一貫性のない品質に苦労していますか, 生産が遅い, またはアルミニウムダイキャスティングの高コスト? これらの問題は、プロジェクトの成功に深刻な影響を与える可能性があります.

ビアンダイキャスト, Foshanでの10年以上の経験があります, 中国, これらの課題への取り組みを専門としています. 当社の最先端の金型設計と効率的な生産方法は、精度を向上させるように設計されています, 製造をスピードアップします, コストを削減します.

私たちはあなたのために違いを生むことができますか? Bian Diecastがキャストの問題を解決し、プロジェクトを次のレベルに導く方法を発見してください.

アルミニウム高圧力鋳造とは何ですか

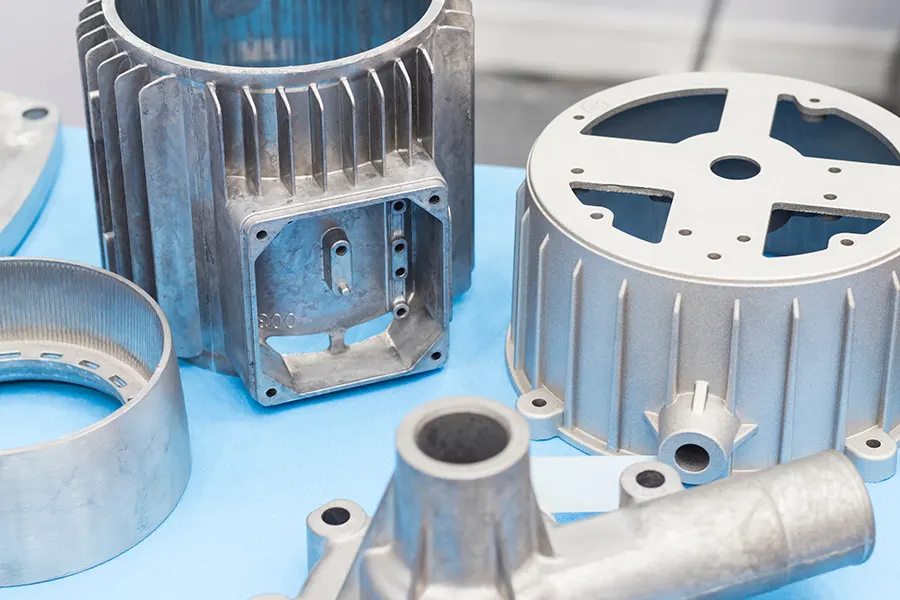

アルミダイカスト 金属部品を製造するプロセスです. ダイキャストパーツまたはコンポーネントがどのように作成されるかには6つの主要なステップがあります:

- 金型設計

- 鋳造の準備

- 注射

- 冷却固化

- 拒否/削除

- CNC加工/表面処理

初め, 目的の部分の形状のスチール型を準備します. それから, アルミニウムは液体状態に加熱され、型に注入されます.

高注入圧力を使用して、アルミニウムがすべての金型の詳細を埋めるようにします. アルミニウムはすぐに冷却され、型内で固まります.

冷やしたら, 型が開いた状態, そして、アルミニウム部分が削除されます. 次, 余分なアルミニウムをトリミングして、部品の品質を調べます.

ついに, 必要に応じて、塗装やコーティングなどの追加の治療を適用できます. このプロセス全体は、複雑な形と高精度の部品を効率的に生成します.

簡単に言えば, アルミニウムダイキャスティングは、溶融アルミニウム合金を鋼型に注入することにより、金属部品を作る方法です.

アルミニウムダイキャスティングにおけるカビのデザインの重要性

各ステップが重要です, しかし、アルミニウム製ダイキャスティング金型デザインの重要性は誇張することはできません。 それが品質に直接影響するからです, 生産効率, アルミニウム鋳造部品のコスト.

適切に設計された金型は、すべてのディテールを均等に満たすことで、正確で滑らかな部分を保証します. デザインが不十分な場合は、泡や不均一な詰め物などの欠陥を引き起こす可能性があります.

金型設計の最適化により、ゲーティングと冷却システムを強化することで生産効率が向上します, サイクル時間の短縮, 欠陥を最小化します. また、金型の寿命も延長されます, メンテナンスコストを削減します.

要約すれば, 優れた金型設計により、高品質の部品と効率的な生産が保証されます, アルミニウムダイキャスティングを成功させるためにそれを不可欠にします.

