Leading Aluminum & Zinc Die Casting Manufacturer in China

Secure your supply chain with our dual-factory strategy. Leverage China’s high-efficiency production and Mexico’s strategic nearshore delivery for ultimate cost optimization.

- Mold Design & DFM Feasibility Analysis

- IATF 16949 Certified

- Multiple Finishing Options

- Real-Time Tracking via MES System

Our Clients

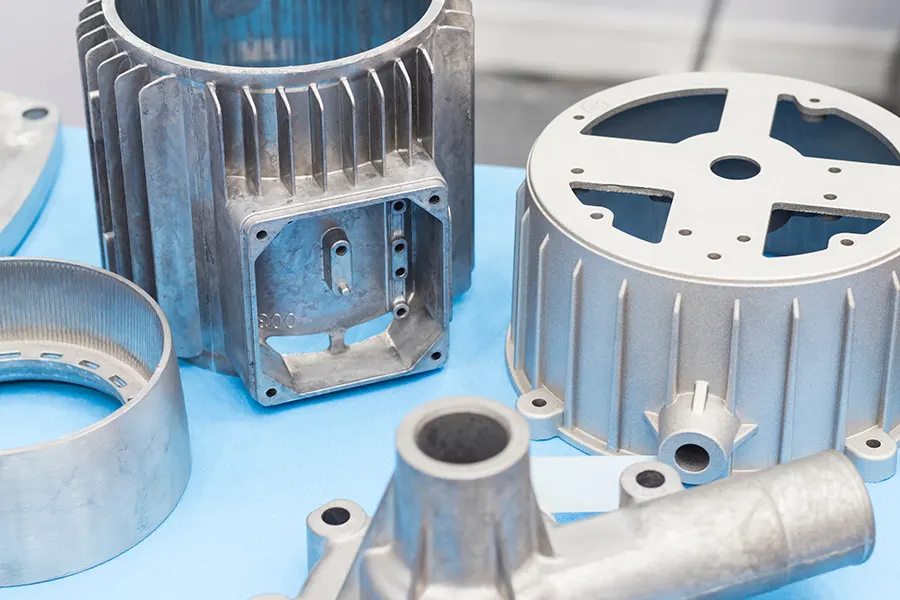

Custom Aluminum Die Casting Parts for A Wide Range of Industries

When precision and reliability matter, custom die cast parts are the go-to solution across various industries. At Bian Diecast, we specialize in crafting high-quality die casting aluminum housing components and custom die cast parts tailored to meet the unique demands of diverse sectors:

Automotive Industry

Lighting Industry

Electronic Industry

Furniture Industry

Construction Industry

With factories in both China and Mexico, BIAN ensures faster delivery and seamless regional support.

Best Aluminum Die Casting Price in the Market

These prices indicate the cost range for producing one unit of a product using the respective die-casting machine. The actual aluminum die casting cost within each range may vary depending on factors such as the complexity of the part, material used, and other production variables.

| Die Casting Machine Model | Pricing for Reference ($ per unit) |

|---|---|

| 1250T Die Casting Machine | $3-5 |

| 900T Die Casting Machine | $1.5-2 |

| 800T Die Casting Machine | $1.0-1.5 |

| 500T Die Casting Machine | $0.7-1.0 |

| 400T Die Casting Machine | $0.5-0.7 |

| 300T Die Casting Machine | $0.3-0.4 |

How We Deliver for You

Purchasing Manager / Engineer

- High Quality, Cost-Effective, Rapid Turnaround.

- Cost Advantage: Low-cost, high-volume production in China

- Speed: Quick processing and nearshore shipping from Mexico.

- One-stop Service: Complete casting, CNC, and finishing in-house.

Supply Chain Director / CPO

- Stable Supply, Transparent Management, Optimized TCO

- Dual-Source Security: Two factories (China & Mexico) for supply backup

- Risk Mitigation:Strategic use of Mexico to reduce tariffs and border issues.

- Management: Real-time production tracking via MES systems.

Product / R&D Lead

- Accelerated Design, Reliable Tooling, Faster Launch

- Veteran Expertise: 20+ years of project engineering and mold design experience.

- Prototyping:Provides DFM, Mold Flow Analysis, and R&D support.

- Certified Quality: IATF 16949 and advanced lab testing.

Versatile Materials for Global Precision Die Casting

Bian Diecast is an aluminium die casting parts manufacturer who takes pride in offering a diverse spectrum of top-tier die-cast aluminum alloys to cater to a wide range of industrial demands. Our carefully curated selection encompasses three primary categories, each distinguished by its unique set of properties and applications.

Common Die-cast Aluminum Alloys

- ADC12

- ADC10

- DC1

- A360

- A380

- YL102

- LM6

EU Grade Aluminum Alloy Materials

- ENAC 44300(AISI12(FE))

- ENAC-47100

- ENAC-46000

High Thermal Conductivity Alloy Materials

- AlSI8

- LHB1

Get Die Casting Services at One Place

Reduce your expenses on finding factories for each of the die casting processes, Bian Diecast has workshops that cover mold design, aluminum and zinc die casting, CNC machining & surface treatment services.

