Aluminum Die Casting Services at One Stop

Boost your business with high quality services

Fulfill your aluminum die casting needs at Bian Diecast’s premier manufacturing facility in China, as well as at our Mexican die-casting factory.

At Bian Diecast, We specialize in crafting high-quality die casting aluminum housing components and custom die cast parts.

- Efficiency & Cost-saving Solution

- Mold Design & Design Analysis

- Precision CNC Machining

- Stringent Quality Control & Tests

- China Die Casting Leader

- Supports Complex Design

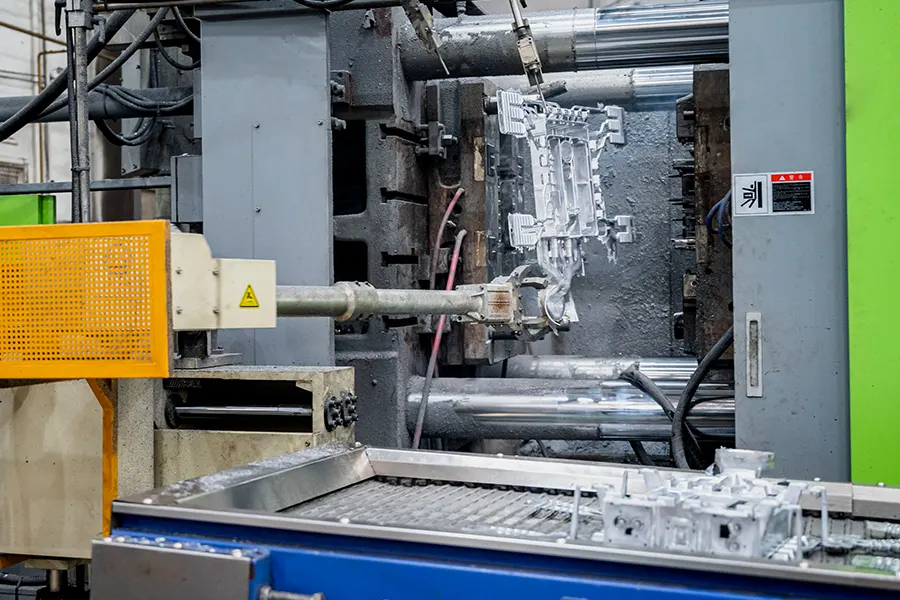

Our Die-casting Machines & Facilities

Customized Service

- Custom Drawing

- 2D to 3D or 3D to 2D,According to the Customer's Draft to Make Production Drawings

- Review and Do Production Feasibility Analysis

- Offer Suggestions or Modification to Customer

- Customer Approval and Manufacturing as Updated Drawing

Send Us Your Request

Bian Diecast provides comprehensive assistance for your project, starting from mold design and extending to surface finishing services.

Take a Tour of High Quality Aluminum Die Casting Process

- Mold design

- Casting preparation

- Injection

- Cooling and solidfication

- Demolding / removal

- CNC machining / surface treatment

Aluminum Die Casting Capabilities Suitable for Projects of All Sizes

Our aluminum high-pressure die casting workshop sets us apart with a range of advanced machines from 88T to 1250T.

- Daily yield reaches up to 2,000~3,000 castings.

- The largest casting area reaches 3125cm².

| 1250T Die Casting Machine | 900T Die Casting Machine | 800T Die Casting Machine |

| 500T Die Casting Machine | 400T Die Casting Machine | 300T Die Casting Machine |

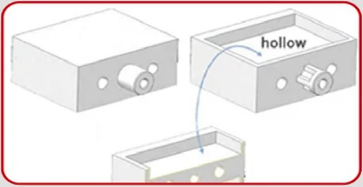

Supports Complex Design

No matter how intricate or shapely your design may be, you can create a complex design with close tolerance through aluminum die casting.

This means that the final product is guaranteed to match your design specifications.

- Reduce production costs

- Enhance mold and die cast products' quality

- Ensure precision and efficiency at every stage of your project

Cutting-edge technologies & skilled workforce

We carry out our production with cutting-edge technologies and equipment. We are keen on quality, hence, we employ first-rate machinery in our manufacturing process.

