Elegir el material de fundición a presión de zinc incorrecto es la única decisión que puede provocar fallas catastróficas en los componentes., forzando costosas retiradas de productos y deteniendo líneas de producción. Una ligera discrepancia entre las propiedades de una aleación y la tensión mecánica de su aplicación o la exposición ambiental puede provocar un agrietamiento prematuro., corrosión, o inestabilidad estructural. Este único punto de falla invalida ciclos completos de ingeniería., residuos de inversiones en herramientas, y pone en riesgo los compromisos de la cadena de suministro.

Esta guía proporciona los datos técnicos definitivos necesarios para especificar la aleación de zinc correcta para su aplicación.. Desglosaremos las diferencias clave entre las aleaciones Zamak y ZA., comparando su resistencia mecánica, dureza, y propiedades térmicas. También cubriremos el diseño esencial para la fabricación. (DFM) principios, incluida la optimización del espesor de la pared, ángulos de tiro, y normas de tolerancia, antes de explorar las opciones de acabado final con fines cosméticos y de protección.

Introducción: Por qué las aleaciones de zinc dominan la fabricación de precisión

Las aleaciones de zinc ofrecen una precisión dimensional superior y menores costos de producción a través de una alta fluidez y una mayor vida útil de la herramienta., haciéndolos ideales para complejos, fabricación de alto volumen.

Lograr tolerancias estrictas con una fluidez superior

La excepcional fluidez del zinc en estado fundido es la clave de su precisión. Esta propiedad permite que la aleación llene completamente las intrincadas cavidades del molde., producir piezas con forma neta con una precisión dimensional inigualable, logrando normalmente tolerancias de ±0,05 mm en fundición a presión y tan finas como ±0,01 mm con mecanizado CNC secundario. Esta precisión permite la creación de componentes con paredes extremadamente delgadas., hasta 0.3 milímetros, sin sacrificar la integridad estructural. Los diseñadores también pueden especificar ángulos mínimos o incluso sin inclinación., lo que simplifica el diseño de piezas y reduce el desperdicio de material. El acabado superficial resultante (Ra ≤ 1.6 µm) Es lo suficientemente suave como para eliminar la necesidad de la mayoría de las operaciones de pulido secundarias., racionalizar aún más la producción.

Reducción de los costos de producción mediante una mayor vida útil de la herramienta

Una importante ventaja económica de las aleaciones de zinc es su bajo punto de fusión de aproximadamente 419,5°C.. Esta temperatura de funcionamiento más baja reduce drásticamente el estrés térmico en los moldes de fundición a presión., extendiendo la vida útil de la herramienta a más 1,000,000 ciclos, mucho más allá de lo que es posible con materiales de mayor temperatura como el aluminio. El material también tiene un alto índice de maquinabilidad. (encima 90%), lo que minimiza el desgaste de la herramienta durante operaciones secundarias y acorta los tiempos de ciclo. El zinc también es totalmente reciclable sin degradación de sus propiedades mecánicas.. Esto permite a las fundiciones refundir y reutilizar todos los desechos del proceso., creando un sustentable, Sistema de circuito cerrado que reduce los costos de materia prima para la producción en masa..

