Otimize a economia de custos & Eficiência, Obtenha uma vantagem competitiva em seu setor

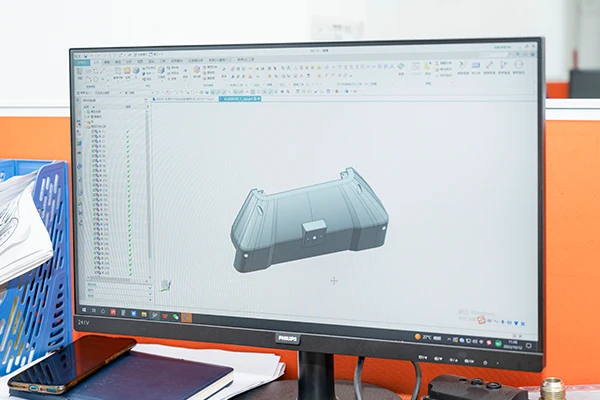

Esteja você familiarizado com técnicas de fundição sob pressão ou não, our R&D teams assist you from the very beginning - projeto de molde. Guided & assisted by DFM & mold flow tool, nossas equipes oferecem os desenhos técnicos mais especializados. Nossa análise DFM é fornecida gratuitamente!

Ao contrário das fábricas normais que fazem apenas o trabalho de fundição sob pressão para você, Bian Diecast está totalmente equipado - você pode realizar seu projeto em um só lugar! Fundição sob pressão, CNC machining & finishing in one stop. Nosso objetivo é economizar seus custos e melhorar a eficiência no processo.

Valorizamos muito suas obras de arte de design e estamos abertos a assinar NDAs mediante sua solicitação. Adicionalmente, podemos fornecer arquivos certificados para peças automotivas, incluindo PPAP, APQP, FMEA, MSA, e CEP, para nossos produtos fundidos.

Nosso serviço é detalhado, até a embalagem. Você pode escolher a embalagem ideal – sacos plásticos de bolhas, caixas de papelão, molduras de plástico, divisórias, e muito mais – para atender às necessidades do seu produto. Também podemos acomodar rapidamente a impressão do logotipo ou outras solicitações personalizadas na embalagem. Basta perguntar!

Ao projetar o molde para seu projeto de fundição de alumínio, priorizamos fatores como capacidade de fabricação e economia. Nossa equipe fornece DFM (Design para Manufaturabilidade) apoiar, garantindo que o molde de fundição sob pressão de alumínio não seja apenas adaptado ao formato e às dimensões da peça desejada, mas também otimizado para uma produção eficiente e econômica. O molde é normalmente composto de duas ou mais metades, facilitando o processo de enchimento e remoção durante a fundição.

Dependendo de requisitos específicos, as peças acabadas podem passar por processos adicionais (Usinagem CNC & serviços de acabamento) como cortar, perfuração, ou revestimento para atender padrões exigentes.

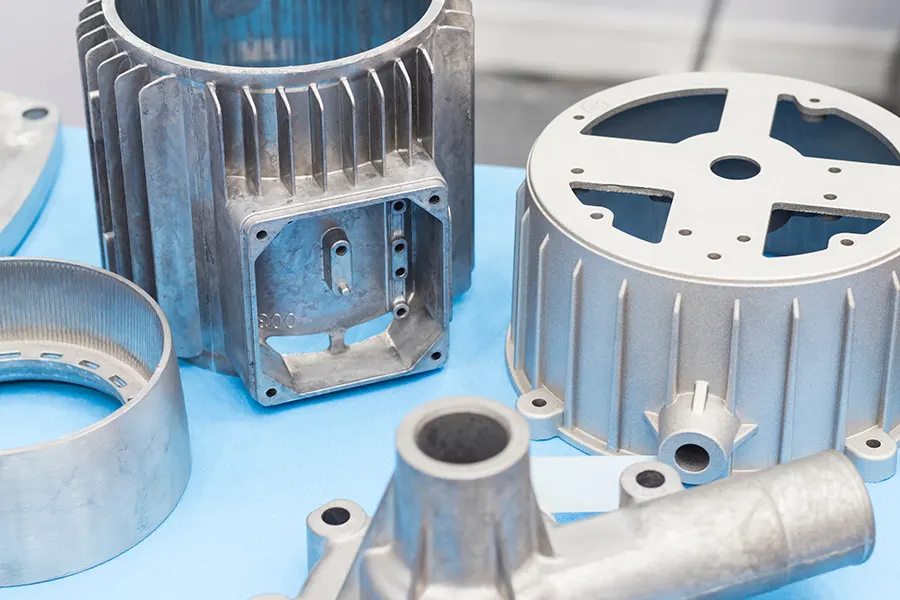

Bian Diecast é um fabricante de peças fundidas de alumínio que se orgulha de oferecer um espectro diversificado de ligas de alumínio fundido de primeira linha para atender a uma ampla gama de demandas industriais.. Nossa seleção cuidadosamente selecionada abrange três categorias principais, cada um distinguido por seu conjunto exclusivo de propriedades e aplicações.

