Optimiser les économies de coûts & Efficacité, Obtenez un avantage concurrentiel dans votre secteur

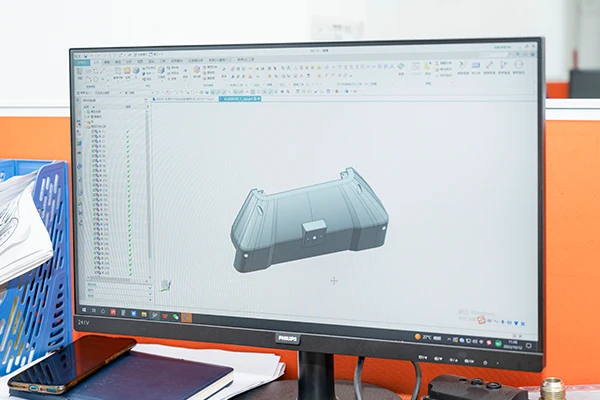

Que vous soyez familier ou non avec les techniques de moulage sous pression, notre R&Les équipes D vous accompagnent dès le début - conception de moules. Guidé & assisté par DFM & outil de flux de moule, nos équipes vous proposent les dessins techniques les plus spécialisés. Notre analyse DFM est fournie gratuitement!

Contrairement aux usines classiques qui font uniquement le travail de moulage sous pression pour vous., Bian Diecast est entièrement équipé - vous pouvez réaliser votre projet en un seul endroit! Moulage sous pression, Usinage CNC & terminer en un seul arrêt. Notre objectif est de réduire vos coûts et d'améliorer l'efficacité du processus..

Nous apprécions grandement vos œuvres de conception et sommes ouverts à signer des NDA à votre demande.. En plus, nous pouvons fournir des fichiers certifiés pour les pièces automobiles, y compris PPAP, APQP, AMDEC, MSA, et CPS, pour nos produits moulés sous pression.

Notre service est détaillé, jusqu'à l'emballage. Vous pouvez choisir l’emballage idéal – les sacs à bulles, boîtes en carton, cadres en plastique, diviseurs, et plus encore – pour répondre aux besoins de votre produit. Nous pouvons également répondre rapidement à l'impression de logo ou à d'autres demandes personnalisées sur l'emballage.. Il suffit de demander!

Lors de la conception du moule pour votre projet de moulage sous pression en aluminium, nous accordons la priorité à des facteurs tels que la fabricabilité et la rentabilité. Notre équipe fournit DFM (Conception pour la fabricabilité) soutien, garantissant que le moule de moulage sous pression en aluminium est non seulement adapté à la forme et aux dimensions de la pièce souhaitée, mais également optimisé pour une production efficace et rentable. Le moule est généralement composé de deux moitiés ou plus, faciliter le processus de remplissage et de retrait pendant la coulée.

D'abord, nous chauffons l'alliage d'aluminium choisi jusqu'à son point de fusion tout en préparant tous les matériaux et équipements nécessaires. Simultanément, la machine d'injection est préparée pour que l'alliage d'aluminium fondu soit injecté dans le moule préconçu.

En fonction des besoins spécifiques, les pièces finies peuvent subir des processus supplémentaires (Usinage CNC & services de finition) comme couper, forage, ou revêtement pour répondre à des normes rigoureuses.

