安全性が重要な自動車部品を設計するには、破損することなく衝撃荷重に耐える材料が必要です. アルミニウムは大型構造パネルに適していますが、, ドアラッチやシートベルトリトラクターなどの複雑な機構に必要な延性が欠けていることがよくあります。. 自動車用亜鉛ダイカスト 高い引張強度を実現し、メーカーが薄壁を限界まで鋳造できるようにすることで、この課題を解決します。 0.15 んん, 大規模な二次加工の必要性を効果的に排除します。.

このガイドでは、亜鉛合金の工学的利点を検討します。, 材料特性に重点を置く, 工具の寿命, およびメッキ規格.

自動車の安全システムにおける亜鉛合金の役割

亜鉛合金, 特にザマック 5 (ZP5) とZA-8, 引張強度が高いため、自動車の安全システムに不可欠です (〜330MPa) プラスチックに比べて耐衝撃性に優れています。. これらの材料により、シートベルト リトラクターなどの重要なコンポーネントが確実に保護されます。, ドアラッチ, ステアリングコラムロックは衝突荷重下でも構造的完全性を維持します, 厳格なENに準拠 12844 とIATF 16949 安全基準.

機械的信頼性と耐衝撃性

エンジニアは次のような亜鉛合金を優先します。 負荷 5 (ASTM AC41A / ZP5) 標準的な商用グレードよりもはるかに優れた機械的ベースラインを提供するため、安全性が重要なコンポーネントに最適. 引張強度は約 330 MPa および降伏強度に近い 295 MPa, これらの合金は、車両の衝突時に発生する瞬間的な衝撃荷重に耐えます。. エンジニアプラスチックとは異なります, 高いひずみ速度の下では予想外に砕けたり変形したりする可能性があります, 亜鉛ダイカストは形状と完全性を維持します, 乗客を固定するハウジングやブラケットの致命的な破損を防止します。.

安全システムの信頼性は材料の一貫性に依存します. の遵守 で 12844 そしてSAE 925 規格は以下の使用を保証します 99.995% 純亜鉛ベースメタル, 鉛などの不純物を厳密に管理, カドミウム, と錫. この高純度の組成により粒界腐食が排除され、衝突試験や長期使用中に合金が予測どおりに機能することが保証されます。. メーカーはこれらの認定合金を使用して、最新の自動車安全プロトコルの厳しい耐久性要件を満たすコンポーネントを製造しています。.

ロックおよび拘束システムにおける精密な用途

亜鉛の高い流動性により、錯体の生成が可能になります。, シートベルトプリテンショナーギヤやドアロック機構に使用されるネットシェイプ部品. これらの部品は、緊急作動時の詰まりを防ぐために、非常に厳しい寸法公差を必要とします。. 亜鉛ダイカストは、大規模な二次加工を行わずにこれらの形状を実現します。, 部品の構造的連続性が損なわれないようにする. この精度は、衝撃時に瞬時に係合する必要があるラッチとリトラクターのシームレスな操作に不可欠です。.

エンジンや排気装置の近くにある安全部品用, ボンネット下のブラケットやファスナーなど, 熱安定性は主な設計上の制約です. 標準的な亜鉛合金は、高温で持続的な負荷がかかるとクリープを示す場合があります。. これに対処するには, メーカーは ZA-12 や ACuZinc5 などの高クリープ抵抗合金を利用しています. これらの特殊な素材は、エンジンの熱にもかかわらずクランプ荷重と寸法安定性を維持します。, 重要な安全ジョイントが車両の動作寿命にわたって緩んだり位置がずれたりしないようにする.

材料選択ガイド: 亜鉛 (負荷) 対. アルミニウム vs. プラスチック

アルミニウムながら (例えば, A380/ADC12) 大規模な軽量化の標準です, エンジニアリングプラスチックス (例えば, PA66GF) 非構造トリムにコスト上の利点を提供します, 亜鉛合金 (負荷 5) 重要なニッチ市場を占める. 高い機械的強度と複雑な幾何学的精度の間のギャップを埋めます。.

