaire du succès, impactant directement la qualité et la durabilité de votre produit final.

Ce blog sert de guide à guichet unique pour naviguer dans le paysage diversifié des matériaux de casting de dé. Nous allons explorer leurs propriétés uniques, applications idéales, et les facteurs à considérer lors de votre choix.

Donc, bouclez-vous et préparez-vous à déverrouiller les secrets derrière les matériaux qui alimentent l'industrie du moulage!

Matériaux de moulage communs

Explorons les propriétés et applications uniques des alliages de zinc, Alliages de magnésium, et alliages en aluminium.

Alliages de zinc

- Largement utilisé pour les coulées de matrices plus petites ou celles nécessitant des sections plus minces.

- Castabilité supérieure permettant une variation significative de l'épaisseur de la section.

- Maintient des tolérances plus étroites que les autres alliages métalliques communs.

Alliages de magnésium

- Connu pour leur rapport force / poids élevé, comme AZ91D, AM60B, et AS41b.

- Offre une bonne résistance à la corrosion et à l'usure, Les rendre idéaux pour des applications spécifiques.

Alliages d'aluminium

- Matériel primaire et hautement économique de la dédaignement avec des propriétés polyvalentes.

- Rapport de force / poids remarquable adapté à l'aérospatiale, automobile, et applications de biens de consommation.

Alliages de cuivre

Les alliages de cuivre offrent une excellente conductivité thermique et électrique, les rendre idéaux pour applications spécifiques. Ces alliages sont connus pour leur résistance à la corrosion et leur durabilité, Assurer la longévité dans divers environnements.

Les applications courantes incluent les composants électriques, luminaires de plomberie, et les échangeurs de chaleur en raison de leurs performances exceptionnelles à des températures élevées. En plus, Ces alliages offrent une bonne machinabilité, Permettre des conceptions complexes et des finitions précises.

Alliages de plomb et d'étain

Les alliages en plomb et en étain offrent de faibles points de fusion, Faciliter des processus de moulage faciles pour des conceptions complexes. Ces alliages sont couramment utilisés dans la production de roulements, matériaux de soudure, et le blindage de rayonnement en raison de leur densité et de leur malléabilité.

Leurs propriétés d'auto-lubrification les rendent adaptés aux applications où la réduction des frictions est cruciale. Malgré les préoccupations environnementales entourant l'utilisation des plombs, Ces alliages continuent d'être appréciés pour leurs caractéristiques uniques.

Propriétés des matériaux de coulée de matrice

Force

Alliages de cuivre, par exemple, Présenter une force et une dureté élevées, Les rendre idéaux pour diverses applications qui nécessitent des composants robustes. Ces alliages offrent une stabilité dimensionnelle exceptionnelle, s'assurer que les pièces moulées maintiennent leur intégrité structurelle même dans des conditions difficiles.

En revanche, alliages de plomb et d'étain sont connus pour leur haute densité, qui contribue à leur force remarquable. Cette caractéristique permet à ces alliages de fournir une précision dimensionnelle extrêmement étroite, essentiel pour les applications où la précision est primordiale. Malgré leur densité, Les alliages de plomb et d'étain offrent des formes uniques de résistance à la corrosion, Les rendre adaptés aux exigences spécialisées de moulage de dé.

Durabilité

Les alliages de cuivre sont réputés pour leur excellente résistance à la corrosion, Assurer la longévité et la fiabilité dans des environnements difficiles. Ces alliages peuvent résister à l'épreuve du temps sans compromettre les performances ou l'intégrité structurelle.

De la même manière, Les alliages de plomb et d'étain offrent une durabilité impressionnante en raison de leur résistance à la corrosion. Leur capacité à maintenir une précision dimensionnelle au fil du temps en fait des choix précieux pour les applications où les performances à long terme sont essentielles.

Machinabilité

Les alliages à base de cuivre tels que le laiton et le bronze offrent de bonnes propriétés de machinabilité, permettant une mise en forme et une finition efficaces des pièces moulées. La machinabilité de ces alliages améliore la productivité en permettant des cycles de production plus rapides sans compromettre la qualité.

Les alliages en plomb et en étain présentent également des caractéristiques de machinabilité favorables, Les rendre adaptés aux applications qui nécessitent des détails complexes ou des géométries complexes. Les fabricants peuvent compter sur la machinabilité de ces alliages pour obtenir des résultats précis avec un minimum d'exigences de post-traitement.

