Q235 स्टील क्या है और यह स्ट्रक्चरल इंजीनियरिंग में क्यों महत्वपूर्ण है

Q235 स्टील एक चीनी मानक कार्बन संरचनात्मक स्टील है (जीबी/टी 700) अपनी ताकत के संतुलन के लिए व्यापक रूप से पहचाना जाता है, लचीलापन, और लागत दक्षता. अमेरिका में ASTM A36 से तुलनीय. और यूरोप में S235JR, यह निर्माण ढांचे के लिए एक लोकप्रिय विकल्प है, पुलों, और मशीनरी भागों. इंजीनियरों के लिए, चीनी आपूर्तिकर्ताओं या एशियाई सामग्रियों से जुड़ी वैश्विक परियोजनाओं के साथ काम करते समय Q235 स्टील को समझना आवश्यक है. वन-स्टॉप कास्टिंग निर्माता के रूप में, आइए एक इंजीनियर के दृष्टिकोण से Q235 स्टील की जांच करें और पता लगाएं कि यह दुनिया भर में आधुनिक संरचनात्मक डिजाइन को आकार क्यों दे रहा है.

Q235 इस्पात संरचना और यांत्रिक गुणों की व्याख्या

Q235 कार्बन स्टील का प्रदर्शन काफी हद तक इसकी Q235 स्टील रासायनिक संरचना और यांत्रिक गुणों से निर्धारित होता है. इसके प्राथमिक मिश्रधातु तत्वों में कार्बन शामिल है (सी), सिलिकॉन (और), मैंगनीज (एम.एन.), फास्फोरस (पी), और सल्फर (एस). प्रत्येक तत्व स्टील की ताकत को प्रभावित करता है, लचीलापन, जुड़ने की योग्यता, और समग्र कार्यशीलता:

| तत्व | विशिष्ट रेंज (%) | सामग्री प्रदर्शन में भूमिका |

| कार्बन (सी) | ≤0.22 | कठोरता और तन्य शक्ति को नियंत्रित करता है; कम कार्बन वेल्डेबिलिटी में सुधार करता है |

| सिलिकॉन (और) | ≤0.35 | ताकत और लोच बढ़ाता है |

| मैंगनीज (एम.एन.) | 0.30–0.70 | कठोरता और कठोरता में सुधार करता है |

| फास्फोरस (पी) | ≤0.045 | छोटी मात्रा ताकत बढ़ाती है लेकिन अत्यधिक P लचीलापन कम कर देता है |

| गंधक (एस) | ≤0.050 | मशीनेबिलिटी में सुधार करता है लेकिन अधिक होने पर कठोरता को कम कर सकता है |

यंत्रवत्, Q235 स्टील लगभग उपज क्षमता प्रदान करता है 235 एमपीए, 370-500 एमपीए की तन्य शक्ति सीमा, और का बढ़ाव 20% या ग्रेड के आधार पर उच्चतर. ये पैरामीटर इसे उन घटकों के लिए उपयुक्त बनाते हैं जिन्हें स्थिर और गतिशील भार का सामना करना पड़ता है.

इन गुणों को समझने से इंजीनियरों को यह अनुमान लगाने की अनुमति मिलती है कि सामग्री तनाव में कैसे व्यवहार करेगी, गर्मी, या वेल्डिंग या झुकने जैसी निर्माण प्रक्रियाओं के दौरान. सुरक्षा-महत्वपूर्ण संरचनाओं को डिज़ाइन करते समय यह पूर्वानुमेयता आवश्यक है.

वास्तविक परिस्थितियों में भौतिक गुण और प्रदर्शन

रासायनिक और यांत्रिक विशेषताओं से परे, Q235 स्टील के भौतिक गुण इंजीनियरिंग अनुप्रयोगों में महत्वपूर्ण भूमिका निभाते हैं. सामग्री का घनत्व लगभग है 7.85 g/cm³ और निकट थर्मल विस्तार के गुणांक को प्रदर्शित करता है 11.7 × 10⁻⁶ /°C, जो अलग-अलग तापमान के तहत आयामी स्थिरता सुनिश्चित करता है.