次の表は、各材料の適切な適用範囲を定義するのに役立つ主要なエンジニアリング指標を比較しています。:

| 特徴 | 亜鉛合金 (負荷 5) | アルミニウム (A380) | プラスチック (PA66 30% GF) |

|---|---|---|---|

| 抗張力 | ~330MPa | ~317MPa | ~160MPa |

| 硬度 (ブリネル) | ~91HB | ~80HB | 該当なし (低い) |

| EMI/RFIシールド | 素晴らしい (ネイティブ) | 良い (ネイティブ) | なし (コーティングが必要です) |

| 分. 壁の厚さ | 0.15 んん | 1.5 – 2.0 んん | 1.0 – 2.0 んん |

| 工具寿命 (サイクル) | > 1,000,000 | ~100,000 | > 1,000,000 |

アプリケーションに適合するようにデータを解釈する

1. 亜鉛合金 (負荷 5 / For-8): 精度 & 耐久性

亜鉛はエンジニアの選択です小さい, 安全性が重要なメカニズム (例えば, シートベルトリトラクター, ドアロックアクチュエーター).

- なぜ: 高い引張強度 (~330MPa) 優れた硬度と (~91HB) 衝撃荷重に耐え、アルミニウムよりも優れた摩耗性を実現します。.

- アドバンテージ: 自然素材のユニークな組み合わせEMIシールド と同じくらい薄い壁をキャストする能力0.15 んん スペースと信号の整合性が最重要視される最新のEVセンサーハウジングに最適です。.

2. アルミニウム (A380 / ADC12): 構造的な軽量化

アルミニウムは依然として主要な材料である大型構造部品 (例えば, トランスミッションのケース, エンジンブロック).

- なぜ: 密度約 2.7 g/cm3 (対. 亜鉛は約6.6 g/cm3), アルミニウムは、かさばる部品に対して比類のない強度対重量比を提供します.

- トレード・オフ: より高い処理温度が必要です, これにより、工具寿命が約半減します。. 100k ショットが可能になり、複雑なキャスト能力が制限されます。, 二次加工なしでマイクロサイズのフィーチャを実現.

3. エンジニアリングプラスチック (PA66 / ポリカーボネート): 非耐荷重トリム

強化プラスチックが最も適しているのは、内装カバーと非構造ブラケット.

- なぜ: 重量と原材料コストが最小限に抑えられます。.

- トレード・オフ: 安全性が重要な衝突コンポーネントに必要な剛性が欠けています。. さらに, 電子アプリケーション用, プラスチックは電磁干渉に対して透明です, を達成するには高価な導電性コーティングまたはインサートが必要です。EMIシールド 亜鉛が自然に提供する.

亜鉛ダイカストの一般的な用途

精密なインテリア, 安全性, およびパワートレインコンポーネント

| アプリケーションカテゴリー | 一次合金 | 代表的なコンポーネント |

|---|---|---|

| インテリア & 化粧品 | 負荷 3 (ZP3) | ドアハンドル, ダッシュボードノブ, 装飾トリム, ウィンドウクランク |

| 安全機構 | 負荷 3, 負荷 5 | シリンダー錠, シートベルトリトラクター, ラッチアセンブリ |

| パワートレイン & シャーシ | 負荷 5, For-8, 12 | バルブ本体, ステアリングコラムブラケット, 燃料システムハウジング |

| エレクトロニクス | 負荷 3, 負荷 5 | ECUカバー, コネクタシェル, センサーハウジング (EMIシールド) |

ザマックなどの亜鉛合金 3 そしてザマック 5 自動車の内装に広く使用されています, 安全機構, 外観の品質と寸法安定性が同様に重要なコンパクトなパワートレイン ハードウェア. 負荷 3 銅、ニッケル、クロムめっきに優れた鋳放し表面と一貫した下地を提供します。, 室内ドアハンドルなどの目に見える部品に最適です。, ベゼル, 最小限の後処理で鏡面仕上げが求められるダッシュボードノブなど.

