効果的なプロトタイプの亜鉛ダイカストは、6 桁の金型の手戻りや製品発売の壊滅的な遅延に対する主な予防策です. エンジニアは、高価な部品を開発する前に部品設計を検証するという絶え間ないプレッシャーに直面しています。, permanent production molds. Choosing a prototyping method that fails to replicate the final material’s performance introduces massive financial risk, as a design flaw discovered after the hard tool is cut can derail an entire project budget and schedule.

This guide provides a technical framework for evaluating your prototyping options. We will analyze the core methods, from CNC machining and gravity casting to soft tooling for pre-production runs. We’ll also break down the material trade-offs between zinc and aluminum alloys, provide a DFM checklist for zinc components, and detail the critical cost and timeline implications for each approach to ensure your design is ready for high-volume manufacturing.

Methods for Creating Zinc Die Cast Prototypes: From CNC to Soft Tooling

Selecting the right zinc prototyping method depends on the specific design characteristics—like mechanical properties or surface finish—that require validation before committing to production tooling.

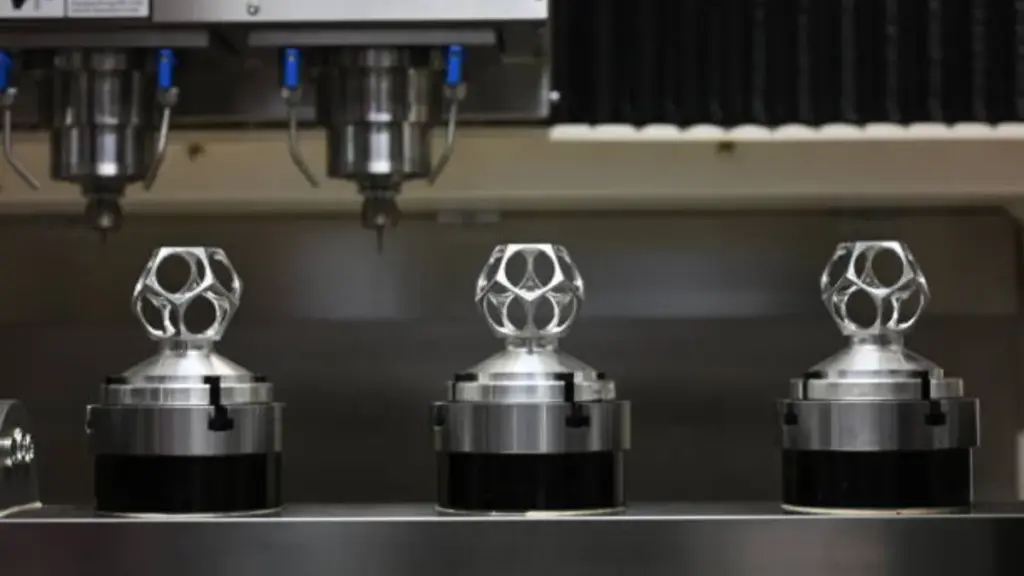

CNC Machining from Solid Zinc Barstock

Machining prototypes directly from solid zinc barstock is the most direct path for validating form and fit without any tooling investment. This subtractive method provides a close approximation of the final part’s mechanical properties, making it ideal for rapid, low-quantity validation cycles. While the per-unit cost is high, it eliminates tooling expenses entirely, offering a fast way to get physical parts for initial testing and feedback.

Plaster Mold Casting for Low-Volume Batches

Plaster mold casting, a form of soft tooling, uses plaster or rubber molds created from an SLA or CNC master pattern. This approach dramatically reduces upfront costs, with tooling investment often around just 10% of a final production die. It is well-suited for cost-effective small batches of 50-100 単位. The process also facilitates quick and inexpensive geometry modifications based on test results from initial samples, allowing for design refinement before hard tooling is finalized.