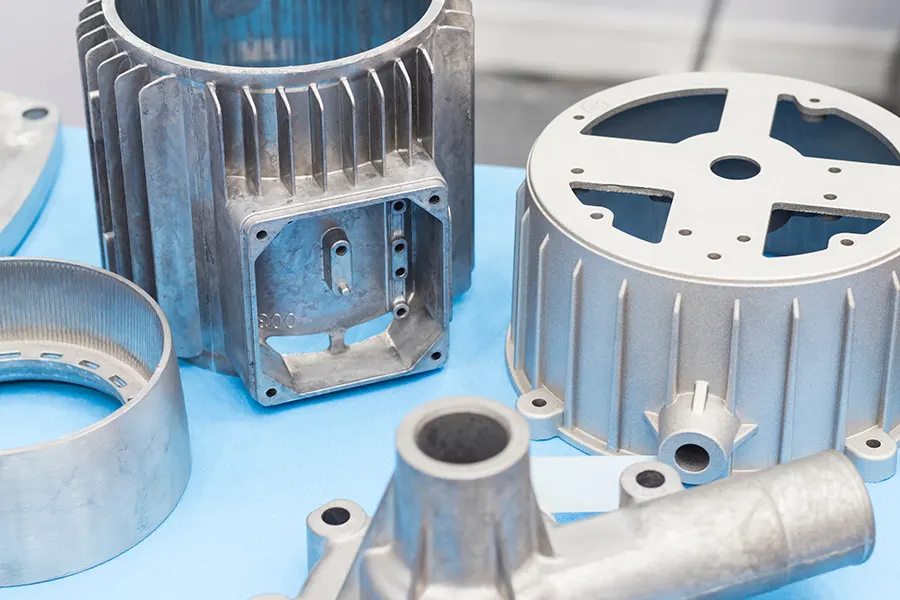

Bian Diecast est un fabricant de pièces moulées sous pression en aluminium qui est fier d'offrir une gamme diversifiée d'alliages d'aluminium moulés sous pression de haut niveau pour répondre à un large éventail de demandes industrielles.. Notre sélection soigneusement organisée comprend trois catégories principales, chacun se distinguant par son ensemble unique de propriétés et d'applications.

Bian Diecast est un fabricant de moulage sous pression à service complet qui peut fournir d'excellents services de moulage sous pression de zinc et d'aluminium pour les exigences spécifiques de votre projet.. Notre expertise en moulage sous pression nous permet de fournir des pièces de haute qualité, des pièces de précision en zinc et en aluminium moulées sous pression qui répondent aux exigences spécifiques de votre projet.

Il existe deux méthodes principales pour le moulage sous pression: moulage sous pression en chambre chaude et moulage sous pression en chambre froide. Pour le moulage sous pression en alliage d'aluminium, nous utilisons principalement des machines de coulée sous pression à chambre froide, tandis que la méthode de la chambre chaude est souvent utilisée pour des alliages comme le zinc en raison de leurs points de fusion plus bas..

Chez Bian moulé sous pression, notre usine est entièrement équipée d'une variété de machines de moulage sous pression. Chaque machine est capable de produire au moins 2000 à 3000 composants de moulage sous pression par jour. La plus grande portée de zone de coulée 3125cm².

| 1250Machine de moulage sous pression T | 900Machine de moulage sous pression T | 800Machine de moulage sous pression T |

| 500Machine de moulage sous pression T | 400Machine de moulage sous pression T | 300Machine de moulage sous pression T |

Ces prix indiquent la fourchette de coûts pour produire une unité d'un produit à l'aide de la machine de moulage sous pression correspondante.. Le coût réel du moulage sous pression de l'aluminium dans chaque plage peut varier en fonction de facteurs tels que la complexité de la pièce., matériel utilisé, et autres variables de production.

| Modèle de machine de moulage sous pression | Prix pour référence ($ par unité) |

|---|---|

| 1250Machine de moulage sous pression T | $3-5 |

| 900Machine de moulage sous pression T | $1.5-2 |

| 800Machine de moulage sous pression T | $1.0-1.5 |

| 500Machine de moulage sous pression T | $0.7-1.0 |

| 400Machine de moulage sous pression T | $0.5-0.7 |

| 300Machine de moulage sous pression T | $0.3-0.4 |

Bian moulé sous pression, une usine de moulage sous pression d'aluminium, est situé dans le district de Nanhai, Ville de Foshan, Chine. Avec plus d'une décennie d'expertise dans le moulage sous pression, nous nous engageons à fournir des services complets de moulage sous pression. Outre la conception et le développement de moules spécialisés, nous avons une usine avancée et ateliers qui intègrent moulage sous pression, Usinage de précision CNC, et services de finition de surface, répondre à divers besoins dans diverses industries.

Actuellement, nous avons accumulé des années d'expérience de service dans le automobile, éclairage, électronique, meubles, et les secteurs du bâtiment. Avec une base solide en gestion de projet, nous visons à devenir un fournisseur stratégique de nombreuses marques mondiales renommées.

Moule de moulage sous pression, également connu sous le nom de dé, est un outil utilisé dans le processus de moulage sous pression pour créer des pièces métalliques avec une grande précision et exactitude. Le moule est une cavité creuse utilisée pour donner au métal en fusion une forme spécifique grâce à un processus appelé moulage sous pression.. Les moules de moulage sous pression sont généralement fabriqués en acier et comportent deux moitiés distinctes qui se réunissent pour former la forme souhaitée de la pièce finale.. Le moule est conçu avec des détails et des caractéristiques complexes pour garantir que la pièce finale répond aux spécifications et tolérances requises.. Les moules de moulage sous pression peuvent être utilisés à plusieurs reprises pour produire de grandes quantités de pièces identiques rapidement et efficacement.

En tant qu'usine de moulage sous pression en Chine, nous fournissons des services de conception de moules de moulage sous pression de haute qualité pour répondre aux critères de qualité de votre projet.