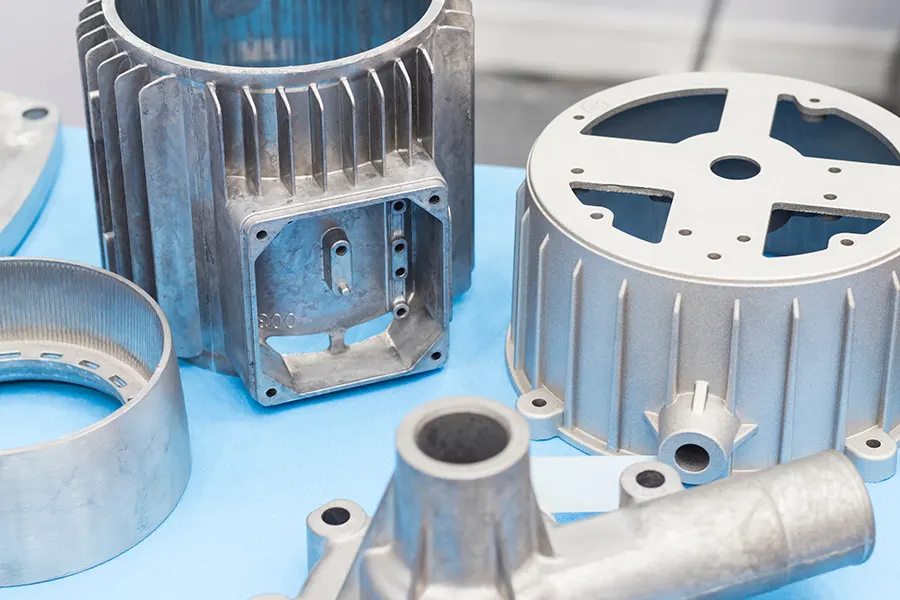

Equilibrio de fuerza, Resistencia al desgaste, y versatilidad

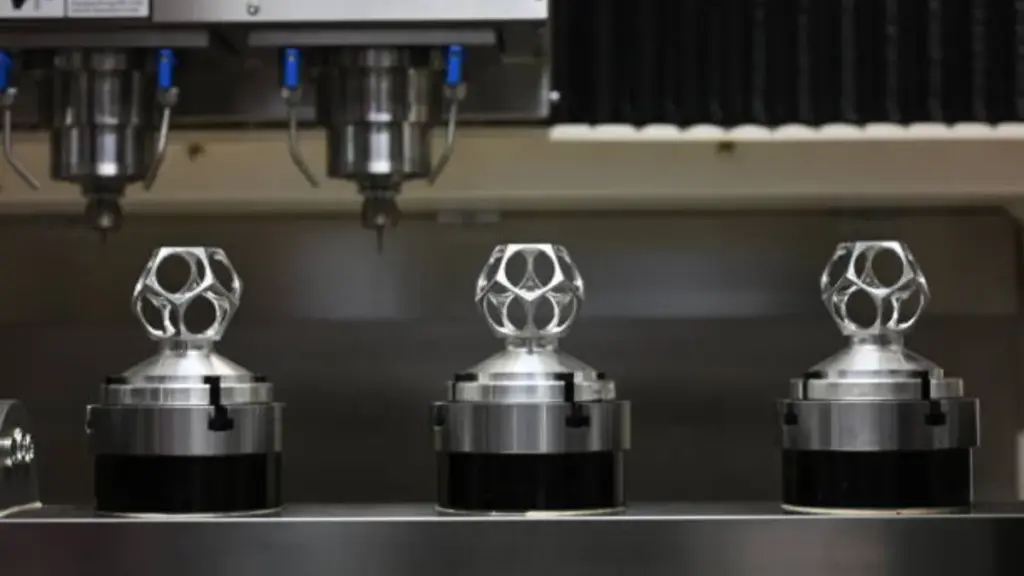

Las aleaciones de zinc ofrecen una sólida combinación de propiedades mecánicas., incluyendo alta resistencia a la tracción (entre 280 y 430 MPa) y resistencia al impacto, haciéndolos adecuados para componentes estructurales que soportan carga. La disponibilidad de aleaciones especializadas permite ajustar el rendimiento para satisfacer demandas de aplicaciones específicas.. Por ejemplo, la familia de aleaciones ZA (como ZA-8) Proporciona mayor dureza y resistencia al desgaste para aplicaciones de rodamientos., mientras que las formulaciones avanzadas como EZAC ofrecen una maquinabilidad superior para instrumentos complejos. Esta versatilidad se extiende a los procesos de fabricación.; El zinc se adapta a la fundición a presión a alta presión., mecanizado CNC de precisión, y conformado en frío, brindando a los ingenieros la flexibilidad para producir geometrías complejas de manera eficiente.

