Grundlagen der Oberflächenbeschaffenheit verstehen

Die Oberflächenbeschaffenheit des Aluminiumdruckgusses bezieht sich auf die Textur, Glätte, und Gesamtqualität der Außenschicht einer Komponente, wie sie durch einen Herstellungsprozess oder eine Folgebehandlung erzeugt wird. Im industriellen Kontext, Die Oberflächenbeschaffenheit umfasst drei Hauptattribute: Rauheit, Welligkeit, und lag. Rauheit ist ein Maß für die Minute, eng beieinander liegende Abweichungen auf der Oberfläche. Welligkeit fängt länger ein, größere Oberflächenschwankungen, die durch Maschinenvibrationen oder Werkzeugauslenkungen verursacht werden. Lay beschreibt die vorherrschende Richtung des Oberflächenmusters, hauptsächlich durch den Bearbeitungsprozess geformt.

Bedeutung der Oberflächenbeschaffenheit in der Fertigung

Die Oberflächenbeschaffenheit bestimmt grundsätzlich die Eignung eines Teils für den vorgesehenen Zweck. In vielen Fällen, Die Nichterfüllung der erforderlichen Oberflächenkriterien kann zu Fehlfunktionen führen, vorzeitiger Verschleiß, übermäßige Reibung, oder suboptimale Leistung. Zum Beispiel, Lagerflächen und gleitende Komponenten erfordern eine strenge Kontrolle der Oberflächenrauheit, um die Reibung zu minimieren und einen stabilen Schmierfilm sicherzustellen. Umgekehrt, Einige Klebe- und Lackiervorgänge erfordern eine rauere Oberfläche, um eine ordnungsgemäße Haftung zu gewährleisten.

In Branchen wie der Automobilindustrie, Luft- und Raumfahrt, und medizinische Geräte, Die Bedeutung der Oberflächenbeschaffenheit von Aluminiumdruckguss geht über die Funktionalität hinaus bis hin zur Einhaltung gesetzlicher Vorschriften und der Sicherheit des Endbenutzers. Für Aluminiumdruckgussteile, Eine gleichmäßige Oberflächenbeschaffenheit ist ein Zeichen für Prozessstabilität und hervorragende Fertigungsqualität. Durch die Aufrechterhaltung einer strengen Oberflächenkontrolle können Hersteller die Nachbearbeitungsschritte reduzieren, geringere Kosten, und beschleunigen Sie die Markteinführung, All dies ist in wettbewerbsfähigen OEM-Lieferketten von entscheidender Bedeutung.

Allgemeine Parameter zur Bewertung der Oberflächenbeschaffenheit

Die Oberflächenbeschaffenheit wird anhand mehrerer Schlüsselparameter quantitativ beschrieben, das prominenteste Wesen Ra (durchschnittliche Rauheit), Rz (mittlere Rautiefe), Und RMS (quadratischer Mittelwert der Rauheit). Die Industrie vergleicht häufig die Oberflächenbeschaffenheit rz mit der ra, um sowohl durchschnittliche als auch extreme Abweichungen zu erfassen.

| Parameter | Definition | Typische Anwendung | Einheit |

| Ra | Arithmetisches Mittel der absoluten Abweichungen | Allgemeine Rauheitskontrolle | μm/Mikrozoll |

| Rz | Mittlere Spitze-zu-Tal-Höhe über der Probe | Hebt Oberflächenextreme hervor | μm/Mikrozoll |

| RMS | Quadratischer Mittelwert der Profilabweichungen | Empfindlich gegenüber großen Fehlern | μm/Mikrozoll |

Diese Parameter werden mit Profilometern gemessen (Kontaktstiftinstrumente), optische Interferometer, oder andere berührungslose Technologien.

Standards und Symbole für die Oberflächenbeschaffenheit

Eine präzise Kommunikation über die Oberflächenbeschaffenheit erfordert die Einhaltung etablierter Standards und die Verwendung allgemein anerkannter Symbole. International, ISO 4287 und ISO 1302, sowie ASME Y14.36M und DIN 4768, bestimmen die Terminologie, Messung, und zeichnerische Darstellung der Oberflächentextur. Diese Standards legen die Probenahmelängen fest, Messtechniken und die zu verwendenden Einheiten.

