製造の領域で, 精度と効率が最重要です. これがここです 5 軸の機械加工が段階的です, 複雑な部品の作成方法に革命をもたらします. しかし、正確には何ですか 5 軸加工, そして、それは従来の機械加工方法とどのように異なりますか? この包括的なガイドで, の世界を掘り下げます 5 軸加工, その基礎を探る, アプリケーション, 利点, などなど.

機械加工の基本を理解する

の複雑さに突入する前に 5 軸加工, 理解して基盤を置きましょう 機械加工の基本. 機械加工は、材料を形成するプロセスです, 通常、金属, 正確な部品またはコンポーネントを作成します. 従来の機械加工方法, のような 3 軸加工, 材料を切断するために3つの線形軸に沿って移動するツールを含む. これらの方法は効果的ですが、複雑な形状と輪郭を作成することに関しては制限があります.

何ですか 5 軸加工?

5 軸加工 2つの追加の回転軸を導入することにより、精密エンジニアリングを次のレベルに引き上げます, 5つの異なる動き軸に沿って移動できるように切削工具を可能にする. とは異なり 3 軸加工, 切削工具が3つの方向にのみ移動できる場所 (上下, 左右, 前後に), 5 軸の機械加工により、ツールは2つの追加軸に沿って回転できます, 通常、AおよびB軸と呼ばれます. この多方向運動は、比類のない柔軟性を与えます, 精度と効率を備えた非常に複雑で複雑な幾何学を作成することを可能にします.

どうしますか 5 軸加工作業?

理解する 5 軸加工, 各軸に沿った動きを把握することが不可欠です:

- x軸: 左から右への水平方向の動き

- Y軸: 正面から背面への水平方向の動き

- z軸: 上下に垂直な動き

- A軸: X軸の周りの回転動き

- B軸: Y軸の周りの回転動き

- デザインとプログラミング:

- CAD (コンピュータ支援設計) パーツのモデルが作成されます.

- カム (コンピューター支援の製造) ソフトウェアは、ツールパスを生成するために使用されます.

- ソフトウェアは、切削工具の最適な動きと角度を計算して、目的のジオメトリを実現する.

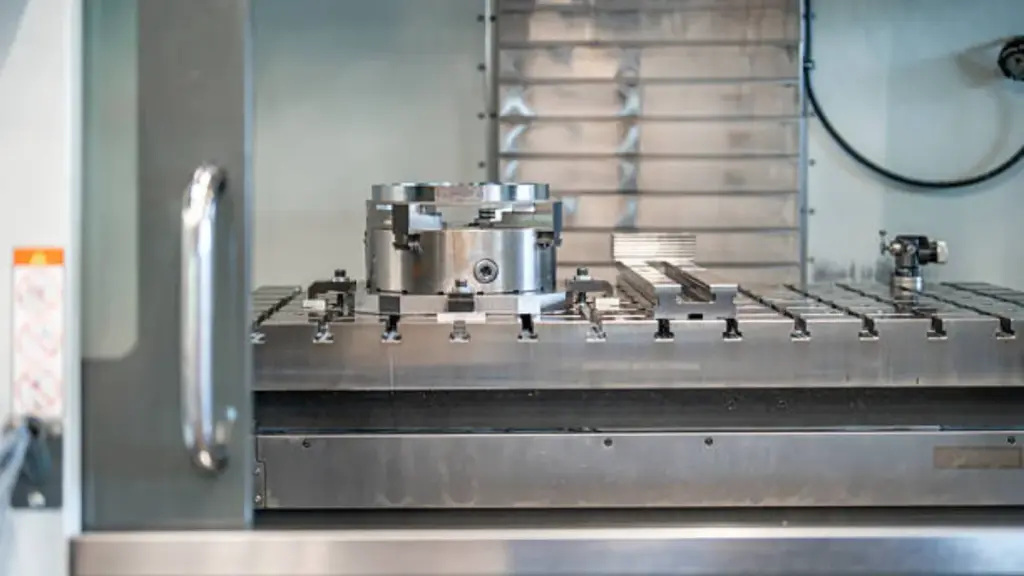

- マシンのセットアップ:

- 原料 (ワークピース) マシンテーブルまたはフィクスチャで固定されています.