El proceso de fundición a presión de zinc: Eficiencia de la cámara caliente

La fundición a presión en cámara caliente integra el horno y el sistema de inyección., permitiendo velocidades de ciclo e integridad del material inigualables para la producción de componentes de zinc en grandes volúmenes.

Diseño de cuello de cisne integrado para ciclos de inyección rápidos

En el proceso de cámara caliente, el mecanismo de inyección, conocido como cuello de cisne, está permanentemente sumergido en el baño de zinc fundido.. Este diseño alimenta metal líquido directamente al cilindro de inyección., eliminando completamente el paso de cuchara requerido en los métodos de cámara fría. El resultado es un tiempo de ciclo mucho más rápido.. Las tasas de producción de piezas estándar suelen oscilar entre 350 a 450 tiros por hora, mientras que las microfundiciones pueden alcanzar tasas de 2,000 a 3,500 por hora. El sistema de émbolo sumergido se recarga automáticamente después de cada disparo., Garantizar un suministro constante e inmediato de metal para el siguiente ciclo., Lo cual es esencial para mantener la eficiencia en la fabricación de alto volumen..

Porosidad reducida mediante inyección directa de metal

Mantener el sistema de inyección completamente sumergido en el metal fundido minimiza la exposición a la atmósfera.. Esto reduce significativamente las posibilidades de atrapamiento de aire y oxidación del metal durante el proceso de inyección.. el directo, la transferencia cerrada produce, Piezas fundidas menos porosas con integridad mecánica superior.. Esto es fundamental para aplicaciones exigentes como componentes estructurales de automoción donde los huecos internos son inaceptables.. Este método también produce un excelente acabado superficial como fundición., a menudo logrando un promedio de rugosidad (Real academia de bellas artes) de 1.6 µm o menos, lo que reduce o elimina la necesidad de mecanizado y pulido secundarios.

Maximizar la longevidad de las herramientas y reducir el uso de energía

El bajo punto de fusión del zinc, alrededor de 419,5°C, es una ventaja operativa y económica clave. Esta temperatura relativamente baja somete a los moldes de fundición a presión de acero a mucho menos choque térmico y desgaste en comparación con la fundición de aleaciones de mayor temperatura como el aluminio.. Esto extiende la vida funcional de un molde típico a más de un millón de ciclos., Reducir drásticamente el coste amortizado de herramientas por pieza.. El diseño del horno integrado también es más eficiente energéticamente, ya que mantiene una temperatura de fusión estable con menos pérdida de calor que los sistemas de horno y cuchara externos. Esto se traduce en un menor consumo total de energía y menores costos de producción..

Fundición a presión certificada por IATF para componentes de misión crítica

Desglose detallado de las aleaciones de zinc: Seleccionar el grado correcto

La elección del grado correcto de aleación de zinc afecta directamente el rendimiento mecánico de un componente., estabilidad dimensional, y costo de producción final. Esta es una decisión de ingeniería crítica., no es una elección de productos básicos.

las cargas 3: El estándar para estabilidad dimensional y acabado

las cargas 3 es la base establecida para la serie Zamak y la aleación de zinc más especificada en Norteamérica, contabilidad de más 70% del volumen de fundición a presión. Proporciona una excelente combinación de propiedades mecánicas., moldeabilidad excepcional, y estabilidad dimensional a largo plazo. Su principal ventaja es su calidad superficial superior., lo que crea un sustrato ideal para enchapar, cuadro, y otros acabados cosméticos. Con una resistencia a la tracción de alrededor 283 MPa, sirve como predeterminado, opción rentable para componentes de uso general, carcasas, y herrajes decorativos donde la precisión y la apariencia son fundamentales.