Zinc dans le casting

Source des images: ne pas éclabousser

Propriétés du zinc

Force et durabilité

Les alliages de zinc offrent exceptionnel force et durabilité par rapport à d'autres matériaux de moulage de dé. La haute précision et la durée de vie de l'outil plus longue fournie par le zinc en font un choix préféré pour diverses applications. Sa capacité à résister aux conditions difficiles assure la longévité des pièces moulées, En faire un matériau idéal pour les processus de fabrication.

Utilisations du zinc dans le moulage

Pièces miniatures

Le zinc est couramment utilisé dans la production de pièces miniatures En raison de son excellente coulée et de sa stabilité dimensionnelle. La polyvalence des alliages de zinc permet la création de conceptions complexes avec des détails précis, En faire une option fiable pour les petites composants dans diverses industries.

Electronique grand public

Dans le royaume de électronique grand public, Le zinc joue un rôle essentiel dans la production de pièces légères mais durables. La résistance à la corrosion et l'attrait esthétique du zinc le rendent adapté aux appareils électroniques qui nécessitent à la fois des fonctionnalités et de l'attrait visuel. Des composants du smartphone aux gadgets domestiques, Le zinc est un matériau polyvalent qui améliore les performances et l'esthétique de l'électronique grand public.

Avantages et limitations

- Avantages: Les pièces moulées du zinc peuvent être plus minces, plus complexe, et plus complexe par rapport à l'aluminium et au magnésium. Il en résulte des pièces plus légères, conduisant à des économies du coût des matériaux et de la consommation d'énergie.

- Limites: Tandis que le zinc offre une haute précision et une durabilité, Il peut ne pas convenir aux applications nécessitant une résistance extrême ou des températures de fonctionnement élevées.

Aluminium dans le moulage

Propriétés de l'aluminium

Versatilité

Aluminium, connu pour son propriétés légères, Offre une polyvalence exceptionnelle dans les applications de moulage de mat. Sa capacité à être facilement moulée en différentes formes et tailles en fait un choix préféré pour les fabricants qui recherchent la flexibilité dans la conception.

La polyvalence de l'aluminium s'étend à sa compatibilité avec différentes techniques de finition, Permettre aux traitements de surface personnalisés pour répondre aux exigences spécifiques.

Températures de fonctionnement élevées

L'un des principaux avantages de l'aluminium dans le moulage de mat. Cette propriété rend l'aluminium idéal pour les applications où les composants sont exposés à des niveaux de chaleur élevés, comme les moteurs automobiles ou les systèmes aérospatiaux.

Utilisations de l'aluminium dans le moulage

Pièces automobiles

L'industrie automobile utilise largement les pièces moulées en aluminium pour divers composants en raison de leur nature et de leur force légères. Des blocs moteurs aux boîtiers de transmission, Les pièces en aluminium contribuent à l'amélioration de l'efficacité énergétique et aux performances globales des véhicules. La résistance à la corrosion de l'aluminium améliore encore la durabilité des pièces automobiles, Assurer la longévité et la fiabilité sur la route.

Composants aérospatiaux

Dans le secteur aérospatial, L'aluminium joue un rôle essentiel dans la production de composants légers mais robustes pour les avions et les vaisseaux spatiaux. Le rapport résistance / poids élevé d'alliages d'aluminium les rend bien adaptés aux applications aérospatiales où la réduction du poids est essentielle sans compromettre l'intégrité structurelle. Des pièces de fuselage aux composants intérieurs, Les moulages en aluminium contribuent à améliorer les performances de vol et l'efficacité énergétique.

Avantages et limitations

- Avantages: Le principal avantage de l'utilisation de l'aluminium dans le moulage de la matrice est son rapport force / poids exceptionnel, En faire un choix idéal pour les applications nécessitant des composants légers mais durables. En plus, La résistance à la corrosion en aluminium et la conductivité thermique ajoutent de la valeur dans diverses industries.

- Limites: Malgré ses nombreux avantages, L'aluminium a des limites en ce qui concerne certaines applications qui exigent une résistance à la traction plus élevée ou une résistance à des conditions extrêmes au-delà de sa plage de température de fonctionnement. Les fabricants doivent soigneusement considérer ces limites lors de la sélection des matériaux pour des projets de moulage spécifiques.

Aluminium Mât Utilisations dans le moulage

ADC12

Cet alliage d'aluminium polyvalent est un choix populaire pour son excellent coulée, ce qui signifie qu'il s'écoule facilement dans les moules, Et bon machinabilité, Permettre des touches finales précises. C'est une option bien équilibrée pour diverses applications.