Auf technischen Zeichnungen, Das Symbol der Anforderungen an die Oberflächenbeschaffenheit wird durch Markierungen wie das Häkchen oder die horizontale Linie dargestellt, manchmal mit zusätzlichen Hinweisen, die auf Verarbeitungsgrenzen hinweisen, zulässige Schlagrichtung, und erforderliche Ra- oder Rz-Werte. Für Aluminiumdruckgussteile, Die Fähigkeit, diese Symbole klar zu spezifizieren und zu interpretieren, gewährleistet das gegenseitige Verständnis zwischen Kunde und Lieferant, Reduzierung von Fehlern und Nacharbeiten.

Hersteller müssen nicht nur mit diesen Standards vertraut sein, sondern auch Geräte betreiben, die auf rückverfolgbare Referenzen kalibriert sind. Diese formale Strenge zeichnet qualitätsorientierte Organisationen in der metallverarbeitenden Branche aus.

Wie sich Druckguss auf die Oberflächenbeschaffenheit auswirkt

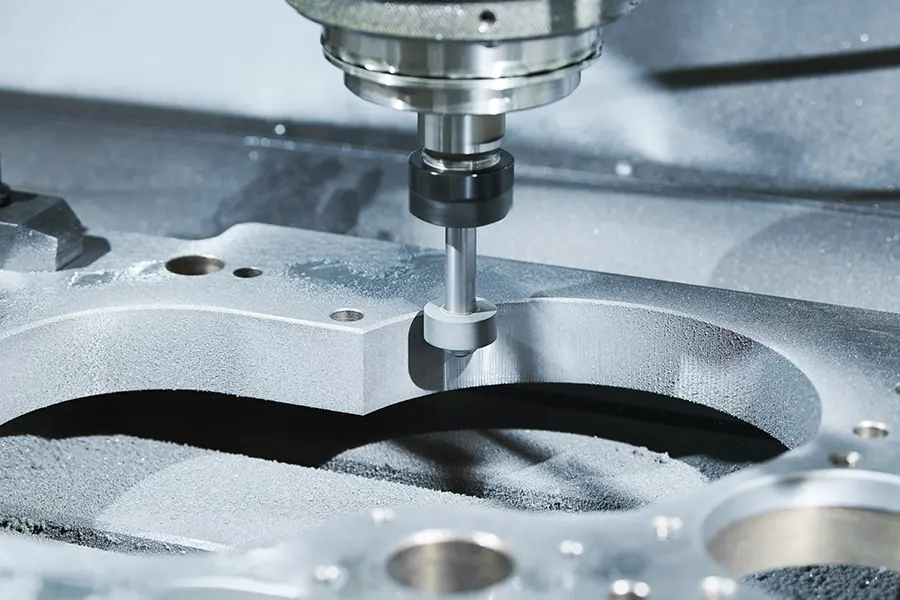

Druckguss ermöglicht die schnelle Herstellung komplexer Metallbauteile mit hervorragender Dimensionsstabilität. Jedoch, Der Prozess selbst hat großen Einfluss auf die erreichbare Oberflächengüte. Beim Druckguss, Geschmolzenes Aluminium wird unter hohem Druck in Stahlformen eingespritzt. Die Qualität des Formhohlraums, die Fließeigenschaften der Metallschmelze, und die Entlüftungsvorkehrungen wirken sich alle auf die resultierende Oberflächentopographie aus.

Mängel wie Kaltabschlüsse, Strömungslinien, und Blitze können die Oberfläche beschädigen, während gut gestaltete Matrizen gepaart mit optimierten Prozessparametern glattere Oberflächen ergeben. Die Gussoberfläche von Aluminiumdruckguss ist in der Regel feiner als bei herkömmlichem Sandguss, sind jedoch möglicherweise weniger glatt als bearbeitete oder polierte Oberflächen. Auch die Textur kann je nach Teil variieren, insbesondere in dünnwandigen oder kompliziert geformten Bereichen.