las cargas 5: Mayor resistencia y dureza

las cargas 5 es una mejora directa del Zamak 3, modificado con aproximadamente 1% contenido de cobre. Esta adición aumenta su resistencia a la tracción a alrededor 331 MPa, una mejora mensurable de aproximadamente 10%, y también aumenta su dureza y resistencia a la fluencia.. La compensación por esta mayor resistencia es una reducción en la ductilidad. (el alargamiento cae de ~10% a ~7%), lo que lo hace menos adecuado para piezas que requieren operaciones de conformado secundarias, como doblar o engarzar después de la fundición.. las cargas 5 Está especificado para aplicaciones que exigen mayor integridad estructural y capacidad de carga., como componentes automotrices y hardware mecánico.

ZA-8: Alternativa de alto rendimiento para rodamientos y desgaste

El Zinc-Aluminio (PARA) Las aleaciones ofrecen propiedades mecánicas que superan a las de la familia Zamak.. ZA-8, con un 8.4% contenido de aluminio, proporciona una resistencia significativamente mayor, dureza, y excelentes propiedades de rodamiento. Con frecuencia se especifica para reemplazar piezas mecanizadas de bronce o hierro fundido en aplicaciones de alto desgaste.. Una ventaja clave de fabricación de ZA-8 es su capacidad de fundirse mediante el eficiente proceso de fundición a presión en cámara caliente., a diferencia de las aleaciones ZA-12 y ZA-27 con alto contenido de aluminio, que requieren el método más lento de cámara fría. Esto convierte al ZA-8 en una solución rentable para componentes mecánicos de alto rendimiento..

Aleación EZAC: Resistencia superior a la fluencia para entornos de alto estrés

EZAC es una formulación avanzada diseñada para resolver una de las principales limitaciones del zinc tradicional.: resistencia a la fluencia, especialmente a temperaturas elevadas. Esta aleación mantiene su integridad dimensional bajo cargas sostenidas donde otras aleaciones de zinc se deformarían con el tiempo.. Ofrece una mejora de orden de magnitud en el rendimiento de fluencia., haciéndolo ideal para aplicaciones críticas con tensión constante. Los usos comunes incluyen conectores estructurales., sujetadores roscados, y componentes automotrices que operan en ambientes térmicos de alto estrés, todo ello conservando las ventajas de producción de la fundición a presión en cámara caliente.

Análisis comparativo para la selección de aplicaciones específicas

La selección de materiales está impulsada por requisitos de rendimiento específicos.. Utilice este marco como punto de partida para decisiones de ingeniería..

- las cargas 3: El valor predeterminado para ser rentable, Piezas de alta precisión que requieren excelentes acabados cosméticos..

- las cargas 5: Elija cuándo un componente requiere un aumento mensurable en la resistencia a la tracción, dureza, y resistencia a la fluencia sobre Zamak 3.

- ZA-8: Seleccione piezas mecánicas que necesiten una durabilidad superior, resistencia al desgaste, y propiedades de rodamiento, especialmente si reemplaza bronce o hierro.

- EZAC: Especificar para aplicaciones críticas donde la carga a largo plazo y la estabilidad de la temperatura no son negociables para evitar la deformación por fluencia..

Propiedades del material fundido a presión de zinc & Datos de rendimiento

Las distintas propiedades del material del zinc permiten una alta precisión, Piezas con forma de red con mayor vida útil de la herramienta., Reducir directamente los costos de producción por unidad para componentes complejos..

Resistencia mecánica & Características físicas

Las aleaciones de zinc ofrecen un equilibrio fiable de alta resistencia a la tracción., resistencia al impacto, y resistencia al desgaste requeridas para aplicaciones industriales y automotrices exigentes. La alta fluidez del material en su estado fundido es una ventaja clave en la fabricación., permitiéndole llenar completamente las intrincadas cavidades del troquel. Esto permite la fundición de piezas complejas con paredes extremadamente delgadas., hasta un mínimo de 0.3 milímetros, sin sacrificar la integridad estructural. El proceso también produce un acabado superficial superior como fundición con valores de rugosidad. (Real academia de bellas artes) de 1.6 µm o menos, a menudo eliminando la necesidad de operaciones secundarias de pulido o acabado..

