La limite d'élasticité est une propriété fondamentale en ingénierie, surtout quand il s'agit de la polyvalence des alliages d'aluminium. Ces alliages jouent un rôle crucial dans diverses industries en raison de leurs propriétés exceptionnelles. Examinons l'importance de la limite d'élasticité et explorons l'importance des alliages d'aluminium en ingénierie..

Qu'est-ce que la limite d'élasticité?

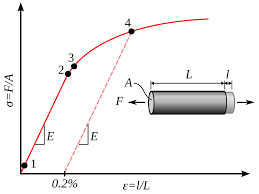

La limite d'élasticité est la mesure de la contrainte maximale qu'un matériau peut supporter sans subir de déformation permanente.. C'est un paramètre essentiel pour déterminer l'intégrité structurelle et les performances des matériaux.. La limite d'élasticité des alliages d'aluminium est évaluée par des tests standardisés, fournir des informations essentielles sur leur comportement mécanique dans différentes conditions.

Alliages d'aluminium et leurs applications

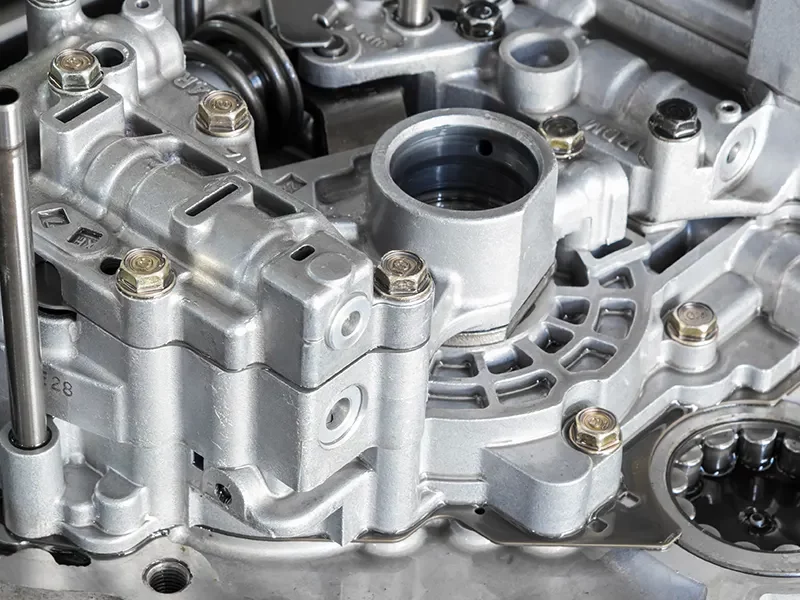

Alliages d'aluminium sont appréciés pour leur légèreté, résistance à la corrosion, et un rapport résistance/poids impressionnant. Ils trouvent de nombreuses applications dans diverses industries, y compris l'aérospatiale, automobile, construction, et électronique grand public. Des composants d'avion à articles ménagers de tous les jours, les alliages d'aluminium sont indispensables dans l'ingénierie moderne.

6061 Limite d'élasticité de l'aluminium

Propriétés de 6061 Aluminium

6061 aluminium est réputé pour ses excellentes propriétés mécaniques, y compris une limite d'élasticité d'environ 276 MPa (40,000 psi). Il possède une soudabilité remarquable, résistance à la corrosion, et usinabilité, ce qui en fait un choix populaire pour diverses applications.

Applications et avantages de 6061 Aluminium

Cet alliage polyvalent est largement utilisé dans les composants structurels, cadres, et applications marines. Sa force exceptionnelle, couplé à sa nature légère, le rend idéal pour les pièces nécessitant une résistance et une durabilité élevées.

7075 Limite d'élasticité de l'aluminium

Propriétés de 7075 Aluminium

7075 L'aluminium est un alliage à haute résistance avec une limite d'élasticité impressionnante d'environ 503 MPa (73,000 psi). S'il offre des propriétés mécaniques exceptionnelles, il est moins résistant à la corrosion que 6061 aluminium.

Applications et avantages de 7075 Aluminium

Principalement utilisé dans les applications aérospatiales et militaires, 7075 l'aluminium est privilégié pour son rapport résistance/poids exceptionnel. Il est couramment utilisé dans les composants d’avions, pièces de missiles, et des éléments structurels à haute contrainte où la résistance est primordiale.

2024 Limite d'élasticité de l'aluminium

Propriétés de 2024 Aluminium

2024 l'aluminium est reconnu pour son excellente résistance et rigidité, bénéficiant d'une limite d'élasticité d'environ 324 MPa (47,000 psi). Il présente une bonne usinabilité et une bonne résistance à la fatigue, ce qui le rend adapté à diverses applications d'ingénierie.

