ダイカストと射出成形のどちらを選択するかは、コンポーネントの構造的完全性に直接影響する製造設計における重要な決定です。, 熱性能, そして最終的な単価. Specifying the wrong process early on introduces significant project risk, potentially leading to catastrophic field failures, expensive tooling rework, or a complete budget overrun that sidelines the entire product launch.

This guide provides a definitive technical comparison to clarify that choice. We will move beyond the simple metal vs. plastic debate and analyze the core process mechanics, 材料特性, and design constraints of each method. We’ll examine the trade-offs between tooling investment and per-part economics, contrast key performance metrics like strength and heat resistance, and detail the different rules governing tolerances and part geometry, providing a clear framework for selecting the right process for your application.

The Core Difference: Molten Metal vs. Molten Plastic

Material state dictates everything; metals demand extreme heat for high stiffness, while plastics offer design flexibility at far lower energy costs.

Thermal Processing and Energy Requirements

The primary distinction lies in melting temperature. Metals require approximately ten times the heat of plastics to become molten. This massive thermal gap forces die casting molds to be built from specialized, heat-resistant tool steels capable of withstanding extreme thermal stress. その結果, the energy needed for metal smelting and die casting is substantially higher than the energy required for plastic injection molding, which operates at much lower thermal loads.

Flow Dynamics and Design Complexity

Molten plastic cools more slowly than molten metal, an attribute that provides significant design advantages. This extended cooling window allows for precise control over flow patterns within the mold, enabling the production of complex, 薄壁, and highly detailed parts that are difficult to achieve with metal. 逆に, the rapid solidification of molten metal requires fundamentally different mold designs, particularly concerning gate placement and venting strategies, to manage its distinct flow mechanics and prevent defects.

Post-Solidification Mechanical Properties

冷却後, the material differences are stark. Solidified metals are roughly 1000 times stiffer than most plastics, making them the default choice for load-bearing structural parts in automotive, industrial, and aerospace applications. Die-cast components solidify into parts with high strength, 耐久性, and wear resistance. While advanced engineering plastics are closing the gap, metals remain superior for applications where rigidity and structural integrity are critical.

Process Mechanics: The Die Cast Process vs. Plastic Injection

The fundamental differences in thermal energy and material state between die casting and plastic injection dictate tooling design, 生産効率, and final component properties.

Material State and Thermal Dynamics

The core distinction between these processes lies in thermal energy. Liquefying metal for die casting requires substantially more heat than melting plastic resins for injection molding—plastics melt at roughly one-tenth the temperature of metals. This thermal gap has major consequences. Die casting tools must be constructed from specialized, heat-resistant steels capable of withstanding extreme thermal stress, as mold temperatures can exceed 700°F (370℃).

The cooling rates and flow characteristics of molten metal versus molten plastic are also completely different. Metal solidifies quickly, demanding precise gating and venting strategies to prevent defects like porosity. Plastic cools more slowly, which allows for greater control when filling complex, thin-walled sections. Each material’s unique behavior requires a distinct approach to mold engineering and process control.

Resulting Mechanical and Structural Properties

固まったら, the performance gap between metal and plastic is clear. Metals exhibit approximately 1000 times greater stiffness than most plastics, giving them superior performance in any load-bearing or structural application. This makes die casting essential for producing high-strength components for automotive, industrial, and communications equipment.