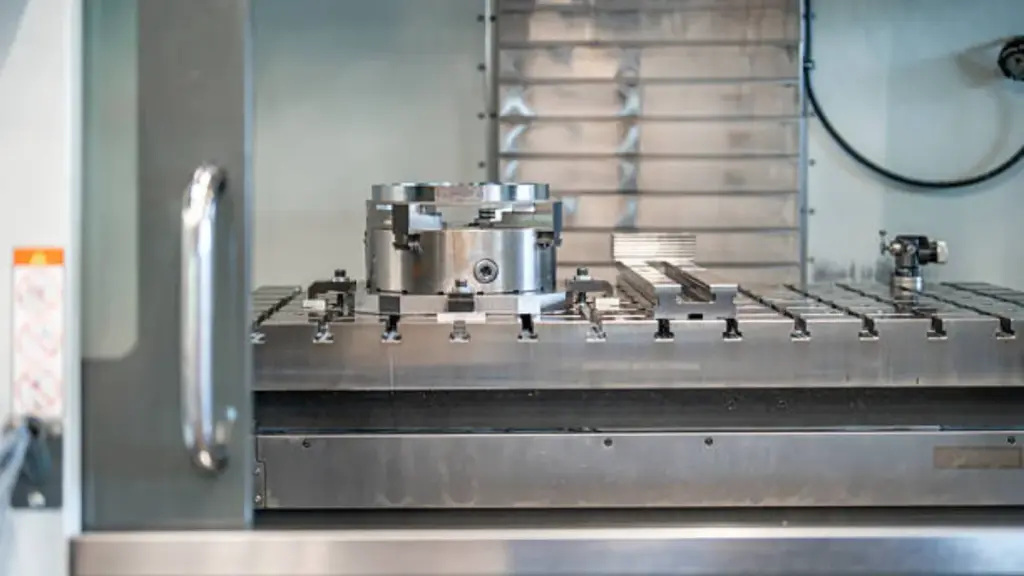

Single Cavity Dies for Production-Grade Validation

Using a single cavity die is the highest fidelity evaluation method available before full-scale production. This process creates prototypes with mechanical properties and surface finishes identical to mass-produced parts because it uses the same production alloys (ザマックみたいに 3 または 5), high pressure, and casting parameters. It serves as the definitive test for performance, 組み立て, and aesthetics, ensuring that the validated design will perform as expected once moved to multi-cavity production tooling.

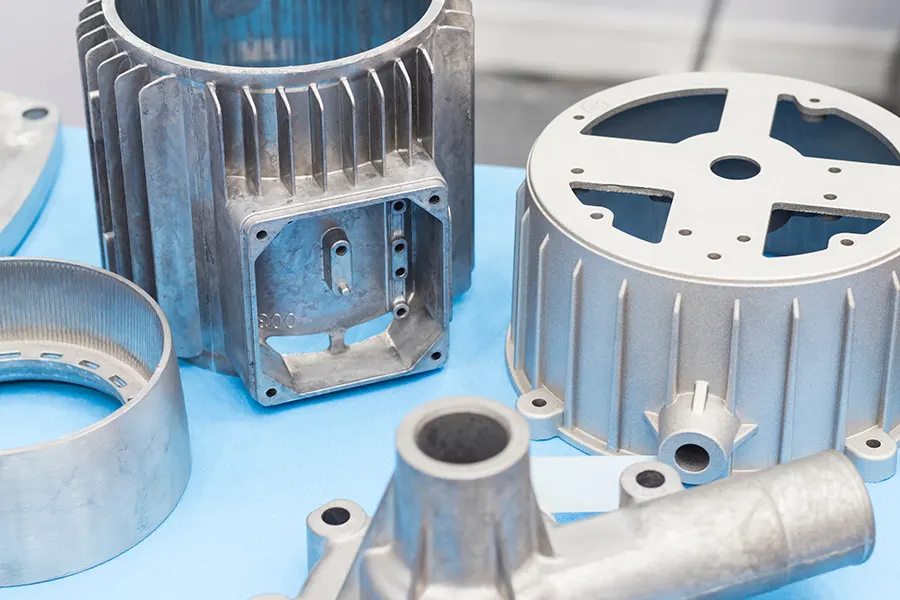

材料の選択: Zinc Die Casting vs Aluminum Die Casting

Choosing between zinc and aluminum is a direct trade-off between weight reduction and the need for high impact strength and net-shape complexity for your component.

Mechanical Properties and Weight-to-Density Ratio

The primary decision between these materials often comes down to fundamental mechanical requirements. Aluminum alloys like A380 offer a superior strength-to-weight ratio with a density around 2.7 g/cm³, making them the default choice for lightweighting in automotive components and large electronic enclosures. If reducing component mass is the main engineering goal, aluminum is the logical starting point.

亜鉛合金, such as Zamak 3 そしてザマック 5, are significantly denser at approximately 5.0 g/cm³ and can be more than twice as strong as aluminum castings. This gives them higher impact strength and better vibration dampening characteristics. Zinc is better suited for applications that demand durability, structural integrity, and the ability to cast complex, net-shape parts with minimal secondary machining.