We have about 80 skilled and experienced workforce, with sufficient industry experience. Given the expertise of our professionals, be assured that we will supply high-quality custom products that suit your specifications.

Customized mold making & Low-cost Mold Design

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days.

Our expert team provides Design for Manufacturability (DFM) services to our clients. We collaborate on designs to ensure efficient production, reducing costs and time to market.

Molding Workshop

Molding Design

Mold Storage

we help reduce your die casting cost

Bian Diecast provides comprehensive assistance for your project, starting from mold design and extending to surface finishing services. Don’t hesitate to get in touch with us!

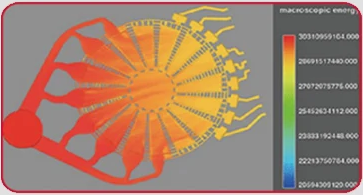

Starting from mold flow analyzing

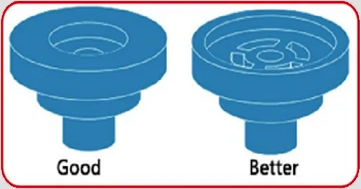

Reduce weight and save material costs

Reduce wall thickness to lower the costs

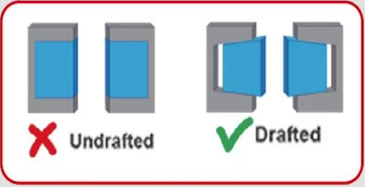

Considering draft to simplify tool manufacturing

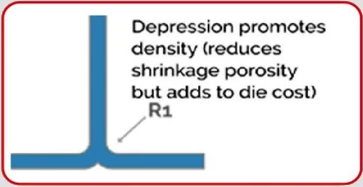

Factor in fillet RADII to avoid stress concentrations

Improving part strength with ribs webs

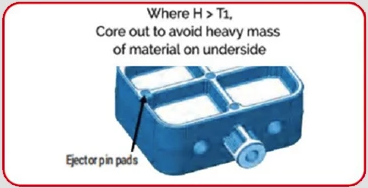

Factor in ejector pins

Avoiding thread misalignment

Common Die-cast Aluminum Alloys

- ADC12

- ADC10

- DC1

- A360

- A380

- YL102

- LM6

EU Grade Aluminum Alloy Materials

- ENAC 44300(AISI12(FE))

- ENAC-47100

- ENAC-46000

High Thermal Conductivity Alloy Materials

- AlSI8

- LHB1

Get Instant Quote Today!

One-stop assistance for your project, including mold design, die casting, CNC machining, & surface finishing services.

About Bian Diecast

Aluminum Die Casting Company

Currently, we have accumulated years of service experience in the automotive, lighting, electronics, furniture, and construction industries. With a solid foundation in project management, we aim to become a strategic supplier to many renowned global brands.

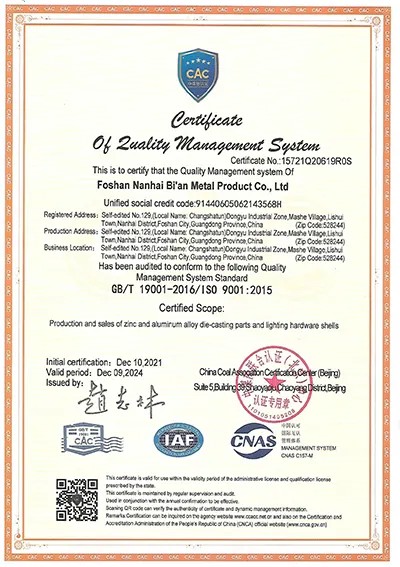

Our Quality Control Measures

Our workshops are equipped with comprehensive sets of facilities from die-casting to final inspection. We will conduct a comprehensive range of quality tests to ensure that the die-cast products meet your specific requirements and standards.

Precise Inspection:

Testing Expertise:

High-efficiency

Our advanced machines such as CNC, machine your die casting parts from the very beginning to necessary post-machining.

Rapid Turnaround

Combing our moulding expertise, skilled workers and fine equipment, parts are delivered to you in as fast as 2 weeks.

Durable and Stable Parts

Die casting parts produced under high pressure are of corrosion resistance. Your mold or part can be from 500 to 10,000 shot life.