Premièrement, notre équipe dédiée collaborera avec vous pour comprendre vos besoins et exigences spécifiques pour le projet. Une fois que tous les détails seront clarifiés et confirmés, nous procéderons à la passation formelle de la commande pour lancer le projet.

| Aspect | Moulage sous pression en chambre chaude | Moulage sous pression en chambre froide |

|---|---|---|

| Types de métaux | Convient aux métaux à bas point de fusion (par ex., zinc, magnésium) | Convient aux métaux à point de fusion élevé (par ex., aluminium, cuivre, certains alliages de zinc) |

| Processus de fusion des métaux | Le métal fond dans la machine | Le métal est fondu dans un four séparé et versé dans la machine |

| Vitesse d'incantation | Processus plus rapide grâce à la disponibilité continue du métal en fusion | Processus plus lent car le métal doit être introduit manuellement dans la machine |

| Taille et complexité des pièces | Idéal pour les pièces petites et complexes nécessitant une haute précision | Idéal pour les pièces plus grandes et plus complexes nécessitant une plus grande résistance et de meilleures finitions de surface |

| Versatilité | Limité aux métaux à bas points de fusion | Peut gérer une large gamme d’alliages métalliques et de tailles de pièces |

| Efficacité | Productivité et efficacité élevées grâce au processus de fusion et d'injection continu | Capacité à contrôler la température du métal pour de meilleures propriétés mécaniques et finitions de surface |

Les exigences de tolérance minimale dépendent de la taille du produit.

Pour dimensions jusqu'à 200 mm, des tolérances de ± 0,1 mm ou mieux sont requises.

Pour dimensions jusqu'à 300 mm, des tolérances de ±0,2 mm ou mieux sont nécessaires;

et pour des dimensions jusqu'à 500mm, des tolérances de ± 0,3 mm ou mieux sont attendues.

Quant aux angles de dépouille, un minimum de 1 un diplôme est requis, mais des angles plus grands sont préférés pour une éjection plus douce du moule.

Ces spécifications de tolérance sont essentielles pour garantir la précision et la qualité des produits moulés sous pression..

50,000 photos avant remplacement ou remise à neuf. Si l'ancien moule de moulage sous pression atteint la fin de sa durée de vie, nous pouvons reproduire un nouveau moule pour vous

Moulage sous pression en chambre froide: Cette méthode convient aux matériaux ayant des points de fusion plus élevés comme l'aluminium et le magnésium.. Le métal est fondu dans un four séparé puis injecté dans la machine à chambre froide. Il est idéal pour couler des pièces durables et légères, mais peut être un peu plus lent en raison de la nécessité d'un transfert de métal..

Moulage sous pression en chambre chaude: Conçu pour les matériaux avec des points de fusion inférieurs, comme le zinc. Dans ce processus, le métal reste à l'état fondu dans un four intégré connecté à la machine. Le moulage sous pression en chambre chaude est plus rapide et plus efficace pour les moulages plus petits, pièces complexes, ce qui le rend rentable pour la production en grand volume.

Nos prix de moules sont justes et raisonnables, et nous ne cherchons pas à profiter excessivement de nos clients sur les coûts de moulage. De plus, pour les clients ayant de gros volumes de commandes, dans le cas où un moule devient inutilisable, nous offrons la possibilité de créer un nouveau moule sans frais supplémentaires. En plus, les facteurs contribuant au prix des moules comprennent la résistance et la sélection des matériaux dans la conception du moule.

La durabilité est une considération clé dans nos opérations. Nous priorisons les pratiques durables en minimisant les déchets, matériaux de recyclage, et mettre en œuvre des processus économes en énergie. Ici à Bian, par souci de pureté matérielle, notre entreprise utilise un four de fusion central pour la fusion concentrée et le raffinage des matériaux recyclés avant leur réutilisation. Nous appliquons des mesures de contrôle strictes tout au long du processus de moulage sous pression de l'aluminium, y compris les inspections des matières premières entrantes, test périodique de la composition du matériau toutes les deux heures, et des tests tiers réguliers.

Nous détenons plusieurs certifications qui attestent de notre engagement envers la qualité et le respect des normes de l'industrie.. Ces certifications incluent ISO 9001 pour la gestion de la qualité, OIN 14001 pour la gestion environnementale, et l'IATF 16949, qui est spécifique à l'industrie automobile. Ces certifications donnent aux clients B2B confiance dans nos processus et dans notre capacité à fournir systématiquement des produits de haute qualité..

– Haute précision et tolérances serrées

– Production efficace de formes complexes

– Léger et résistant

-Excellente dissipation thermique

-Rentable pour les grandes quantités

Oui, notre équipe d'experts fournit une conception pour la fabricabilité (DFM) services à nos clients. Nous collaborons sur les conceptions pour garantir une production efficace, réduire les coûts et les délais de commercialisation.