Thermal Conductivity and Electrical Performance

Aluminum’s excellent thermal conductivity makes it the industry standard for heat dissipation. It’s the go-to material for thermal management in applications like high-power LED outdoor lighting housings and New Energy Vehicle (NEV) パワートレインコンポーネント. The material’s ability to efficiently transfer heat is critical to the electronic assembly’s performance and lifespan.

Both materials provide effective EMI shielding for sensitive electronics. Zinc’s inherent properties, しかし, can offer a performance edge in high-frequency applications, making it a strong candidate for 5G communication enclosures where signal integrity is paramount. Your material choice will directly inform the entire thermal management strategy for the product.

Surface Finishing Options and Corrosion Resistance

Finishing requirements are a major differentiator. Zinc is exceptionally well-suited for high-quality decorative and protective plating, including chrome, nickel, and satin finishes. Its as-cast surface is inherently smoother than aluminum’s, which often reduces or eliminates the need for secondary polishing steps before finishing.

Aluminum is the only option for anodizing, an electrochemical process that creates a hard, 耐食性, and often decorative oxide layer. This finish is integral to the part itself and cannot be applied to zinc. While aluminum naturally has higher corrosion resistance, the performance of both materials can be further enhanced with processes like passivation and powder coating, with final performance typically validated through standardized salt spray testing.

Your One-Stop IATF 16949 Die Casting Partner

の “Material Gap”: Simulating Zamak 3 Performance with Gravity Casting

Gravity-cast prototypes offer a rapid, low-cost method for validating part geometry, but their performance data is only directional due to the inherent material gap with production die casting.

Rationale for Gravity-Cast Prototyping

Gravity-cast prototyping provides a cost-effective path for early-stage design validation by dramatically reducing initial investment. Tooling for this method, often using plaster molds, typically costs only about 10% of a final production die. This approach accelerates the development cycle, delivering initial physical parts for geometric assessment and fit-checks within 2-3 週. The process also supports rapid design modifications, as engineers can use easily adjusted SLA or CNC master patterns to refine the component’s form before committing to expensive hard tooling.

Comparing Mechanical Properties: Gravity vs. Pressure

Engineers must recognize that gravity-cast prototypes do not replicate the mechanical strength of high-pressure die casting. The gravity process lacks the force needed to achieve the same material consolidation and density, resulting in parts with lower ductility and toughness. その結果, you should expect wider dimensional tolerances and lower precision compared to the final production parts. The surface finish from plaster molds is also a rough approximation and does not match the quality achievable with a production-tooled component.

Bridging Prototype Data to Production Planning

Use the data from gravity-cast prototypes strategically to inform the transition to mass production. The primary value lies in physical validation, not performance testing. A clear plan ensures that prototype insights correctly guide production planning without creating false expectations about final part capabilities.

- Use gravity-cast prototypes to confirm fit, form, and overall geometric integrity within the intended assembly.

- Identify critical areas, such as mating surfaces or precision bores, that will require finish machining to meet final specifications.

- Treat all mechanical performance data as directional, understanding that final design validation requires parts cast from the actual production tooling.

の “Soft Tooling” Strategy: Bridging Prototype and Production

Soft tooling validates part geometry and function with true cast properties, de-risking the substantial investment required for hardened steel production molds used in mass manufacturing.

Plaster Mold Casting for Low-Volume Validation

Plaster mold casting, also known as rubber plastic mold casting (RPM), is a proven method for creating functional prototypes without committing to full production tooling. The process begins by using an SLA or CNC-machined master pattern to create reusable silicon rubber foundry tooling. This approach dramatically reduces upfront costs, with the initial tooling investment landing at approximately 10% of a production steel die. The low cost and speed of this method facilitate rapid and inexpensive geometry modifications, allowing engineering teams to iterate and refine designs before locking them into hard tooling. It’s a practical solution for producing batches of up to several thousand parts for rigorous functional testing or for an early market entry.

Additive Manufacturing for Rapid Pattern and Die Creation

Additive manufacturing accelerates the New Product Introduction (NPI) cycle by shortening the path from digital design to the first physical metal parts. Stereolithography (SLA) models can be used to directly create short-run H-13 steel dies for pressure die casting. This ensures that the resulting prototypes have thermal and mechanical properties that match those from a full production run, offering highly reliable data for validation. While 3D printed plastic parts offer an inexpensive way to perform visual assessments and packaging validation, they cannot be used for performance evaluation. The real value is in using additive techniques to build temporary tooling that delivers production-grade metal components quickly.

Evaluating Trade-offs Against Machined Prototypes

Choosing between soft tooling and CNC machining from barstock depends entirely on the validation goal. One tests the casting process, while the other tests the raw material. The decision requires a clear understanding of the cost structure and engineering objectives for the prototype.

