Precision Die-Casting, Perfected: See what meticulous tests we've adopted to elevate quality

Quality Control Overview

Our Quality Control Measures

Our workshops are equipped with comprehensive sets of facilities from die-casting to final inspection. We will conduct a comprehensive range of quality tests to ensure that the die-cast products meet your specific requirements and standards.

Precise Inspection:

Testing Expertise:

Stringent Quality Tests Deliver Products That Exceed Expectations

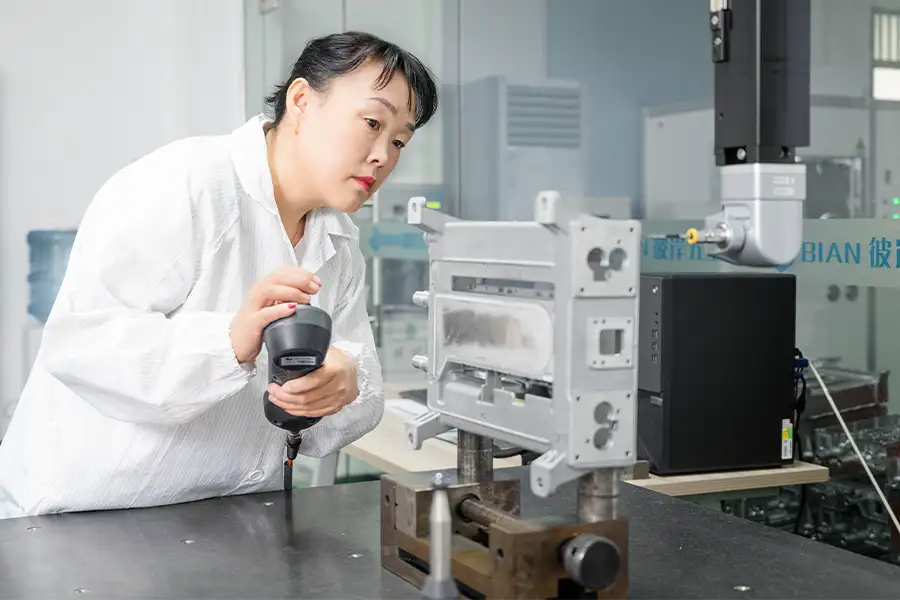

Coordinate Measuring Machine (CMM)

For precision dimension measurement.

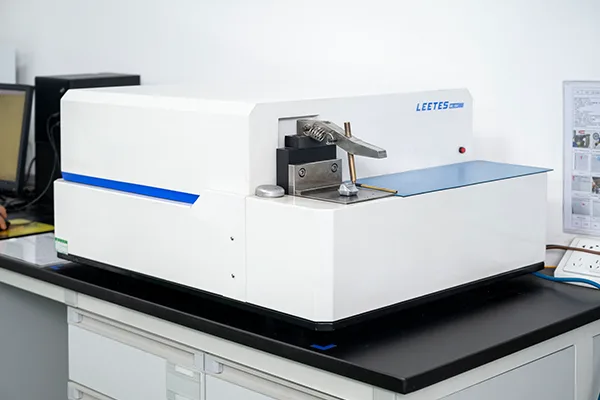

Direct Reading Spectrometer

Material composition analysis.

Electronic Density Meter

Measuring the density of materials used in the die-casting process.

X-ray Non-Destructive Testing System

Internal porosity inspection.

Air-Tightness Testing Equipment Vacuum Chamber Helium Leak Detection Device

Product air-tightness inspection.

Cleanliness Scanning Analyzer

A precision instrument used to inspect and assess the cleanliness and quality of surfaces.

Friction and Scratch Tester CS-10F

It's a friction and scratch tester used for evaluating material durability and surface quality.

Maximum Thread Failure Torque Testing

Corrosion resistance testing.

Alcohol & Rubber Friction Testing Machine

Surface coating wear resistance testing.

Colorimeter

Coating color difference detection.

Film Thickness Gauge

Coating thickness measurement.

Paper Strip Abrasion Tester

Designed to assess the wear resistance of materials, particularly paper products.

2.5D Measurement Instrument

Used for precise measurements in manufacturing and quality control, combining 2D data with depth or height information.

World-class Quality Certifications & Expertise Offer Sound Guarantees

RoHS (Restriction of Hazardous Substances) 2.0 Compliance:

Our materials meet the stringent requirements of RoHS 2.0, ensuring that they are free from hazardous substances.

RoHS (Restriction of Hazardous Substances) 2.0 Compliance:

Our materials meet the stringent requirements of RoHS 2.0, ensuring that they are free from hazardous substances.

RoHS (Restriction of Hazardous Substances) 2.0 Compliance:

Our materials meet the stringent requirements of RoHS 2.0, ensuring that they are free from hazardous substances.

Mechanical Performance Reports:

Our materials undergo rigorous testing to ensure they meet required mechanical performance standards.

Physical Performance Reports:

These reports detail the physical properties of our materials, helping you choose the right material for your needs.

Halogen (Halogens) Reports:

We provide information about the halogen content in our materials, important for specific applications.

Our Quality Methodologies and Tools Boost Manufacturing Excellence

PPAP (Production Part Approval Process):

Ensures our production process consistently meets your specifications, ensuring product quality.

APQP (Advanced Product Quality Planning):

Proactively identifies and mitigates issues in product development, ensuring top-notch quality.

FMEA (Failure Modes and Effects Analysis):

Helps us foresee and address potential issues, ensuring product reliability.

MSA (Measurement System Analysis):

Guarantees accurate measurements, underpinning product quality.

SPC (Statistical Process Control):

Ensures our production process consistently meets your specifications, ensuring product quality.