Gestión de proyectos

Descripción general de la gestión de proyectos

- Reducir los costos de producción

- Mejorar la calidad de los productos de molde y fundición a presión.

- Garantice precisión y eficiencia en cada etapa de su proyecto

Excelencia en la gestión de proyectos

Gerentes de proyecto dedicados

Para atender las diversas necesidades de proyectos de fundición a presión de nuestros clientes., Bian Diecast ha establecido un sistema integral de gestión de proyectos. Hemos formado equipos de proyecto especializados para cada proyecto., Abarcando aspectos como negociaciones comerciales., apoyo técnico, control de calidad, y más. Esta configuración garantiza una coordinación perfecta y una resolución eficaz de los asuntos relacionados con el proyecto..

Transparente & Actualizaciones de proyectos rastreables

No dude en consultarnos sobre el progreso de su proyecto de fundición a presión.. Nuestro MES (Sistema de ejecución de fabricación) Proporciona actualizaciones en tiempo real sobre el estado de producción., y nuestro equipo siempre está listo para ayudar con cualquier pregunta.. Está seguro, Los miembros de nuestro dedicado equipo de proyecto mantienen registros exhaustivos para garantizar el avance fluido de su proyecto..

Cuidamos al máximo su proyecto

Escenario 1

Consulta & Comunicación

- Consulta de pedido

- Comunicación para futuras cooperaciones. & soportes tecnicos

- Reunión de inicio del proyecto. & establecimiento del equipo del proyecto

- Comunicación técnica con el cliente.

- Realización de pedidos formales

Escenario 2

Fabricación de moldes & Ensayo

- Elaboración de documento estándar de fabricación de moldes.

- Nueva reunión de moldes

- Confirmación de proveedores de materiales y componentes.

- Confirmación de requisitos técnicos y estándares.

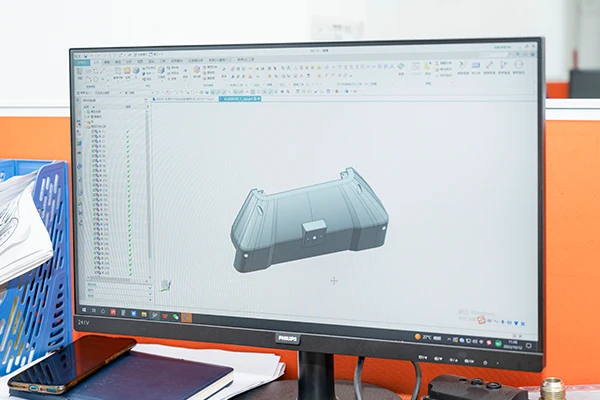

- Modelado y estructura del producto con análisis de flujo de molde.

- Revisión de la estructura del molde. (2D/3D) diseño

- Confirmación del cliente del diseño del molde.

- Preparación del proceso y cronograma de fabricación de moldes.

- Control del proceso de adquisiciones

- Inspección de materiales de moldes y piezas estándar.

Escenario 3

Preparación del molde & Diseño

- Recepción de suministros de materiales y repuestos.

- Seguimiento del progreso de fabricación de moldes y tarjetas de proceso.

- Seguimiento del proceso de fabricación de moldes.

- Preparación de prueba de molde

- Prueba de molde y archivo de vídeo.

- Inspección de muestra de prueba e informe CMM.

- Confirmación del cliente de la muestra T1

- Aprobación y aprobación de muestras

- Producción de prueba en lotes pequeños

- Comentarios sobre la producción de prueba & resumen

Escenario 4

Grabación de procesos & Revisar

- Liberación controlada de SOP/SIP

- Establecimiento de registros del proyecto.

- Creación de tarjetas de gestión de moldes.

- Optimización y mejora continua