Q235 स्टील थर्मल और यांत्रिक स्थिरता यह इसे संरचनात्मक वातावरण में विश्वसनीय रूप से कार्य करने की अनुमति देता है जहां तापमान में उतार-चढ़ाव और चक्रीय भार अपेक्षित होते हैं. इंजीनियर यांत्रिक तनाव के तहत इसके पूर्वानुमानित विरूपण व्यवहार पर भरोसा कर सकते हैं, अप्रत्याशित विफलताओं के जोखिम को कम करना.

इसके अतिरिक्त, पर्यावरणीय कारक जैसे आर्द्रता, संक्षारण क्षमता, और थकान चक्र सामग्री चयन को प्रभावित करते हैं. Q235 का थकान के प्रति मध्यम प्रतिरोध और सामान्य सतह उपचारों के साथ इसकी अनुकूलता इसे उजागर संरचनात्मक घटकों के लिए एक भरोसेमंद विकल्प बनाती है. इसके भौतिक गुणों को समझकर, इंजीनियर सुरक्षा और दीर्घायु बनाए रखते हुए सामग्री के उपयोग को अनुकूलित कर सकते हैं.

Q235 उप-ग्रेड को समझना: ए, बी, सी, और डी

Q235 स्टील को चार उप-ग्रेडों में विभाजित किया गया है: ए, बी, सी, और डी. भेदभाव मुख्य रूप से प्रभाव परीक्षण तापमान और गुणवत्ता मानकों के आसपास घूमता है:

| उप ग्रेड | प्रभाव परीक्षण तापमान | विशिष्ट उपयोग का मामला |

| Q235A | किसी प्रभाव परीक्षण की आवश्यकता नहीं है | कमरे के तापमान पर सामान्य संरचनात्मक अनुप्रयोग |

| Q235B | 20डिग्री सेल्सियस | मानक संरचनात्मक घटक |

| Q235C | -20डिग्री सेल्सियस | ठंड के मौसम में निर्माण और बाहरी अनुप्रयोग |

| Q235D | -40डिग्री सेल्सियस | अत्यधिक ठंडा वातावरण या विशेष परियोजनाएँ |

सही उप-ग्रेड का चयन पर्यावरणीय परिस्थितियों पर निर्भर करता है, लोड आवश्यकताएँ, और सुरक्षा कारक. उदाहरण के लिए, ठंडी जलवायु के लिए Q235C या D बेहतर है, यह सुनिश्चित करना कि स्टील के घटक कम तापमान पर लचीलापन और कठोरता बनाए रखें. उप-ग्रेड को समझने से इंजीनियरों को ओवरडिज़ाइनिंग या सुरक्षा से समझौता किए बिना सामग्री उपयुक्तता के बारे में सूचित निर्णय लेने की अनुमति मिलती है.

Q235 दुनिया भर में स्टील समकक्ष ग्रेड

अंतर्राष्ट्रीय परियोजनाओं के लिए, इंजीनियरों को अक्सर Q235 स्टील समकक्ष सामग्री की पहचान करने की आवश्यकता होती है. विभिन्न क्षेत्र मानकीकृत ग्रेड का उपयोग करते हैं जो इसके गुणों से मेल खाते हैं:

| क्षेत्र | समतुल्य ग्रेड | मानक |

| यूएसए | एएसटीएम ए36 | एएसटीएम ए36/ए36एम |

| यूरोप | एक S235JR | में 10025 |

| जापान | यह SS400 है | वह G3101 |

| जर्मनी | सेंट से 37-2 | से 17100 |

जबकि रासायनिक संरचना और यांत्रिक गुण मोटे तौर पर समान हैं, छोटे-मोटे मतभेद हो सकते हैं. उदाहरण के लिए, स्वीकार्य कार्बन सामग्री या तन्य शक्ति सीमा थोड़ी भिन्न हो सकती है, वेल्डेबिलिटी या विरूपण विशेषताओं को प्रभावित करना. संरचनात्मक अखंडता सुनिश्चित करने के लिए अंतरराष्ट्रीय स्तर पर सामग्री की सोर्सिंग करते समय इंजीनियरों को सावधानीपूर्वक विनिर्देशों की तुलना करनी चाहिए.