ADC10

ADC10 établit un équilibre entre coulée et résistance mécanique. C'est une bonne option lorsque vous avez besoin d'un matériau qui peut gérer une certaine pression tout en étant facile à travailler pendant le processus de coulée.

A360

A360 brille avec son exceptionnel résistance à la corrosion. Cela en fait un choix parfait pour les produits exposés à des environnements extérieurs durs, comme les matériaux de construction ou les composants marins.

A380

Cet alliage en aluminium priorise étanchéité à la pression. Il excelle dans les applications où les composants doivent contenir des liquides ou des gaz en toute sécurité, comme les blocs moteurs ou les navires de pression.

Magnésium dans le moulage

Propriétés du magnésium

Poids léger

Le magnésium se démarque dans le moulage pour ses propriétés légères exceptionnelles, En faire un choix préféré pour les applications où la réduction du poids est cruciale. La faible densité des alliages de magnésium contribue à la production de composants légers sans compromettre la résistance ou la durabilité. Cette caractéristique est particulièrement avantageuse dans les industries telles que l'automobile et l'aérospatiale, où l'efficacité énergétique et les performances sont primordiales.

Dureté

En plus de sa nature légère, Les alliages de magnésium sont également appréciés pour leur ténacité impressionnante. La résistance inhérente au magnésium le rend adapté aux applications qui nécessitent des pièces robustes et résistantes à l'impact. Que ce soit utilisé dans les composants structurels automobiles ou les enclos d'électronique grand public, La ténacité du magnésium assure la longévité et la fiabilité des produits moulés.

Utilisations du magnésium dans le moulage

Industrie automobile

L'industrie automobile utilise largement les alliages de magnésium pour divers composants en raison de leurs caractéristiques légères mais durables. Des pièces du moteur aux boîtiers de transmission, Le magnésium joue un rôle essentiel dans l'amélioration de l'efficacité énergétique et des performances globales des véhicules. La résistance à la corrosion du magnésium contribue encore à la longévité et à la fiabilité des composants automobiles.

Electronique grand public

Dans le domaine de l'électronique grand public, Les alliages de magnésium trouvent des applications dans la production d'appareils élégants et légers. La combinaison de propriétés légères et d'intégrité structurelle fait du magnésium un choix idéal pour les smartphones, ordinateurs portables, et autres gadgets électroniques. Les fabricants bénéficient de la polyvalence du magnésium dans la création de conceptions innovantes qui priorisent à la fois l'esthétique et les fonctionnalités.

Avantages et limitations

- Avantages: Le magnésium offre une combinaison unique de poids léger, force, et la ténacité, En faire un matériel polyvalent pour diverses industries. Son excellente machinabilité permet des conceptions complexes avec des détails précis, répondant à divers besoins de fabrication.

- Limites: Malgré ses nombreux avantages, Le magnésium peut poser des défis en termes de résistance à la corrosion dans certains environnements. En plus, La réactivité élevée du magnésium nécessite une manipulation minutieuse pendant le processus de coulée de la matrice pour assurer des résultats optimaux.

Alliages de cuivre dans le moulage

Propriétés et caractéristiques

- Conductivité élevée: Alliages de cuivre sont réputés pour leur conductivité électrique et thermique exceptionnelle, Les rendre idéaux pour les applications qui nécessitent un transfert de chaleur efficace et une conduction électrique.

- Résistance à la corrosion: Les propriétés inhérentes à alliages de cuivre fournir une excellente résistance à la corrosion, Assurer la longévité et la durabilité dans divers environnements.

- Durabilité: En mettant l'accent sur l'intégrité structurelle, alliages de cuivre Offrir une durabilité élevée, Les rendre adaptés aux applications où des composants robustes sont essentiels.

Applications communes

- Composants électriques: Alliages de cuivre Trouvez une utilisation étendue dans la production de composants électriques tels que le câblage et les connecteurs en raison de leur conductivité supérieure.

- Luminaires de plomberie: La résistance à la corrosion de alliages de cuivre En fait un choix préféré pour les luminaires de plomberie, Assurer la fiabilité et la longévité.

- Échangeurs de chaleur: En raison de leur excellente conductivité thermique, alliages de cuivre sont couramment utilisés dans les échangeurs de chaleur pour un transfert de chaleur efficace.

