When it comes to metal materials, cast iron and steel are two commonly used options in various industries. Both have unique properties that make them suitable for different applications. Understanding the key differences between cast iron and steel is essential for choosing the right material for your project.

What Is Cast Iron?

Cast iron is a type of iron-carbon alloy renowned for its distinctive properties and applications. Unlike steel, cast iron contains a higher carbon content ranging from 2-4%. This elevated carbon level contributes to its characteristic hardness and brittleness.

Cast iron hardness, heat retention and distribution make it popular for various applications, especially in cooking. Its versatile composition is ideal for manufacturing cooking utensils like skillets and Dutch ovens, ensuring consistent and reliable results for chefs and home cooks.

Types of Cast Iron

There are several types of cast iron that vary in composition and properties, each tailored for specific applications. Some common types include:

- Gray Cast Iron: Known for its graphite flakes and excellent machinability, used in engine blocks and machinery.

- White Cast Iron: Carbide-rich and highly wear-resistant, suitable for grinding balls and mill liners.

- Ductile Cast Iron: Contains nodular graphite for enhanced ductility and strength, used in automotive components and heavy machinery.

- Malleable Cast Iron: Heat-treated for improved toughness and ductility, ideal for pipe fittings and agricultural equipment.

- Compacted Graphite Iron (CGI): Unique graphite structure for high thermal conductivity and strength, preferred for automotive engine parts.

From superior wear resistance to enhanced ductility, each type of cast iron offers distinct advantages for various industrial and commercial purposes.

What Is Steel?

Steel, on the other hand, is an alloy of iron and carbon in which the carbon content is typically less than that of cast iron. It is renowned for its strength, durability, and flexibility, making it a popular choice for a wide range of applications across industries. With its exceptional properties, steel is utilized in construction, automotive manufacturing, machinery production, and countless other sectors.

Types of Steel

There are various types of steel with different compositions and properties, each designed for specific applications.

- Carbon Steel: Standard steel with varying carbon content levels, providing different strength and hardness characteristics.

- Alloy Steel: Steel alloyed with elements like nickel and chromium to enhance properties such as strength and corrosion resistance.

- Stainless Steel: Contains chromium for corrosion resistance, available in different grades like austenitic and martensitic for various applications.

- Tool Steel: Hard and tough steel used for tool and die making applications in cutting tools and industrial equipment.

- High-Speed Steel: Known for its heat resistance and wear properties, commonly used in cutting tools and machining applications.

Each type of steel offers unique properties suited for specific applications, from structural components to cutting tools and machinery parts.

Cast Iron vs. Steel, What’s the Difference?

| Property | Cast Iron | Steel |

| Carbon Content | Higher carbon content (2-4%) | Lower carbon content (<2%) |

| Heat Conductivity | Lower thermal conductivity | Higher thermal conductivity |

| Compressive Strength | Lower strength and more brittle | Higher strength and toughness |

| Corrosion Resistance | More prone to rust and corrosion | Better resistance to corrosion |

| Impact Resistance | More brittle and prone to fracturing | Tougher and more impact-resistant |

| Castability | Excellent castability for complex shapes | More challenging to cast |

| Applications | Cooking utensils, engine blocks, etc. | Construction, automotive, aerospace, etc. |

| Cost | Generally less expensive | Generally more expensive |

Carbon Content

One of the key differences between cast iron and steel is the carbon content. Cast iron typically contains 2-4% carbon, while steel contains less than 2% carbon. This higher carbon content gives cast iron its hardness and brittleness, while steel is known for its strength and ductility.

Heat Conductivity

Another important difference between cast iron and steel is their heat conductivity. Cast iron has a lower thermal conductivity than steel, which means it retains heat better and distributes it more evenly. This is why cast iron is commonly used in cooking utensils that require even heating.

Compressive Strength

When it comes to compressive strength, steel is typically stronger than cast iron. Steel has a higher tensile strength and yield strength, making it more suitable for applications that require high strength and durability. Cast iron, on the other hand, is more brittle and prone to fracturing under high loads.

Corrosion Resistance

Steel is more resistant to corrosion than cast iron. This is because steel can be alloyed with other elements such as chromium and nickel to enhance its corrosion resistance. Cast iron, on the other hand, is more prone to rust and corrosion if not properly maintained.

Impact Resistance

Steel is known for its toughness and impact resistance, making it suitable for applications that require high durability and impact resistance. Cast iron, on the other hand, is more brittle and prone to fracturing under impact. This makes steel a better choice for applications where impact resistance is critical.