Bian Diecast é um fabricante de fundição sob pressão com serviço completo que pode fornecer excelentes serviços de fundição sob pressão de zinco e alumínio para os requisitos específicos do seu projeto.. Nossa experiência em fundição sob pressão nos permite fornecer produtos de alta qualidade, peças fundidas sob pressão de zinco e alumínio de precisão que atendem aos requisitos específicos do seu projeto.

Existem dois métodos principais para fundição sob pressão: fundição sob pressão em câmara quente e fundição sob pressão em câmara fria. Para fundição em liga de alumínio, empregamos principalmente máquinas de fundição sob pressão de câmara fria, enquanto o método de câmara quente é frequentemente usado para ligas como o zinco devido aos seus pontos de fusão mais baixos.

Em Bian Diecast, nossa fábrica está totalmente equipada com uma variedade de máquinas de fundição sob pressão. Cada máquina é capaz de produzir pelo menos 2000 para 3000 componentes de fundição sob pressão por dia. O maior alcance de área de fundição 3125cm².

| 1250Máquina de fundição sob pressão T | 900Máquina de fundição sob pressão T | 800Máquina de fundição sob pressão T |

| 500Máquina de fundição sob pressão T | 400Máquina de fundição sob pressão T | 300Máquina de fundição sob pressão T |

Estes preços indicam a faixa de custo para produzir uma unidade de um produto utilizando a respectiva máquina de fundição sob pressão. O custo real da fundição de alumínio dentro de cada faixa pode variar dependendo de fatores como a complexidade da peça, material usado, e outras variáveis de produção.

| Modelo de máquina de fundição sob pressão | Preços para referência ($ por unidade) |

|---|---|

| 1250Máquina de fundição sob pressão T | $3-5 |

| 900Máquina de fundição sob pressão T | $1.5-2 |

| 800Máquina de fundição sob pressão T | $1.0-1.5 |

| 500Máquina de fundição sob pressão T | $0.7-1.0 |

| 400Máquina de fundição sob pressão T | $0.5-0.7 |

| 300Máquina de fundição sob pressão T | $0.3-0.4 |

Bian Diecast, uma fábrica de fundição de alumínio, está localizado no distrito de Nanhai, Cidade de Foshan, China. Com mais de uma década de experiência em fundição sob pressão, estamos comprometidos em fornecer serviços abrangentes de fundição sob pressão. Além do projeto e desenvolvimento de moldes especializados, temos uma fábrica avançada e oficinas que integram fundição sob pressão, Usinagem CNC de precisão, e serviços de acabamento de superfície, atendendo a diversas necessidades em vários setores.

Atualmente, acumulamos anos de experiência de serviço no automotivo, iluminação, eletrônicos, mobília, e indústrias de construção. Com uma base sólida em gerenciamento de projetos, pretendemos nos tornar um fornecedor estratégico para muitas marcas globais de renome.

Molde de fundição, também conhecido como dado, é uma ferramenta usada no processo de fundição sob pressão para criar peças metálicas com alta precisão e exatidão. O molde é uma cavidade oca usada para moldar o metal fundido em uma forma específica por meio de um processo conhecido como fundição sob pressão.. Os moldes de fundição sob pressão são normalmente feitos de aço e possuem duas metades distintas que se unem para formar o formato desejado da peça final.. O molde é projetado com detalhes e recursos intrincados para garantir que a peça final atenda às especificações e tolerâncias exigidas.. Os moldes de fundição sob pressão podem ser usados repetidamente para produzir grandes quantidades de peças idênticas de forma rápida e eficiente.

Como uma fábrica de fundição sob pressão na China, fornecemos serviços de design de moldes de fundição sob pressão de alta qualidade para atender aos critérios de qualidade do seu projeto.