Avantages et limitations

- Avantages:

- Alliages de cuivre Offrir une conductivité thermique et électrique exceptionnelle, Fournir une efficacité dans le transfert de chaleur et les applications électriques.

- La résistance à la corrosion de alliages de cuivre assure la longévité et la fiabilité dans divers environnements.

- Ces alliages présentent une bonne machinabilité, Permettre des conceptions complexes avec des finitions précises.

- Limites:

- Alors que alliages de cuivre offrir de nombreux avantages, Ils peuvent ne pas convenir aux applications nécessitant une résistance extrême ou des températures de fonctionnement élevées au-delà de leurs limites.

Alliages de plomb et d'étain en détails

Propriétés et caractéristiques

- Alliages de plomb et d'étain sont réputés pour leurs points de fusion bas, Les rendre idéaux pour des dessins complexes et des pièces moulées détaillées.

- Ces alliages présentent une excellente fluidité pendant le processus de coulée, Assurer une réplication précise des moules avec des caractéristiques complexes.

- La malléabilité de Alliages de plomb et d'étain Permet une forme et une personnalisation faciles, Répondant à un large éventail d'exigences de conception.

Applications communes

- Roulements: Alliages de plomb et d'étain sont couramment utilisés dans la production de roulements en raison de leurs propriétés d'auto-lubrification, Réduire la friction et l'usure.

- Matériaux de soudure: Les points de fusion bas de ces alliages les rendent adaptés aux applications de soudage en électronique et en plomberie.

- Blinchage de rayonnement: En raison de leur densité, Alliages de plomb et d'étain sont efficaces dans les applications de blindage de rayonnement où la protection est primordiale.

Avantages et limitations

- Avantages:

- Facilité de casting: Les points de fusion bas de ces alliages facilitent les processus de coulée faciles pour les conceptions complexes.

- Auto-lubrification: Leurs propriétés d'auto-lubrification les rendent idéales pour les applications nécessitant une frottement réduit.

- Malléabilité: La nature malléable des alliages de plomb et d'étain permet des options de mise en forme polyvalente dans le moulage de la matrice.

- Limites:

- Préoccupations environnementales: Les réglementations environnementales restreignent l'utilisation du plomb en raison de ses dangers potentiels.

- Résistance limitée: Ces alliages peuvent ne pas convenir aux applications nécessitant une résistance ou une durabilité à traction élevée dans des conditions extrêmes.

Matériaux émergents dans le moulage

Nouveaux développements en alliage

- Les innovations dans les matériaux de coulée de matrice continuent de stimuler les progrès des processus de fabrication. Les fabricants explorent nouveaux développements en alliage Pour améliorer les performances et l'efficacité des composants moulés. Ces alliages subissent des tests rigoureux pour garantir des propriétés optimales pour des applications spécifiques, Offrir une force améliorée, durabilité, et résistance à la corrosion.

- L'introduction de matériaux composites a révolutionné l'industrie du moulage en combinaison en combinant plusieurs éléments pour créer des alliages hybrides avec des caractéristiques uniques. Les matériaux composites offrent un équilibre des propriétés telles que la conception légère, résistance mécanique améliorée, et augmentation de la conductivité thermique. Cette approche innovante ouvre des portes à diverses applications dans toutes les industries, de l'ingénierie automobile aux appareils électroniques. En tirant parti des matériaux composites, Les fabricants peuvent obtenir une qualité de produit et une innovation supérieures dans les technologies de coulée de matrice.

Processus de sélection des matériaux

Étapes pour choisir le bon matériau

- Identifiez les exigences spécifiques de votre projet, considérer des facteurs tels que la force, durabilité, et la conductivité. La compréhension des caractéristiques souhaitées vous guidera dans la sélection du matériel de moulage de filière le plus approprié.

- Évaluez les propriétés de différents matériaux disponibles pour le moulage, se concentrer sur leurs forces et limites uniques. Comparez des facteurs comme la résistance à la corrosion, machinabilité, et la conductivité thermique pour déterminer le choix optimal pour votre application.

- Considérez les conditions environnementales dans lesquelles le produit final fonctionnera. Assurez-vous que le matériau sélectionné peut résister aux variations de température, exposition aux produits chimiques, et d'autres facteurs externes sans compromettre les performances.

