In the global manufacturing ecosystem, while many associate mold manufacturing purely with plastics, the highest-value applications often lie in metal.

This guide will compare processes, breaking down costs, and detailing exactly what you should look for in a partner.

What is Industrial Mold Manufacturing?

At its core, industrial mold manufacturing is the engineering discipline of creating a negative cavity—typically from hardened steel—that shapes molten material into a final component.

Procurement managers and engineers must differentiate between two core technologies:

- Injection Molds (Plastic): These molds shape thermoplastics (like ABS, Polycarbonate).

- Die Casting Molds (Metal): Engineers design these molds to withstand the extreme thermal shock and high-pressure injection of molten metals (Aluminum, Zinc, Magnesium).

Why this matters

While injection molding holds the largest market share by volume, die casting molds are the backbone of high-strength industries. In sectors like automotive (EV battery housings), aerospace, and heavy electronics, plastic simply cannot provide the EMI shielding, thermal conductivity, or structural integrity required. If your project demands metal, you are looking for a Die Casting Mold Manufacturer, not a generic injection molder.

Injection Molding vs. Die Casting: Which Mold Do You Need?

The right process is determined by your part’s function and material requirements. The following comparison highlights why metal die casting is the superior choice for structural components.

| Feature | Injection Molding (Plastic) | Die Casting (Metal) |

| Primary Material | Resins (ABS, PP, Nylon) | Non-ferrous Alloys (Aluminum, Zinc, Magnesium) |

| Process Temperature | ~200°C – 300°C | ~400°C (Zinc) to ~700°C (Aluminum) |

| Mold Material | Aluminum or Steel (P20, NAK80) | Premium Hot-Work Steel (H13, SKD61) |

| Part Strength | Low to Medium | High (Structural Integrity) |

| Typical Application | Consumer packaging, toys, enclosures | Engine blocks, heatsinks, rigid frames |

| EMI Shielding | Requires conductive coating | Inherent (Natural property of metal) |

Key Takeaway: If your part needs to dissipate heat, shield electronics, or carry a load, you need a Die Casting Mold.

The Step-by-Step Industrial Mold Manufacturing Process

Creating a production-grade industrial mold is not a simple “print” job. It is a sequence of subtractive manufacturing processes that demand micron-level precision.

Step 1: DFM Analysis & Mold Design

Before steel is cut, engineering teams perform a Design for Manufacturability (DFM) analysis. Using mold flow simulation software, engineers predict how molten metal will fill the cavity, identifying potential “air traps” or “cold shuts.” This digital twin stage is where 90% of potential production failures are prevented.

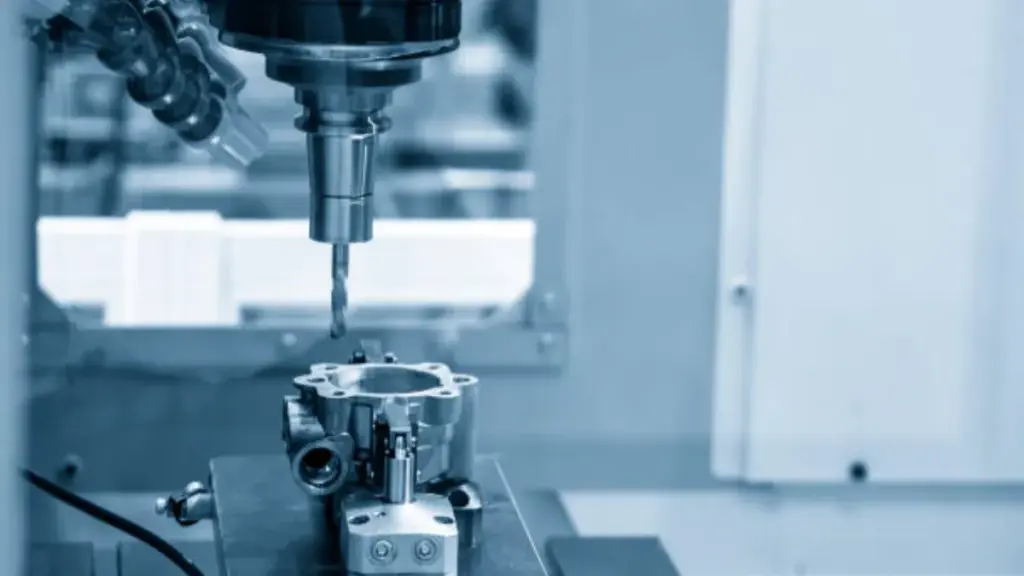

Step 2: CNC Machining & EDM (Electrical Discharge Machining)

This is the heart of mold creation.

