Image source: pexels

Aluminum die casting and sand casting, each method shapes our world in unique ways, from the cars we drive to the gadgets we can’t live without.

But what sets these processes apart? Why choose one over the other?

In this post, we’ll dive into the molten core of die casting vs. sand casting. We’ll explore their strengths, weaknesses, and the industries they’ve revolutionized. Whether you’re an engineer, a business owner, or simply curious about how things are made, this comparison will shed light on the hidden artistry in everyday objects.

Overview of Casting Methods

Aluminum Die Casting

Process Description

- Molten metal is forced into reusable steel molds under high pressure.

- The molds, known as dies, are designed to create intricate shapes accurately and consistently.

- Parts produced have well-defined features and can exhibit smooth or textured surfaces.

Materials Used

- Aluminum: Commonly used due to its lightweight and excellent thermal properties.

- Other Alloys: Zinc, magnesium, and copper-based alloys are also utilized for specific applications.

Advantages

- Precision: Offers high dimensional accuracy and repeatability for complex parts.

- Surface Finish: Provides a range of attractive finishes suitable for various industries.

- Efficiency: Enables the production of parts with minimal post-processing requirements.

Disadvantages

- Initial Cost: Requires investment in tooling and setup for die creation.

- Limited Size: Not ideal for large parts due to mold constraints.

Sand Casting

Process Description

- Involves pouring molten metal directly into sand molds without high pressure.

- Allows for the creation of net shapes within a quarter-inch tolerance level.

- Offers versatility in producing parts with varying complexities.

Materials Used

- Sand Molds: Cost-effective molds that cater to a wide range of part sizes and shapes.

- Metal Alloys: Suitable for casting a variety of metals like iron, steel, aluminum, and bronze.

Advantages

- Versatility: Accommodates larger parts with more flexibility in design changes.

- Cost-Effective Tooling: Requires less initial investment compared to die casting methods.

Disadvantages

- Surface Finish: Results in rougher textures compared to die casting finishes.

- Dimensional Accuracy: May require additional post-casting processes for precision adjustments.

Detailed Comparison

Image source: unsplash

Production Speed and Volume

Aluminum Die casting speed vs. sand casting speed

- Aluminum die casting excels in rapid production, achieving high speeds due to its automated processes.

- Sand casting, although versatile, operates at a slower pace as it involves manual labor in mold design.

Suitability for different production volumes

- Aluminum Die Casting:

- Ideal for high-volume production runs requiring precise dimensional accuracy.

- Suited for components with intricate designs and consistent quality demands.

- Sand Casting:

- More suitable for low to medium production volumes of larger parts.

- Offers flexibility in adapting to varying part sizes without significant tooling adjustments.

Part Complexity and Size

Capabilities and limitations of each method

- Aluminum Die Casting: Excels in producing complex shapes with tight tolerances without the need for extensive post-casting machining.

- Sand Casting: Better suited for large components with less stringent accuracy requirements, allowing for more forgiving design variations.

Typical part sizes for die casting and sand casting

- Die Casting: Specializes in smaller to medium-sized parts that demand precision and thin walls.

- Sand Casting: Accommodates larger parts with thicker walls, ideal for applications prioritizing cost-effectiveness over dimensional precision.

Surface Finish and Dimensional Accuracy

Achievable tolerances

- Aluminum Die Casting:

- Maintains close tolerances even in intricate geometries, reducing the need for secondary operations.

- Sand Casting:

- Tolerances are generally looser due to the nature of the process, often requiring additional finishing steps for precision adjustments.

Surface quality comparisons

- Die cast parts exhibit smoother finishes with finer details compared to sand castings known for their rougher textures.

Material Options

Alloys suitable for die casting

- Aluminum: Widely used in die casting for its lightweight properties and excellent thermal conductivity.

- Zinc: Ideal for intricate parts due to its low melting point and high ductility.

- Magnesium: Offers exceptional strength-to-weight ratio, suitable for lightweight components.

- Copper-based Alloys: Provide enhanced corrosion resistance and thermal conductivity.

Alloys suitable for sand casting

- Iron: Commonly used in sand casting for its cost-effectiveness and machinability.

- Steel: Offers versatility in producing a wide range of part sizes with varying complexities.

- Aluminum: Suitable for sand casting due to its low melting point and good fluidity.

- Bronze: Provides excellent wear resistance, making it ideal for applications requiring durability.

Tooling and Setup Costs

Initial investment for dies vs. sand molds

- Die Casting:

- Requires significant upfront investment in steel molds tailored to specific part designs.

- Initial tooling costs can be higher but offset by long-term benefits of mass production.

- Sand Casting:

- Involves lower initial costs as sand molds are more affordable than steel dies.

- Tooling expenses are minimized, making it a cost-effective option for smaller production runs.

Long-term cost considerations

- Die Casting:

- Long-term savings realized through high-volume production capabilities and minimal material waste.

- Reduced machining requirements contribute to overall cost efficiency over extended production cycles.

- Sand Casting:

- Offers economical solutions for low to medium production volumes with less tooling maintenance costs.

- Flexibility in design changes reduces additional expenses associated with altering mold configurations.

Design Flexibility

Ability to make design changes

- Die casting allows intricate design modifications without extensive tooling adjustments, ensuring quick adaptability to evolving requirements.

- Sand casting provides flexibility in altering part geometries during the mold-making process, accommodating design variations efficiently.

Prototyping capabilities

- Die Casting:

- Enables rapid prototyping of complex parts with precise dimensional accuracy, facilitating efficient testing phases.

- Sand Casting:

- Supports prototype development of larger components with diverse geometries, allowing for iterative design improvements.