アルミニウムダイキャスティングカビのデザインの歴史

アルミニウムダイキャスティングカビのデザインの歴史は、テクノロジーが時間の経過とともにどのように進歩したかを示しています.

それ から始まりました で使用される基本的な砂と石の型 古代. 産業革命の間, 機械化された生産と鋼などの強力な材料により、カビの設計が改善されました. 20世紀初頭, コンピューター支援設計 (CAD) ソフトウェアはフィールドに革命をもたらしました, 金型デザインをより正確で効率的にします. 今日, 金型設計では、高度なシミュレーションと3D印刷を使用して、プロトタイプを改良およびテストする. 将来を見据えて, モノのインターネットのような新しいテクノロジー (IoT) および人工知能 (AI) 精度と効率をさらに促進するように設定されています。

全体, これらの進歩により、製造プロセスと製品の品質が大幅に改善されました.

アルミニウムダイキャスティングカビの設計プロセスを最適化する方法

アルミニウムダイキャスティングカビの設計プロセスを最適化するため, いくつかの重要な領域の改善に焦点を当てることができます:

1. 要件を理解します:

現在のアプローチ: いつもの, 基本的な要件分析が行われます.

最適化: 詳細な分析から始めて、必要なすべての情報を事前に収集します. 実際の制作を開始する前に、3Dモデリングとシミュレーションを使用してアイデアをテストし、問題を見つけます。.

2. デザインステージ:

現在のアプローチ: デザインは手動で作成およびレビューされます.

最適化: CADおよびCAEソフトウェアを使用して、金型を設計およびテストする. 潜在的な問題を早期に修正するために、さまざまなゲーティングと冷却のセットアップで金型がどのように機能するかをシミュレートする.

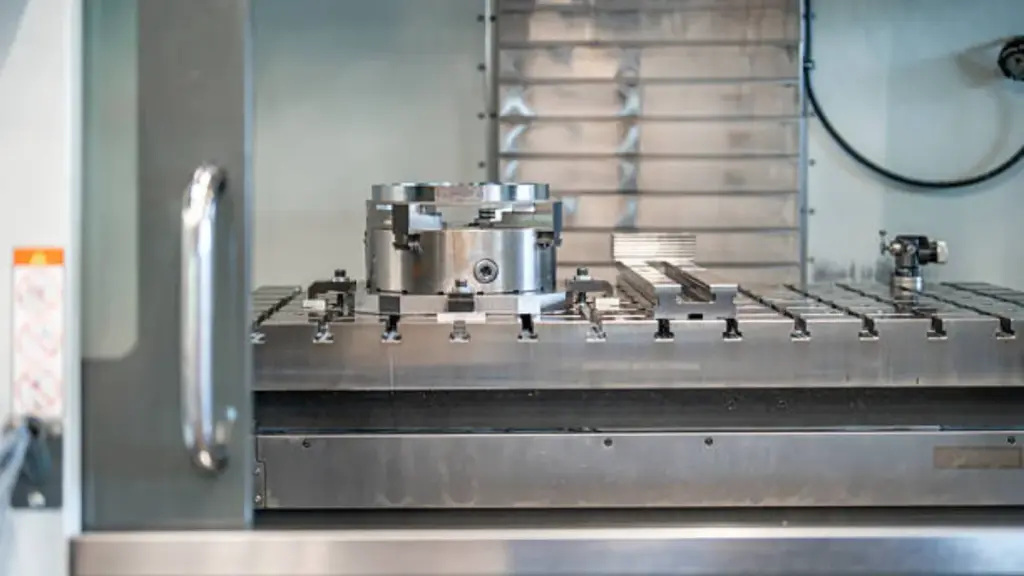

3. 製造業:

現在のアプローチ: 金型は、多くの場合、手動の方法で作られています, 複数の調整が必要になる場合があります.

