Workshops

Die Casting Service in One Place

Aluminum Die Casting Workshops Overview

Bian Diecast serves as your premier one-stop aluminum die casting factory. With a diverse array of die cast machinery, we cater to various industries, including automotive, lighting, electronics, furniture, construction, etc. Take a tour of our comprehensive workshops, encompassing mold design, CNC centers, polishing & surface treatment, and inspection.

Molding Workshop

Molding Design

Mold Storage

Aluminum High Pressure Die Casting Worshop

| 1250T Die Casting Machine | 900T Die Casting Machine | 800T Die Casting Machine |

| 500T Die Casting Machine | 400T Die Casting Machine | 300T Die Casting Machine |

We serve multiple industries, including automotive, lighting, electronics, furniture, and construction. Our daily production reaches up to 2000 to 3000 castings, delivering innovation and dedication in every piece.

CNC Machining Workshop

| 3-axis CNC machine: These machines can move along the X, Y, and Z axes. |

| 4-axis CNC machine: These machines have the capability to move along the X, Y, Z axes, plus an additional rotary axis (often referred to as the A-axis). |

| 5-axis CNC machine: These advanced machines can move along all three linear axes (X, Y, Z) and has two additional rotary axes (A and B or A and C). |

CNC Milling Machine

CNC milling workshop is equipped with milling machines used for flat milling, contour milling, hole drilling, and other operations. It is commonly employed in the production of parts such as flats, grooves, holes, and continuous threads.

CNC Turning Machine

The CNC turning workshop features lathes used for rotational machining, including external contour machining, end-face machining, and thread machining. It is frequently used for processing components like shafts.

Wire EDM Machining

Wire EDM machining, also known as wire-cut electrical discharge machining, is an electrothermal cutting process. Compared to traditional mechanical cutting methods, Wire EDM machining offers higher precision and surface quality, and it can handle more complex geometric shapes.

Polishing Workshop

| Polishing |

Machine Polishing

Machine polishing offers a highly efficient and cost-effective solution for finishing die-cast parts. This automated process is particularly well-suited for larger and less complex models, where consistency and speed are essential.

Manual Polishing

Manual polishing is the preferred method when intricate detailing and a meticulous finish are paramount. This method is particularly effective for complex and delicate parts that require a human touch to improve quality.

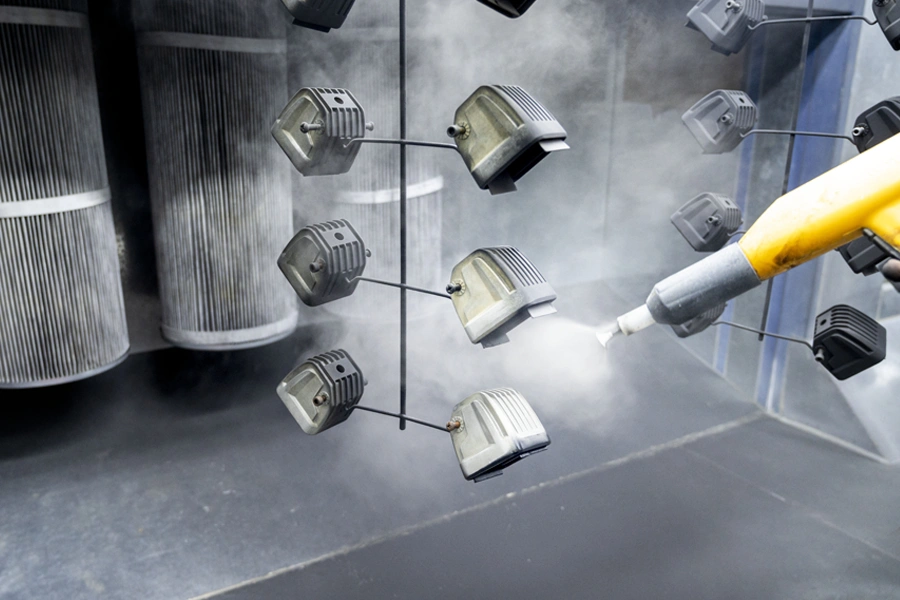

Surface Treatment Workshop

Powder coating

Powder coating is a method of applying a dry powder to a surface, which is then heated to create a durable and protective coating. It is widely used for its corrosion resistance and decorative qualities.

Lacquer Coating

Lacquer coating involves applying a clear or colored lacquer to a surface to provide protection and a glossy finish. It is often used in woodworking and automotive applications.

Sand Blasting

Sand blasting is a surface preparation technique that uses abrasive materials propelled at high velocity to remove rust, paint, or contaminants from a surface. It is commonly used in cleaning and preparation processes.

Shot Blasting

Shot blasting is a similar process to sand blasting, but it uses small metallic particles (shots) instead of abrasive sand. It is often used for cleaning, deburring, and preparing surfaces for coatings.

Anodizing

Anodizing is an electrochemical process that enhances the corrosion resistance and appearance of metals like aluminum. It creates a protective oxide layer on the metal’s surface, which can be colored for decorative purposes.

Inspection Workshop

Coordinate Measuring Machine (CMM)

For precision dimension measurement.

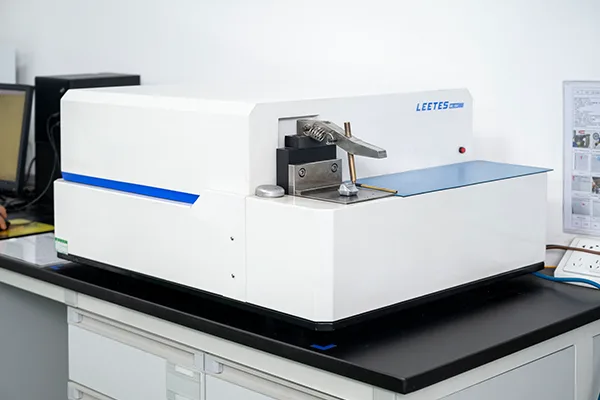

Direct Reading Spectrometer

Material composition analysis.

Electronic Density Meter

Measuring the density of materials used in the die-casting process.

X-ray Non-Destructive Testing System

Internal porosity inspection.

Air-Tightness Testing Equipment Vacuum Chamber Helium Leak Detection Device

Product air-tightness inspection.

Cleanliness Scanning Analyzer

A precision instrument used to inspect and assess the cleanliness and quality of surfaces.

Friction and Scratch Tester CS-10F

It's a friction and scratch tester used for evaluating material durability and surface quality.

Maximum Thread Failure Torque Testing

Corrosion resistance testing.

Paper Tape/Alcohol & Rubber Friction Testing Machine

Surface coating wear resistance testing.

Film Thickness Gauge

Coating thickness measurement.

Colorimeter

Coating color difference detection.

Paper Strip Abrasion Tester

Designed to assess the wear resistance of materials, particularly paper products.

2.5D Measurement Instrument

Used for precise measurements in manufacturing and quality control, combining 2D data with depth or height information.