For procurement and engineering teams, navigating alloy specifications while managing global supply chain risks is a constant high-stakes challenge.

This guide serves as a technical standard operating procedure for specifying, qualifying, and sourcing critical components. We analyze the mechanical and thermal trade-offs between aluminum, magnesium, and zinc alloys for specific applications. We also provide a framework for controlling common defects, mitigating supplier risks with a resilient sourcing strategy, and adapting to new manufacturing trends like giga casting for electric vehicle platforms.

Why Die Casting Dominates Modern Automotive Manufacturing

Die casting provides the essential combination of lightweight strength, high-volume speed, and complex part consolidation that modern vehicle platforms demand.

Achieving Lightweight Strength for Powertrain and Structural Parts

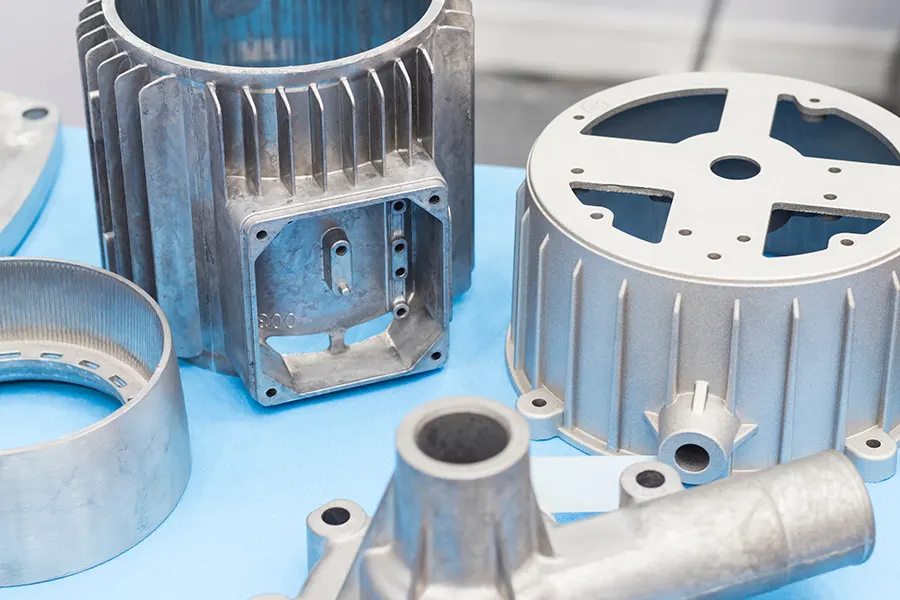

Weight reduction is a primary driver in automotive design, directly impacting fuel economy in internal combustion engines and extending range in electric vehicles. Die casting addresses this by using lightweight aluminum alloys like A380 and ADC12, or even lighter magnesium alloys like AZ91D. The high-pressure process creates components with an exceptional strength-to-weight ratio, making them ideal for mission-critical parts like engine blocks, transmission cases, and structural shock towers. The resulting metal structure is dense and non-porous, delivering superior heat dissipation and EMI shielding—critical properties for protecting sensitive electronics in modern powertrains and EV battery systems.

Enabling High-Volume Production with Low Per-Unit Costs

The automotive industry operates on massive scale, and die casting is engineered for this reality. With rapid cycle times often as short as 10 to 60 seconds, manufacturers can produce thousands of identical parts daily. While the initial investment in tooling is significant, the per-unit cost drops dramatically as production volume increases. This economic model makes it the go-to process for large-scale manufacturing. The process is also highly efficient, creating near-net-shape parts that minimize material waste and drastically reduce the need for expensive and time-consuming secondary machining operations.