- ツールとマシンは、精度を確保するために校正されています.

- 加工プロセス:

- CNCコントローラーはCAMプログラムを解釈し、マシンのモーターに正確なコマンドを送信します.

- 切削工具はxに沿って移動します, Y, z軸と同時にAとB軸の周りを回転します.

- この調整された動きにより、ツールは実質的にあらゆる角度からワークピースにアプローチすることができます, 複雑な形状と機能を1つのセットアップで機械加工できるようにする.

のアプリケーション 5 軸加工

の汎用性 5 軸の機械加工は、さまざまな業界に適用を拡張します. 製造プロセスに革命をもたらす方法は次のとおりです:

航空宇宙産業

航空宇宙工学の, コンポーネントが最大限の精度と複雑さを必要とする場合, 5 軸の加工は不可欠です. タービンブレードから航空機の構造コンポーネントまで, 5 Axisマシンは、航空宇宙セクターの厳しい基準を満たすために必要な精度と複雑さを提供します.

自動車製造

の 自動車産業 から非常に利益を得ています 5 軸加工, 特にエンジンコンポーネントの生産で, トランスミッション部品, 複雑なボディパネル. と 5 軸機, メーカーは、優れた表面仕上げと緊密な許容範囲を達成できます, 車両の最適なパフォーマンスと信頼性を確保します.

医療セクター

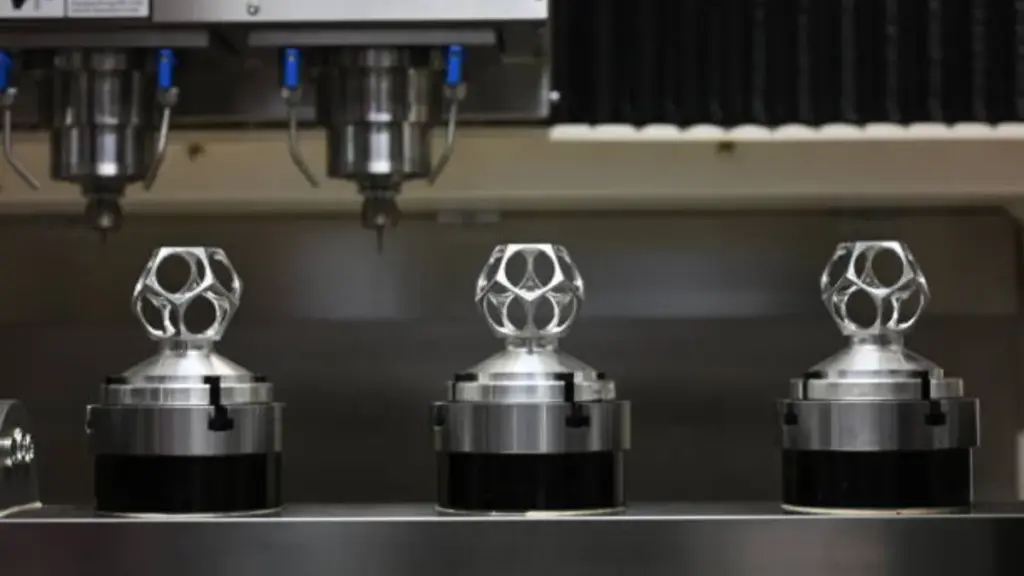

医療分野で, カスタマイズされたインプラントと補綴物には複雑な設計が必要です, 5 軸加工は、比類のない精度と汎用性を提供します. 整形外科インプラントかどうか, 歯の補綴, または手術器具, 5 軸の機械加工により、複雑な医療機器の生産が優れた精度で生産される可能性があります.

ツールとダイ作り

5 軸の機械加工はツールのゲームチェンジャーであり、ダイ作り, 複雑な型や死亡は、正確な幾何学を必要とします. 採用することによって 5 軸機, ツールメーカーは、複雑な輪郭と細かい詳細で型や死ぬことができます, 製造業の厳しい基準を満たしています.

の利点 5 軸加工

の採用 5 軸の機械加工は無数の利益をもたらします, 精度と効率を求めるメーカーにとって好ましい選択肢になる:

精度の強化

複数の軸に沿って同時に操作する機能を備えています, 5 軸加工により、比類のない精度が保証されます, 最大限の正確さで複雑な幾何学の製造を可能にする.

