車や電化製品の複雑な金属部品がどのように作られているのか疑問に思ったことはありますか?? 使用されている最も優れた方法の 1 つは重力ダイカストです。. 科学を組み合わせた興味深いプロセスです, 美術, 高品質の金属コンポーネントを作成するためのエンジニアリング. 重力ダイカストの世界に飛び込んで、何が動くのか見てみましょう.

重力ダイカストの基礎

重力ダイカストとは?

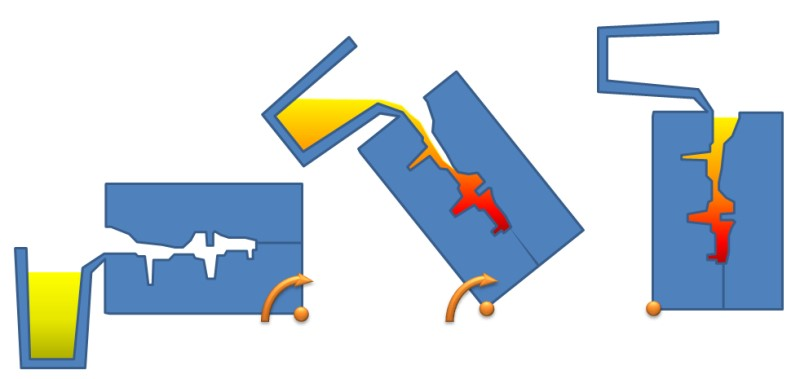

重力ダイカスト, 簡単に言えば, 重力を利用して溶融金属を型に流し込む方法です。. 外圧がかからない; 金属はその重量により金型に充填されます. このテクニックは堅牢な製品を作成するのに最適です, 寸法精度に優れた高品質部品.

他のダイカスト法との違い?

圧力ダイカストなどの他の方法とは異なります。, 金属が高圧下で金型に押し込まれる場所, 重力ダイキャスティングは、重力のみに依存しています. これは、機械と圧力による合併症が少ないことを意味します, その結果、よりシンプルで多くの場合、より費用対効果の高いプロセスが得られます. しかし, それはすべてどのように機能しますか?

重力ダイキャスティングプロセス

準備

金属が溶ける前に, 準備が重要です.

#1: カビのデザインと作成: 旅は型の設計と作成から始まります. これらの型は通常、溶融金属の高温に耐えるために鋼または鋳鉄から作られています. 金型設計の精度により、最終製品が正確な仕様を満たすことが保証されます.

#2: 材料の選択: 次, 適切な材料を選択する必要があります. アルミニウムと亜鉛 優れたキャスティングの特性と強さのために人気のある選択肢です.

キャストプロセス

今, プロセスの中心に!

#3: 融解と注ぐ: 選択した金属を炉で液体状態になるまで溶かします。. この溶けた金属は、予熱された型に慎重に注がれます。. ここでは重力が働きます, 金属が流れて金型の隅々まで満たされるようにします。.

#4: 冷却固化: 型に充填したら, 冷ましておきます. 冷めるにつれて, 金属が固まる, 型の形を取る. この冷却プロセスは、鋳造部品の構造的完全性を確保するために非常に重要です。.

キャスト後の手順

金属が固まってから, プロセスはまだ完全に終わっていません.

#5: 鋳物を型から外す: 固まった部分を型から丁寧に取り外します. これには、金型を開けるか、一時的な金型部品を取り外すことが含まれる場合があります。.

#6: 仕上げと検査: ついに, 鋳物は掃除されています, 余分な素材は切り取られます, そして品質基準を満たしていることを確認するために検査を受けます. これには機械加工が含まれる場合があります, 研磨, または、希望の仕様を達成するためのその他の仕上げ技術.

重力ダイカストで使用される材料

一般的に使用される金属

金属が異なれば、強度も異なります:

- アルミニウム: 軽量, 耐食性, 細かいキャストに最適. 自動車産業や航空宇宙産業でよく使用されています.

- 亜鉛: 強度と耐久性で知られています, 亜鉛は磨耗に耐える必要がある部品に最適です.

重力ダイカストで人気の合金

合金を使用すると強度などの特性が向上します, 延性, 耐腐食性. 例えば, アルミニウムとシリコンを組み合わせることで流動性が向上し、冷却時の収縮が軽減されます。.

重力ダイカストの利点

品質と精度

- 高品質の出力: 重力ダイカストにより、滑らかな表面と優れた寸法精度を備えた部品が製造されます. この高品質により、後処理作業が軽減されます.

- 精度と一貫性: 金型により、各部品が同一であることが保証されます, これは精度が重要な産業にとって極めて重要です.

費用対効果

- コストメリット: 圧力ダイカストなどの方法と比較して, 重力ダイカストはプロセスと設備が簡単なため、多くの場合安価です。.

- 長期的な節約: 重力ダイカストで使用される耐久性のある金型は、交換が必要になるまでに数千の部品を生産できます。, 長期的にはコストを節約する.