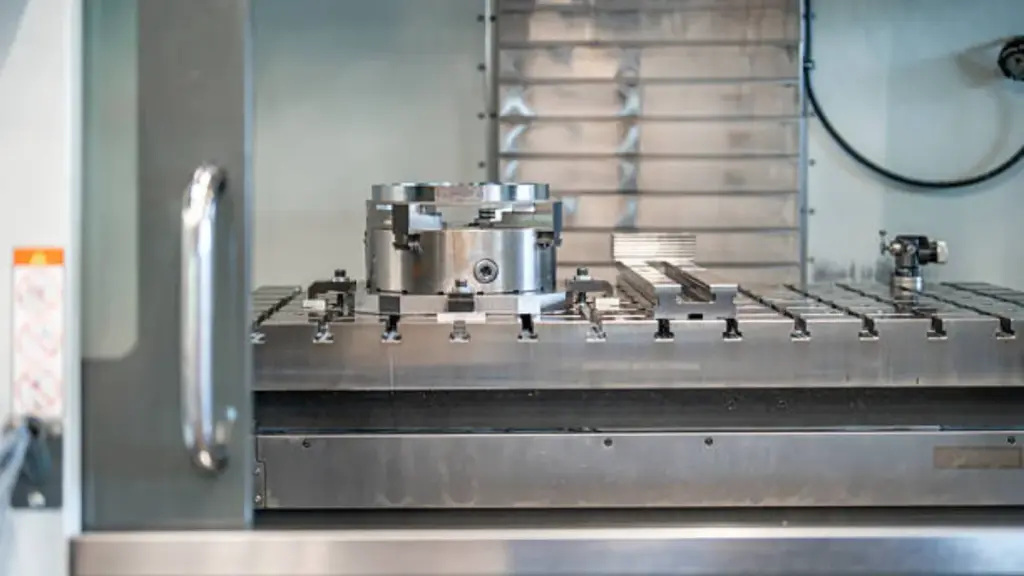

Estabilidad dimensional & Estándares de tolerancia

La principal ventaja del zinc sobre los materiales de la competencia es su excepcional estabilidad dimensional y precisión.. Mantiene constantemente una precisión dimensional de fundición a presión de ±0,05 mm., un estándar que rivaliza con muchos procesos de mecanizado. Para funciones que requieren una precisión aún mayor, El mecanizado CNC posterior puede alcanzar tolerancias estrechas de ±0,01 mm.. Este alto nivel de precisión permite a los ingenieros diseñar componentes con ángulos muy pequeños o incluso sin ángulos de inclinación.. Esta capacidad permite la producción de piezas con forma neta que optimizan el volumen interno y la eficiencia mecánica., Reducir tanto el desperdicio de material como los pasos de posprocesamiento..

Térmico & Rendimiento de maquinabilidad

Los beneficios operativos y económicos del zinc están directamente relacionados con sus propiedades térmicas y maquinabilidad..

- Un bajo punto de fusión de alrededor de 419,5 °C reduce el estrés térmico en las herramientas, extendiendo dramáticamente la vida útil del molde más allá 1,000,000 ciclos, superando con creces la vida útil de las matrices utilizadas para la fundición de aluminio.

- El zinc tiene un excelente índice de maquinabilidad. (encima 90), lo que minimiza el desgaste de la herramienta durante operaciones secundarias y reduce el tiempo total de procesamiento.

- El material es total e infinitamente reciclable sin pérdida de propiedades mecánicas., Apoyar iniciativas de sostenibilidad y fabricación de circuito cerrado..