セットアップ時間の短縮

異なる角度にアクセスするために複数のセットアップを必要とする従来の機械加工方法とは異なり, 5 軸の機械加工は、単一のセットアップで複雑なカットを完了します, セットアップ時間を大幅に削減し、効率を向上させます.

効率の向上

ワークピースを再配置する必要性を排除することにより, 5 軸の加工により、製造プロセスが合理化されます, 効率の向上と生産サイクルの速さにつながります.

最適化された表面仕上げ

の多方向運動 5 軸マシンは、より滑らかなカットとより細かい表面仕上げを可能にします, 優れた審美的な魅力と機能的パフォーマンスを備えた優れた品質の部品をもたらす.

設計の自由を拡大しました

5 Axis Machiningは、デザイナーに比類のない自由を提供し、複雑な形状と輪郭を作成します, 革新の境界を押し広げ、製品設計における新しい可能性へのドアを開く.

課題と考慮事項

その間 5 軸加工は多くの利点を提供します, また、一連の課題と考慮事項が付属しています:

複雑なプログラミング

の可能性を最大限に活用します 5 軸加工には、複雑なツールパスを生み出し、切断戦略を最適化するために高度なプログラミングスキルが必要です, 専門的なトレーニングと専門知識を必要とする.

機械のコストとメンテナンス

投資 5 軸加工技術は、かなりの前払いコストを伴います, そして、これらの洗練されたマシンを維持するには、定期的な維持と熟練した技術者が必要です, 全体的な運用費用に加えます.

ワークアクセシビリティ

その汎用性にもかかわらず, 5 軸加工は、複雑なワークピースの特定の領域にアクセスする際に制限に直面する可能性があります, 完全な機械加工のカバレッジを確保するために、創造的なソリューションと専門的な固定具のテクニックが必要です.

ツール干渉

の複雑な性質 5 軸の機械加工は、ツール干渉のリスクをもたらします, ここでツール, ホルダー, または、スピンドルはワークピースまたはフィクスチャと衝突する場合があります, このような発生を軽減するために、慎重な計画とシミュレーションを必要とします.

結論

現代の製造の動的な風景の中で, 5 軸の機械加工は、精密エンジニアリングの頂点として際立っています, ますます複雑で複雑な部分の要求を満たすための比類のない機能を提供する. デザインの革新の境界を押し広げる能力を持って, 効率を向上させます, 優れた品質のコンポーネントを提供します, 5 軸の機械加工は、多様な産業全体で製造の未来を再定義し続けています. 協力します キャストのビアン, トップティアを提供しています 5 軸CNC加工サービス 複雑なコンポーネントの製造において最高の品質と効率性を確保する.

FAQをオンにします 5 軸加工

1. 恩恵を受ける主要な産業は何ですか 5 軸加工?

5 軸の機械加工は、航空宇宙に広範なアプリケーションを見つけます, 自動車, 医学, ツールとダイメイキング産業, とりわけ.

2. どうしますか 5 軸の機械加工は、従来の機械加工方法とは異なります?

3つの線形軸に沿って動作する従来の機械加工方法とは異なり, 5 軸の機械加工により、2つの回転軸が2つ追加されます, 多方向切断機能を有効にします.

3. の重要な利点は何ですか 5 軸加工?

の重要な利点のいくつか 5 軸の機械加工には、精度の強化が含まれます, セットアップ時間の短縮, 効率の向上, 最適化された表面仕上げ, 設計の自由を拡大しました.

4. 関連する主な課題は何ですか 5 軸加工?

の課題 5 軸の機械加工には、複雑なプログラミングが含まれます, 高い機械のコストとメンテナンス, ワークアクセシビリティ, ツール干渉のリスク.

5. w帽子はaです 5 軸フライス材?

あ 5 Axis Milling MachineはCNCの一種です (コンピュータ数値制御) 5つの異なる軸に沿って切削工具を同時に移動できるマシン. 伝統とは異なり 3 軸機, xに沿って移動します, Y, およびz線形軸, a 5 Axis Milling Machineには、2つの追加の回転軸も含まれています (通常、AおよびB軸と呼ばれます).