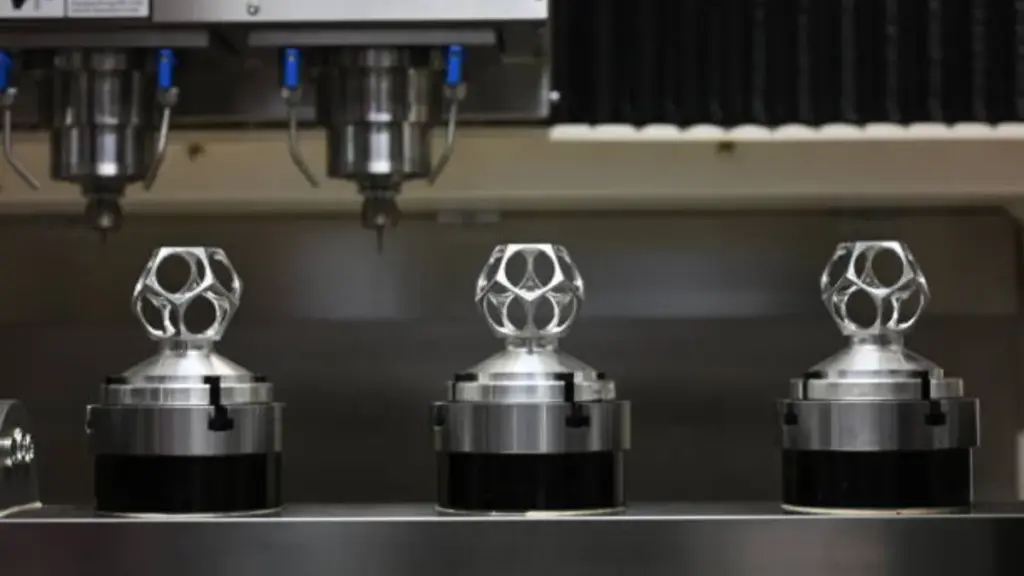

Manufacturing Complex Geometries with High Dimensional Accuracy

Die casting gives engineers immense design freedom. It produces parts with tight tolerances and excellent surface finishes directly from the mold, eliminating entire production steps. Engineers can consolidate multiple functions into a single component by integrating features like mounting bosses, cooling fins, and intricate thin walls. This part consolidation reduces assembly complexity and potential points of failure. The process also ensures extremely high part-to-part consistency, a non-negotiable requirement for today’s automated assembly lines and for meeting the stringent quality demands of the IATF 16949 automotive standard.

Comparing Aluminum, Magnesium, and Zinc

Alloy selection directly dictates a component’s weight, strength, precision, and final cost. This choice is the foundation for meeting performance targets in automotive and industrial applications.

Alloy selection is the point where most die-cast programs win (or lose) on weight, performance, and machining cost—before you invest in tooling.

Use the quick picks below to shortlist a material, then validate the trade-offs in the comparison table (so you don’t repeat the same details twice).

- Aluminum (A380 / ADC12): The balanced, general-purpose option for many automotive housings and structural parts.

- Magnesium (AZ91D): Best when maximum lightweighting is the primary target.

- Zinc (Zamak 3 / 5): Best for high-precision, near-net-shape parts with excellent surface finish, especially in very high-volume production.

| Material / Common Grades | Key Strengths | Trade-offs | Typical Automotive Use Cases | Sourcing & DFM Notes |

|---|---|---|---|---|

| Aluminum A380 / ADC12 |

Balanced “default” choice for many parts. ADC12 is preferred for complex geometries. | Heavier than magnesium. Zinc is better for ultra-high-volume tiny parts. | General housings, structural components, powertrain castings. | Specify grade; confirm if thin-wall design (favors ADC12). |

| Magnesium AZ91D |

Low density (~1.81 g/cm³); weight reduction. Excellent EMI shielding. | Requires tighter process handling and corrosion protection. | Lightweight brackets; EMI-sensitive electronics housings. | Align on finishing and EMI validation requirements early. |

| Zinc Zamak 3 / Zamak 5 |

High-precision, smooth surface. Tooling life >1,000,000 shots. | Higher density; less suitable for lightweight structural parts. | Precision mechanical components; small-to-mid size parts. | Best for high volume + tight tolerances; quantify machining reduction. |

Critical Automotive Components Produced via Die Casting

Die casting produces the high-strength, lightweight, and dimensionally stable components essential for a vehicle’s core powertrain, structural, and electronic systems.