Applications et avantages de 2024 Aluminium

Largement utilisé dans l'aérospatiale, automobile, et applications structurelles, 2024 l'aluminium est préféré pour sa haute résistance et sa résistance à la fatigue. Il trouve des applications dans les structures aéronautiques, longerons d'aile, et équipements sportifs de haute performance.

6063 Limite d'élasticité de l'aluminium

Propriétés de 6063 Aluminium

6063 l'aluminium offre une limite d'élasticité d'environ 241 MPa (35,000 psi) avec une excellente résistance à la corrosion et une excellente formabilité. Il est connu pour sa finition de surface lisse et est souvent utilisé dans des applications architecturales et décoratives..

Applications et avantages de 6063 Aluminium

Cet alliage est couramment utilisé dans des formes extrudées à des fins architecturales., cadres de fenêtres, cadres de portes, et divers composants structurels. Sa combinaison de force, formabilité, et sa résistance à la corrosion en font un choix polyvalent en matière de construction et de conception.

5052 Limite d'élasticité de l'aluminium

Propriétés de 5052 Aluminium

5052 l'aluminium possède une limite d'élasticité d'environ 193 MPa (28,000 psi) et est très apprécié pour son excellente résistance à la corrosion et sa soudabilité. C'est un alliage non traitable thermiquement connu pour sa formabilité et sa durabilité..

Applications et avantages de 5052 Aluminium

Largement utilisé dans la marine, automobile, et applications électroniques, 5052 l'aluminium est privilégié pour sa résistance exceptionnelle à la corrosion par l'eau salée. Il est couramment utilisé dans les composants marins, panneaux de véhicules, et boîtiers électroniques où la résistance à la corrosion est cruciale.

Analyse comparative de la limite d'élasticité

Comparaison 6061, 7075, 2024, 6063, et 5052

Chaque alliage d'aluminium offre des propriétés et des avantages uniques. Alors que 7075 l'aluminium possède la limite d'élasticité la plus élevée, 6061 l'aluminium est apprécié pour son excellente combinaison de résistance, soudabilité, et résistance à la corrosion. 2024 l'aluminium est réputé pour sa haute résistance et sa résistance à la fatigue, ce qui le rend adapté aux applications aérospatiales. D'autre part, 6063 et 5052 l'aluminium est préféré pour sa formabilité exceptionnelle, résistance à la corrosion, et polyvalence dans les applications architecturales et marines.

Facteurs affectant la limite d'élasticité dans les alliages d'aluminium

Plusieurs facteurs influencent la limite d'élasticité des alliages d'aluminium, y compris la composition de l'alliage, procédés de traitement thermique, et écrouissage. La composition de l'alliage joue un rôle important dans la détermination des propriétés mécaniques des alliages d'aluminium, tandis que les processus de traitement thermique tels que la trempe et le vieillissement peuvent améliorer leur résistance et leur durabilité.. Écrouissage, résultant d'une déformation plastique, augmente encore la limite d'élasticité des alliages d'aluminium.