- Part Properties: Soft tooling produces parts with true cast properties, including grain structure and potential porosity. CNC machining from solid barstock validates the material’s inherent strength but does not replicate any effects from the casting process itself.

- Cost Structure: Machining carries no tooling investment but has a high cost per piece, making it ideal for quantities under five. Soft tooling requires a modest investment but achieves a significantly lower per-unit cost for batches ranging from dozens to thousands of parts.

- 表面仕上げ: The surface finish from plaster molds more closely represents the final die-cast part’s texture and appearance than a machined surface does. This is critical for validating both aesthetics and certain functional requirements like sealing surfaces.

製造用のデザイン (DFM) Checklist for Zinc Parts

A disciplined DFM review for zinc parts is the most direct path to reducing tooling rework, controlling unit costs, and accelerating time to market.

Alloy Selection and Wall Thickness Uniformity

The DFM process begins with material selection. Specifying standard zinc alloys like Zamak 3 or Zamak 5 ensures consistent material properties and predictable performance, which is critical when manufacturing across global bases in China, メキシコ, またはベトナム. The part’s geometry must complement the alloy’s flow characteristics. Designing for uniform wall thickness is essential for promoting complete mold filling, preventing defects like porosity, and ensuring consistent cooling rates. Abrupt changes in thickness create stress concentrations. To improve both molten metal flow during casting and the final part’s structural strength, incorporate generous radii on all internal and external corners. Sharp internal corners impede flow and create weak points prone to cracking under load.

抜き勾配角度, 公差, および表面仕上げ

Every feature on a die-cast part must be designed for manufacturability. Apply draft angles to all surfaces parallel to the die’s direction of pull; this is non-negotiable for ensuring easy part ejection without damaging the component or the tool. Your design should also define realistic dimensional tolerances. While pressure die casting can hold general tolerances of ±0.1 mm, specifications tighter than this often require secondary CNC machining, which increases both the cost per part and the lead time. Clearly mark drawings to indicate which surfaces are cosmetic and which are purely functional. This allows for targeted finishing operations, preventing unnecessary costs on non-critical areas of the component.

Prototyping Path for Design Validation

Choosing the right prototyping method depends entirely on your validation goals. There is no single perfect method, and each path presents a different balance of cost, スピード, and fidelity to the final production part. Prototypes made using different methods will not have identical mechanical properties or surface finishes compared to a pressure die-cast production part.

- CNC加工: Machining a part from solid zinc bar stock is the fastest way to validate form and fit. It requires no tooling investment but has a high cost per piece and does not replicate the grain structure or surface of a cast part.

- Single Cavity Dies: For testing true mechanical properties, a single cavity prototype die is the closest you can get to a production part. It uses the same production alloy and high-pressure process, making it ideal for rigorous functional testing.

- Plaster Mold Casting: This gravity-based method offers a cost-effective way to produce small batches of parts with complex geometries. It is well-suited for iterating on a design before committing to the high cost of production tooling.

料金 & Timeline Analysis: Prototyping vs. Production Molds

Selecting the right tooling path balances upfront investment against per-unit cost, directly impacting project profitability and time-to-market.

Initial Investment Breakdown by Tooling Type

The initial tooling investment is the most significant financial decision in a die casting project. Full production molds, which we develop at our China facility to optimize costs, represent the largest capital outlay. For validation and bridge production, soft tooling like plaster molds offers a lower barrier to entry, with an investment of approximately 10% of a production die’s cost. CNC machining eliminates direct tooling investment entirely, as costs are calculated on a per-part basis, making it ideal for initial form-and-fit samples. Occupying the middle ground, single-cavity prototype dies require a moderate investment but yield parts with mechanical properties nearly identical to final production units.

Analyzing Per-Unit Costs Across Production Volumes

Per-unit costs are inversely proportional to the initial tooling investment. Production molds deliver the lowest per-unit cost, making them the only viable option for mass production runs of 3,000 units or more, where the high tooling expense is amortized effectively. Soft tooling, such as plaster mold casting, is cost-effective for short or bridge production runs up to several thousand units. A single-cavity prototype die offers a moderate per-unit cost, useful for validating critical part characteristics before committing to expensive multi-cavity tooling. CNC machining carries the highest per-unit cost by a wide margin, rendering it impractical for anything beyond a few initial samples for physical review.

Project Timelines: From Design Finalization to First Parts

The timeline to receive first parts varies drastically with the chosen method. Full production molds fabricated in our China facility require 25-35 days for tooling before the first article inspection (FAI) can occur. Prototyping methods offer significantly faster turnarounds.