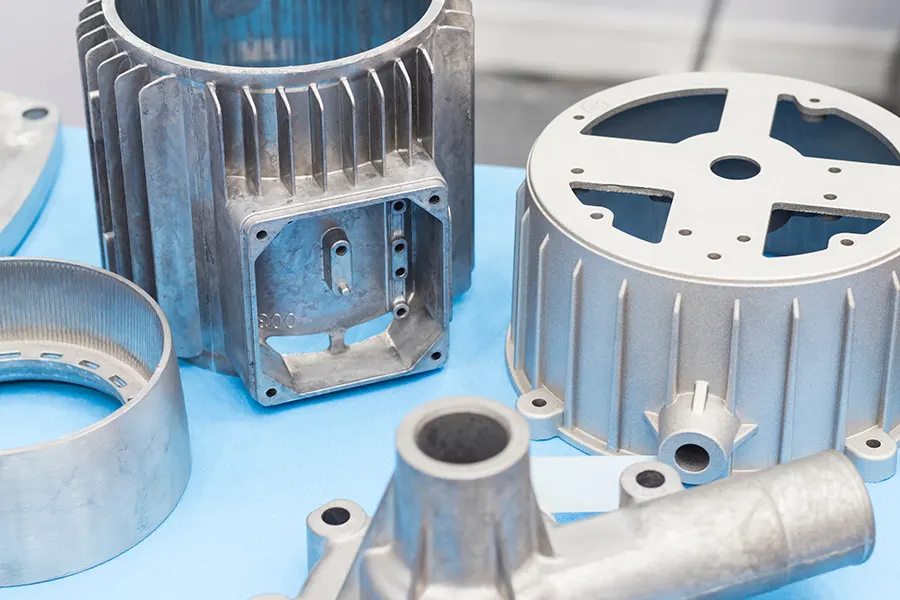

Die-cast parts made from aluminum, 亜鉛, or magnesium alloys deliver a combination of properties that plastics cannot match. These include:

- High Durability: Excellent resistance to wear, fatigue, and impact.

- EMIシールド: The inherent conductivity of the metal provides effective shielding for sensitive electronics, a critical feature for 5G and NEV applications.

- 熱伝導率: Metals efficiently dissipate heat, a key advantage for LED lighting and power electronics housings.

Plastic injection is better suited for applications that require material flexibility, electrical insulation, または耐食性. Yet for structural integrity, die casting remains the necessary choice.

Implications for Design and Production Efficiency

Plastic molding’s lower operating temperatures and slower cooling cycles give engineers greater design freedom for highly complex or thin-walled geometries not easily achievable in die casting. 対照的に, die-cast parts often require secondary CNC machining to achieve the tightest tolerances, which adds a step and associated costs to the production cycle.

From an efficiency standpoint, injection molding consumes significantly less energy. This makes it a cost-effective solution for high-volume runs of non-structural components. Die casting’s higher energy use is justified by the superior mechanical properties of the final metal part, making it the efficient choice for applications where strength and durability are the primary drivers of value.

Reduce Defects with IATF 16949 ダイカスト

材料 & Process Alternatives: Metal Injection Molding vs. ダイカスト

This choice defines your part’s final properties: MIM offers geometric complexity for small parts, while die casting provides structural strength for larger, high-volume components.

Processing Temperatures and Tooling Requirements

The fundamental difference between the two processes is the state of the metal. Die casting injects fully molten metal, such as aluminum at temperatures over 660°C, into hardened, heat-resistant steel dies. This extreme thermal stress dictates the design and material of the tooling. Metal Injection Molding (MIM) uses a feedstock made of fine metal powder mixed with a polymer binder. This composite material is injected at significantly lower temperatures, much like plastic injection molding. The lower thermal load on MIM tooling allows for more complex and intricate mold designs, which would fail under the high-heat conditions of die casting.

Final Mechanical Properties and Material Density

Die-cast parts gain their high structural integrity directly from the solidification of a homogenous molten metal, making them an excellent choice for load-bearing applications. The process can sometimes trap gases, creating porosity that acts as a structural weak point. MIM, 一方で, requires secondary debinding and sintering steps to fuse the metal particles into a solid mass. This results in a final part that achieves 95-99% of the material’s theoretical density with a uniform, fine-grained microstructure. MIM also offers a much wider selection of alloys, including stainless steels, titanium, and other high-performance metals that are difficult or impossible to die cast, enabling parts with specific wear, magnetic, or corrosion-resistant properties.