Quality Control

Producing quality parts is our top priority. We comply to quality control standards at every step. Each part is meticulously machined for you.

Easy Assembly

Die casting parts have bosses and studs fastening internal elements. We do necessary machinery work while assembling.

Smooth Surface

Die casting parts have a flat surface without burrs and edges. And CNC machines could help to achieve excellent accuracy and surface smoothness.

Precision CNC Machining Capability

Our CNC machining centers, including 3-axis, 4-axis, & advanced 5-axis CNC machines, capable of precision machining a portfolio of complex & intricate products.

The largest machining dimension is up to 1000cm.

CNC Milling

CNC milling workshop is equipped with milling machines used for flat milling, contour milling, hole drilling, and other operations.

CNC Turning

The CNC turning workshop features lathes used for rotational machining, including external contour machining, end-face machining, and thread machining.

EDM Machining

Compared to traditional mechanical cutting methods, Wire EDM machining offers higher precision and surface quality, and it can handle more complex geometric shapes.

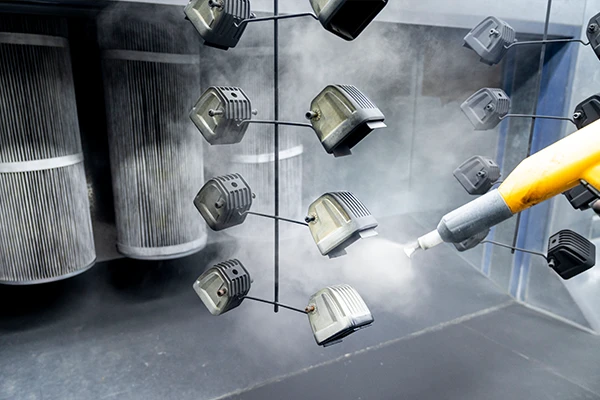

surface finishing service

Polishing

powder coating

lacquer coating

sand blasting

shot blasting

anodizing

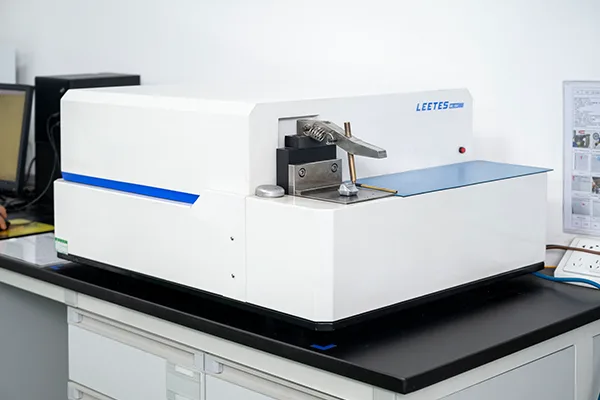

A Full-scale of Meticulous Tests

Direct Reading Spectrometer

Material composition analysis.

Coordinate Measuring Machine (CMM)

For precision dimension measurement.

Electronic Density Meter

Measuring the density of materials used in the die-casting process.

X-ray Non-Destructive Testing System

Internal porosity inspection.

Air-Tightness Testing Equipment Vacuum Chamber Helium Leak Detection Device

Product air-tightness inspection.

Cleanliness Scanning Analyzer

A precision instrument used to inspect and assess the cleanliness and quality of surfaces.

Friction and Scratch Tester CS-10F

It's a friction and scratch tester used for evaluating material durability and surface quality.

Maximum Thread Failure Torque Testing

Corrosion resistance testing.

Alcohol & Rubber Friction Testing Machine

Surface coating wear resistance testing.

Colorimeter

Coating color difference detection.

Film Thickness Gauge

Coating thickness measurement.

Paper Strip Abrasion Tester

Designed to assess the wear resistance of materials, particularly paper products.

2.5D Measurement Instrument

Used for precise measurements in manufacturing and quality control, combining 2D data with depth or height information.

Steps to place an order

Upload Your Files

Available file formats: step, stp, igs, iges, prt, sldprt, sat, x_t

Get a quotation

Specify your parts configuration to get price and lead time.

Manufacturing

On time and quality parts guaranteed by robust manufacturing network.

Shipping

Carefully wrap up the inspected parts and send to your hands.