機能部品用, 亜鉛合金の高い流動性と強度により、周囲までの薄肉化が可能 0.8 mm および厳しい鋳放し公差, シリンダー錠の確実な作動をサポート, ラッチシステム, 繰り返し機械的負荷がかかる小さなブラケット. ザマックなどの高強度グレード 5 ZA-8はステアリングコラムブラケットの耐摩耗性と剛性を高めます。, ペダルリンケージ, および伝送関連ハードウェア, スペースに制約のあるボンネット下の環境でもコンパクトな設計が可能になり、車両の寿命を通じて構造的完全性を維持できます。.

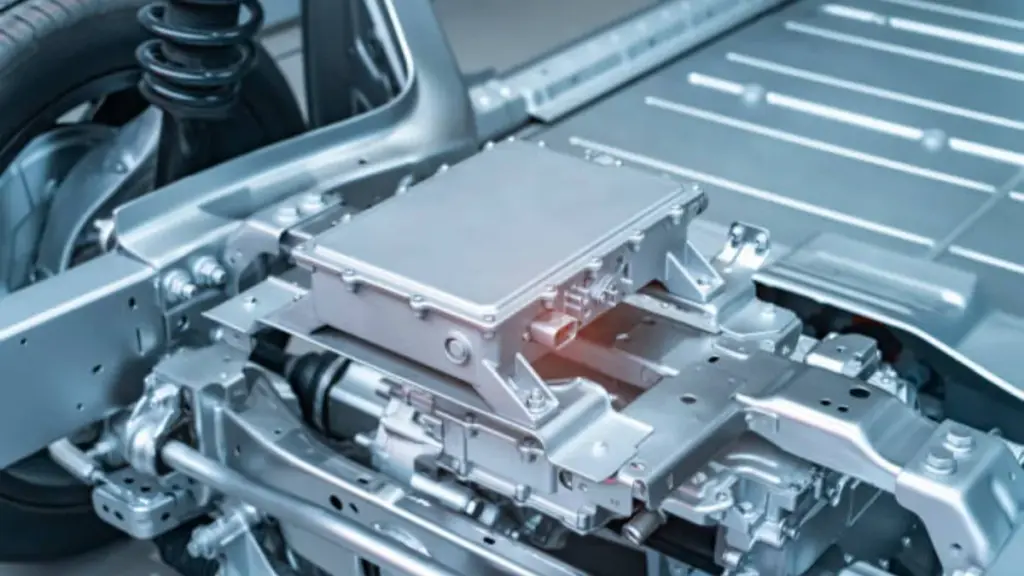

電気自動車の亜鉛ダイカスト (EV) & ADAS システム

これらの電子アプリケーションに基づいて構築する, 電気自動車とADASアーキテクチャでは、シールド性能とパッケージ密度に対してさらに高い要求が課されます, 特にインバータ周り, バッテリー管理システム, および知覚センサー.

