Project Management

Project Management Overview

At Bian Diecast, we embrace a project management ethos rooted in the “craftsman spirit,” where we dedicate ourselves to getting the job done right the first time.

- Reduce production costs

- Enhance mold and die cast products' quality

- Ensure precision and efficiency at every stage of your project

Project Management Excellence

Dedicated Project Managers

To cater to various die casting project needs from our clients, Bian Diecast has established a comprehensive project management system. We've formed specialized project teams for each project, encompassing aspects like business negotiations, technical support, quality control, and more. This setup ensures seamless coordination and effective resolution of project-related matters.

Transparent & Traceable Project Updates

Feel free to inquire about the progress of your die casting project. Our MES (Manufacturing Execution System) provides real-time updates on production status, and our team is always ready to assist with any questions. Rest assured, our dedicated project team members maintain thorough records to ensure the seamless advancement of your project.

We Take the Utmost Care of Your Project

Stage 1

Inquiry & Communication

In this initial phase, Bian Diecast starts by receiving and reviewing inquiries and orders from customers. We will establish a project team to handle the project and engage in technical discussions with the customer before confirming and placing the formal order.

- Order inquiry

- Communication for futher cooperations & technical supports

- Project intiation meeting & establishment of project team

- Technical comminication with customer

- Formal order placement

Stage 2

Mold Making & Trial

In this phase, we focus on mold preparation and design. We will compile a standard document for mold making, hold meetings to discuss new molds, confirm material and component suppliers, and establish the technical requirements and standards for the project. The design process is reviewed and confirmed with the customer, and the mold-making process and schedule are determined.

- Preparation of mold making standard document

- New mold meeting

- Confirmation of material and component suppliers

- Confirmation of technical requirements and standards

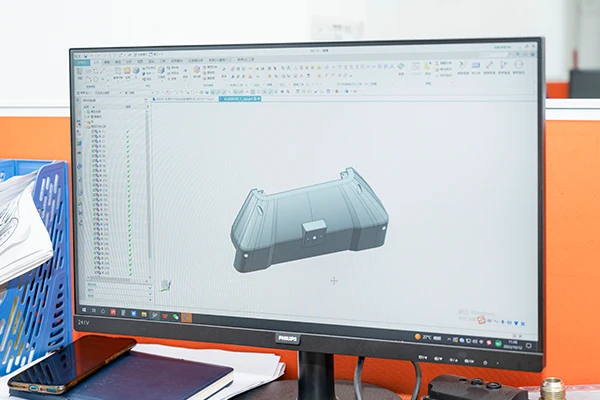

- Modeling and product structure with mold flow analysis

- Review of mold structure (2D/3D) design

- Customer confirmation of mold design

- Preparation of mold making process and schedule

- Procurement process control

- Inspection of mold materials and standard parts

Stage 3

Mold Preparation & Design

During this phase, Bian Diecast receives material supplies and spare parts, closely monitors the progress of mold making, and prepares for mold trials. We’ll conduct mold trials, document the process and results, and seek customer confirmation of the T1 sample. Once approved,we proceed with small-batch trial production and summarize the trial production experience.

- Receipt of material supplies and spare parts

- Monitoring of mold making progress and process cards

- Monitoring of mold making process

- Mold trial preparation

- Mold trial and video archiving

- Inspection of trial sample and CMM report

- Customer confirmation of T1 sample

- Sample approval and sign-off

- Small-batch trial production

- Trial production feedback & summary

Stage 4

Process Recording & Review

In the final phase, Bian Diecast establishes standard operating procedures (SOP) and standard inspection procedures (SIP). We’ll create project records, including mold management cards, to ensure that the project is well-documented and controlled. Continuous improvement efforts are ongoing to enhance processes and outcomes.

- Controlled release of SOP/SIP

- Establishment of project records

- Creation of mold management cards

- Optimization and continuous improvement