Custom Aluminum Die Casting Parts

Bian Diecast specializes in crafting high-quality custom die-cast parts for various industries.

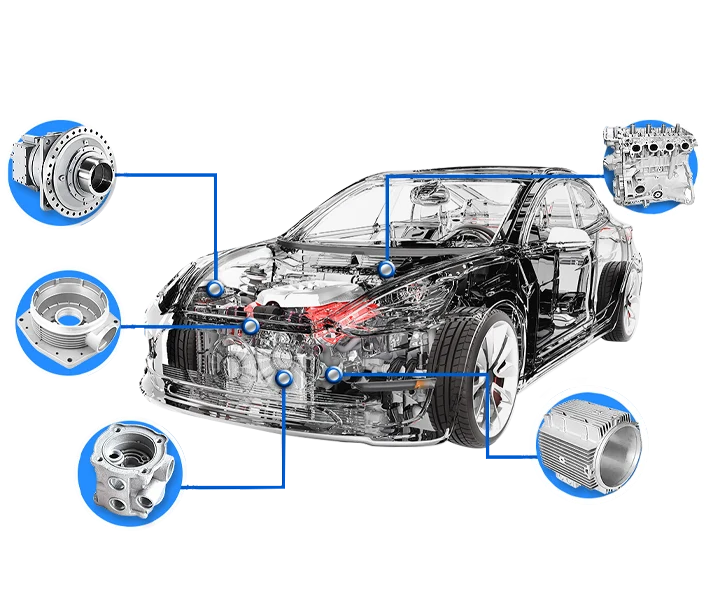

AUTOMOTIVE PARTS

- Engine & chassis parts: Cylinder head, Crankcase, Fuel pump housing, …

- Transmission components: Transfer case,

Clutch housings, Transfer case cover… - Electrical system parts: Battery box, Generator housing, Control module casing…

- Body, interior & exterior parts: Steering wheel cover, Dashboard cover, Handlebar housing…

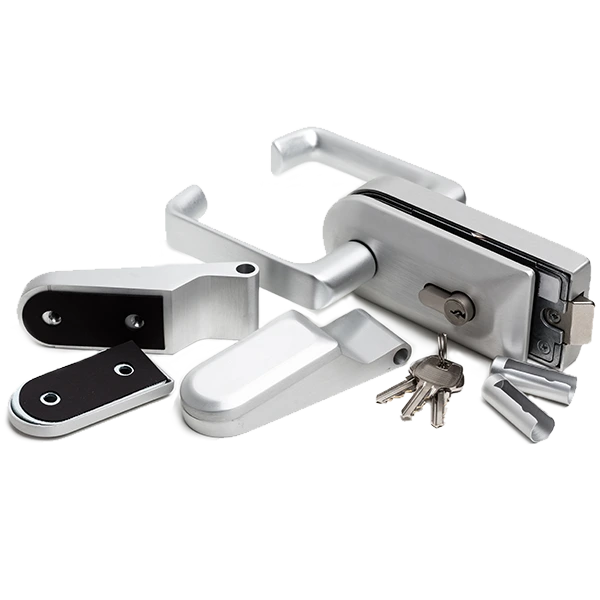

Furniture PARTS

- Engine & chassis parts: Cylinder head, Crankcase, Fuel pump housing, …

- Transmission components: Transfer case,

Clutch housings, Transfer case cover… - Electrical system parts: Battery box, Generator housing, Control module casing…

- Body, interior & exterior parts: Steering wheel cover, Dashboard cover, Handlebar housing…

Get Instant Quote Today!

One-stop assistance for your project, including mold design, die casting, CNC machining, & surface finishing services.

Streamlined Service Capabilities Enhance Your Die Casting Business

Our Clients

Get A Quote for Die Casting Services Today!

-

.No. 128-129, East Industrial Zone,

Mashe East, Lishui Town, Nanhai District, Foshan, Guangdong, China

- Contact:katherine

- Phone:+86 189 4247 5007

- E-mail:Katherine@mag-cast.com

- WhatsApp:+86-159 1863 4657

- Contact:Reno

- Phone:+86 177 9601 9842

- E-mail:sales3@mag-cast.com

- WhatsApp:+86-186 6688 2487