| 特徴 | 亜鉛合金 (負荷 5) | アルミニウム (A380) | プラスチック (PA66 30% GF) |

|---|---|---|---|

| 抗張力 | ~330MPa | ~317MPa | ~160MPa |

| 硬度 (ブリネル) | ~91HB | ~80HB | 該当なし (低い) |

| EMI/RFIシールド | 素晴らしい (ネイティブ) | 良い (ネイティブ) | なし (コーティングが必要です) |

| 分. 壁の厚さ | 0.15 んん | 1.5 – 2.0 んん | 1.0 – 2.0 んん |

| 工具寿命 (サイクル) | > 1,000,000 | ~100,000 | > 1,000,000 |

EVプラットフォームにおいて, 亜鉛ダイカストはバッテリーコネクターに広く使用されています, コントロールユニットカバー, コンパクトな形状と寸法安定性がシールとコネクタの位置合わせに重要なセンサー ハウジング. 大面積の熱拡散が必要な場合には、アルミニウム製ハウジングが引き続き有利です, 一方、低負荷の化粧カバーにはエンジニアリングプラスチックが依然として好まれています。; 亜鉛はこれらの材料をより小さく補完します, 機械的強度の組み合わせから恩恵を受ける、安全関連または信号に重要なコンポーネント, シールド性能, および薄肉機能.

自動車用精密ダイカスト ソリューション

亜鉛薄肉形状の最適化 (DFM)

自動車用途向けの亜鉛ダイカスト部品を設計するには、極度の薄肉機能と充填のための堅牢なプロセスウィンドウのバランスをとる必要があります。, 排出, そして長期的な耐久性. 亜鉛合金は日常的に周囲の壁セクションを実現できます。 0.5 んん, 特殊なツールとゲート戦略により、実現可能な厚さを押し上げる 0.15 局所的な特徴の mm. 比較すると, アルミニウム ダイカストは通常、同様の部品エンベロープの場合、1.5 ~ 2.0 mm の範囲で快適に動作します。, そのため、パッケージングの制約や細部がデザインを支配する場合、亜鉛のほうがより自由度が高くなります。.

ほとんどの自動車部品に対応, エンジニアは、一次壁を 0.5 ~ 2.0 mm の範囲に保ち、可能な限り均一な厚さを維持して、熱勾配と収縮に関連する気孔率を減らすことで、信頼性の高いパフォーマンスを実現します。. より高い剛性が必要な場合, 通常、リブとコアリングを追加して材料を再配分することは、単に肉厚を増やすよりも効果的です, リブは金属の流れを改善し、鋳物がより均一に固まるのを助けながらセクションを強化するためです。.

亜鉛は流動性が高いため、他の多くのダイカスト合金と比較して抜き勾配を小さくすることもできます。. 外壁では通常、開始点として 0.5° 付近の抜き勾配が使用されます。, ツーリング時に選択した領域で抜き勾配がほぼゼロに近づく可能性がある, 表面仕上げ, 排出条件は注意深く管理されています. 内部機能, 深い肋骨, または、テクスチャーのある表面の場合は、一貫したリリースをサポートし、金型の摩耗を最小限に抑えるために、追加の抜き勾配が必要になる場合があります。, そのため、機能要件と製造可能性を調整するには、設計段階の早い段階でダイカストと協力することが不可欠です。.

メッキと装飾仕上げのガイド

自動車用亜鉛ダイカストめっきは厳密な 4 段階のプロセスを経ます: シアン化銅フラッシュ, 酸性銅, ニッケルバリア, そしてクロムトップコート.

| めっきステージ | 一次機能 | 技術仕様 |

|---|---|---|

| シアン化銅フラッシュ | 反応性亜鉛を酸性浴から保護します。 | 接着用の初期ストライク層 |

| 酸性銅 | 表面を平らにし、導電性を高めます | 鏡面仕上げ用ファンデーション |

| ニッケル層 | 主な腐食障壁を提供します | 一般的な厚さ 5 ~ 25 μm |

| クロムトップコート | 硬度と耐変色性を実現 | ~0.2 ~ 0.3 μm の装飾フラッシュ |

多層電気化学めっきプロセス

亜鉛合金で自動車グレードの装飾仕上げを実現するには、金属の高い反応性に対抗する特定の電気化学スタックが必要です. プロセスはシアン化銅のフラッシュから始まります, これは、後続の酸性浴が亜鉛基材を化学的に攻撃するのを防ぐ保護バリアとして機能します。. 保護されたら, 部品には酸性銅めっきが施され、表面のレベリングと導電性が向上します。. この層は滑らかな表面を作成します, 内装トリムや外装ハンドルに求められる高光沢外観に必要な均一なベース.