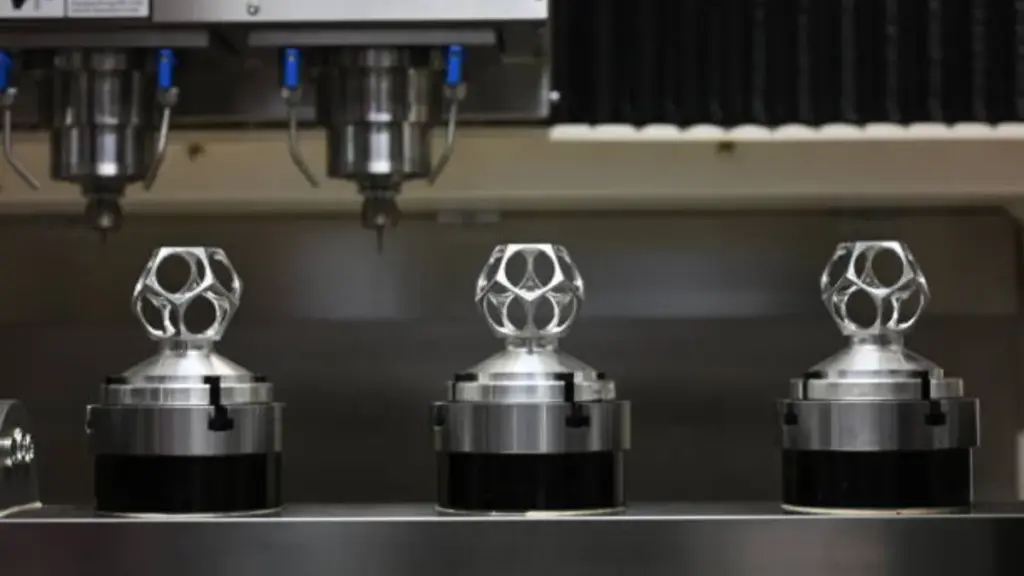

- Effectuer le prototypage et les tests pour valider la compatibilité du matériau choisi avec vos spécifications de conception. Le prototypage vous permet d'évaluer dans quelle mesure le matériel répond aux exigences structurelles et aux attentes fonctionnelles avant la production à grande échelle.

Importance du prototypage et des tests

- Prototypage joue un rôle crucial dans le raffinement de votre conception et de votre processus de sélection des matériaux en fournissant un modèle tangible pour l'évaluation. Il vous permet d'identifier tout problème potentiel dès le début et d'effectuer les ajustements nécessaires pour optimiser les performances.

- Essai Valide la fonctionnalité et la durabilité des composants moulés dans des conditions réelles. En soumettant des prototypes à des tests rigoureux, Vous pouvez vous assurer que le matériel choisi répond aux normes de qualité et aux exigences réglementaires.

- Prototypage itératif Permet une amélioration continue en fonction des résultats des tests, conduisant à des performances et à la fiabilité accrus des produits. À travers une approche itérative, Vous pouvez affiner la sélection des matériaux pour une efficacité maximale dans les processus de moulage.

En suivant une approche systématique qui comprend une évaluation approfondie, prototypage, et tester, Vous pouvez rationaliser le processus de sélection des matériaux pour les projets de moulage de mat.