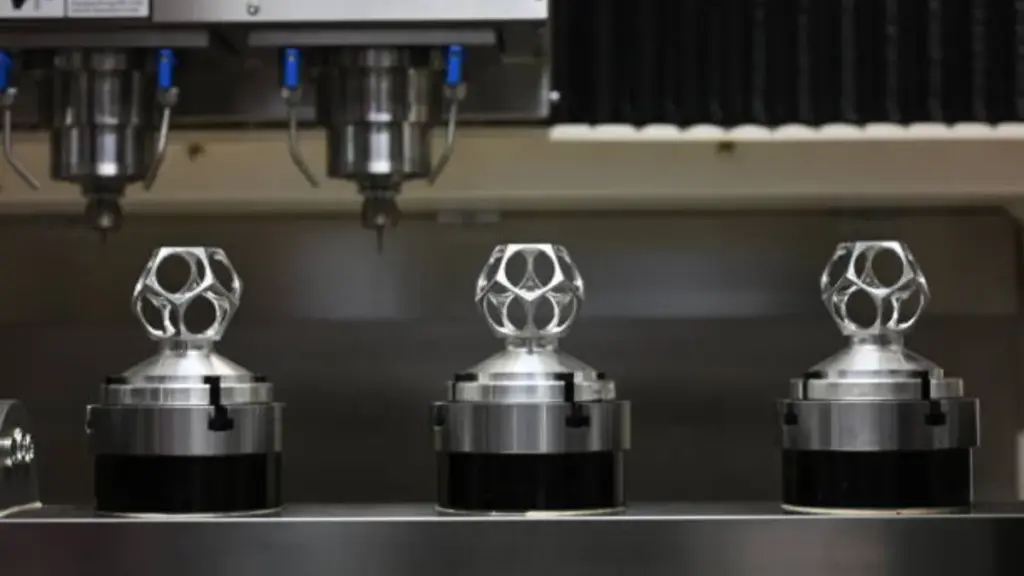

Geometric Complexity and Net-Shape Capability

MIM excels at producing small, highly complex parts that include fine details, undercuts, and thin walls. The process frequently achieves “net-shape,” meaning the part comes out of the mold requiring no secondary machining. Die casting is better suited for larger, simpler structural components where mechanical strength and rapid cycling are the primary objectives. Because of its precision at the molding stage, MIM can achieve tighter dimensional tolerances (例えば, ±0.05mm) on small, complex features directly from the tool, before the final sintering locks in the part’s geometry.

Mechanical Properties: 強さ, Heat Resistance & EMIシールド

Die-cast metals provide non-negotiable structural integrity, thermal stability, and EMI shielding—critical for reliable performance in automotive, 電気通信, and industrial applications.

Strength and Structural Integrity for Load-Bearing Parts

Die-cast aluminum alloys like ADC12 and A380, along with zinc alloys, deliver the high stiffness required for structural components in demanding environments. This high strength-to-weight ratio is essential for lightweighting initiatives in New Energy Vehicle (NEV) powertrain systems, where reducing mass without compromising durability is a primary engineering goal. Unlike plastics, which can deform under sustained loads, die-cast metals ensure long-term wear resistance and dimensional stability, making them the default choice for load-bearing automotive and industrial parts that face constant vibration and mechanical stress.

Thermal Management and High-Temperature Performance

Metal alloys maintain their structural form and strength at high operating temperatures, a critical requirement for parts used in LED lighting housings and automotive engine compartments. The material’s excellent thermal conductivity allows enclosures to double as effective heat sinks, passively dissipating thermal energy and protecting sensitive internal electronics from overheating. This intrinsic property ensures components maintain their precise dimensions even under significant thermal stress, preventing the warping or fitment issues common with engineering plastics in high-heat applications.

Inherent EMI Shielding for Electronic Housings

The conductive nature of die-cast metal provides a significant advantage for modern electronics. It functions as a natural Faraday cage, offering built-in electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding without needing secondary coatings or treatments. This is a crucial performance characteristic for sensitive equipment.

- Blocks Interference: The metal enclosure effectively blocks external electromagnetic waves from disrupting internal components.

- Protects Sensitive Systems: This is vital for the reliable operation of 5G communication base stations, NEV battery management systems, and vehicle control units.

- Intrinsic Property: The shielding is an inherent material property, delivering more reliable and consistent performance than conductive paints or coatings applied to plastic parts.

Design Constraints: 壁の厚さ, Geometry & 公差

Mastering die casting design rules for wall thickness, 下書き, and tolerances is non-negotiable for preventing defects and minimizing secondary machining costs.

Optimizing Wall Thickness for Material Flow

Maintaining uniform wall thickness is a core principle in die casting design. When molten metal cools at different rates in thick and thin sections, it introduces stress and defects like porosity or sink marks. For common aluminum alloys such as A380 and ADC12, the target thickness is typically between 1.5mm and 3.0mm. Zinc alloys like Zamak can often achieve even thinner walls without compromising integrity. Any necessary changes in thickness must be gradual. Designing smooth transitions between sections ensures the molten metal can flow and fill the entire die cavity completely, which is critical for the final part’s structural strength.