耐久性と美観はその後のニッケル層とクロム層に大きく依存します。. 複数のニッケル層が腐食に対する主な防御を提供します, 塩水噴霧試験において部品の寿命を決定する高密度のシールドとして機能します。 (ASTM B117). プレミアムアプリケーションの場合, メーカーは “銅バフ” プロセス, 最終的なニッケルクロム塗布の前に、厚い銅の堆積物を機械的にバフ研磨して、微細な欠陥を除去します。. 最終のクロムトップコート, 多くの場合、厚さはわずか 0.2 ~ 0.3 ミクロンです, 特徴的な青白色の輝きと、傷や摩耗に耐える十分な硬度を備えています。.

最適な接着のための設計ガイドライン

めっきの成功は設計段階から始まります, 特定の幾何学的特徴が電着の品質に直接影響するため. 鋭いエッジは過剰な電流密度を引きつけます, 荒れにつながる “ビーズ” または “ツリーイング” メッキ金属の. これを防ぐには, エンジニアは最小半径を適用する必要があります。 0.4 すべての端まで mm, と 0.8 mmは均一なコーティング分布の好ましい標準です. さらに, 凹部とネジ穴については慎重な考慮が必要です; 標準的なめっき浴では金属を深い空洞に流し込むのに苦労します. 止まり穴は最小直径を維持する必要があります。 5.6 溶液の流れと適切なめっき厚さを確保するための mm.

表面トポロジは最終的なビジュアル品質にも影響します. 大きい, 平らな表面は、めっき後の基板の小さな欠陥やフローマークを強調する傾向があります. わずかなクラウンまたは凸面を組み込む - 少なくとも推奨 0.015 mm/mm - 銅層をレベリングすることでこれらの欠陥を隠すのに役立ちます, ガラスのような仕上がりになります. 表面のテクスチャリングやクラウニングは、美観を向上させるだけでなく、めっき浴間の溶液の排出にも役立ちます。, 化学物質のキャリーオーバーと汚染のリスクを軽減します.

亜鉛ダイカスト金型寿命の利点

亜鉛ダイカスト金型は、より低い動作温度と金型に優しいホットチャンバープロセスを組み合わせることで、大量生産の自動車プログラムに明らかに長寿命の利点をもたらします。. ザマックなどの亜鉛合金 3 そしてザマック 5 419 ~ 440 °C 付近で溶ける, 660℃付近の典型的なアルミニウムダイカスト温度を大幅に下回る, H13 工具鋼への熱衝撃を軽減し、金型表面の熱チェックなどの疲労現象を遅らせます。.

亜鉛プロセスでは一般にホットチャンバー装置が使用され、射出圧力が低いためです。, ゲートとランナーの機械的浸食が少なく、はんだ付けが起こりにくい, 長期間の生産にわたって金型が元の表面仕上げと寸法精度を維持できるようにします。. 実際に, 適切にメンテナンスされた亜鉛ダイスは、多くの場合、 1,000,000 ショット, 多くのアルミニウム工具では約 100,000 ~ 300,000 サイクルであるのと比較して, 重要なフィーチャーが工具寿命の長い期間にわたって±0.025 mm程度の公差を維持できるようになり、工具への投資をより大きな部品ボリュームで償却できるようになります。.

