Casting is a fascinating manufacturing process that turns molten metal into solid parts through molds. Whether you’re making intricate jewelry or massive engine components, the type of casting you choose can make a world of difference. Let’s dive into the eight different types of casting, explore their unique attributes, and see which one might be the best fit for your needs.

#1: Sand Casting

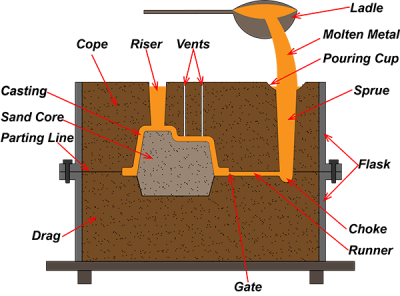

What is Sand Casting?

Sand casting is one of the oldest and most widely used casting methods. It involves creating a mold from a mixture of sand, clay, and water. Once the mold is ready, molten metal is poured in, filling the cavity and forming the desired shape once cooled and solidified.

Applications of Sand Casting

Sand casting is perfect for large parts and low to medium-volume production. It’s commonly used in manufacturing engine blocks, machinery parts, and even artistic sculptures. Its flexibility makes it a popular choice across various industries.

Pros and Cons of Sand Casting

Pros:

- Cost-effective: Low tooling costs make it suitable for small and large runs.

- Versatile: Can accommodate a wide range of sizes and complexities.

Cons:

- Surface Finish: Typically rougher compared to other methods.

- Dimensional Tolerance: Less precise, which can lead to additional machining.

Common Materials Used

Sand casting is often used with metals like cast iron, aluminum, and bronze. These materials are well-suited for the sand mold’s porous nature.

#2: Investment Casting

What is Investment Casting?

Investment casting, also known as lost-wax casting, involves creating a wax pattern of the part, which is then coated in a ceramic shell. Once the shell is hardened, the wax is melted away, and molten metal is poured into the cavity to create the final part.

Applications of Investment Casting

This method is ideal for producing high-precision components used in aerospace, automotive, and medical industries. It’s perfect for parts requiring intricate details and smooth finishes.

Pros and Cons of Investment Casting

Pros:

- High Precision: Capable of producing complex geometries with excellent surface finish.

- Versatility: Works with a wide range of metals, including exotic alloys.

Cons:

- Cost: Higher initial costs due to complex patterns and shells.

- Production Speed: Generally slower compared to other methods.

Common Materials Used

Investment casting commonly uses materials like stainless steel, carbon steel, and superalloys, thanks to their ability to flow into intricate mold cavities.

#3: Die Casting

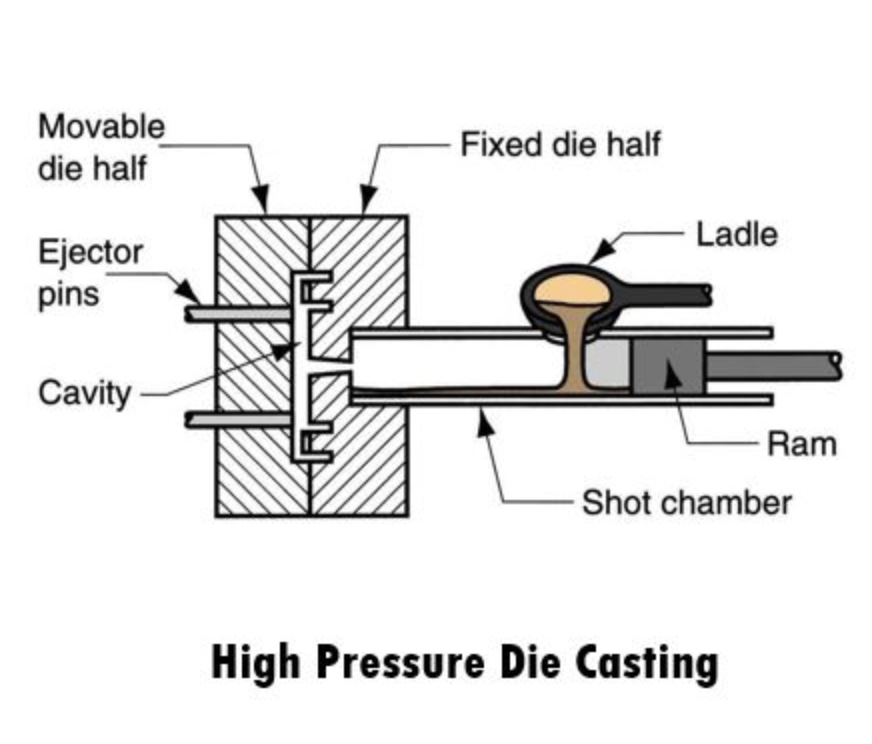

What is Die Casting?

Die casting involves forcing molten metal into a mold cavity under high pressure. The molds, or dies, are usually made from steel and are designed to be reusable for high-volume production.

