Quando você pensa em criar algo do zero, seja um gadget legal ou uma peça de mobiliário elegante, você pode se deparar com dois termos: fundição e moldagem. Ambos os processos são essenciais na fabricação, mas eles têm suas próprias vibrações e usos únicos. Então, qual é a diferença entre fundição e moldagem? Vamos mergulhar!

Os princípios básicos da fundição

Tipos de processos de fundição

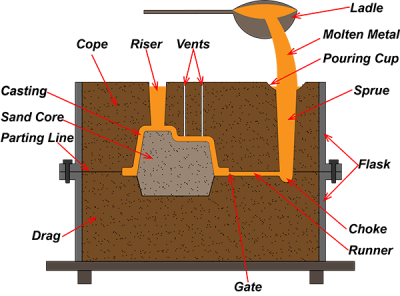

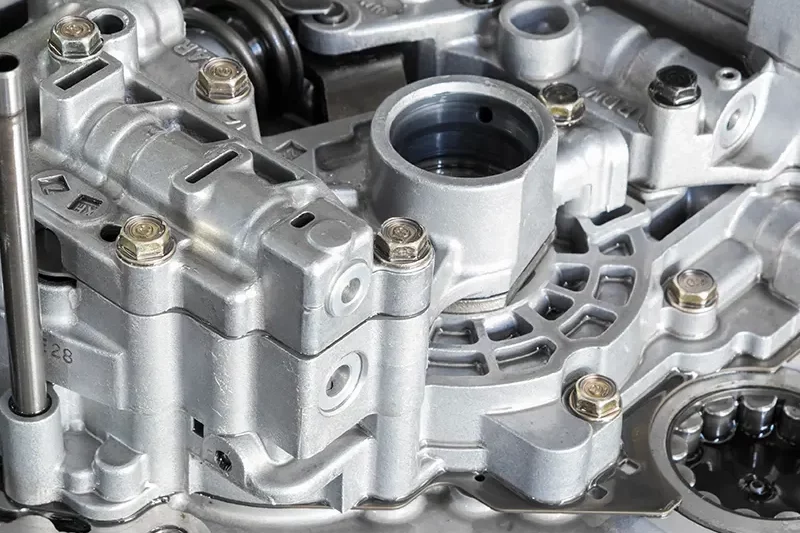

Fundição trata-se de despejar material líquido em um molde e deixá-lo solidificar. É como fazer um bolo: misture os ingredientes (ou materiais), despeje em uma panela (o molde), e espere que ele configure. Aqui estão alguns métodos de fundição populares:

- Fundição em Areia: Este é o método clássico onde a areia é compactada em torno de um padrão, criando um molde. É ótimo para itens maiores e relativamente barato.

- Fundição de investimento: Já ouviu falar em fundição por cera perdida? Esta técnica utiliza um modelo de cera revestido de cerâmica. Quando a cera derrete, você fica com um molde detalhado - perfeito para designs complexos!

- Fundição sob pressão: Pense nisso como a versão fast-food do casting. Metal fundido é injetado em um molde sob alta pressão, tornando-o ideal para produção em massa.

- Fundição Centrífuga: Este processo gira o molde, permitindo que o material seja forçado contra as paredes do molde. É incrível para fazer tubos e formas cilíndricas.

Vantagens da fundição

A fundição apresenta várias vantagens importantes que a tornam um processo de fabricação de destaque:

1. Capacidade de criar formas complexas: A fundição é excelente na produção de designs complexos e detalhes finos. Se você precisa de uma peça com geometria complicada, este método pode lidar com isso com facilidade.

2. Versatilidade em Materiais: Acomoda uma ampla gama de materiais, Incluindo:

- Metais: Alumínio, bronze, ferro, e mais.

- Plásticos: Vários tipos dependendo da técnica de fundição.

- Vidro: Alguns métodos podem até lidar com fundição de vidro.

3. Adaptabilidade para diferentes aplicações: Se você precisa de pequenos itens decorativos ou grandes componentes funcionais, a fundição pode ser adaptada para produzir uma variedade de tamanhos e formas.

4. Precisão e exatidão: O processo de fundição permite alta precisão, garantindo que o produto final corresponda ao design original.

5. Custo-benefício para grandes tiragens de produção: Embora a configuração inicial possa ser mais cara, a fundição torna-se econômica ao produzir grandes quantidades do mesmo item.

Os princípios básicos da moldagem

Tipos de processos de moldagem

Moldagem, por outro lado, tem tudo a ver com moldar materiais em formas específicas. Pense nisso como um artesanato com Play-Doh. Você pode apertar e modelar como quiser! Aqui estão alguns métodos de moldagem comuns:

- Moldagem por injeção: É aqui que o plástico derretido é injetado em um molde. É muito popular para fazer itens de uso diário, como recipientes e brinquedos.

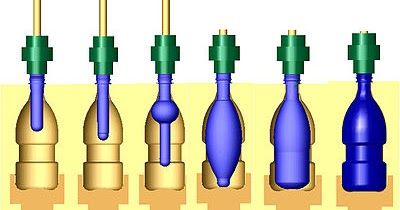

- Moldagem por sopro: Esta técnica é usada para itens ocos como garrafas. O ar é soprado em um tubo de plástico aquecido, que se expande no molde.

- Moldagem Rotacional: Aqui, um molde é preenchido com pó e girado. À medida que aquece, o pó derrete e cobre o interior do molde, criando produtos fortes e ocos.