Incorporating Draft Angles and Radii for Manufacturability

Features that aid manufacturability are not optional; they are essential for a successful production run. A draft angle, 通常 1-2 degrees, must be applied to all surfaces parallel to the die-pull direction. This slight taper allows the solidified part to eject cleanly from the tooling without damage. Complex internal features and undercuts should be minimized, as they require costly side-cores and slides in the mold, increasing both tooling cost and cycle time. Generous radii and fillets on all inside and outside corners serve two key functions: they improve metal flow to prevent defects and reduce stress concentrations in the final part, which also significantly increases the operational life of the die.

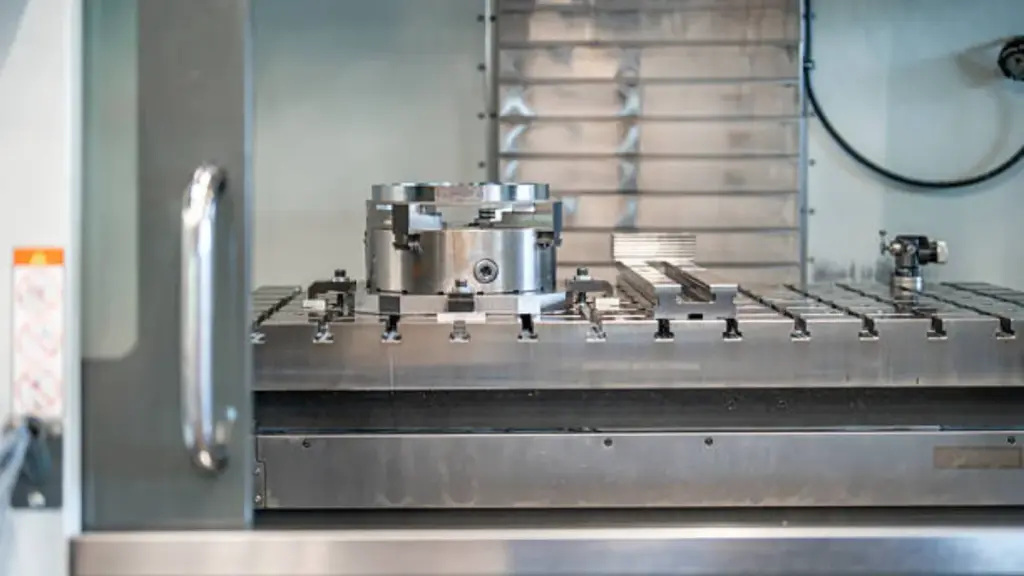

Defining As-Cast Tolerances vs. Post-Machining

Die casting is valued for its ability to produce parts with tight ‘as-cast’ 公差, often reducing the need for extensive secondary operations. The achievable precision depends on the material; Zinc alloys typically hold tighter tolerances than Aluminum or Magnesium. Standard die casting can achieve tolerances around ±0.1mm for the first 25mm. But for critical features like bearing bores, ネジ穴, or precise mating surfaces that demand tolerances beyond this capability, the design must specify machining allowances. This practice involves intentionally adding extra material to the casting in specific areas, which is later removed through CNC machining to meet the final, high-precision requirements.

コスト分析: 工具への投資 vs. Per-Unit Economics

Balancing the one-time tooling investment against variable production costs is essential for optimizing total landed cost and achieving target per-part economics across global supply chains.

Analyzing the Upfront Tooling Investment

The initial tooling represents a one-time capital expenditure for your project. We develop all molds in our China facility to leverage our R&D center and optimize initial costs. This fixed fee is prepaid, and the standard development lead time is 25-35 days from kickoff to completion. This investment is then amortized over the entire production run, directly influencing the final cost-per-part calculation. A durable, well-engineered mold is a long-term asset that drives down unit costs as production volume scales.

