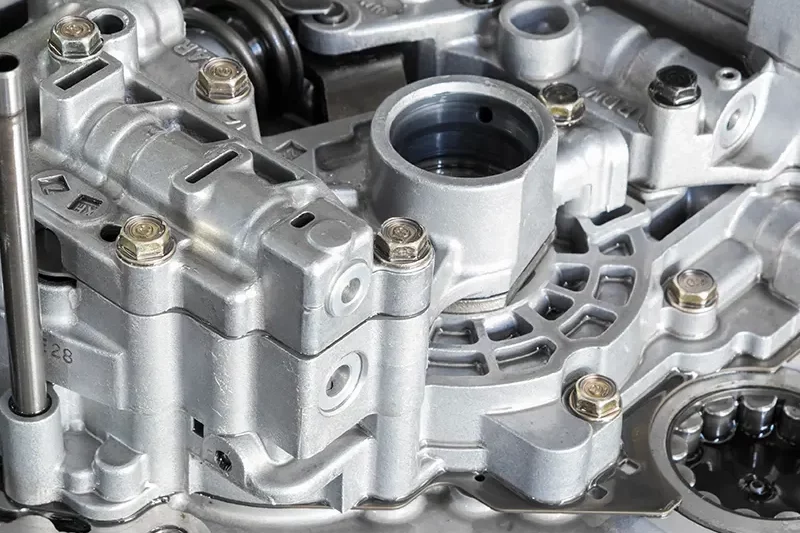

Je vous suis déjà demandé comment ces pièces en aluminium et en zinc se déroulent dans vos gadgets et appareils? Vous regardez la magie du casting de moules! Ce processus permet la création de composants métalliques complexes et précis utilisés dans tout, pièces automobiles de moulage de moulage aux ustensiles de cuisine. Mais choisir le bon métal pour votre projet peut être un cordant de tête. Entrez du zinc et de l'aluminium, Deux poids lourds dans le monde du moulage en métal, chacun se vantait de son propre ensemble de forces. Alors bouclez, Parce que nous sommes sur le point de plonger profondément dans la bataille des métaux.

Qu'est-ce que le moulage sous pression?

Réfléchir à moulage sous pression En tant que sorcier moulante en métal. Un métal fondu (Comme du zinc ou de l'aluminium) est injecté dans un dé, Un peu comme verser de la pâte dans un moule à gâteau. Le métal refroidisse, solidifier, Et le tour est joué - vous avez une pièce finie, Prêt à rock and roll. C'est un rapide, efficace, et méthode polyvalente pour produire des composants métalliques de haute qualité.

Moulage sous pression de zinc

Le zinc est le champion des outsider du monde du casting de moules, Souvent négligé mais débordant d'avantages. Passons dans la nity-gritty:

Propriétés du zinc

Le zinc est un métal connu pour sa polyvalence, Tout comme cet ami qui peut secouer un costume et toujours conquérir une piste de danse. C'est relativement doux, Facile à travailler avec, et a une capacité unique à atténuer les vibrations du son. Plus, Le zinc a un faible point de fusion, En faire un choix économique pour le moulage.

Avantages de l'utilisation du zinc

Pourquoi devriez-vous choisir du zinc pour votre prochain projet de casting de dé? Voici la basse:

- Rentabilité: Le zinc est un métal pour le budget, En faire une option attrayante pour les entreprises qui cherchent à économiser de la pâte.

- Durabilité et force: Ne laissez pas sa douceur vous tromper, Le zinc est étonnamment dur. Il est durable et peut gérer son poids - un excellent choix pour les composants qui doivent résister à l'usure.

- Précision et détail: La capacité du zinc à capturer des détails complexes change. Vous voulez créer une pièce avec des ridules et des formes complexes? Le zinc peut le gérer comme un pro.

Applications de la moulage du zinc

Casting de zinc die, avec son mélange unique de propriétés, est devenu un élément essentiel dans un vaste gamme d'industries. C'est comme le caméléon des métaux, s'adapter de manière transparente à diverses applications. Pensez à votre vie quotidienne: Cet élégant, bouteille de désinfection des mains ergonomiques que vous transportez, La poignée de porte robuste que vous utilisez tous les jours, Même ces pièces de voiture élégantes qui ajoutent une touche d'élégance à votre véhicule - il y a de chances, Le zinc travaille tranquillement dans les coulisses.

C'est un métal qui n'a pas peur de se salir les mains, de la création de composants complexes pour l'industrie automobile à la fabrication de pièces délicates pour l'électronique. La polyvalence du zinc transparaît dans sa capacité à créer des articles fonctionnels et décoratifs, En faire un choix populaire pour tout, de la construction de matériel aux luminaires décoratifs.

Moulage sous pression en aluminium

Déhibons les engrenages et vérifions l'aluminium, Le métal incontournable pour de nombreuses applications de moulage.

Propriétés de l'aluminium

L'aluminium est comme le frère sportif des métaux - léger, fort, Et avec un profil élégant. C'est aussi très résistant à la corrosion, En faire un choix de premier plan pour les applications extérieures.

