Fundição sob pressão de precisão, Aperfeiçoado: Veja quais testes meticulosos adotamos para elevar a qualidade

Visão geral do controle de qualidade

Nossas medidas de controle de qualidade

Nosso oficinas estão equipados com conjuntos abrangentes de instalações, desde a fundição até a inspeção final. Conduziremos uma ampla gama de testes de qualidade para garantir que os produtos fundidos atendam aos seus requisitos e padrões específicos.

Inspeção Precisa:

Experiência em testes:

Testes de qualidade rigorosos fornecem produtos que excedem as expectativas

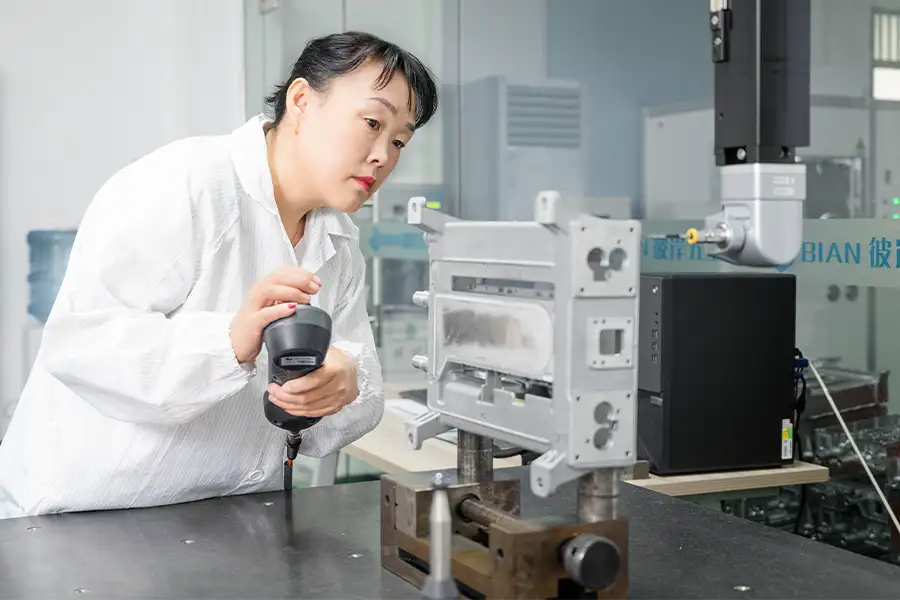

Máquina de medição por coordenadas (CMM)

Para medição precisa de dimensões.

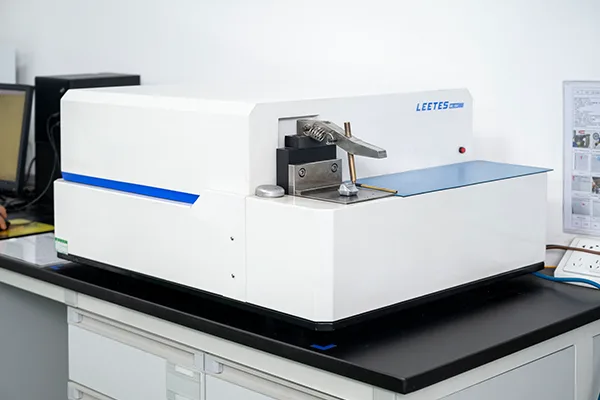

Espectrômetro de leitura direta

Análise de composição de materiais.

Medidor de densidade eletrônica

Medindo a densidade dos materiais utilizados no processo de fundição sob pressão.

Sistema de testes não destrutivos de raios X

Inspeção de porosidade interna.

Dispositivo de detecção de vazamento de hélio da câmara de vácuo do equipamento de testes de estanqueidade

Inspeção de estanqueidade do produto.

Analisador de varredura de limpeza

Um instrumento de precisão usado para inspecionar e avaliar a limpeza e a qualidade das superfícies.

Testador de fricção e arranhões CS-10F

É um testador de fricção e arranhões usado para avaliar a durabilidade do material e a qualidade da superfície.

Teste de torque máximo de falha de rosca

Teste de resistência à corrosão.

Álcool & Máquina de teste de fricção de borracha

Teste de resistência ao desgaste de revestimento de superfície.

Colorímetro

Detecção de diferença de cor de revestimento.

Medidor de espessura de filme

Medição da espessura do revestimento.

Testador de abrasão de tira de papel

Projetado para avaliar a resistência ao desgaste de materiais, especialmente produtos de papel.

2.5Instrumento de medição D

Usado para medições precisas na fabricação e controle de qualidade, combinando dados 2D com informações de profundidade ou altura.

Certificações de qualidade de classe mundial & Experiência oferece garantias sólidas

RoHS (Restrição de Substâncias Perigosas) 2.0 Conformidade:

Nossos materiais atendem aos rigorosos requisitos da RoHS 2.0, garantindo que eles estejam livres de substâncias perigosas.

RoHS (Restrição de Substâncias Perigosas) 2.0 Conformidade:

Nossos materiais atendem aos rigorosos requisitos da RoHS 2.0, garantindo que eles estejam livres de substâncias perigosas.

RoHS (Restrição de Substâncias Perigosas) 2.0 Conformidade:

Nossos materiais atendem aos rigorosos requisitos da RoHS 2.0, garantindo que eles estejam livres de substâncias perigosas.

Relatórios de desempenho mecânico:

Nossos materiais passam por testes rigorosos para garantir que atendam aos padrões de desempenho mecânico exigidos.

Relatórios de desempenho físico:

Esses relatórios detalham as propriedades físicas de nossos materiais, ajudando você a escolher o material certo para suas necessidades.

Halogênio (Halogênios) Relatórios:

Fornecemos informações sobre o conteúdo de halogênio em nossos materiais, importante para aplicações específicas.

Nossas metodologias e ferramentas de qualidade impulsionam a excelência na fabricação

PPAP (Processo de aprovação de peças de produção):

Garante que nosso processo de produção atenda consistentemente às suas especificações, garantindo a qualidade do produto.

APQP (Planejamento Avançado da Qualidade do Produto):

Identifica e mitiga proativamente problemas no desenvolvimento de produtos, garantindo qualidade de primeira linha.

FMEA (Análise de modos de falha e efeitos):

Ajuda-nos a prever e resolver possíveis problemas, garantindo a confiabilidade do produto.

MSA (Análise do Sistema de Medição):

Garante medições precisas, sustentando a qualidade do produto.

CEP (Controle Estatístico de Processo):

Garante que nosso processo de produção atenda consistentemente às suas especificações, garantindo a qualidade do produto.