O lugar onde a precisão combina estética com praticidade

Esteja você familiarizado com técnicas de fundição sob pressão ou não, nosso r&D equipes o ajudam desde o início - projeto de molde. Guiado & ASSISTIDO POR DFM & Ferramenta de fluxo de molde, nossas equipes oferecem os desenhos técnicos mais especializados. Nossa análise DFM é fornecida gratuitamente!

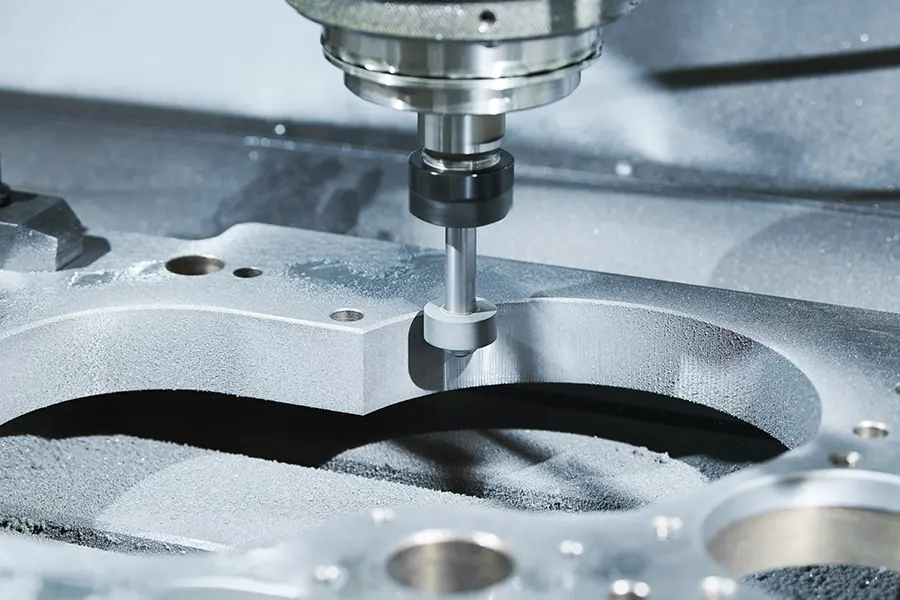

Ao contrário das fábricas normais que fazem apenas o trabalho de fundição sob pressão para você, Bian Diecast está totalmente equipado - você pode realizar seu projeto em um só lugar! Fundição sob pressão, Usinagem CNC & Terminando em uma parada. Nosso objetivo é economizar seus custos e melhorar a eficiência no processo.

Valorizamos muito suas obras de arte de design e estamos abertos a assinar NDAs mediante sua solicitação. Adicionalmente, podemos fornecer arquivos certificados para peças automotivas, incluindo PPAP, APQP, FMEA, MSA, e CEP, para nossos produtos fundidos.

Nosso serviço é detalhado, até a embalagem. Você pode escolher a embalagem ideal – sacos plásticos de bolhas, caixas de papelão, molduras de plástico, divisórias, e muito mais – para atender às necessidades do seu produto. Também podemos acomodar rapidamente a impressão do logotipo ou outras solicitações personalizadas na embalagem. Basta perguntar!

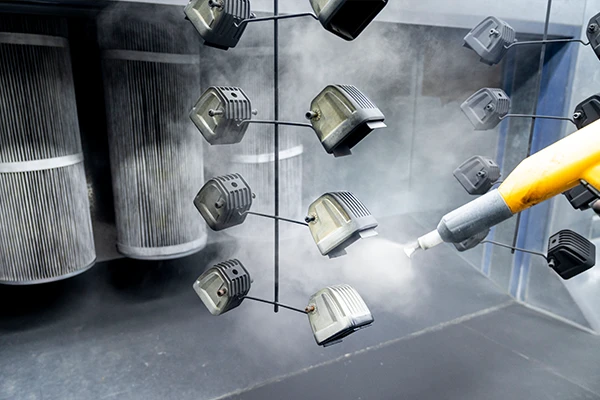

O acabamento da superfície é uma etapa crucial no processo de fabricação que aprimora a aparência, durabilidade, e funcionalidade dos componentes de metal fundido. Em Bian Diecast, Oferecemos uma gama abrangente de serviços de acabamento de superfície de metal para atender às diversas necessidades de nossos clientes em vários setores.