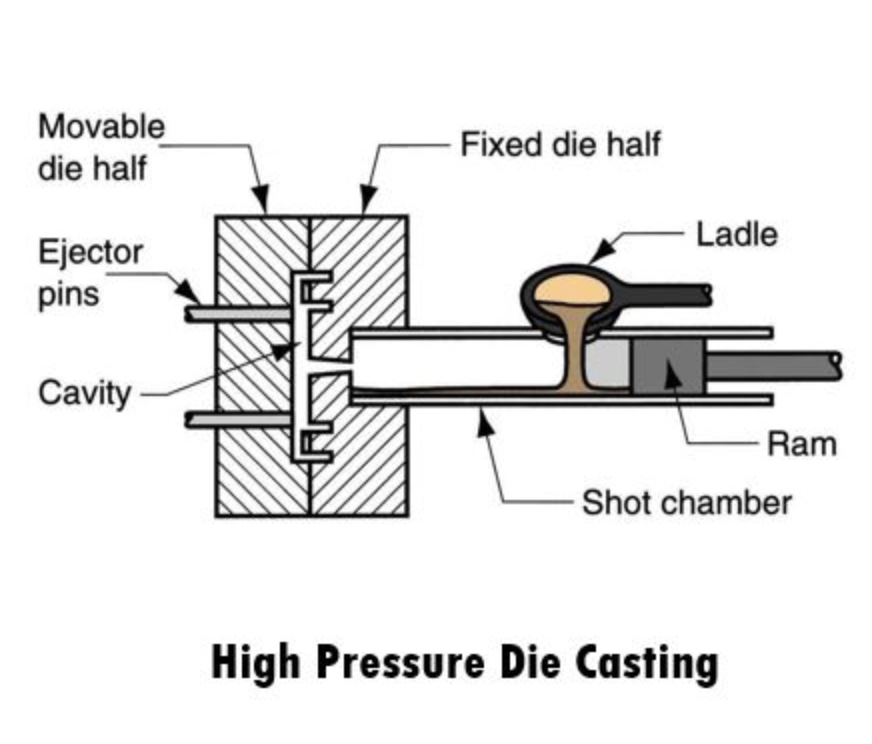

Castability

One of the advantages of cast iron is its excellent castability. Cast iron can be easily cast into complex shapes and designs, making it ideal for applications that require intricate details. Steel, on the other hand, is more challenging to cast and may require additional processing to achieve the desired shape.

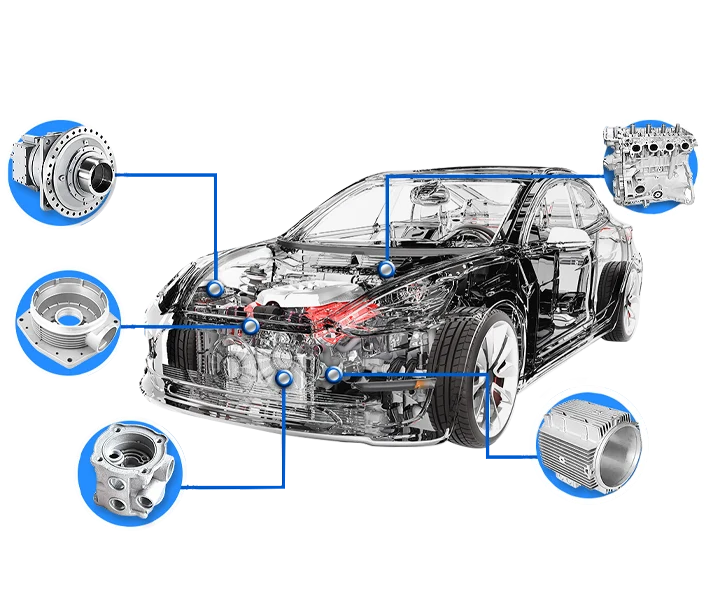

Applications

Both cast iron and steel have a wide range of applications in various industries. Cast iron is commonly used in cooking utensils, engine blocks, and machine tool structures. Steel is used in construction, automotive manufacturing, aerospace, and shipbuilding, among other industries.

Cost

The cost of cast iron and steel can vary depending on the specific grade and quality of the material. In general, steel is more expensive than cast iron due to its higher strength and durability. However, the long-term benefits of using steel often outweigh the initial cost.

Cast Iron vs. Steel, Which Is Better?

Pros and Cons of Cast Iron

Pros of Cast Iron

- Excellent heat retention and distribution

- Versatile for manufacturing kitchen utensils and heavy machinery

- Durable and long-lasting material

- Provides a unique cooking surface for enhancing flavors

- Relatively inexpensive compared to other materials

Cons of Cast Iron

- More prone to rust and corrosion

- Can be heavy and cumbersome to handle

- Brittle and prone to cracking if not handled properly

- Requires seasoning and maintenance to prevent rust

- Limited in terms of shape complexity compared to other materials

Pros and Cons of Steel

Pros of Steel

- High strength and durability

- Versatile for a wide range of applications

- Excellent corrosion resistance, especially in stainless steel

- Recyclable and environmentally friendly

- Can be easily fabricated and customized for various needs

Cons of Steel

- Heavy and can be cumbersome to handle

- Susceptible to rust if not properly protected

- May be more expensive than some other materials

- Limited heat conductivity compared to materials like aluminum

- Some types of steel can be challenging to weld or work with

If you are looking for high-quality metal die casting services, Bian Diecast is the perfect choice. With years of experience and expertise in casting aluminum, iron, and steel, we can help you with your casting needs. Contact us today to learn more about our services.

Conclusion

In conclusion, the choice between cast iron and steel depends on the specific requirements of your project. While cast iron is known for its hardness and heat retention, steel offers superior strength and durability. Whether you need a material that offers superior strength, heat retention, or corrosion resistance, there is a metal casting solution that meets your needs. Choose the right material for your application and enjoy the benefits of high-quality metal components.

FAQs

1. Is cast iron stronger than steel?

While cast iron is harder than steel due to its higher carbon content, steel is generally stronger and more durable than cast iron.

2. What is cast iron made of?

Cast iron is primarily made of iron with a high carbon content, typically ranging from 2-4%. In addition to iron and carbon, cast iron may also contain other elements such as silicon, manganese, sulfur, and phosphorus.

3. How to tell if something is cast iron?

You can usually tell if something is cast iron by its appearance and weight. Cast iron is heavier and more brittle than steel, and it often has a rough texture and visible casting marks.