Die Casting

- Free DFM Analysis Report

- Tolerances down to ±0.004" (0.1mm)

- High Volume Production: Up to 3000 Pcs/Day

- Utilizing Diverse Die Casting Alloys

Precision Tooling

- Aluminium Die Casting Mold Design

- Full Mold Flow Simulation & Optimization

- Guaranteed 50,000 Shots Before Refurbishment

- Seamless Mold Assembly & Trials

CNC Machining

- 3 axis, 4 axis & 5 axis precision machining

- Tolerances down to ±0.02mm

- Max Machining Dimension Up to 1000cm

- Sample Inspection & Delivery

Finishing Services

- Multiple Finishing Options

- Polishing & Lacquer Coating

- Sand Blasting & Anodizing

- (Optional: Powder Coating)

Get A Quote for Die Casting Services Today!

Cold Chamber HIGH Pressure Die Casting Capability

There are two primary methods for die casting: hot chamber die casting and cold chamber die casting. For aluminum alloy die casting, we primarily employ cold chamber pressure die casting machines, while the hot chamber method is often used for alloys like zinc due to their lower melting points.

At Bian Diecast, our factory is fully equipped with a variety of die casting machines. Each machine is capable of producing at least 2000 to 3000 die casting components per day. The largest casting area reach 3125cm².

A brief list of our high pressure die casting machines catering to different sizes of parts:

| 1250T Die Casting Machine | 900T Die Casting Machine | 800T Die Casting Machine |

| 500T Die Casting Machine | 400T Die Casting Machine | 300T Die Casting Machine |

Aluminum Die Casting Services in China

The Bian Diecast Differences

Bian Diecast, an aluminum die casting factory, is located in Nanhai District, Foshan City, China. With over a decade of expertise in die casting, we are committed to providing comprehensive die casting services. Apart from specialized mold design and development, we have an advanced factory and workshops that integrate die casting, CNC precision machining, and surface finishing services, catering to diverse needs across various industries.

Currently, we have accumulated years of service experience in the automotive, lighting, electronics, furniture, and construction industries. With a solid foundation in project management, we aim to become a strategic supplier to many renowned global brands.

delivering value to your die casting supply chain

We are not just an experienced Chinese die casting manufacturer – we also operate a modern factory in Mexico, providing the North American market with fast, low-risk supply chain solutions.

Reduced Total Cost

Competitive manufacturing costs combined with lower import duties and logistics expenses.

Faster Delivery

Located near the US-Mexico border, our logistics and lead times significantly outperform overseas shipments.

Premium Quality Standards

Operated to IATF 16949 standards, focusing on automotive and high-end electronics clients.

Local Support

Our Mexico-based team (Aluminum Die Casting Companies in Mexico) ensures real-time communication and efficient project management.

FAQs on Die Casting

The minimum tolerance requirements depend on the size of the product.

For dimensions up to 200mm, tolerances of ±0.1mm or better are required.

For dimensions up to 300mm, tolerances of ±0.2mm or better are necessary;

and for dimensions up to 500mm, tolerances of ±0.3mm or better are expected.

As for draft angles, a minimum of 1 degree is required, but larger angles are preferred for smoother ejection from the mold.

These tolerance specifications are essential to ensure the precision and quality of die-cast products.

50,000 shots before replacement or refurbishment. If the old die-casting mold reaches the end of its service life, we can replicate a new mold for you

Cold Chamber Die Casting: This method is suitable for materials with higher melting points like aluminum and magnesium. The metal is melted in a separate furnace and then injected into the cold chamber machine. It’s ideal for casting durable and lightweight parts but can be a bit slower due to the need for metal transfer.

Hot Chamber Die Casting: Designed for materials with lower melting points, such as zinc. In this process, the metal remains in a molten state within an integrated furnace connected to the machine. Hot chamber die casting is faster and more efficient for casting smaller, intricate parts, making it cost-effective for high-volume production.

Our mold prices are fair and reasonable, and we don’t aim to profit excessively from our customers on mold costs. Moreover, for customers with large order volumes, in the event that a mold becomes unusable, we offer the option of creating a new mold at no additional cost. Additionally, factors contributing to the pricing of molds include the strength and material selection in the mold design.

Sustainability is a key consideration in our operations. We prioritize sustainable practices by minimizing waste, recycling materials, and implementing energy-efficient processes. Here at Bian, for the sake of material purity, our company utilizes a central melting furnace for the concentrated melting and refining of recycled materials before their reuse. We enforce strict control measures throughout the aluminum die casting process, including incoming raw material inspections, periodic testing of material composition every two hours, and regular third-party testing.

We hold several certifications that attest to our commitment to quality and adherence to industry standards. These certifications include ISO 9001 for quality management, ISO 14001 for environmental management, and IATF 16949, which is specific to the automotive industry. These certifications provide B2B clients with confidence in our processes and our ability to consistently deliver high-quality products.

– High precision and tight tolerances

– Efficient production of complex shapes

– Lightweight and durable

-Excellent heat dissipation

-Cost-effective for large quantities

Yes, our expert team provides Design for Manufacturability (DFM) services to our clients. We collaborate on designs to ensure efficient production, reducing costs and time to market.

How We Work Together

1. DFM & Tooling Validation

2. High-Pressure Injection

3. Solidification & Quality Check

4. Turnkey Finishing

Get Aluminum Die Casting Services at One Stop!

-

.No. 128-129, East Industrial Zone,

Mashe East, Lishui Town, Nanhai District, Foshan, Guangdong, China

- Contact:katherine

- Phone:+86 189 4247 5007

- E-mail:Katherine@mag-cast.com

- WhatsApp:+86-159 1863 4657

- Contact:katherine

- Phone:+86 189 4247 5007

- E-mail:Katherine@mag-cast.com

- WhatsApp:+86-159 1863 4657