Primeiramente, nossa equipe dedicada entrará em contato com você para entender suas necessidades e requisitos específicos para o projeto. Depois que todos os detalhes forem esclarecidos e confirmados, prosseguiremos com a colocação formal do pedido para dar início ao projeto.

| Aspecto | Fundição sob pressão de câmara quente | Fundição sob pressão em câmara fria |

|---|---|---|

| Tipos de metal | Adequado para metais de baixo ponto de fusão (por exemplo, zinco, magnésio) | Adequado para metais com alto ponto de fusão (por exemplo, alumínio, cobre, algumas ligas de zinco) |

| Processo de fusão de metais | O metal é derretido na máquina | O metal é derretido em um forno separado e colocado na máquina |

| Velocidade de lançamento | Processo mais rápido devido à disponibilidade contínua de metal fundido | Processo mais lento, pois o metal precisa ser colocado manualmente na máquina |

| Tamanho e complexidade da peça | Melhor para peças menores e complexas que exigem alta precisão | Ideal para peças maiores e mais complexas que necessitam de maior resistência e melhores acabamentos superficiais |

| Versatilidade | Limitado a metais com baixos pontos de fusão | Pode lidar com uma ampla variedade de ligas metálicas e tamanhos de peças |

| Eficiência | Alta produtividade e eficiência devido ao processo contínuo de fusão e injeção | Capacidade de controlar a temperatura do metal para melhores propriedades mecânicas e acabamentos superficiais |

Os requisitos mínimos de tolerância dependem do tamanho do produto.

Para dimensões até 200mm, tolerâncias de ± 0,1 mm ou melhores são necessárias.

Para dimensões até 300mm, tolerâncias de ±0,2 mm ou melhores são necessárias;

e para dimensões até 500mm, são esperadas tolerâncias de ±0,3 mm ou melhores.

Quanto aos ângulos de inclinação, um mínimo de 1 é necessário diploma, mas ângulos maiores são preferidos para uma ejeção mais suave do molde.

Estas especificações de tolerância são essenciais para garantir a precisão e a qualidade dos produtos fundidos sob pressão..

50,000 fotos antes da substituição ou reforma. Se o antigo molde de fundição atingir o fim de sua vida útil, podemos replicar um novo molde para você

Fundição sob pressão em câmara fria: Este método é adequado para materiais com pontos de fusão mais elevados, como alumínio e magnésio.. O metal é derretido em um forno separado e depois injetado na máquina de câmara fria. É ideal para fundir peças leves e duráveis, mas pode ser um pouco mais lento devido à necessidade de transferência de metal.

Fundição sob pressão de câmara quente: Projetado para materiais com pontos de fusão mais baixos, como o zinco. Neste processo, o metal permanece em estado fundido dentro de um forno integrado conectado à máquina. A fundição sob pressão em câmara quente é mais rápida e eficiente para fundir peças menores, peças complexas, tornando-o econômico para produção de alto volume.

Nossos preços de moldes são justos e razoáveis, e não pretendemos lucrar excessivamente com nossos clientes em custos de moldes. Além disso, para clientes com grandes volumes de pedidos, no caso de um molde ficar inutilizável, oferecemos a opção de criar um novo molde sem custo adicional. Adicionalmente, os fatores que contribuem para o preço dos moldes incluem a resistência e a seleção do material no projeto do molde.

A sustentabilidade é uma consideração fundamental em nossas operações. Priorizamos práticas sustentáveis minimizando desperdícios, reciclando materiais, e implementação de processos energeticamente eficientes. Aqui na Bian, por uma questão de pureza material, nossa empresa utiliza um forno de fusão central para fusão concentrada e refino de materiais reciclados antes de sua reutilização. Aplicamos medidas de controle rigorosas em todo o processo de fundição sob pressão de alumínio, incluindo inspeções de entrada de matérias-primas, testes periódicos da composição do material a cada duas horas, e testes regulares de terceiros.

Possuímos diversas certificações que atestam nosso compromisso com a qualidade e aderência aos padrões do setor. Essas certificações incluem ISO 9001 para gestão de qualidade, ISO 14001 para gestão ambiental, e IATF 16949, que é específico para a indústria automotiva. Essas certificações proporcionam aos clientes B2B confiança em nossos processos e em nossa capacidade de fornecer produtos de alta qualidade de forma consistente..

– Alta precisão e tolerâncias restritas

– Produção eficiente de formas complexas

– Leve e durável

-Excelente dissipação de calor

-Econômico para grandes quantidades

Sim, nossa equipe de especialistas fornece Design para Manufaturabilidade (DFM) serviços aos nossos clientes. Colaboramos em projetos para garantir uma produção eficiente, reduzindo custos e tempo de lançamento no mercado.

Direitos autorais © 2024, Bian Diecast. Todos os direitos reservados.