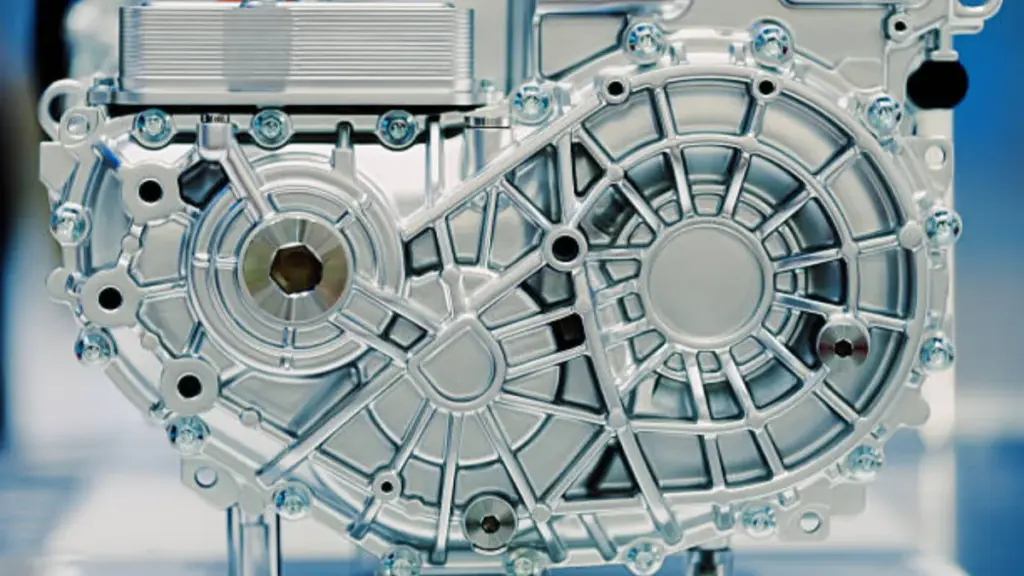

Powertrain and Drivetrain Systems

The shift to New Energy Vehicles (NEVs) has expanded the role of die casting in powertrains. High-pressure die casting creates the complex, rigid enclosures required for electric motors, battery packs, and power controllers. These parts must provide structural protection and effective heat dissipation. The process remains critical for traditional vehicles, producing internal combustion engine blocks and transmission cases that withstand extreme temperatures and operational pressures. For both vehicle types, components like gearbox and clutch housings rely on die casting to achieve the high dimensional stability needed for reliable mechanical performance.

- Enclosures for New Energy Vehicle (NEV) motors, battery packs, and power controllers.

- Traditional internal combustion engine blocks and transmission cases.

- Housings for gearbox and clutch assemblies requiring high dimensional stability.

Structural Body and Chassis Parts

Automakers use die casting to manufacture large, intricate structural parts that reduce vehicle mass without compromising safety. Lightweight aluminum and magnesium alloys are cast into shock towers and chassis subframes, directly contributing to improved fuel efficiency and EV range. The process is also used for body-in-white (BIW) structural nodes, such as A-pillars and cross-car beams, where complex geometries can be consolidated into a single, high-strength part. This reduces part count and assembly complexity. High-strength mounting brackets for suspension and engine systems also depend on die casting to handle significant mechanical loads.

- Lightweight shock towers and chassis subframes to reduce overall vehicle mass.

- Body-in-white structural nodes like A-pillars and cross-car beams.

- Mounting brackets for suspension and engine systems that demand high strength.

Housings for Electronic and Auxiliary Systems

Modern vehicles rely on a network of sensitive electronics that require robust protection. Die casting produces durable, thin-walled housings for Electronic Control Units (ECUs) and Advanced Driver-Assistance Systems (ADAS) modules, providing excellent EMI shielding and environmental sealing. In steering systems, components like steering wheel frames and pump bodies are die-cast for their precise tolerances and mechanical integrity. The process is also vital for thermal management in auxiliary systems, creating complex heat sinks and enclosures for advanced LED lighting that effectively dissipate heat and ensure long-term reliability.