Variable Production Costs by Manufacturing Base

Once tooling is complete, the per-unit production costs are determined by your selected manufacturing base: 中国, メキシコ, またはベトナム. This strategic choice allows for tariff optimization; producing in Vietnam or Mexico can significantly reduce landed costs for North American and European markets. The variable cost for each part is a composite of several key production stages.

- Raw Materials: Cost of certified alloys like ADC12, A380, or Zamak 3, compliant with ASTM, で, およびJIS規格.

- ダイカスト: The core manufacturing process to form the net shape.

- CNC加工: Secondary processing for precision features and critical tolerances.

- 表面仕上げ: Application of powder coating, 陽極酸化処理, or other specified finishes.

Impact of Order Volume on Total Cost per Part

The total cost per part has an inverse relationship with order volume. Higher production quantities distribute the fixed tooling investment across more units, effectively lowering the amortized cost for each component. For shipments originating from our Vietnam and Mexico facilities, we recommend a Minimum Order Quantity (MOQ) of 3,000 に 5,000 単位. This volume makes the cross-border logistics and operational overhead economically viable. We support lower volume trial orders of 500-1,000 単位, typically produced in China, but these initial runs will reflect a higher cost-per-part until the project transitions to mass production.

Surface Finishes & 後処理: Plating vs. Texturing

Selecting the right surface finish—plating for functional hardness or texturing for protection—directly impacts a die-cast component’s long-term durability and performance in its intended environment.

Functional Goals of Electroplating on Die-Cast Parts

Electroplating applies a thin metallic layer to a component, creating a molecular bond with the substrate for functional enhancements. This process significantly improves corrosion resistance, a critical requirement for parts used in automotive systems or outdoor LED lighting that are exposed to harsh weather. We verify this resilience through rigorous salt spray testing. Plating also increases surface hardness and wear resistance, essential for high-contact industrial automation components where friction can degrade untreated surfaces. Common finishes like chrome, nickel, and zinc can be selected to provide specific properties, from a premium decorative look to enhanced electrical conductivity.

Methods for Applying Surface Texture

Applying surface texture is focused on aesthetics, grip, and creating a durable protective barrier. One efficient method is to integrate the texture pattern directly into the die casting mold itself, which produces a consistent finish on every part as it is cast. For a uniform matte appearance, secondary processes like bead blasting are used to prepare the surface or create the final finish. A highly effective and common method is applying a textured powder coating. This creates a thick, 耐久性のある, non-reflective surface that resists chipping and abrasion, making it ideal for enclosures and structural components that need robust protection.

Selecting a Finish Based on Alloy and Application

The choice of finish is closely tied to the base metal alloy and the part’s end-use. Plating is a frequent choice for zinc alloys such as Zamak 3 そしてザマック 5, where achieving a premium, mirror-like decorative appearance is often the primary goal. For aluminum alloys like ADC12 and A380, a textured powder coating is a more practical and cost-effective solution, delivering the robust protection needed for housings and structural parts without the complexity of plating on aluminum.

- Choose Plating for parts requiring superior wear resistance, electrical conductivity, or a high-end decorative metallic finish.

- Choose Texturing for enhanced grip, non-reflective aesthetics, or to cost-effectively hide minor surface imperfections from the casting process.

Decision Framework: When to Choose Which Process

Selecting the right manufacturing process requires a disciplined evaluation of material strength, thermal needs, geometric complexity, and total cost of ownership.

Evaluating Material Strength and Load-Bearing Needs

Choose die casting for structural components that require high stiffness, long-term durability, and wear resistance. Metals are approximately 1000 times stiffer than standard plastics, making them the default choice for any load-bearing application where failure is not an option. Injection molding is better suited for non-structural parts like housings, ノブ, or internal brackets. Some advanced engineering plastics can approach metal-like strength, but these are specialty materials for specific use cases, not general-purpose replacements for the inherent rigidity of a die-cast part.

Assessing Thermal Management and EMI Shielding Requirements

Select die casting when a part must actively manage heat or shield sensitive electronics. Metal’s high thermal conductivity allows die-cast components to function effectively as heat sinks, dissipating energy from critical systems like LED lighting or NEV powertrains. This same conductivity provides inherent EMI/RFI shielding, which is critical for protecting 5G communication hardware and other high-frequency electronics. プラスチック, 対照的に, are natural thermal and electrical insulators. Achieving any level of shielding requires special additives or secondary plating operations, which adds cost and complexity.