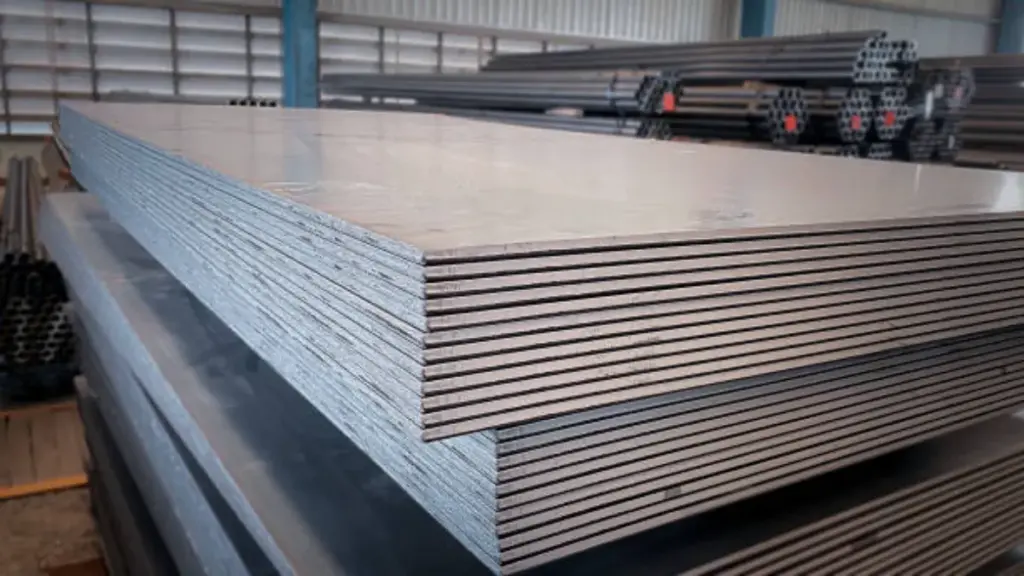

Q235 स्टील के सामान्य रूप और औद्योगिक अनुप्रयोग

Q235 स्टील विभिन्न इंजीनियरिंग अनुप्रयोगों के अनुरूप कई रूपों में उपलब्ध है. आम तौर पर आपूर्ति किए जाने वाले फॉर्म में स्टील प्लेट शामिल हैं, , coils, बार, और संरचनात्मक अनुभाग. प्रत्येक फॉर्म निर्माण आवश्यकताओं के आधार पर अलग-अलग लाभ प्रदान करता है:

- स्टील प्लेट्स - लोड-असर संरचनात्मक घटकों या वेल्डेड ढांचे के लिए आदर्श.

- कॉयल - शीट मेटल बनाने और उच्च मात्रा में उत्पादन के लिए सुविधाजनक.

- बार्स - कंक्रीट संरचनाओं में मशीनिंग या सुदृढीकरण के लिए उपयुक्त.

- संरचनात्मक अनुभाग – किरणें, चैनल, और निर्माण ढांचे के लिए कोण.

स्टील की बहुमुखी प्रतिभा उद्योगों में इसके व्यापक उपयोग की व्याख्या करती है, निर्माण से लेकर औद्योगिक मशीनरी तक. Q235 स्टील ताकत और लागत को संतुलित करता है, इसे उन परियोजनाओं के लिए एक डिफ़ॉल्ट विकल्प बनाना, जिनके लिए विशेष मिश्रधातु या महंगी प्रसंस्करण के बिना विश्वसनीय प्रदर्शन की आवश्यकता होती है.