- CNC Machining: High-speed milling centers carve the rough shape of the mold core and cavity from a block of steel.

- EDM: For intricate details—like deep ribs or sharp corners that a spinning cutter cannot reach—an electrode is used to “spark” the metal away. This process is essential for achieving precise geometries in hardened steel.

Step 3: Heat Treatment

Die casting molds face violent thermal cycles. To prevent “heat checking” (surface cracking), the H13 steel mold undergoes vacuum heat treatment, hardening it to HRC 42-48. This ensures the mold can withstand tens of thousands of shots without deforming.

Step 4: Mold Assembly & T1 Trial

The final components (cores, slides, ejector pins) are assembled by master fitters. The mold is then mounted onto a die casting machine for its first “shot” (T1 Sample). This is the moment of truth where the physical part is verified against the CAD design.

Key Design Standards (DFM) for Industrial Molds

To ensure your mold runs efficiently and produces defect-free parts, three critical design parameters must be respected.

- Draft Angles: Unlike a 3D print, a molded part must physically slide out of the steel tool. Vertical walls require a “draft”—a slight taper (typically 1° to 3°). Without this, the part will drag against the mold surface during ejection, causing “galling” or sticking.

- Wall Thickness: Consistency is king. In die casting, varying wall thicknesses cause uneven cooling. Thick sections cool slower, leading to shrinkage porosity (internal voids). Maintaining a uniform wall thickness (e.g., 2.5mm – 4mm for aluminum) ensures the metal solidifies evenly.

- Cooling Channels: A mold is essentially a heat exchanger. Strategic cooling lines drilled through the steel are vital for regulating temperature. Efficient cooling reduces cycle time (saving money) and prevents part warpage.

How to Choose a Reliable Industrial Mold Manufacturer?

Sourcing a mold manufacturer is a strategic investment. Do not rely solely on the lowest quote; verify their capabilities using this checklist.

- Certifications: Ensure the factory holds ISO 9001 (Quality Management) at a minimum. For automotive parts, IATF 16949 is non-negotiable, as it indicates strict adherence to process control and traceability.

- Equipment List: Request a verified equipment list. A true manufacturer will have in-house CNC centers and EDM machines. Many “manufacturers” are actually trading companies that outsource tooling. In-house tooling means faster repairs and tighter control over the schedule.

- Transparency: Will they provide a T1 trial video? A reliable partner will happily share footage of the mold running and the first parts being ejected. This transparency proves the mold exists and works as promised.

Why Bian Diecast is Your Premier Partner for Aluminum Die Casting

At Bian Diecast, we understand that you aren’t just buying a mold. You are investing in a production capability.

- One-Stop Solution: We streamline the entire supply chain. From the initial mold design and flow analysis to high-pressure die casting, precision CNC machining, and final surface finishing, we handle every step under one roof.

- Global Presence: Uniquely, we offer the cost advantages of manufacturing in our China Factory combined with the logistical flexibility of our Mexico Factory. This dual-shore strategy mitigates supply chain risks for North American clients.

- Experience: With decades of specialized experience in aluminum and zinc alloys, we don’t just build molds, we engineer production solutions that last.

FAQs About Industrial Mold Manufacturing

1. How long does it take to manufacture an industrial mold?

Typically, a production-grade die casting mold requires 4 to 6 weeks for manufacturing (T1 samples). Complex molds with multiple slides may take up to 8 weeks.

2. What is the lifespan of a die casting mold?

Mold life depends on the steel and maintenance. A quality H13 steel mold for aluminum die casting typically lasts 50,000 to 100,000 shots. Regular maintenance can extend this lifespan.

3. Can you modify the mold after it is made?

Yes, but it is limited. Removing metal (to add material to the part) is easy—”steel safe.” However, adding metal back to the mold (to remove material from the part) requires welding and re-machining, which is costly and can compromise mold integrity. This is why DFM is critical.