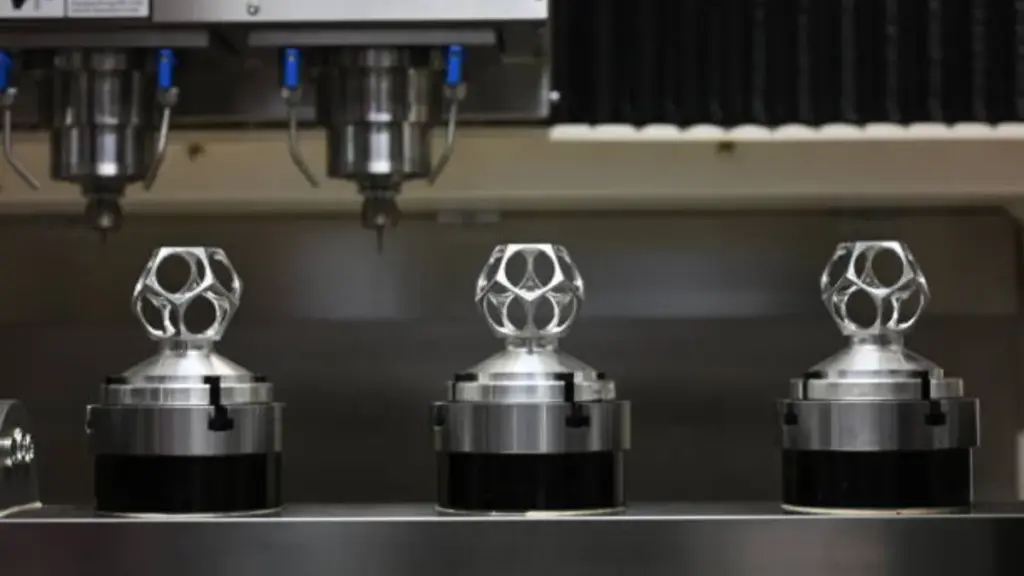

Sekundäre Endbearbeitungsprozesse – einschließlich Entgraten, sprengen, Schleifen, oder sogar CNC-Bearbeitung – werden häufig eingesetzt, um kritische Bereiche weiter zu verbessern oder einen bestimmten Ra- oder Rz-Wert zu erreichen. Für leistungsstarke und ästhetische Komponenten, enge Zusammenarbeit zwischen Design, Werkzeuge, und die Fertigung ist unerlässlich, um Erwartungen und Ergebnisse zu synchronisieren.

Verbesserung der Oberflächenbeschaffenheit beim Aluminiumdruckguss

Die Verbesserung der Oberflächenbeschaffenheit von Aluminiumdruckgussteilen hängt sowohl von einem präzisen Formdesign als auch von effektiven Nachbehandlungen nach dem Guss ab. Zu den Kernstrategien gehören::

- Verwendung hochglanzpolierter Stahlformen zur Verbesserung der Gussstruktur

- Optimierung der Formentlüftung und des Wärmemanagements für einen besseren Metallfluss

- Auswahl hochwertiger Legierungen mit geringen Einschlüssen für weniger Unregelmäßigkeiten

Überblick über gängige Oberflächenveredelungstechniken:

| Endbearbeitungsmethode | Typischer Ra-Bereich (μm) | Hauptmerkmale | Hauptanwendungen |

| Schleifen | 0.1 – 0.4 | Sehr glatt, enge Toleranz | Lagerflächen, Dichtflächen |

| Polierende Endbearbeitung | 0.05 – 0.2 | Spiegelglanz, ästhetischer Schwerpunkt | Dekorativ, optisch, oder Anzeigekomponenten |

| Taumeln/Vibrieren | 0.4 – 1.6 | Entgraten, Chargeneffizienz | Kleine bearbeitete und gegossene Teile |

| Perlenstrahlen | 1.0 – 3.2 | Gleichmäßig matt, sauberes Aussehen | Kosmetische Aluminiumgehäuse, Vorbereitung zum Beschichten |

| Eloxieren | 0.8 – 3.2* | Korrosionsbeständigkeit, Farbe | Elektronisch, Automobil, Konsumgüter |

| Galvanisieren | 0.1 – 1.6 | Härte, Verschleißfestigkeit | Anschlüsse, hochbelastbare Oberflächen |

*Notiz: Die endgültige Rauheit hängt auch von der Vorbehandlung ab.

Die meisten Aluminiumdruckgussteile profitieren von diesen Nachbearbeitungen, um ihre Funktionalität zu gewährleisten, ästhetisch, oder regulatorische Anforderungen. Führende Lieferanten wie Bian Diecast nutzen automatisierte Reinigung und Echtzeitprüfung, um eine gleichbleibende Qualität sicherzustellen.

Kosten vs. Funktion: Die Wahl des richtigen Finishs

Die Auswahl der richtigen Oberflächenbeschaffenheit für Aluminiumdruckguss ist eine strategische Entscheidung. Während glattere Oberflächen die Funktion oder Ästhetik verbessern können, Ihre Erreichung führt zu einem höheren Werkzeugverschleiß, längere Zykluszeiten, und die Notwendigkeit sekundärer Prozesse. Diese Faktoren verursachen zusätzliche Kosten und verlängern möglicherweise die Lieferfristen.