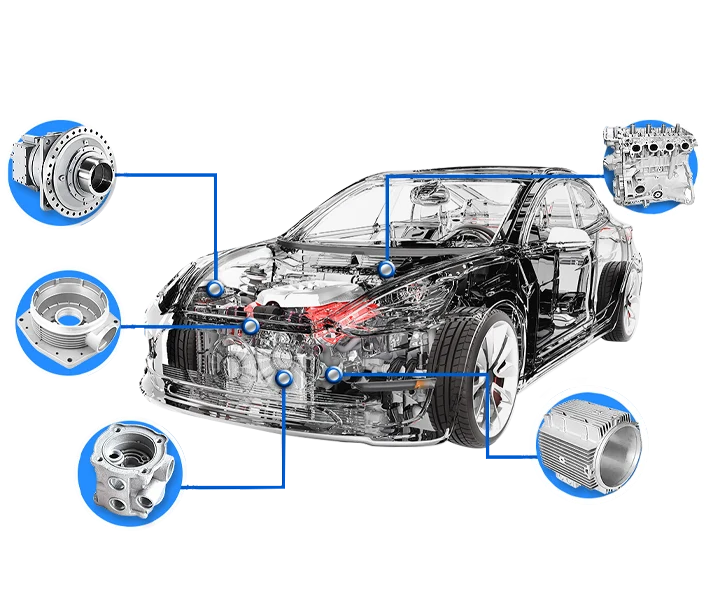

Applications of Die Casting

Die casting is widely used in the automotive industry for producing parts like engine components and transmission housings. It’s also popular in electronics and consumer goods for its ability to create complex shapes with high precision.

Pros and Cons of Die Casting

Pros:

- Precision: Excellent dimensional accuracy and surface finish.

- Efficiency: High production rates and consistency.

Cons:

- Tooling Costs: High initial costs for die creation.

- Material Limitations: Best suited for non-ferrous metals like aluminum and zinc.

Common Materials Used

Aluminum, zinc, and magnesium are commonly used in die casting due to their ability to flow easily into intricate molds and their suitability for high-pressure applications.

#4: Permanent Mold Casting

What is Permanent Mold Casting?

Permanent mold casting involves pouring molten metal into a reusable metal mold. Unlike sand molds, these permanent molds are made from materials like steel or iron and can be used repeatedly.

Applications of Permanent Mold Casting

This method is often used for producing medium to high-volume parts with good dimensional accuracy. Common applications include automotive parts, pump housings, and small machinery components.

Pros and Cons of Permanent Mold Casting

Pros:

- Durability: Reusable molds lead to lower long-term costs.

- Good Surface Finish: Produces parts with a better surface finish compared to sand casting.

Cons:

- Initial Cost: Higher tooling costs for making the metal molds.

- Complexity: Less flexible in producing very intricate designs.

Common Materials Used

Aluminum, magnesium, and certain alloys are often used in permanent mold casting due to their ability to solidify quickly and consistently in reusable molds.

#5: Shell Casting

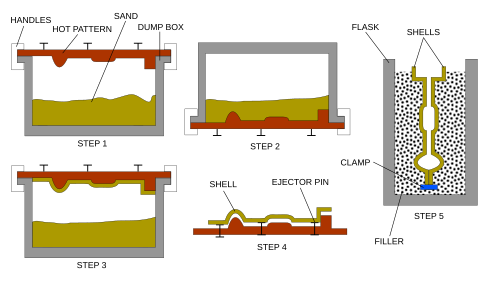

What is Shell Casting?

Shell casting, or shell mold casting, involves creating a thin ceramic shell around a pattern. Once the shell hardens, the pattern is removed, and molten metal is poured into the cavity to form the final part.

Applications of Shell Casting

This method is well-suited for producing high-precision and intricate parts, particularly in the aerospace and jewelry industries. It’s ideal for parts requiring a fine surface finish and complex details.

Pros and Cons of Shell Casting

Pros:

- Precision: Excellent for intricate and high-detail parts.

- Surface Finish: Provides a smooth, high-quality finish.

Cons:

- Cost: High initial setup costs due to the ceramic shell.

- Production Speed: Slower compared to other casting methods.

Common Materials Used

Shell casting is typically used with metals like stainless steel, aluminum, and titanium, chosen for their ability to fill the fine mold details and produce high-quality components.

#6: Centrifugal Casting

What is Centrifugal Casting?

Centrifugal casting involves pouring molten metal into a rotating mold. The centrifugal force pushes the metal to the outer edges of the mold, forming a solid part with dense and uniform properties.

Applications of Centrifugal Casting

This method is used for making cylindrical parts like pipes, tubes, and bearings. It’s ideal for applications requiring high strength and uniformity, such as in industrial machinery and construction.

Pros and Cons of Centrifugal Casting

Pros:

- Uniform Density: Results in dense, high-quality parts with fewer defects.

- Cost-Effective: Efficient for producing long, hollow components.

Cons:

- Shape Limitation: Primarily suited for cylindrical parts.

- Setup Costs: Requires specific equipment and molds.