Directrices de diseño para la fundición a presión de zinc (DFM)

Diseño eficaz para la fabricabilidad (DFM) para fundición de zinc reduce directamente los costos al minimizar las operaciones secundarias y garantizar la precisión de los componentes desde el principio.

Espesor de pared, ángulos de tiro, y tolerancias

La alta fluidez del zinc permite el diseño de complejos, Piezas ligeras con paredes extremadamente finas., especificado tan bajo como 0.3 mm sin comprometer la integridad estructural. Esta propiedad del material también permite la incorporación de ángulos de inclinación mínimos., incluyendo características de cero tiro en superficies internas cuando sea posible, reduciendo la necesidad de mecanizado posterior. Para componentes de alta precisión utilizados en automoción o electrónica, Los diseños pueden alcanzar con confianza tolerancias de fundición a presión estándar de ±0,05 mm., un nivel de precisión difícil de lograr con aluminio o plásticos moldeados.

Selección de materiales: las cargas 3 vs. las cargas 5

Elegir la aleación correcta es fundamental para el rendimiento. las cargas 3 es el estándar para aplicaciones que exigen una estabilidad dimensional superior y excelentes características de acabado para enchapado o pintura.. Cuando el diseño requiere mayores prestaciones mecánicas, seleccione Zamak 5. Es 1% El contenido de cobre proporciona aproximadamente 10% aumento de la resistencia a la tracción (hasta 331 MPa) y resistencia a la fluencia mejorada, haciéndolo ideal para componentes estructurales. En Bian Diecast, Todas las especificaciones de materiales cumplen con ASTM., EN, y estándares JIS para garantizar la coherencia global en toda nuestra China, México, e instalaciones de Vietnam.

- las cargas 3: Lo mejor para precisión dimensional y acabados decorativos..

- las cargas 5: Preferido para aplicaciones de carga que necesitan mayor resistencia a la tracción y dureza..

Integración de funciones para reducir el mecanizado secundario

Una de las principales ventajas de fabricación del zinc es su capacidad para producir piezas con forma neta.. Aprovechando la alta fluidez de la aleación, puedes diseñar hilos fundidos, jefes, enfrentamientos, y se inserta directamente en el componente. Esta estrategia elimina todos los pasos de ensamblaje posteriores al procesamiento., Reducir los costos laborales y los tiempos del ciclo de producción.. El objetivo es lograr un acabado superficial de fundición de Ra ≤ 1.6 µm, lo que a menudo minimiza o evita por completo la necesidad de un pulido posterior, agilizar aún más el flujo de trabajo de fabricación desde el molde hasta la pieza terminada.

Opciones de acabado de superficies: Enchapado y Recubrimiento

El acabado superficial adecuado determina la durabilidad del componente, resistencia a la corrosión, y rendimiento eléctrico: una elección de ingeniería fundamental para la confiabilidad de aplicaciones específicas.

Recubrimiento para mayor durabilidad y estética

Ofrecemos dos soluciones de recubrimiento primario basadas en los requisitos de las piezas.. El recubrimiento en polvo aplica una capa gruesa, barrera de polímero duradera, creando un duro, Carcasa similar al plástico ideal para piezas industriales y automotrices que exigen una alta resistencia a la corrosión., rayones, y exposición a los rayos UV. Para aplicaciones donde la apariencia es la prioridad, La pintura húmeda ofrece una amplia paleta de colores y puede lograr un alto brillo., Acabados clase A. Nuestro sistema unificado de gestión de calidad garantiza la uniformidad del color y el acabado en todas las bases de fabricación en China., México, y Vietnam, Garantizar que se cumplan los estándares de su marca independientemente del origen de la producción..