In praktischer Hinsicht, Die optimale Oberflächenbeschaffenheit wird durch die Abwägung der funktionalen Anforderungen mit dem Budget bestimmt. Für Druckgussteile, Angabe nur des erforderlichen Glätteniveaus – unabhängig davon, ob es durch Ra quantifiziert wird, Rz, oder durch das richtige Symbol der Oberflächenbeschaffenheit – können erhebliche Einsparungen erzielen, ohne die Leistung zu beeinträchtigen. Unter fachkundiger Anleitung, Überprüfung anwendungsspezifischer Standards, Durch das Benchmarking der Lieferantenfähigkeiten können Entwicklungs- und Beschaffungsteams fundierte Entscheidungen umsetzen.

Hersteller wie Bian Diecast können kostenpflichtige Optionen basierend auf verschiedenen Oberflächenqualitäten anbieten, Kunden dabei zu helfen, wertorientierte Entscheidungen zu treffen, ob Oberflächenintegrität, Aussehen, oder Kostenkontrolle ist das vorrangige Anliegen.

Warum sollten Sie sich für Bian Diecast für eine hochwertige Oberflächenbeschaffenheit entscheiden?

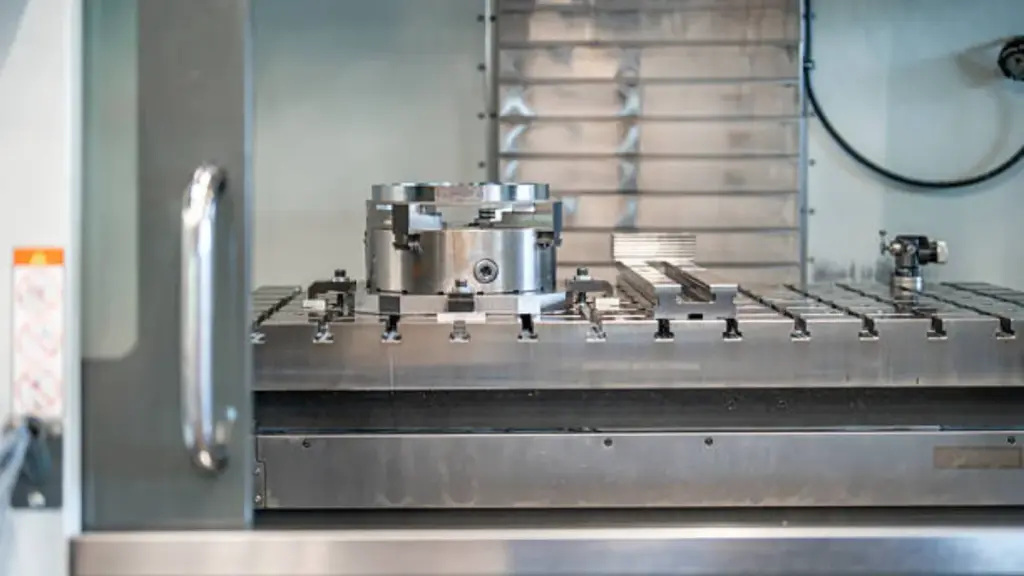

Bei der Auswahl eines Lieferanten für Aluminium-Druckguss Projekte, Die Zuverlässigkeit und Konsistenz der gelieferten Oberflächenbeschaffenheit sollte ein entscheidender Faktor sein. Bian Diecast zeichnet sich durch den Einsatz fortschrittlicher Stanztechnologie aus, strenge Prozesskontrolle, und ein ganzheitlicher Ansatz für das Qualitätsmanagement, Sicherstellen, dass jedes Teil die Kundenerwartungen hinsichtlich der Oberflächenintegrität erfüllt oder übertrifft.

Durch Investitionen in modernste Ausrüstung und kontinuierliche Schulungen, Bian Diecast liefert gegossene und kundenspezifisch gefertigte Teile mit präzisen Ra- und Rz-Werten, minimale Mängel, und maßgeschneiderte Oberflächenqualitäten, die für eine Vielzahl von Branchen geeignet sind. Das Engagement des Unternehmens für Transparenz ermöglicht es Planern, tatsächliche Testdaten zu überprüfen und beenden Messberichte vor Abschluss von Design und Produktion.

Zu den einzigartigen Fähigkeiten gehören:

- Die hauseigene Werkzeugwartung garantiert gleichbleibend glatte Werkzeugoberflächen

- Effiziente Sekundärveredelung für verbesserte kosmetische und funktionelle Leistung

- Echtzeitinspektion und Datenrückverfolgbarkeit für jedes Los

- Reaktionsschnelle technische Unterstützung zur Optimierung des Teiledesigns für gezielte Endbearbeitungen

Für weitere Details und Anfragen, besuchen Website von Bian Diecast.