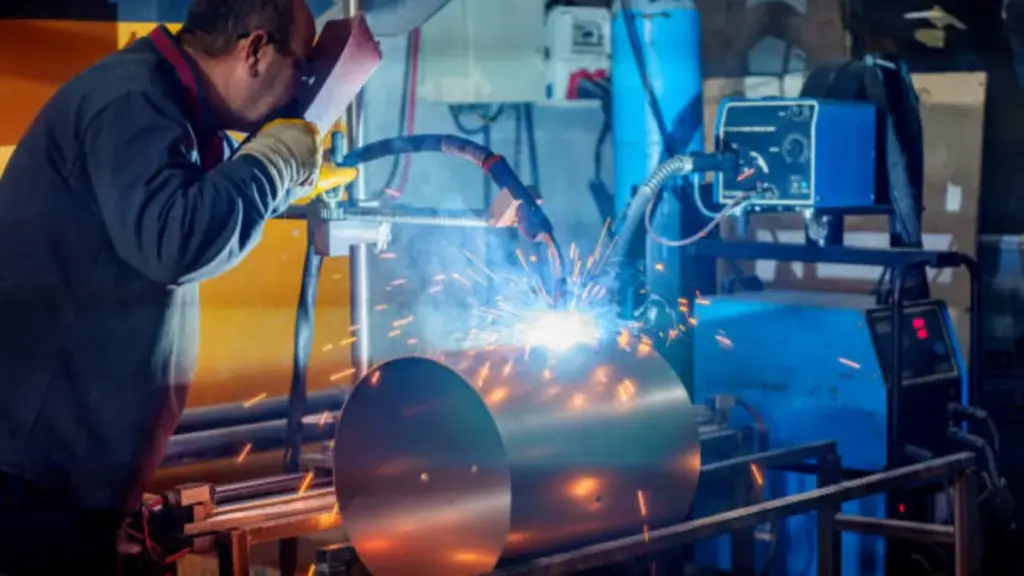

Q235 डिज़ाइनों को वास्तविक भागों में बदलना

जबकि Q235 स्टील संरचनात्मक घटकों के लिए मूलभूत ताकत प्रदान करता है, किसी परियोजना की सफलता विनिर्माण प्रक्रिया की प्रभावशीलता पर निर्भर करती है. धातु कास्टिंग डिज़ाइन को कार्यात्मक भागों में बदलने में महत्वपूर्ण भूमिका निभाता है, विशेष रूप से जटिल ज्यामिति या उच्च परिशुद्धता घटकों के लिए.

कास्टिंग इंजीनियरों को सामग्री वितरण को अनुकूलित करने की अनुमति देता है, जटिल आकार प्राप्त करें, और तनाव के तहत लगातार यांत्रिक प्रदर्शन बनाए रखें. बेस प्लेट जैसे घटक, कोष्ठक, या आवासों को इस दृष्टिकोण से लाभ होता है, खासकर जब वेल्डिंग या मशीनिंग परिवर्तनशीलता ला सकती है.

पर कास्ट की तरह, हम प्रदान वन-स्टॉप मेटल कास्टिंग समाधान स्टील के लिए, अल्युमीनियम, और जिंक मिश्र धातु. हमारी क्षमताओं में शामिल हैं साँचे का डिज़ाइन, परिशुद्धता कास्टिंग, सीएनसी मशीनिंग, सतह समापन, और अधिक. यह एकीकरण सुनिश्चित करता है कि डिज़ाइन या अन्य इंजीनियर घटक टिकाऊ में तब्दील हो जाएं, उच्च परिशुद्धता वाले हिस्से उत्पादन के लिए तैयार हैं. उन्नत विनिर्माण के साथ सामग्री विशेषज्ञता को जोड़कर, इंजीनियर लगातार परिणाम प्राप्त कर सकते हैं और परियोजना जोखिम को कम कर सकते हैं.

अपनी इंजीनियरिंग आवश्यकताओं के लिए सही सामग्री चुनना

किसी भी इंजीनियरिंग परियोजना के लिए उपयुक्त सामग्री का चयन करने के लिए प्रदर्शन में संतुलन की आवश्यकता होती है, लागत, और विनिर्माण क्षमता. Q235 स्टील संरचनात्मक ताकत का संयोजन प्रदान करता है, जुड़ने की योग्यता, और आर्थिक दक्षता, इसे कई अनुप्रयोगों के लिए पहली पसंद का विकल्प बना दिया गया है.

तथापि, इसकी सीमाओं को समझना, पर्यावरणीय संवेदनशीलता या थकान विशेषताओं सहित, जरूरी है. कुछ मामलों में, विशिष्ट डिज़ाइन चुनौतियों के लिए पूरक सामग्री या उन्नत धातु कास्टिंग समाधान अधिक उपयुक्त हो सकते हैं.

जैसे अनुभवी निर्माता के साथ साझेदारी कास्ट की तरह यह सुनिश्चित करता है कि इंजीनियर इष्टतम प्रदर्शन प्राप्त करने के लिए भौतिक गुणों और विनिर्माण क्षमताओं दोनों का लाभ उठा सकते हैं. क्या Q235 स्टील समकक्ष सामग्री या अन्य मिश्र धातुओं का उपयोग किया जा रहा है, व्यापक योजना और सटीक निर्माण एक कार्यात्मक डिजाइन और दीर्घकालिक संरचनात्मक सफलता के बीच अंतर करते हैं