ザマックの機械的性質 5 合金

負荷 5 (ZnAl4Cu1) は、次のように定義される高強度亜鉛合金です。 1% 銅添加, 極限引張強さを向上させます。 328 MPa および硬度 ~91 ブリネル. ザマックに比べて耐クリープ性と剛性に優れていますが、 3, これらの機械的利点と引き換えに、わずかな延性を犠牲にします。, 自動車の構造部品や複雑なブラケットに最適な選択肢です。.

| 機械的性質 | メトリック値 (ASTM B240) | 工学的意義 |

|---|---|---|

| 極限引張強さ | 328 MPa (分) | ザマックを超える 3 (~283MPa) より高い耐荷重能力を実現. |

| 降伏強さ (0.2% オフセット) | 228 MPa | 構造の安定性と永久変形に対する耐性を確保. |

| 硬度 (ブリネル) | ~91HB | ねじ込み機能と滑り接触の耐摩耗性の向上. |

| 弾性率 | 96 GPa | 薄肉のハウジングやブラケットに高い剛性を提供. |

合金組成と強度特性

ザマックの特徴 5 (ASTM AC41A または ZnAl4Cu1 として指定) 銅の含有量は, これはおよそ 1% 合金組成の 4% アルミニウム. この特定の添加により、銅を含まないザマックと比較して微細構造が根本的に変化します。 3, その結果、より硬い材料が得られます, より強い, クリープに対する耐性が向上. 表面硬度の向上, およその測定 91 ブリネル, この合金は、タッピングなどの二次加工を受ける部品や、適度な摩擦や摩耗にさらされる部品に特に効果的です。.

エンジニアがザマックを選択 5 用途が標準の亜鉛ダイカスト合金が提供できるよりも高い機械的性能を要求する場合, しかし、この強度には延性の低下が伴います. ザマックの間 3 クリンチおよびリベット締め作業に高い伸びを提供します, 負荷 5 より低い伸びを示します (その周り 7%). その結果, 設計者は、鋳造後の大規模な変形が必要な部品を開発する場合、この成形性の低下を考慮する必要があります。, 合金の剛性が、柔軟な組み立て機能ではなく構造の安定性のために利用されるようにする.

主要な機械的データと性能限界

負荷 5 ASTM B240 規格から直接導き出された堅牢なエンジニアリング値を提供します, 亜鉛ファミリーの構造上の主力製品としての位置付け. この合金は究極の引張強度を達成します。 (UTS) 328~331MPa, を大幅に上回っている 280 ザマックの典型的な MPa 範囲 3. この強度プロファイルは、次の降伏強度によって裏付けられています。 228 MPa (0.2% オフセット), これにより、相当な静的荷重がかかってもコンポーネントの形状が確実に維持されます。, 自動車用ブラケットとハウジングアセンブリの重要な要件.

引張性能を超えて, 負荷 5 せん断力と衝撃力に対して優れた耐性を示します. せん断強度 262 MPa および衝撃強さの範囲は 52 ~ 56 J, 材料は衝撃荷重に効果的に耐えます, 自動車の安全ハウジングに適しています. さらに, その弾性率は次のようになります。 96 GPa, 硬いものをサポートするために必要な剛性を提供します, 動作ストレス下でもたわみに耐える薄肉設計.