Test de la limite d'élasticité des alliages d'aluminium

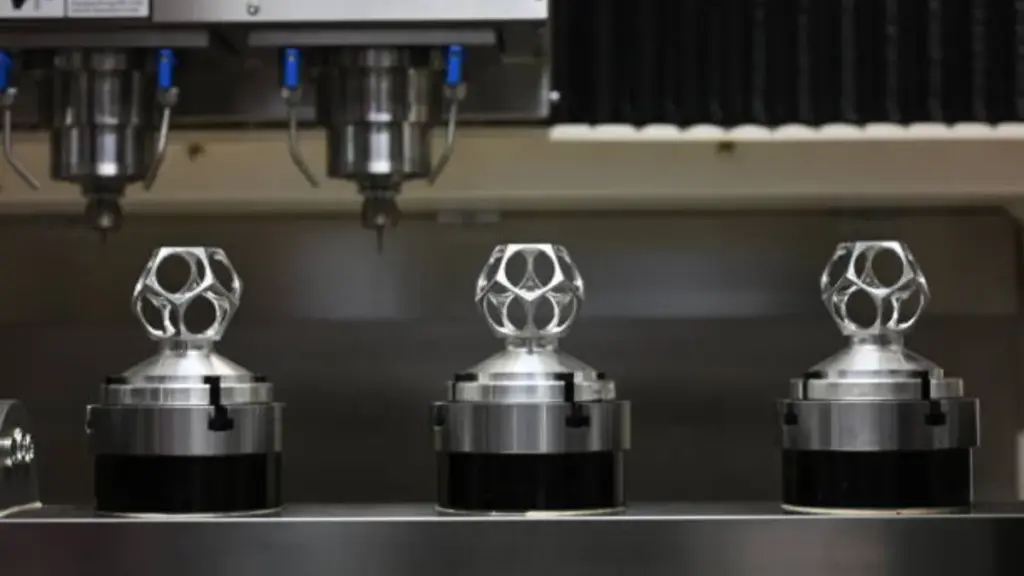

Méthodes de test standard

La limite d'élasticité des alliages d'aluminium est généralement déterminée par des tests standardisés tels que des tests de tension ou des tests de compression.. Ces tests consistent à appliquer des charges contrôlées au matériau jusqu'à ce qu'il subisse une déformation plastique., permettant aux ingénieurs d'évaluer avec précision sa limite d'élasticité.

Tests en laboratoire vs. Tests sur le terrain

Alors que les tests en laboratoire fournissent des mesures précises dans des conditions contrôlées, les tests sur le terrain offrent des informations concrètes sur les performances des alliages d'aluminium dans des applications réelles. Les deux méthodes sont utiles pour évaluer la limite d'élasticité et les propriétés mécaniques des alliages d'aluminium., garantir leur adéquation aux exigences techniques spécifiques.

Conclusion

En conclusion, la limite d'élasticité est un paramètre critique dans l'évaluation des alliages d'aluminium, déterminer leur intégrité structurelle et leurs performances dans diverses applications d'ingénierie. De la haute résistance 7075 aluminium au polyvalent 6061 alliage, chaque alliage d'aluminium offre des propriétés et des avantages uniques. À mesure que les progrès se poursuivent dans la composition des alliages, technologies de traitement thermique, et méthodes de test, l'avenir des alliages d'aluminium dans l'ingénierie semble prometteur, proposer des solutions innovantes pour une large gamme d’applications.

FAQ

1. Quelle est la différence entre la limite d'élasticité et la résistance à la traction?

La limite d'élasticité est la contrainte maximale qu'un matériau peut supporter sans subir de déformation permanente., tandis que la résistance à la traction est la contrainte maximale à laquelle il peut résister avant de se fracturer sous tension. La limite d'élasticité indique le point auquel un matériau commence à se déformer plastiquement, alors que la résistance à la traction représente sa résistance ultime sous tension.

2. Comment le traitement thermique affecte-t-il la limite d'élasticité?

Les processus de traitement thermique tels que la trempe et le vieillissement peuvent affecter considérablement la limite d'élasticité des alliages d'aluminium.. La trempe implique un refroidissement rapide du matériau pour augmenter sa résistance, tandis que le vieillissement ou le durcissement par précipitation améliore encore ses propriétés mécaniques, y compris la limite d'élasticité.

3. Les alliages d’aluminium peuvent-ils être utilisés dans des applications à fortes contraintes?

Oui, certains alliages d'aluminium tels que 7075 et 2024 sont spécialement conçus pour les applications à fortes contraintes, y compris l'aérospatiale, militaire, et ingénierie structurelle. Ces alliages offrent des rapports résistance/poids exceptionnels, ce qui les rend adaptés aux applications exigeantes où la résistance et la durabilité sont primordiales.

4. Quels sont les avantages environnementaux de l’utilisation des alliages d’aluminium?

Les alliages d'aluminium sont des matériaux hautement durables et respectueux de l'environnement. Ils sont légers, recyclable, et économe en énergie, contribuant à réduire les émissions de carbone et l’impact environnemental par rapport aux autres métaux. Le recyclage de l'aluminium nécessite beaucoup moins d'énergie et de ressources que la production primaire, ce qui en fait un choix privilégié pour les solutions d'ingénierie durables.

5. Comment puis-je déterminer la limite d'élasticité d'un alliage d'aluminium inconnu?

La limite d'élasticité d'un alliage d'aluminium inconnu peut être déterminée grâce à des méthodes d'essai standardisées telles que les essais de traction ou les essais de compression.. En soumettant le matériau à des charges contrôlées et en analysant son comportement en déformation, les ingénieurs peuvent évaluer avec précision sa limite d'élasticité et ses propriétés mécaniques. Alternativement, consulter des experts en matériaux ou effectuer des tests en laboratoire peut fournir des informations précieuses sur la limite d'élasticité d'alliages d'aluminium inconnus.