Escolhendo os processos de tratamento de superfície apropriados, Os clientes podem melhorar a competitividade de seus produtos no mercado. O acabamento da superfície fundido de alta qualidade pode aumentar o apelo visual de um produto, ajudando a se destacar em um mercado competitivo.

Em Bian Diecast, Suas peças de alumínio fundido personalizado podem se beneficiar de um serviço único, eliminando a necessidade de você investir e manter equipamentos e instalações de tratamento de superfície. Você não terá que passar pelo aborrecimento de procurar outro fabricante com serviços de tratamento de superfície.

Através do controle rigoroso do processo, seleção de materiais, e treinamento de funcionários, Garantimos que cada etapa do processo de acabamento da superfície atenda aos padrões de alta qualidade. Isso garante que seus produtos fundidos tenham aparência e desempenho consistentes, Atendendo às suas especificações de projeto.

Ajudamos os clientes em análise econômica, Garantir que os requisitos de qualidade sejam atendidos sem despesas desnecessárias. Considere o ROI de longo prazo, Como alguns tratamentos podem aumentar os custos iniciais, mas economizam despesas com o ciclo de vida de um produto.

Bian Diecast, uma empresa de fundição de alumínio, está localizado no distrito de Nanhai, Cidade de Foshan, China. Com mais de uma década de experiência em fundição sob pressão, estamos comprometidos em fornecer serviços abrangentes de fundição sob pressão. Além do projeto e desenvolvimento de moldes especializados, temos uma fábrica avançada e oficinas que integram fundição sob pressão, Usinagem CNC de precisão, e serviços de acabamento de superfície, atendendo a diversas necessidades em vários setores.

Atualmente, acumulamos anos de experiência de serviço no automotivo, iluminação, eletrônicos, mobília, e indústrias de construção. Com uma base sólida em gerenciamento de projetos, pretendemos nos tornar um fornecedor estratégico para muitas marcas globais de renome.

Os serviços de acabamento desempenham um papel crucial na melhoria da qualidade geral e aparência das peças fundidas. Eles são essenciais para alcançar o acabamento superficial desejado, textura, e cor, Tornando as peças mais visualmente atraentes. Além disso, Processos de acabamento aumentam a resistência à corrosão e a resistência ao desgaste dos componentes de fundação, garantindo que eles possam suportar condições ambientais duras e uso prolongado. Removendo quaisquer imperfeições e arestas, Os serviços de acabamento contribuem para dimensões precisas e tolerâncias apertadas, Fazendo as peças funcionarem perfeitamente em seus aplicativos pretendidos.

Várias opções de acabamento estão disponíveis para peças fundidas, atendendo a uma estética diferente, funcional, e requisitos ambientais. Alguns dos métodos de acabamento mais comuns incluem revestimento em pó, anodização, revestimento, pintura, e usinagem CNC. A escolha do método de acabamento depende das necessidades específicas e dos resultados desejados para peças fundidas.

Sim, Os serviços de acabamento podem estender significativamente a vida útil das peças fundidas em condições exigentes. Opções como anodização e revestimento em pó fornecem resistência excepcional à corrosão, produtos químicos, e exposição UV, tornando -os ideais para peças expostas a ambientes severos.

Selecionar o método de acabamento certo depende de fatores como o uso pretendido da parte, aparência desejada, e condições ambientais. Nossos especialistas podem fornecer orientação com base em seus requisitos específicos, garantindo que você escolha a opção de acabamento mais adequada para o seu projeto.

Solicitar uma cotação é fácil. Basta entrar em contato com nossa equipe com os detalhes do seu projeto, incluindo o tipo de peças, quantidade, Método de acabamento desejado, e quaisquer requisitos específicos. Forneceremos prontamente uma cotação abrangente adaptada às suas necessidades.

O revestimento em pó fornece peças de molde com um durável, Acabamento resistente à corrosão. Ele também oferece uma ampla gama de opções de cores.

A anodização é um processo de acabamento valioso para aprimorar as propriedades dos componentes do chast, particularmente ao lidar com peças de alumínio. Veja como a anodização contribui para melhorar o desempenho e a estética:

– Resistência à corrosão: Anodizando forma uma camada de óxido controlado na superfície do alumínio, Selando -o efetivamente de fatores ambientais. Esta camada de óxido atua como uma barreira, Aumentar significativamente a resistência à corrosão da parte do molde.

– Melhoria estética: A anodização fornece peças de alumínio fundido com um acabamento atraente e uniforme. O processo oferece

Sim, Oferecemos soluções de acabamento personalizáveis para atender aos seus requisitos específicos.