Common Materials Used

Common materials include cast iron, steel, and nickel alloys, which are chosen for their ability to benefit from the centrifugal process to produce high-strength parts.

#7: Plaster Casting

What is Plaster Casting?

Plaster casting involves creating a mold from plaster, which is then used to cast molten metal. This method is similar to investment casting but uses plaster instead of a ceramic shell.

Applications of Plaster Casting

Plaster casting is commonly used for producing detailed and precise parts in smaller quantities. It’s often used for art pieces, jewelry, and prototypes due to its ability to capture fine details.

Pros and Cons of Plaster Casting

Pros:

- Detail: Excellent for producing intricate and detailed parts.

- Cost-Effective: Lower tooling costs compared to some other methods.

Cons:

- Material Limitations: Generally used for lower melting point metals.

- Durability: Plaster molds are not as durable as metal molds.

Common Materials Used

Materials such as aluminum, brass, and certain low-melting-point alloys are often used in plaster casting for their compatibility with the process.

#8: Vacuum Casting

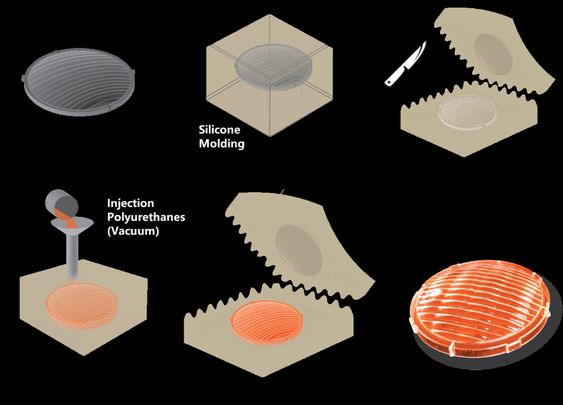

What is Vacuum Casting?

Vacuum casting involves pouring molten metal into a mold while creating a vacuum to remove air and gases. This method helps reduce defects and improve the quality of the cast parts.

Applications of Vacuum Casting

Vacuum casting is ideal for high-precision and high-quality parts, often used in aerospace, automotive, and electronics industries. It’s particularly useful for applications where air bubbles or gas porosity can compromise the part’s integrity.

Pros and Cons of Vacuum Casting

Pros:

- High Quality: Produces parts with fewer defects and better surface finishes.

- Precision: Excellent for detailed and complex components.

Cons:

- Cost: Higher costs associated with vacuum equipment and materials.

- Complexity: More complex setup and process compared to other casting methods.

Common Materials Used

Vacuum casting is often used with materials like aluminum, stainless steel, and titanium, which benefit from the improved quality and reduced porosity provided by the vacuum process.

Comparison of Casting Methods

Cost Efficiency

When it comes to cost, sand casting and plaster casting are generally more affordable due to lower tooling and setup costs. However, methods like die casting and investment casting, while more expensive initially, can be more cost-effective in the long run for high-volume production due to their efficiency and consistency.

Material Suitability

Different casting methods are suited to different materials. For example, die casting excels with non-ferrous metals like aluminum and zinc, while investment casting can handle a wide range of alloys, including high-temperature materials.

Precision and Accuracy

If precision is your top priority, investment casting and vacuum casting are excellent choices due to their ability to produce highly detailed and accurate parts. On the other hand, sand casting and plaster casting may offer less precision but are more versatile in handling larger and less complex parts.

Production Speed

Production speed varies significantly among casting methods. Die casting and centrifugal casting are known for their high-speed capabilities, making them suitable for large production runs. In contrast, methods like investment casting and shell casting can be slower due to their complex processes and detailed mold requirements.

Choosing the Right Casting Method

Factors to Consider

When selecting the best casting method, consider factors such as the required precision, the volume of production, and the type of material. Each casting method has its own strengths and limitations, so understanding these aspects will help you make an informed decision.

Material Requirements

Different materials have specific casting needs. For example, aluminum and zinc are well-suited for die casting, while high-temperature alloys may require investment or vacuum casting to ensure proper filling and structural integrity.

Desired Product Characteristics

Think about the final product’s characteristics—such as surface finish, strength, and dimensional accuracy. Methods like investment casting and vacuum casting are excellent for detailed, high-precision parts, whereas sand casting might be better for larger, less detailed components.

Cost Considerations

Budget constraints play a crucial role in choosing a casting method. If you’re working with a tight budget and small production runs, sand casting or plaster casting might be more economical. However, for high-volume production where long-term cost efficiency is key, die casting and permanent mold casting could be the better investment.

Conclusion

Selecting the right casting method can make a significant impact on the quality, cost, and efficiency of your manufacturing process. Each of the eight casting types—sand casting, investment casting, die casting, permanent mold casting, shell casting, centrifugal casting, plaster casting, and vacuum casting—offers distinct advantages and is suited to different applications. By understanding these options and considering your project’s specific needs, you can make an informed decision that ensures the best results for your casting requirements.