- CNC Machined Prototypes: The fastest option, delivering physical parts within days of CAD file submission.

- Plaster Mold Prototypes: Delivers initial cast parts within a 2-3 week timeframe.

- Rapid Die Casting (SLA Patterns): Produces initial samples in 5-8 週, influenced by the part’s geometric complexity.

Design Modification: Flexibility and Cost Impact

The ability to modify a design is a critical factor during development. Modifying a hardened steel production mold is a complex, costly, and time-consuming process that can introduce significant project delays. 対照的に, soft tooling made from materials like plaster or silicone allows for quick and inexpensive adjustments to part geometry, facilitating an iterative design refinement process. The highest degree of flexibility comes from CNC machining and 3D printing; design changes are simply updated in the CAD file for the next part run, with no physical tooling to alter.

Strategic Tooling Selection for the NPI Lifecycle

A successful New Product Introduction (NPI) uses different tooling strategies at each phase to manage risk and cost. This structured approach ensures that design validation occurs before committing to high-volume manufacturing.

- Concept Phase: Use CNC machining or 3D printing for the first physical models to validate basic form and fit.

- Refinement Phase: Employ soft tooling for iterative functional testing where frequent design changes are expected and need to be implemented quickly and affordably.

- Pre-Production Phase: Use single-cavity prototype dies to produce parts with production-level mechanical properties, confirming material performance and surface finish standards before scaling.

- Mass Production Phase: Commit to multi-cavity, hardened steel production molds for high-volume manufacturing, which can then be deployed at our facilities in China, メキシコ, or Vietnam to meet specific tariff and logistics goals.

結論

Selecting the right prototyping method for zinc die casting is a critical first step. It involves balancing the need for speed, budget constraints, and material fidelity to ensure the final design is manufacturable. A well-planned prototype strategy directly impacts production tooling success and reduces costly revisions down the line.

If you are developing a new zinc component, our engineering team can help you choose a method that aligns with your budget and timeline. We can provide a clear analysis to support your transition from prototype to mass production.

よくある質問

How much does a zinc die casting prototype cost?

The cost of a zinc die casting prototype varies significantly depending on the method. For methods like CNC machining, there is no initial tooling investment, but the cost per piece is typically high. あるいは, soft tooling (plaster mold casting) offers a more cost-effective approach where the tooling costs approximately 10% of a final production die, making it suitable for creating initial samples for evaluation.

Can you 3D print zinc metal?

While 3D printing technologies like SLA and FDM are used in the prototyping process, they typically create patterns for other casting methods or inexpensive models for visual assessment. According to the research, 3D printed parts are suitable for visual and packaging tests but do not allow for performance evaluation of the metal’s mechanical properties. The provided content does not describe direct 3D printing of functional zinc metal parts.

What is soft tooling for die casting?

Soft tooling, also known as plaster mold casting or rubber plastic mold casting (RPM), is a prototyping method for zinc, アルミニウム, およびマグネシウム合金. It uses master patterns, often created via SLA or CNC, to produce reusable silicon rubber foundry tooling. This gravity-based casting process facilitates quick and easy geometry modifications, making it ideal for refining a design before committing to production tooling.

How long does it take to get die cast samples?

The lead time for die cast samples depends on the prototyping method. Using plaster mold casting (a form of soft tooling), initial prototypes can typically be produced in 2 に 3 週. For other rapid prototyping techniques where patterns are created via methods like stereolithography (SLA), samples can take five to eight weeks to produce, depending on the part’s geometry.

Are prototype parts as strong as production parts?

This depends entirely on the prototyping method. A single cavity prototype die can produce castings with the same mechanical properties as production parts because it uses identical alloys and processes. 対照的に, parts machined from zinc barstock offer a reasonable indication of mechanical potential, while prototypes from 3D printing are not suitable for performance evaluation.

What is the minimum order for prototypes?

The research material does not specify a universal minimum order quantity for prototypes, as it varies by the chosen method. 例えば, CNC machining is suitable for single parts since there is no tooling investment. Other methods, like plaster mold casting or rapid die casting, are capable of producing short runs of up to several thousand parts, offering flexibility for different project needs.

SEO

Title: 亜鉛ダイカストプロトタイプに関するエンジニア向けガイド: メソッド, 材料, とコスト

Description: Zinc Die Casting Prototypes from an IATF 16949 manufacturer. We specialize in Zamak 3/5 alloys for complex OEM/ODM projects.

URL: zinc-die-casting-prototypes

Keywords: Zinc Die Casting Prototypes