多用途性

- 応用範囲: 自動車から航空宇宙まで, 重力ダイカストは幅広い産業に十分な多用途性を持っています.

- カスタマイズオプション: このプロセスにより、金型設計の変更が可能になります, 特定のニーズに合わせたカスタムパーツの作成が可能になります.

重力ダイカストの欠点

初期設定費用

- 高額な初期投資: 初期の金型と設備のセットアップには費用がかかる場合があります, ただし、これらのコストは長期にわたる生産期間で相殺されます。.

- 金型作成コスト: 精密な金型の設計と製造には多額の初期費用がかかります.

材料の制限

- 特定の金属および合金に限定される: すべての金属が重力ダイカストに適しているわけではありません, 材料の選択肢が制限される可能性がある.

- 特定の材料に関する課題: 一部の金属は十分に流動しない場合や、より高い温度が必要な場合があります, プロセスが複雑になる.

生産量

- さまざまな生産量への適合性: 重力ダイカストは中規模から大規模の生産には最適ですが、非常に少量または非常に大量の生産では費用対効果が低い場合があります。.

- さまざまな規模での効率性: この方法は、金型設計と金属の流れに制限があるため、非常に大きな部品や非常に小さな部品の場合は効率が低くなります。.

重力ダイカストの応用例

自動車産業

- エンジンコンポーネント: 重力ダイカストは強度を高めるのに最適です, 精密なエンジン部品.

- 構造部品: この方法により、耐久性があり軽量な構造コンポーネントが製造されます。.

航空宇宙産業

- 航空機部品: 精度と強度により、航空機の重要なコンポーネントに最適です.

- 特殊なコンポーネント: 重力ダイカストは航空宇宙で必要な複雑な形状の部品を製造できます.

消費財

- 電子機器および家電製品: 電子機器や家庭用品の多くの耐久性のある詳細な部品は、重力ダイカストを使用して製造されています.

- 家庭用品: ハンドルからフレームまで, 多くの日用品がこの鋳造法の恩恵を受けています.

産業用途

- 機械部品: 丈夫で信頼性の高い機械部品は、多くの場合この方法で製造されます.

- 工具と設備: 重力ダイカストは産業用ツールや機器に必要な耐久性を提供します.

他の鋳造法との比較

砂型鋳造

- 相違点と類似点: 砂型鋳造は砂型を使用します, 柔軟性は高くなりますが、精度は低くなります. 大きなパーツには最適ですが、細かい部分には適していません.

- 長所と短所: 砂型鋳造は、短期間の生産や大型部品の場合には安価です, しかし、重力ダイカストはより優れた精度と表面仕上げを提供します.

圧力ダイカスト

- 相違点と類似点: 圧力ダイカストでは、高圧を使用して金属を金型に押し込みます。, 優れた精度を提供しますが、コストは高くなります.

- 長所と短所: 圧力ダイカストは小型から中型の部品の大量生産に最適です, 一方、中程度の生産では重力ダイカストの方がコスト効率が高くなります。.

インベストメント鋳造

- 相違点と類似点: インベストメント鋳造ではワックスパターンとセラミックモールドを使用します, 高精度で滑らかな仕上がりを実現, しかし、より高いコストがかかります.

- 長所と短所: インベストメント鋳造は小型の鋳物に最適です, 複雑な部品, 一方、重力ダイカストは、より広範囲の部品に対してコストと精度のバランスをとります。.

結論

重力ダイカストは製造業界の原動力です, 品質のブレンドを提供する, 精度, そして費用対効果. 自動車業界にいるかどうか, 航空宇宙, または消費財業界, このプロセスを理解することで、より適切な製造上の意思決定を行うことができます. 独特の利点といくつかの制限があります, 重力ダイカストが現代の製造において重要な位置を占めていることは明らかです.

よくある質問

- 重力ダイカストと圧力ダイカストの主な違いは何ですか? 重力ダイカストは重力に依存して金型を充填します。, プレッシャーダイカストは高圧を使用しますが、. この違いは、各方法が最適な部品の種類に影響します。.

- 重力ダイカストは複雑な形状にも使用できますか? はい, 重力ダイカストは複雑な形状を製造可能, 特に適切に設計された金型を使用する場合, ただし、非常に複雑なデザインの場合は、他の方法の方が適している可能性があります。.

- 重力ダイカストで使用される最も一般的な金属は何ですか? アルミニウムと亜鉛が最も一般的です, 優れた鋳造特性と強度のおかげで.

- 重力ダイカストはどのようにして高精度を保証するのか? 精度は精緻な金型と制御された冷却プロセスから生まれます。, 一貫した品質と寸法精度を保証します.

- 重力ダイカストの環境上の利点は何ですか? 重力ダイカストは、高圧法と比較してエネルギー消費が少なく、材料や金型をリサイクルして再利用できるため、より環境に優しいことができます。.