Impact du choix des matériaux sur le processus de moulage de la matrice

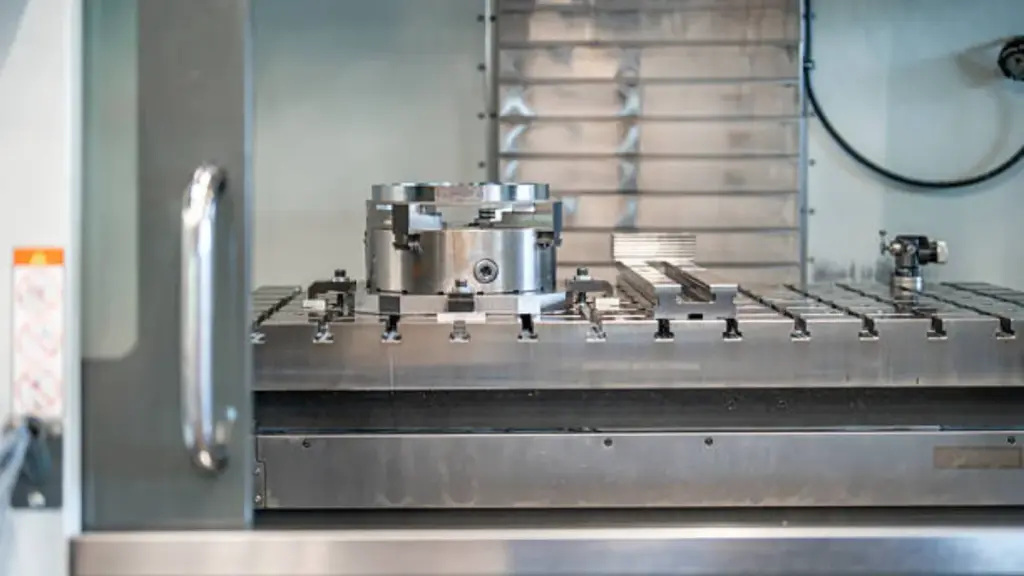

Effets sur la sélection des machines

- Opter pour le bon matériau dans les projets de coulée de dé, répétabilité, et la durabilité en partie.

- Les alliages de moulage en aluminium offrent une excellente résistance à la corrosion, résilience à la température, et conductivité thermique et électrique. Ces propriétés font des alliages en aluminium un choix approprié pour les pièces complexes et fines.

- Le matériau sélectionné pour la coulée de matrice doit résister à des températures élevées, pressions, et les demandes des applications d'utilisation finale.

Influence sur la conception

- Le choix du matériel joue un rôle crucial dans la détermination de la conception de la matrice utilisée dans le processus de coulée.

- Différents matériaux ont des caractéristiques variables qui ont un impact sur la façon dont ils remplissent les moules et maintiennent l'intégrité structurelle pendant le refroidissement.

- La sélection de matériaux avec des propriétés spécifiques garantit que la conception de la matrice s'aligne sur les résultats souhaités du produit final.

Implications pour le post-traitement

- Le matériau choisi pour la coulée de matrice a des implications pour les procédures de post-traitement telles que la fin, usinage, ou traitements de surface.

- Les matériaux avec une bonne machinabilité peuvent nécessiter moins de post-traitement pour obtenir la finition de surface souhaitée.

- La prise en compte des propriétés du matériel au départ peut rationaliser les efforts de post-traitement et améliorer l'efficacité globale de la production.

Applications des matériaux de moulage de mat

Industrie automobile

Les alliages en aluminium sont largement utilisés dans l'industrie automobile pour leurs propriétés légères et leur rapport force / poids exceptionnel. La résistance à la corrosion des alliages d'aluminium les rend idéales pour divers composants automobiles, y compris les pièces du moteur et les boîtiers de transmission. En incorporant des pièces moulées en aluminium, Les fabricants peuvent améliorer l'efficacité énergétique et les performances globales des véhicules. La durabilité et la longévité des alliages d'aluminium garantissent des performances fiables sur la route, contribuant au succès des projets d'ingénierie automobile.

Electronique grand public

Dans le domaine de l'électronique grand public, Les alliages de magnésium jouent un rôle crucial dans la production d'appareils élégants et légers. La combinaison des propriétés légères du magnésium et de l'intégrité structurelle en fait un choix idéal pour les smartphones, ordinateurs portables, et autres gadgets électroniques. Les fabricants bénéficient de la polyvalence du magnésium dans la création de conceptions innovantes qui priorisent à la fois l'esthétique et les fonctionnalités. Avec sa ténacité et sa durabilité impressionnantes, Le magnésium assure la longévité et la fiabilité des produits moulés dans le monde dynamique de l'électronique grand public.

Industrie aérospatiale

Le secteur aérospatial s'appuie sur des moulages en aluminium pour la production de composants légers mais robustes essentiels pour les avions et les vaisseaux spatiaux. Le rapport forte force / poids d'alliages en aluminium les rend bien adaptés aux applications aérospatiales où la réduction du poids est cruciale sans compromettre l'intégrité structurelle. Des pièces de fuselage aux composants intérieurs, Les moulages en aluminium contribuent à améliorer les performances de vol, efficacité énergétique, et les normes de sécurité globales dans l'industrie aérospatiale.

Conclusion

Avec une compréhension des diverses propriétés et applications des matériaux de moulage, Vous êtes en bonne voie pour débloquer le potentiel de ce processus de fabrication polyvalent. Souviens-toi, La sélection du métal de moulage droit ne concerne pas seulement le produit final; il a un impact direct sur la rentabilité, qualité, et l'efficacité globale du processus de moulage lui-même lui-même.

En avant, Les tendances futures indiquent une demande croissante de moulage de dépérisation dans divers secteurs, souligner l'importance de rester informé des matériaux émergents et des développements de l'industrie.