- Protective housings for Electronic Control Units (ECUs) and ADAS modules.

- Steering system components, including steering wheel frames and pump bodies.

- Heat sinks and enclosures for advanced LED lighting systems.

Controlling Porosity and Common Defects

Effective porosity control is non-negotiable for ensuring the structural integrity and pressure-tightness of die-cast parts, directly preventing component failure and reducing costly scrap rates.

Identifying Porosity Types and Their Causes

Porosity defects fall into two main categories. Gas porosity results from trapped air or dissolved gases within the molten alloy during injection. Shrinkage porosity occurs when sections of the metal cool and solidify improperly, creating voids. Both compromise the mechanical strength and pressure tightness of the final component. Before any steel is cut for a new tool, we analyze material flow simulations to identify high-risk areas within the mold design. This predictive step allows our engineers to optimize gate and runner placement, ensuring smooth metal flow and strategically positioning vents to allow trapped gases to escape during solidification.

Process Parameter Optimization for Material Integrity

Achieving a dense, fine-grain metal structure requires strict control over the manufacturing process. We calibrate key parameters like injection pressure, shot speed, and die temperature to prevent gas absorption and shrinkage defects. For aluminum engine parts, this means maintaining precise thermal windows, including melt temperatures between 660-710°C and die temperatures from 180-220°C. Our unified IATF 16949 quality system ensures these protocols are synchronized across our facilities in China, Mexico, and Vietnam. This guarantees consistent molten alloy quality and process control, so a part cast in one facility meets the exact material integrity standards as a part cast in another.

Applying Advanced Inspection for Defect Verification

Visual inspection is insufficient for verifying the quality of mission-critical automotive components. We use a suite of non-destructive and metrological tests to validate both internal structure and functional performance. This multi-step verification process confirms that every part meets stringent design specifications before it ships.

- X-Ray Flaw Detection: This is essential for identifying internal voids, inclusions, and other subsurface defects that are invisible to the naked eye. X-ray inspection provides direct confirmation of the part’s structural soundness.

- CMM Full Dimensional Inspection: We use Coordinate Measuring Machines (CMM) to verify that the part’s geometry conforms precisely to the original CAD model, ensuring all critical dimensions and tolerances are met.

- Airtightness Testing: For components like housings and valve bodies that must contain pressure, functional airtightness testing is performed to guarantee a perfect seal and prevent leaks under operational conditions.

BIAN Strategy: Mitigating Risks with a Global Footprint

As an aluminium die cast automotive parts manufacturer, Bian Diecast builds a multi-origin manufacturing footprint to improve supply chain resilience and support tariff optimization—helping protect programs from geopolitical disruption while maintaining continuous production for global clients.

The “China + 2” Operational Framework

Bian Diecast is an aluminium die cast automotive parts manufacturer with a global manufacturing strategy built on a “China + 2” model to balance cost, speed, and risk. The China facility acts as the central technology and R&D hub, specializing in tooling development and complex supply chain sourcing. For clients targeting North American markets, our Mexico base provides a nearshoring option for rapid logistics and distribution. The Vietnam facility completes the triangle, offering a low-cost manufacturing platform with significant tariff advantages for global exports, especially to the US and Southeast Asia.

Ensuring Material and Quality Consistency Across Bases

Maintaining identical quality standards across geographically separate facilities is non-negotiable. We achieve this through a strictly enforced, unified quality management system compliant with IATF 16949 and ISO 9001 standards. This ensures every component meets automotive-grade requirements, regardless of its origin.

- Unified Material Standards: Core materials like ADC12, A380, Zamak 3/5, and AZ91D are sourced and verified against ASTM, EN, and JIS standards at all locations.

- Standardized Testing Protocols: Every facility uses identical performance testing equipment and procedures, including X-Ray Flaw Detection and CMM full-dimensional inspection.