Revestimiento y tratamientos químicos para el rendimiento funcional

Cuando las propiedades funcionales son el objetivo principal, Utilizamos tratamientos químicos y de recubrimiento específicos.. La galvanoplastia aplica finas capas metálicas., como níquel o cromo, para mejorar la conductividad eléctrica, mejorar la resistencia al desgaste, o proporcionar una protección superior contra la corrosión. Para componentes de aluminio, el anodizado crea una dureza, Capa de óxido no conductora que aumenta significativamente la durabilidad de la superficie.. La pasivación es un proceso químico que maximiza la resistencia natural a la corrosión del material base formando una película protectora en la superficie., un paso crítico para piezas expuestas a condiciones ambientales exigentes.

Hacer coincidir el acabado con la aplicación

Seleccionar el acabado correcto es una decisión de ingeniería basada en la aplicación. No existe una solución única para todos los escenarios.

- Automotor & Industrial: Seleccionamos acabados que cumplen con IATF 16949 estándares, centrándose en el rendimiento verificado en pruebas de niebla salina y la resistencia al desgaste a largo plazo.

- 5GRAMO & Electrónica: Los recubrimientos se eligen por sus capacidades de blindaje EMI y propiedades de gestión térmica para garantizar una integridad de señal confiable y una disipación de calor efectiva en gabinetes sensibles..

- Equipo al aire libre: Para componentes como carcasas de iluminación LED, Aplicamos recubrimientos en polvo estables a los rayos UV y resistentes a la intemperie para garantizar confiabilidad operativa a largo plazo contra la exposición ambiental..

Análisis de sostenibilidad y rentabilidad

Una estrategia de fabricación de bases múltiples combina la eficiencia de los materiales, optimización de tarifas, y redundancia de suministro para reducir los costos totales de aterrizaje y garantizar la estabilidad de la producción a largo plazo..

Ciclo de vida del material y eficiencia del proceso

Nuestro proceso de fabricación se basa en la sostenibilidad y la reducción de costes de conformidad con la norma ISO. 14001 estándares. Utilizamos aluminio altamente reciclable., zinc, y aleaciones de magnesio para minimizar el desperdicio. Las aleaciones de zinc ofrecen una clara ventaja debido a su bajo punto de fusión de aproximadamente 419,5 °C., lo que reduce significativamente el consumo de energía durante la fundición. Esta baja temperatura operativa también minimiza el estrés térmico en las herramientas., extender la vida útil del molde de fundición a presión más allá 1,000,000 ciclos. Esta durabilidad da como resultado un menor costo amortizado de herramientas por pieza., un ahorro directo repercutido a nuestros clientes.

Este enfoque en la eficiencia se extiende a toda nuestra cadena logística.. Diseñamos diseños de carga de contenedores optimizados para todo el transporte marítimo para maximizar el uso espacial.. Este enfoque táctico reduce el costo de envío por unidad y reduce las emisiones de carbono asociadas a cada envío., Alinear el ahorro de costos con la responsabilidad ambiental..

Estrategia global de producción para la optimización arancelaria

Operamos un “Porcelana + 2” Diseño de fabricación global diseñado específicamente para gestionar los aranceles y el riesgo geopolítico.. Trasladando la producción en masa a Vietnam o México, los clientes pueden aprovechar los acuerdos de libre comercio (TLC) Reducir sustancialmente o eliminar los derechos de importación de productos que ingresan a los mercados de América del Norte y Europa.. Esta estrategia proporciona una ventaja de costos directa y predecible en el entorno comercial actual..

Nuestro modelo centraliza las altas habilidades, operaciones rentables donde tienen más sentido. Introducción de nuevos productos (NPI) y el desarrollo de herramientas de precisión se gestionan en nuestro centro tecnológico de China. Una vez validado, La producción en masa se transfiere al lugar con mayor ventaja arancelaria para la fundición y el montaje finales.. Para que este modelo transfronterizo sea económicamente eficaz, Los envíos desde Vietnam y México tienen cantidades mínimas de pedido recomendadas. (MOQ) de 3,000 a 5,000+ unidades. Este volumen amortiza los gastos logísticos y operativos., maximizar el ahorro de costos totales.