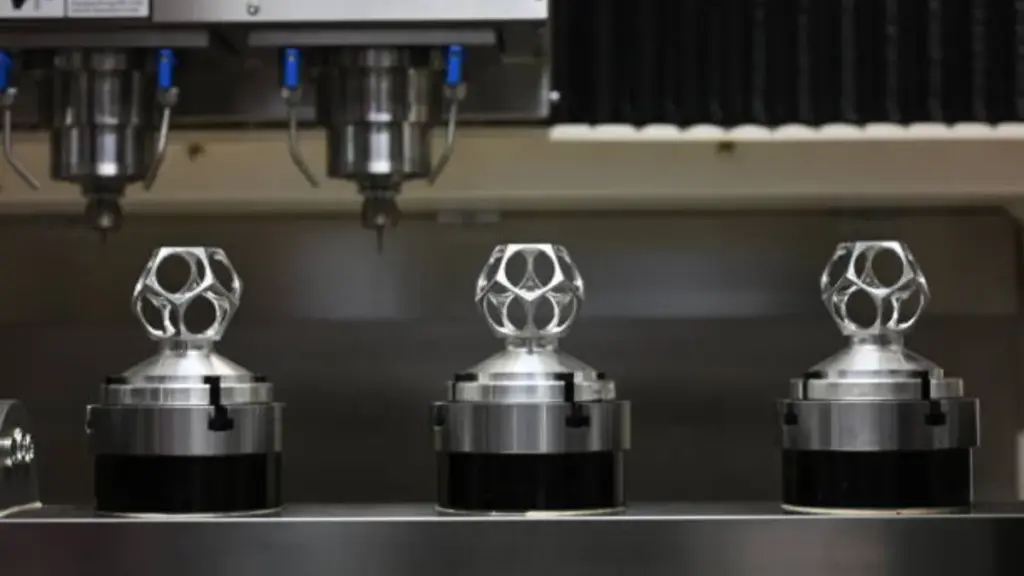

最適化: CNCマシンに切り替えて、正確な金型製造を行います. プロトタイプに3D印刷を使用して、最終制作の前にデザインをすばやくテストおよび改良することを検討してください.

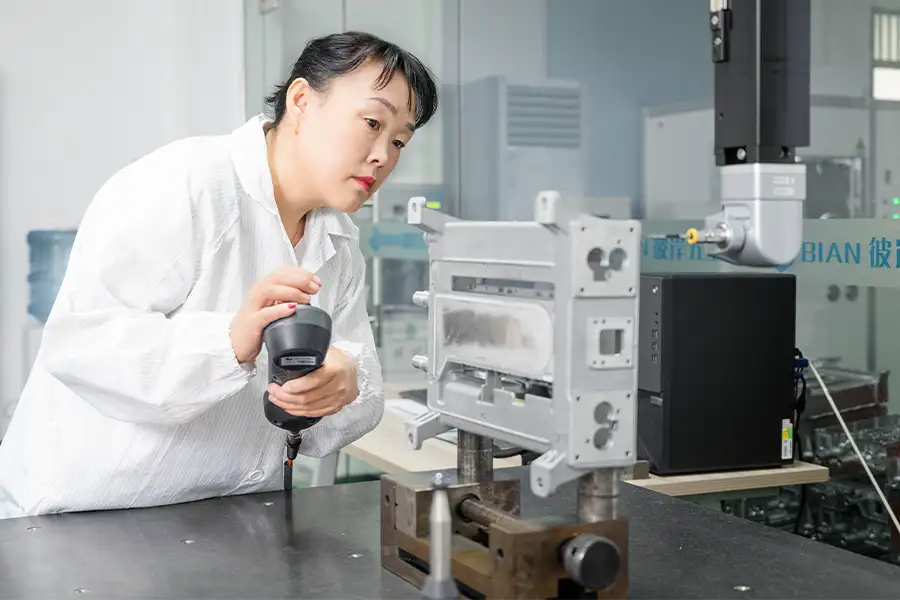

4. テストと検証:

現在のアプローチ: トライアルの実行は、金型をテストおよび調整するために使用されます.

最適化: 物理的な試験を減らすために、設計段階でより多くの仮想テストを行う. 金型のパフォーマンスを圧力と冷却テストで徹底的に確認して、基準を満たしていることを確認してください.

5. 生産とメンテナンス:

現在のアプローチ: 標準のメンテナンスルーチンに従ってください.

最適化: 詳細なメンテナンススケジュールを設定し、センサーを使用して金型の状態をリアルタイムで監視します. データを分析して、メンテナンスが必要な時期を予測します, ダウンタイムを最小限に抑え、カビの寿命を延ばします.

これらの手順に焦点を当てることによって, 金型の設計プロセスをより正確にすることができます, 効率的, そして費用対効果, より良い品質の製品とよりスムーズな生産につながります.