Avantages de l'utilisation de l'aluminium

L'aluminium a son propre ensemble de fonctionnalités gagnantes:

- Propriétés légères: L'aluminium est un champion de poids plume, Le rendre idéal pour les composants qui doivent être légers et agiles, comme ceux trouvés dans les industries aérospatiales et automobiles.

- Résistance à la corrosion: L'aluminium est un cookie dur en ce qui concerne la rouille et la corrosion. Il peut résister aux conditions difficiles, En faire un excellent choix pour les meubles d'extérieur, cadres de fenêtres, et d'autres applications exposées aux éléments.

- Conductivité thermique et électrique: L'aluminium est un conducteur de chaleur et d'électricité, En faire un ajustement parfait pour les applications où ces propriétés sont cruciales, comme les dissipateurs de chaleur et les composants électriques.

Applications de la moulage en aluminium

Moulage sous pression en aluminium est un vrai caméléon du monde manufacturier, s'adapter parfaitement à un large éventail d'industries. Ce n'est pas seulement un métal; C'est un outil polyvalent utilisé pour créer tout, des éléments constitutifs de notre monde aux composants complexes qui alimentent nos gadgets. Vous trouverez des moulages en aluminium dans pièces de construction, où ils contribuent à des structures durables et légères, Et dans le monde de pièces électroniques, où leur capacité à mener la chaleur et l'électricité les rend essentielles aux composants sensibles.

La légèreté de l'aluminium est un atout clé, Permettre de s'enfoncer dans l'industrie aérospatiale, où le poids est un facteur critique. C'est aussi un ingrédient vital dans l'industrie automobile, Aider à créer des véhicules économes en carburant et à améliorer les fonctionnalités de sécurité. Et n'oublions pas ces vélos élégants qui ornent nos rues, Propulsé par des composants rendus possibles par le moulage en aluminium. Même ces gadgets de fantaisie dont vous ne pouvez pas vivre, des smartphones aux tablettes, Comptez sur les propriétés uniques de l'aluminium pour fonctionner parfaitement.

Zinc contre. Moulage sous pression en aluminium

Maintenant, Pour l'épreuve de force, nous attendons tous: zinc contre aluminium! Pesourons leurs avantages et ses inconvénients en tête-à-tête:

Zinc contre. Aluminium: Force

Lorsque vous comparez l'alliage de zinc vs. force d'aluminium, L'aluminium prend les devants dans la catégorie de force, Bénéficiant d'une résistance à la traction plus élevée que le zinc. C'est comme le muscleman du monde du métal. Mais ne sous-estimez pas le zinc! C'est toujours un concurrent solide et est souvent plus que assez fort pour de nombreuses applications.

Considérations de poids

Les propriétés de poids plume de l'aluminium en font le gagnant clair ici. C'est le champion de la conception légère, autorisé Fabricant de pièces de coulée en aluminium Pour créer des pièces coulées en aluminium plus légères sans compromettre la force. Le zinc est plus lourd, Mais c'est toujours un choix solide pour de nombreuses applications où le poids du produit de moulage en zinc n'est pas une préoccupation majeure.

Coût de moulage

Le casting en alliage en alliage zinc est le choix budgétaire. C'est comme l'option de menu de valeur, Offrir de la qualité sans se ruiner. L'aluminium peut être plus cher, Mais ses propriétés uniques peuvent justifier le coût plus élevé pour des applications spécifiques.

Conclusion

Donc, qui remporte la bataille ultime du zinc vs. aluminium? Il n'y a pas de réponse unique. Tout dépend de vos besoins et de vos applications spécifiques. Besoin d'un poids léger, fort, et composant résistant à la corrosion? L'aluminium est votre champion. À la recherche d'un, durable, et partie orientée vers le détail? Le zinc est votre go-to. Finalement, Il s'agit de comprendre les exigences de votre projet et de choisir le métal qui convient le mieux à vos besoins.

FAQ

1. Quelles sont les principales différences entre le moulage du zinc et de l'aluminium?

Le zinc est connu pour sa rentabilité, durabilité, et capacité à capturer les détails fins, tandis que l'aluminium brille dans ses propriétés légères, résistance à la corrosion, et conductivité thermique.

2. Quel métal est le meilleur pour la production à haut volume?

Le zinc et l'aluminium conviennent à la production à haut volume, Mais le zinc est souvent préféré en raison de son coût inférieur.

3. Le zinc peut-il être utilisé pour les applications en plein air?

Tandis que le zinc est naturellement résistant à la corrosion, Ce n'est pas aussi résistant à la corrosion que l'aluminium. Pour des conditions extérieures dures, L'aluminium est le meilleur choix.

4. Quels facteurs dois-je considérer lors du choix entre le zinc et l'aluminium?

Considérez les exigences de votre projet, y compris le poids, force, résistance à la corrosion, niveau de détail, et le coût.

5. Le zinc et l'aluminium peuvent-ils être recyclés?

Oui, Le zinc et l'aluminium sont des métaux hautement recyclables, les faire des choix respectueux de l'environnement.