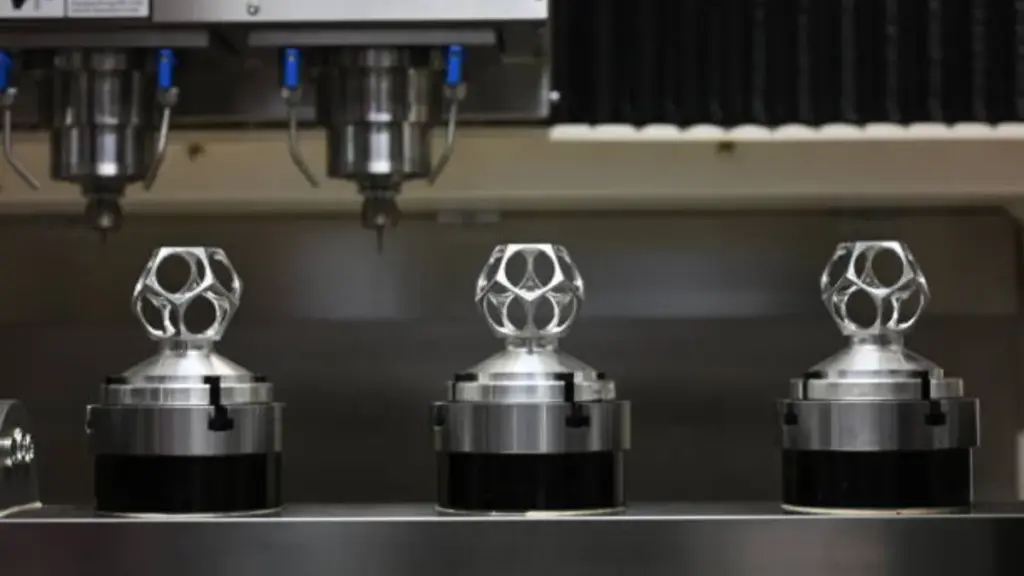

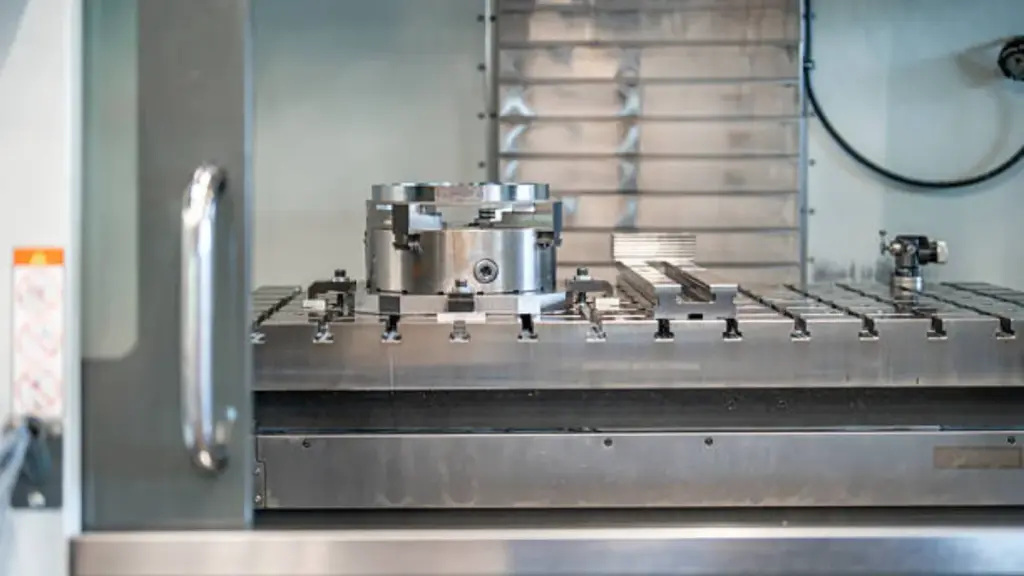

Bian の精密ホットチャンバー ダイカスト

Bian は、次の範囲の型締力を持つ 3 台の特殊なホットチャンバー ダイカスト マシンを利用しています。 88 に 168 トン. このセットアップは亜鉛合金用に特別に設計されています, 迅速なサイクルタイムと高精度の生産が可能になります。, コネクタ本体やセンサーハウジングなどの薄肉自動車部品.

ビアンダイキャスト 薄肉形状の組み合わせに重点を置いた特殊な亜鉛ダイカストです。, 厳しい公差, ブラケットなどの小型から中型コンポーネント向けの自動車グレードの表面仕上げ, コネクタハウジング, 安全性が重要なメカニズム. 同社は、次のようなクランプ力を備えた専用のホットチャンバー亜鉛ラインを運用しています。 88 に 168 トン, 社内CNC加工によるサポート, 掘削, たたく, そして 仕上げ 重要な寸法を選択したフィーチャで約 ±0.02 mm に、より広い範囲にわたって約 ±0.1 mm に維持します。.