Analyzing Geometric Complexity and Fine-Detail Feasibility

Opt for injection molding to efficiently produce parts with intricate features, very thin walls, or complex internal geometries directly from the tool. The slower cooling rate of molten plastic allows it to flow into and fill fine details in the mold cavity before solidifying. This makes it ideal for producing complex parts in a single step. Die casting is better suited for creating robust, durable shapes. While it can produce complex parts, achieving extremely fine details or sharp internal corners often requires post-cast CNC machining, which increases the final piece price and production time.

Calculating Total Cost Based on Volume, Tooling, and Post-Processing

A true cost analysis goes beyond the per-unit price. Injection molding’s lower processing temperatures translate to lower energy costs, making it highly efficient for mass-producing plastic parts. Die casting demands significantly more energy to melt metal, but this is partially offset by the high recyclability of aluminum and zinc alloys. The critical factor to include in your calculation is post-processing. Die-cast parts frequently require secondary operations like deburring, 掘削, or milling to meet final specifications, and these costs must be added to determine the total cost of ownership.

Determining Requirements for Dimensional Stability Under Load

Use die casting for any application where the component must maintain tight tolerances under sustained mechanical stress and temperature changes. Plastic parts are susceptible to “creep”—a slow, permanent deformation that occurs over time when subjected to a constant load, especially at elevated temperatures. The inherent rigidity of die-cast metal ensures long-term dimensional stability. This makes it essential for precision industrial automation and automotive components that must perform reliably for years in demanding operational environments without warping or failing.

結論

Selecting the right manufacturing process, whether die casting or injection molding, directly influences a product’s mechanical performance, longevity, そして最終的な費用. Die casting offers superior strength, 熱散逸, and EMI shielding for demanding applications, while injection molding provides flexibility for complex geometries with lower-cost materials. The decision ultimately balances tooling investment against per-unit economics and the specific functional requirements of your component.

If your application requires the durability and performance of metal, our engineering team can help analyze your project’s total cost of ownership. We develop cost-effective tooling in our China facility and offer flexible mass production options in Mexico or Vietnam to optimize your supply chain and tariff exposure.

よくある質問

Is die casting more expensive than injection molding?

はい, die casting is generally more expensive. The process demands greater energy for melting metal and requires specialized, heat-resistant dies. さらに, cast metal parts often need additional post-processing like milling or grinding, which adds to the overall cost. 対照的に, injection molding is less energy-intensive and more cost-effective for high-volume production.

Can injection molding replace die casting?

It depends on the application. While advanced engineering plastics can now rival metal strength, die casting remains essential for parts requiring extreme stiffness, high load-bearing capacity, and superior heat resistance. Injection molding can replace die casting in many cases, but metals are still the superior choice for demanding structural components in automotive, 航空宇宙, and industrial applications.

Which process produces tighter tolerances?

Injection molding generally produces parts with tighter tolerances and finer detail. The lower processing temperatures and slower cooling of molten plastic allow for more precise control over material flow into complex mold cavities. This enables the creation of intricate, thin-walled geometries with a high degree of precision that is often harder to achieve with the high temperatures and rapid cooling of die casting.

Is die casting mold life shorter than injection molding?

はい, the mold life for die casting is typically shorter. Die casting dies endure far greater thermal stress from molten metal, which can be 10 times hotter than molten plastic. This extreme temperature cycling leads to faster wear and thermal fatigue. 対照的に, injection molding tools operate under much lower thermal loads, resulting in a significantly longer operational lifespan.

Why use aluminum instead of engineering plastics?

Aluminum is used over engineering plastics for applications demanding superior stiffness, 強さ, 耐久性, and wear resistance. Metals are approximately 1000 times stiffer than plastics, making them the ideal choice for structural, load-bearing, and heat-resistant components common in the automotive, 航空宇宙, and industrial sectors where performance under stress is critical.

What is the difference in tooling cost?

Tooling for die casting is significantly more expensive. Die-casting dies must be constructed from specialized, heat-resistant tool steels to endure the extreme thermal stress of molten metal. 対照的に, tools for injection molding can be made from more cost-effective materials because they only need to withstand the comparatively modest temperatures of molten plastic.