Resiliencia de la cadena de suministro y mitigación de riesgos

Nuestro modelo de fabricación tri-base, con instalaciones en China, Vietnam, y mexico, está diseñado para la resiliencia de la cadena de suministro. Esta huella distribuida proporciona redundancia de producción inmediata.. Si una interrupción del comercio regional o un evento de fuerza mayor afecta una ubicación, Podemos redirigir la producción a otras instalaciones para garantizar la continuidad absoluta del suministro para nuestros clientes..

La calidad de los componentes no es negociable., independientemente del origen. Hacemos cumplir una única, Sistema de gestión de calidad unificado en todas las instalaciones., certificado ante la IATF 16949 estándar automotriz. Esto garantiza que una pieza fundida en México sea dimensional y funcionalmente idéntica a una fundida en Vietnam o China., Prevenir defectos y garantizar una integración perfecta en su línea de producción.. Este enfoque diversificado ofrece resultados críticos, beneficios a largo plazo.

- Redundancia de producción: Mitiga los riesgos de disputas comerciales regionales o cuellos de botella logísticos.

- Estabilidad geopolítica: Permite una asignación flexible de la producción para navegar las cambiantes políticas comerciales internacionales..

- Precios estables a largo plazo: Reduce la exposición a fluctuaciones monetarias o implementaciones arancelarias repentinas en cualquier país..

Conclusión

Elegir la aleación de zinc adecuada, del versátil Zamak 3 a calidades ZA de alta resistencia, impacta directamente el rendimiento de los componentes, costo, y capacidad de fabricación. La aplicación de los datos de propiedades del material y las pautas de diseño descritas aquí ayuda a garantizar que sus piezas cumplan con requisitos funcionales precisos.. Este enfoque informado evita el exceso de ingeniería y alinea la selección de materiales con las demandas mecánicas y ambientales específicas de su proyecto..

Utilice esta información para perfeccionar su próximo diseño o para auditar las especificaciones de un componente existente.. Cuando esté listo para evaluar a un socio fabricante, Nuestro equipo puede revisar sus dibujos técnicos para proporcionar una cotización detallada y un análisis DFM..

Preguntas frecuentes

¿Cuál es la diferencia entre Zamak? 3 y zamak 5?

El contenido de investigación proporcionado no especifica las diferencias entre Zamak 3 y zamak 5. Se centra en las propiedades generales de las aleaciones de zinc y destaca aleaciones especializadas como ZA. 8 y EZAC por su alto rendimiento en aplicaciones específicas.

¿Se oxida la fundición a presión de zinc??

Las aleaciones de fundición a presión de zinc ofrecen una resistencia a la corrosión superior en comparación con el aluminio y el acero mecanizado.. Esta propiedad inherente ayuda a protegerlos de la degradación ambiental como el óxido..

¿Cuál es la aleación de fundición a presión de zinc más fuerte??

La investigación destaca aleaciones especializadas como ZA 8 por su excepcional resistencia al desgaste y sus altas relaciones resistencia-peso, haciéndolos ideales para aplicaciones exigentes de automoción y maquinaria..

¿Se pueden soldar aleaciones de zinc??

El contenido de investigación proporcionado no menciona si las aleaciones de zinc se pueden soldar.. Detalla su adaptabilidad a procesos de fabricación como la fundición a presión., Mecanizado CNC, y conformado en frío.

¿La fundición a presión de zinc es buena para uso en exteriores??

Sí, La fundición a presión de zinc es adecuada para uso en exteriores debido a su resistencia superior a la corrosión.. Esta cualidad proporciona una excelente durabilidad frente a factores ambientales., especialmente en comparación con alternativas como el aluminio y el acero mecanizado.

¿Cuál es el punto de fusión del zamak? 3?

El contenido de la investigación afirma que el zinc tiene un punto de fusión bajo de aproximadamente 419,5°C.. Esta característica contribuye a su rentabilidad en la fundición a presión al extender significativamente la vida útil de las herramientas del molde..