デュアルプラントのサプライチェーンにより、配送の回復力と物流効率がさらに強化されます, 佛山市に主要製造拠点を置く, 中国, そして追加の施設 メキシコ 米国とメキシコの顧客に現地生産を提供します, より短い輸送ルート, 関税エクスポージャーの削減. ISOに準拠した品質および環境マネジメントシステム 9001 およびISO 14001 自動車プログラムが生産ライフサイクル全体を通じて顧客と規制の厳しい期待に応えるのを支援します.

結論

亜鉛合金は密度のユニークな組み合わせを提供します, 強さ, 標準のアルミニウムグレードでは再現できない流動性を備えています。, 複雑な部品. ロックシリンダーやリトラクターなどの安全機構に必要な正確な寸法を維持しながら、コンポーネントが高い衝撃荷重に耐える必要がある場合、エンジニアはこれらの材料を選択します。. ドラフトゼロで非常に薄い壁を鋳造できるため、軽量の製品を作成できます。, 乗員保護に不可欠な構造的完全性を損なうことなく、スペース効率の高い設計を実現.

適切な鋳造方法を選択するには、初期の金型への投資と長期的な生産価値を比較検討する必要があります。. 亜鉛の融点が低いため、代替金属よりもはるかに金型の寿命が長くなります。, 数百万サイクルにわたる単位コストの安定化. 自動車サプライヤー向け, このプロセス効率と優れためっき受容性を組み合わせることで、機能的なハードウェアと装飾トリムが車両の耐用年数を通じて耐久性と仕上げ品質に関する厳しい業界基準を確実に満たすことが保証されます。.

よくある質問

亜鉛ダイカストに最適な自動車部品はどれですか?

亜鉛は小型製品に最適な材料です, 高精度の安全部品・装飾部品. 一般的な用途には屋外ドアハンドルが含まれます, ロックシリンダー, ウィンドウクランク機構, シートベルトリトラクター, およびキャブレターハウジング. 薄い壁をキャストする能力 (まで 0.5 んん) 複雑な電子エンクロージャやセンサーハウジングに最適です.

亜鉛ダイカストの強度はアルミニウムと比べてどうですか?

一方、大型の構造部品ではアルミニウムの方が優れた強度対重量比を提供します。, 亜鉛合金 (ザマックみたいに 5) 優れた硬度と衝撃強度を提供します. 亜鉛は衝撃荷重下での強度が大幅に向上し、延性が向上します。 (伸長), 小型の場合、標準的なアルミニウム ダイカストよりも脆性破壊が起こりにくくなります。, ストレスを受けたコンポーネント.

亜鉛ダイカスト金型の平均寿命はどれくらいですか??

亜鉛鋳造ははるかに低い温度で動作します (約. 420℃) アルミニウムより, 工具への熱衝撃を大幅に軽減します. 適切に設計された亜鉛鋳型は通常、次の期間に持続します。 200,000 そして 1,000,000 ショット, アルミニウムやマグネシウムの金型と比較して、プロジェクトのライフサイクル全体にわたってユニットあたりの工具コストが大幅に低くなります。.

自動車の外装トリムに亜鉛ダイカスト部品をクロムメッキできますか?

はい, 亜鉛は高品質クロムめっきの標準的な下地です。. 銅-ニッケル-クロムメッキスタックを適用することにより, メーカーは、厳しい自動車腐食基準を満たす鏡のような装飾仕上げを実現しています。, 通過などの 500+ 時間 ASTM B117 塩水噴霧試験.

精密亜鉛ダイカストで達成できる公差?

亜鉛合金は、あらゆる金属鋳造プロセスの中で最も厳しい公差を実現します。, 多くの場合、二次加工が不要になります. 標準の直線公差は通常、±0.05 mm に保たれます。, しかし、高精度の自動車部品では、±0.02 mm という厳しい公差を達成できます。 (±0.001インチ) 重要な機能について.