Wall Thickness

Minimum achievable thickness for each method

In aluminum die casting, the minimum wall thickness can reach as low as 1mm, allowing for intricate designs with precise details. This method excels in producing thin-walled parts that maintain structural integrity. On the other hand, sand casting typically requires thicker walls, with a minimum thickness of around 3mm due to the nature of the process. The increased wall thickness in sand casting provides more flexibility during production and allows for a forgiving post-casting process to correct any inaccuracies efficiently.

Implications for part weight and strength

When considering aluminum die casting vs sand casting, the wall thickness directly impacts the weight and strength of the final parts. Thinner walls achieved through aluminum die casting result in lighter components without compromising durability. In contrast, sand cast parts with thicker walls tend to be heavier but offer enhanced strength, making them suitable for applications requiring robust structures.

Post-Processing Requirements

Finishing needs for die cast parts

Aluminum die cast parts often require minimal post-processing due to their high dimensional accuracy and smooth surface finishes. However, some finishing touches may be needed to enhance aesthetics or functionality. Common post-processing techniques include deburring, shot blasting, and powder coating to refine the appearance and performance of die-cast components.

Finishing needs for sand cast parts

In sand casting, post-processing plays a crucial role in refining the rough textures inherent to this method. Sand cast parts usually undergo extensive finishing processes such as grinding, sanding, or machining to achieve desired surface qualities and dimensional accuracies. Additional treatments like painting or plating may also be applied to improve the overall look and functionality of sand-cast components.

Environmental Considerations

Energy efficiency

When comparing aluminum die casting vs sand casting from an environmental perspective, energy efficiency is a key factor. Aluminum die casting involves melting metal at high temperatures using significant energy resources. In contrast, sand casting consumes less energy as it does not require intense heating processes. The lower energy consumption in sand casting contributes to reduced environmental impact and operational costs.

Material waste and recyclability

Both aluminum die casting and sand casting generate waste materials during production; however, their recyclability differs significantly. Die-cast scrap can be easily recycled back into new components without compromising quality or performance. On the other hand, sand molds used in sand casting have limited recyclability due to contamination issues from molten metal exposure. Proper waste management practices are essential to minimize environmental impact while maximizing resource efficiency.

Applications and Suitability

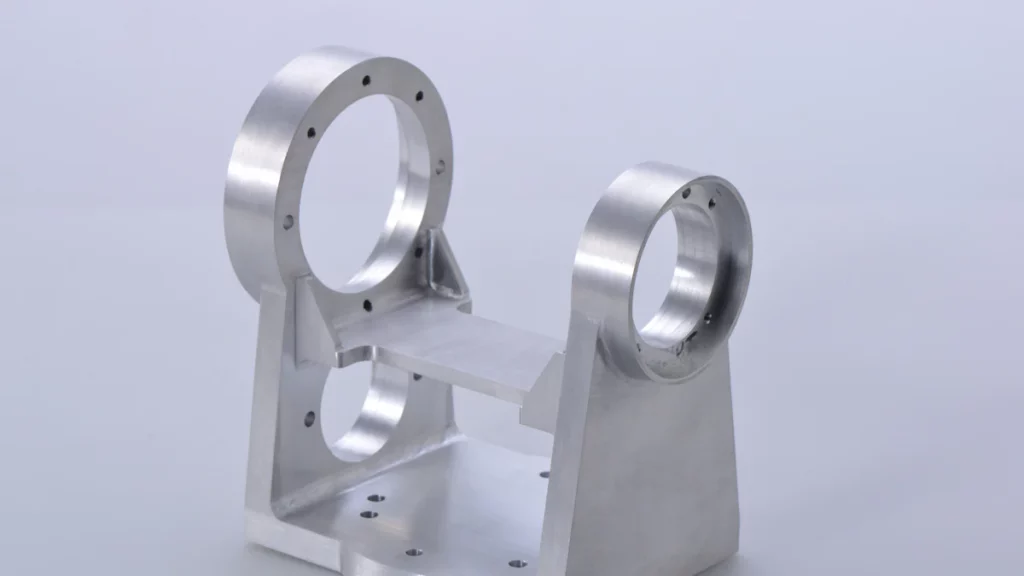

Image source: pexels

Aluminum Die Casting

Ideal Applications

- Manufacturing intricate components with precise geometries.

- Producing lightweight parts with excellent thermal properties.

- Creating high-quality automotive prototypes for testing and validation.

Suitability for Precision Parts

- Ensuring dimensional accuracy in critical components.

- Achieving consistent quality standards for aerospace applications.

- Providing reliable solutions for medical equipment manufacturing.

Sand Casting

Ideal Applications

- Fabricating large-scale industrial machinery components.

- Crafting artistic sculptures and ornamental pieces.

- Developing cost-effective architectural elements for construction projects.

Suitability for Large Parts

- Catering to the production of oversized marine engine parts.

- Constructing durable agricultural equipment components.

- Building structural elements for infrastructure development projects.

The study on Additive Manufacturing for Rapid Sand Casting highlights the mechanical and microstructural investigation of aluminum alloy automotive prototypes, emphasizing the importance of maintaining ductility levels during prototyping phases to enhance component properties effectively. Future research endeavors aim to optimize manufacturing processes further while improving mechanical characteristics to meet evolving industry demands efficiently (Metals, 2024).

Conclusion

When comparing aluminum die casting and sand casting, the key differences lie in production speed, part complexity, and material options. Aluminum die casting excels in precision and surface finish, ideal for intricate components. On the other hand, sand casting offers versatility for larger parts with cost-effective tooling. Based on your application needs, choose die casting for precise geometries and sand casting for large-scale components. Consider the historical significance of sand casting’s origins in ancient China and the rapid advancements in additive manufacturing for aluminum prototypes to make an informed decision on the right casting method.