From China NPI to Global Production

Our project lifecycle is designed for efficiency and flexibility. New Product Introduction (NPI), rapid prototyping, and initial tooling are centralized in our China facility to leverage its advanced engineering capabilities. Once the tooling is approved, we schedule mass production at the base that best aligns with the client’s specific cost, delivery speed, and tariff requirements. Minimum Order Quantities (MOQs) are structured to reflect regional logistics; we recommend higher volumes of 3,000-5,000 pieces for Vietnam or Mexico shipments to effectively amortize cross-border operational costs.

Eliminate Defects with IATF 16949 Die Casting

Future Trends: EV Lightweighting and Giga Casting

Combining lightweight alloys with giga casting is the definitive strategy for extending EV range, enhancing structural integrity, and radically simplifying vehicle assembly.

Aluminum and Magnesium Alloys for Extended EV Range

OEMs are aggressively adopting lightweight alloys to reduce overall vehicle mass, which directly improves battery efficiency. By replacing heavier materials with proven aluminum alloys like A380 and AlSi12, or the even lighter magnesium alloy AZ91D, manufacturers can cut significant weight from key components. A 10% decrease in vehicle weight can extend driving range by 6-8%. This strategy has become a baseline requirement for meeting the stringent global efficiency and emissions standards mandated for 2026 model year vehicles.

Giga Casting for Structural Component Integration

Giga casting fundamentally alters vehicle assembly by consolidating dozens of stamped and welded parts into a single, large-format die-cast component, such as a monolithic underbody structure. The operational benefits are immediate: it streamlines the assembly line and drastically cuts costs associated with robotic welding, complex fixtures, and labor. Beyond cost savings, these single-piece structures enhance the vehicle’s torsional rigidity for better handling and improve crash performance by creating more predictable energy absorption pathways.

Global Production Models for Large-Format Parts

High-precision, large-format molds are developed and validated in specialized technology centers, like those in China, to leverage deep engineering expertise. Once proven, mass production can be deployed to regional facilities—Mexico for North American nearshoring or Vietnam for tariff optimization. The critical element is maintaining absolute quality consistency. All facilities must operate under a unified IATF 16949 quality system, ensuring material specifications and component tolerances are identical regardless of the manufacturing site. This provides supply chain resilience without compromising automotive-grade standards.

Conclusion

A robust sourcing strategy, leveraging a global manufacturing footprint, is equally critical for managing costs, navigating tariffs, and ensuring supply chain stability. This integrated approach ensures your components meet strict performance standards while optimizing for market dynamics.

Review your current automotive supply chain to identify opportunities for cost savings and risk mitigation. Contact our engineering team to discuss how a multi-region manufacturing strategy can strengthen your sourcing.

Frequently Asked Questions

What is the best alloy for automotive die casting?

While the “best” alloy depends on the specific application, the automotive industry favors aluminum and magnesium alloys for die casting. These materials are chosen for their ability to produce lightweight components, which is critical for improving fuel efficiency and meeting modern emissions standards.

How do you ensure porosity control in engine parts?

Porosity is controlled through the high-pressure injection process inherent to die casting. This method creates compact, rigid metal structures with fine grain formation, resulting in parts with exceptional strength and durability suitable for demanding applications like engine blocks.

Can die casting replace stamped steel parts?

Yes, die casting can replace stamped steel parts, particularly where complex geometries and weight reduction are priorities. The process excels at creating intricate shapes with high dimensional accuracy that are difficult to achieve with other methods, making it ideal for components like shock towers and subframes.

What is the lead time for automotive tooling?

The provided research focuses on per-part cycle times (typically 10-60 seconds) and the cost-effectiveness after the initial die investment. However, it does not specify the initial lead time for designing and manufacturing the automotive tooling itself.

Do you offer PPAP Level 3 documentation?

Our manufacturing process adheres to the strict safety and quality standards required by the automotive industry to ensure superior precision and mechanical properties. The available documentation does not specifically mention PPAP (Production Part Approval Process) Level 3.

How does weight reduction impact EV range?

Weight reduction is especially valuable for electric vehicles (EVs), where reduced vehicle weight directly translates to an extended driving range. Lighter components mean the vehicle requires less energy to operate, allowing it to travel further on a single charge.