アルミニウムダイキャスティングのカビ設計における考慮事項

アルミニウム押出金型を設計するとき, 金型設計管理 最適なパフォーマンスと品質を確保するために、いくつかの重要な考慮事項が含まれます. 重要な要因の内訳は次のとおりです:

要件の定義

何よりもまず, 製品の寸法を定義することが重要です, 公差, およびパフォーマンス要件. これらのパラメーターを明確に指定します, 型が最終用途の要求を効果的に満たすようにします.

材料の選択

次, 材料の選択 不可欠です, これは、適切なアルミニウム合金を選択することを意味します. 合金の選択は、押出プロセスと最終製品の強度に影響します, 耐食性, 熱伝導率と. したがって, 製品のニーズに合わせた素材を選択することが重要です.

ダイデザイン

プロファイルデザイン

Die Designに移動します, 押出の目的の断面形状に一致するプロファイルを作成する. これにより、素材がダイを通してスムーズかつ一貫して流れることが保証されます.

冷却システム

さらに, 効率的な冷却システムを統合します. 適切な冷却は、ダイ温度を維持するのに役立ちます, 一貫した製品品質と正確な寸法を確保します.

ビレットのサイズと温度

さらに, 押出プロセスに適したビレットサイズと温度を選択します. この選択は、物質的な流れと最適な押出特性さえ達成するために重要です.

フロー分析

その後, 流出分析を実施して、押出中に溶融アルミニウムがどのように動作するかを予測する. この分析は、潜在的な問題を特定するのに役立ちます, ダイブロッキングや不均一な流れなど, 必要な設計調整を可能にします.

換気

さらに, 金型設計に適切な換気を組み込みます. ガスを放出し、ボイドや包含物のような欠陥を防ぐためには、適切な通気が不可欠です, ダイを通る滑らかな材料の流れを確保します.

ツーリングと製造

さらに, カビの設計が製造に可能であることを確認してください. 工具機器の機能と、生産の課題を回避するためにDIEの機能に必要な精度を考えてみましょう.

プロトタイプとテスト

設計が完了したら, プロトタイプダイを作成し、テストの押し出しを実施します. テストは、フルスケール制作を開始する前に、ダイのパフォーマンスを評価し、デザインの欠陥を特定するための重要なステップです.

メンテナンスと長寿

ついに, メンテナンスを念頭に置いて金型を設計します. 簡単なクリーニングと部品の交換を容易にする機能を含めます, 押し出しプロセスの高い圧力と温度に耐えることができる耐久性のある材料を選択してください.

ビアンダイキャストとアルミニウムダイキャスティングカビのデザイン

Bian Diecastはaです 大手アルミニウムダイキャスティングカンパニー 南海区に拠点を置く, 佛山市, 中国. 業界で10年以上, 金型設計など、一流のサービスを提供しています, ダイカスト, CNC加工, そして表面仕上げ.

私たちの近代的な施設と熟練したチームは、さまざまな産業に高品質のソリューションを提供することに専念しています, 自動車など, 点灯, エレクトロニクス, 家具, そして建設.

Bian Diecastのアルミニウムダイキャスティングカビのデザインは、実用的で費用対効果の高い金型の製造に焦点を当てています. 製造可能性に優れたデザインを使用しています (DFM) 私たちの金型があなたの部分の正確な形状に合わせて効率的に機能するようにするためのテクニック.

- DFMとは何ですか?

DFM, または 製造用のデザイン, エンジニアリングと製品設計で使用されるコンセプトです. それは、製造がより簡単で安価な方法で製品を設計することを意味します. それで, DFMには、製品の作成方法を考慮した製品設計の作成が含まれます.

アルミニウムダイプストの生産プロセスを最適化するために, 次の目的がターゲットになります:

- 必要なアルミニウムの量を使用するための設計.

- 部品がスムーズにダイから出てくることを確認してください.

- 冷却を最適化して、固化プロセスを高速化します.

- 最小限のキャスティング後の処理が必要になるように部品を設計します.

- 最終製品が必要に応じてそのアプリケーションで実行されることを確認してください.

結論

アルミニウムダイキャスティングは、正確な金属部品を作成することです, そして、金型のデザインを正しくすることが重要です. 優れた金型デザインは精度を高めます, 生産をスピードアップします, コストを削減します.

ビアンダイキャストにて, 最高品質の金型とキャスティングサービスを作成するのに10年以上の経験があります. 私たちの高度なツールとテクニックはあなたの部品が完全に出てくることを保証します.

キャスティングプロセスを改善したい? Bian Diecastに手を差し伸べてください 今日、私たちがあなたのアイデアを生き生きとさせるのを助けることができる方法を見てください!