- Termoformagem: Uma folha de plástico é aquecida até ficar flexível, então formado sobre um molde. Isso é comum para materiais de embalagem e bandejas.

Vantagens da Moldagem

A moldagem oferece várias vantagens significativas, particularmente na eficiência da produção e gestão de recursos:

- Velocidade de produção: A moldagem é excelente na produção rápida de grandes quantidades de produtos idênticos, tornando-o perfeito para produção em massa.

- Consistência: O processo garante que cada item seja uniforme em qualidade e aparência, reduzindo a variabilidade e aumentando a confiabilidade do produto.

- Eficiência Material: A moldagem normalmente usa menos material do que a fundição, que não só economiza dinheiro, mas também reduz o desperdício.

- Custo-benefício: O menor uso de materiais e a produção rápida se traduzem em custos gerais reduzidos, especialmente ao fabricar grandes volumes.

- Benefícios Ambientais: Minimizando o desperdício e utilizando materiais de forma mais eficiente, a moldagem contribui para práticas de fabricação mais sustentáveis.

Principais diferenças entre fundição e moldagem

Materiais Utilizados

Então, qual é a diferença de fundição e moldagem em materiais? A fundição geralmente envolve metais ou certos plásticos, enquanto a moldagem lida predominantemente com plásticos. É como escolher entre biscoitos e brownies – ingredientes deliciosos, mas diferentes!

Visão geral do processo

Os processos são onde residem as verdadeiras diferenças. No elenco, você está resfriando um líquido para formar um sólido. Com moldagem, você está frequentemente aquecendo e remodelando materiais. É uma dança de temperaturas que cria aqueles lindos produtos que todos usamos.

Aplicativos

Tanto a fundição quanto a moldagem são usadas em todos os setores. De peças automotivas a utensílios de cozinha, as aplicações são vastas. No entanto, a fundição costuma ser a escolha certa para peças pesadas, enquanto a moldagem é preferida para peso leve, itens produzidos em massa.

Comparação de custos

Custos de configuração inicial

A fundição pode ter uma configuração inicial mais elevada devido à criação de moldes, especialmente para designs complexos. Moldagem, embora muitas vezes seja mais barato configurar para produção em massa, pode ser caro para execuções de baixo volume. É como pagar por um serviço de assinatura: você economiza mais quanto mais o usa!

Custos de produção

Em termos de custos de produção, a moldagem geralmente vence para grandes volumes. É eficiente e usa menos material. Fundição, embora seja ótimo para peças únicas, pode ficar caro se você estiver fazendo centenas do mesmo item.

Considerações ambientais

Geração de Resíduos

Ambos os processos geram resíduos, mas a moldagem normalmente produz menos material residual. Com fundição, você pode ter sobras de metal ou areia que precisam ser descartadas.

Consumo de energia

O uso de energia varia, também. A fundição pode consumir muita energia devido ao processo de fusão, enquanto a moldagem pode ser mais eficiente em termos energéticos depois de configurada. É como comparar correr uma maratona com correr; ambos usam energia, mas é preciso mais resistência!

Elenco versus. Moldagem: Qual método escolher?

Antes de mergulhar nas especificidades de cada método, é essencial avaliar os requisitos do seu projeto. Faça a si mesmo as seguintes perguntas:

1. Que material você precisa?

A fundição é frequentemente preferida para metais e certos plásticos, enquanto a moldagem é normalmente melhor para uma variedade de plásticos. Se o seu projeto envolve componentes metálicos, o elenco pode ser o caminho a percorrer.

2. Quais são as formas e detalhes desejados?

Você precisa de designs intrincados ou geometrias complexas? Se for assim, a fundição pode oferecer a precisão que você precisa. A moldagem é excelente para formas mais simples, mas pode ter problemas com detalhes finos.

3. Quantas unidades você precisa?

Você está procurando um pequeno lote ou produção em massa? A moldagem é excelente na produção de grandes quantidades de forma rápida e consistente, tornando-o a escolha certa para necessidades de alto volume.

Conclusão

Resumindo, enquanto a fundição e a moldagem podem parecer semelhantes, cada um deles tem métodos distintos, materiais, e aplicações. Compreender a diferença entre moldagem e fundição pode ajudá-lo a tomar decisões informadas na fabricação ou mesmo quando você está apenas curioso sobre como as coisas são feitas. Se você precisa de designs de metal complexos ou itens de plástico produzidos em massa, conhecer o processo certo pode fazer toda a diferença.

Perguntas frequentes

1. Quais materiais são comumente usados na fundição?

A fundição geralmente envolve metais como alumínio, ferro, e bronze, mas alguns plásticos e vidros também podem ser fundidos.

2. Quanto tempo normalmente leva o processo de fundição?

O tempo pode variar muito dependendo do método, mas geralmente leva mais tempo do que a moldagem devido ao tempo de resfriamento.

3. Quais são as limitações da moldagem?

A moldagem pode ser menos eficaz para projetos complexos e normalmente é limitada a certos materiais como plásticos.

4. A fundição e a moldagem podem ser usadas de forma intercambiável??

Não exatamente. Eles têm processos e aplicações diferentes, por isso é importante escolher com base em suas necessidades específicas.

5. Quais indústrias usam principalmente fundição e moldagem?

Ambos os processos são amplamente utilizados na automotivo, bens de consumo, aeroespacial, e indústrias de construção, entre outros.