Custom Die Casting Manufacturer

We are committed to providing comprehensive die-casting services for various industries.

Our one-stop advantages include:

- Die casting mold design

- Speciality aluminum die casting

- CNC precision machining

- Surface finishing services

Custom Aluminum Die Casting Parts

Bian Diecast specializes in crafting high-quality custom die-cast parts for various industries.

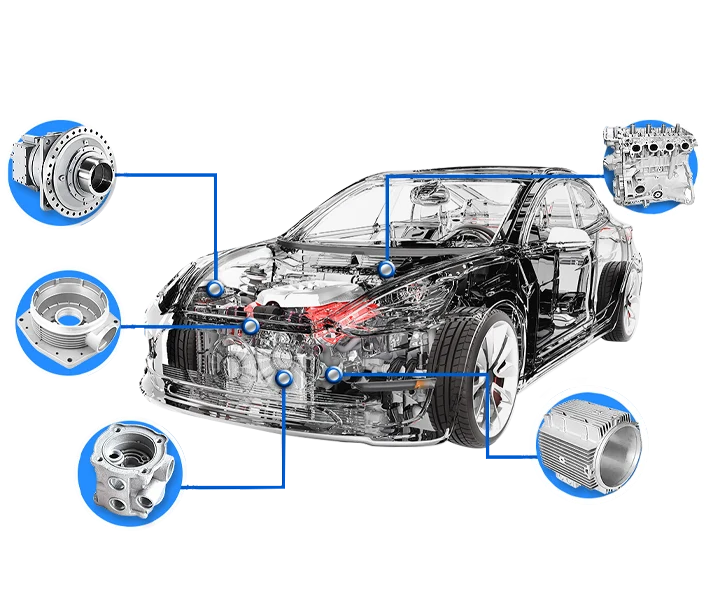

AUTOMOTIVE PARTS

- Engine & chassis parts: Cylinder head, Crankcase, Fuel pump housing, …

- Transmission components: Transfer case,

Clutch housings, Transfer case cover… - Electrical system parts: Battery box, Generator housing, Control module casing…

- Body, interior & exterior parts: Steering wheel cover, Dashboard cover, Handlebar housing…

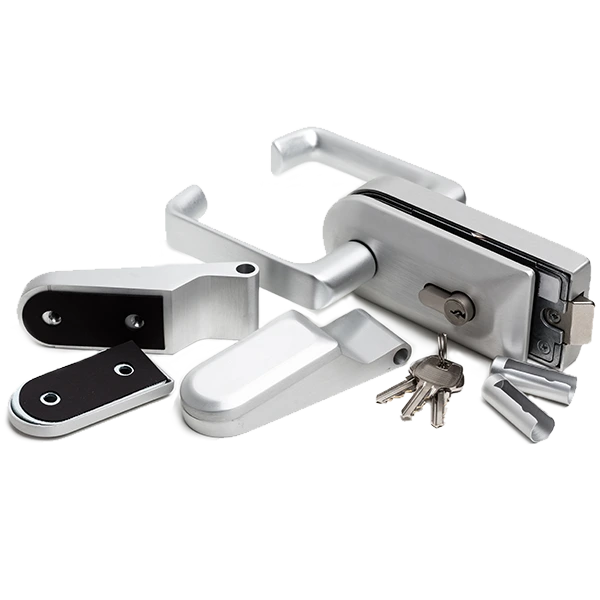

Furniture PARTS

- Engine & chassis parts: Cylinder head, Crankcase, Fuel pump housing, …

- Transmission components: Transfer case,

Clutch housings, Transfer case cover… - Electrical system parts: Battery box, Generator housing, Control module casing…

- Body, interior & exterior parts: Steering wheel cover, Dashboard cover, Handlebar housing…

Different Types of Aluminums for Selection

Bian Diecast takes pride in offering a diverse spectrum of top-tier die-cast aluminum alloys to cater to a wide range of industrial demands.

Common Die-cast Aluminum Alloys

Excellent flowability, mechanical properties, and corrosion resistance. Used for various aluminum die-cast parts.

- ADC12

- ADC10

- DC1

- A360

- A380

- YL102

- LM6

EU Grade Aluminum Alloy Materials

Excellent fluidity and abrasion resistance. Used for complex-shaped parts and components.

- ENAC 44300(AISI12(FE))

- ENAC-47100

- ENAC-46000

High Thermal Conductivity Alloy Materials

Excellent thermal conductivity. Widely used in electronics, automotive, and other high-temperature environments.

- AlSI8

- LHB1

Cold Chamber HIGH Pressure Die Casting Capability

For aluminum alloy die casting, we primarily employ cold chamber pressure die casting machines.

There are six major steps of how we manufacturer custom die-cast parts:

- Step 1 : Mold design

- Step 2 : Casting preparation

- Step 3 : Injection

- Step 4 : Cooling & solidfication

- Step 5 : Demolding / Removal

- Step 6 : Cooling & solidfication

Aluminum Die Casting Price

Our factory is equipped with a variety of die-casting machines. Each machine is capable of producing at least 2000 to 3000 die-casting components per day. The largest casting area reaches 3125cm².

The actual cost within each range may vary depending on factors such as the complexity of the part, the material used, and other production variables.

| Die Casting Machine Model | Pricing for Reference ($ per unit) |

|---|---|

| 1250T Die Casting Machine | $3-5 |

| 900T Die Casting Machine | $1.5-2 |

| 800T Die Casting Machine | $1.0-1.5 |

| 500T Die Casting Machine | $0.7-1.0 |

| 400T Die Casting Machine | $0.5-0.7 |

| 300T Die Casting Machine | $0.3-0.4 |

Get A Quote for Die Casting Services Today!

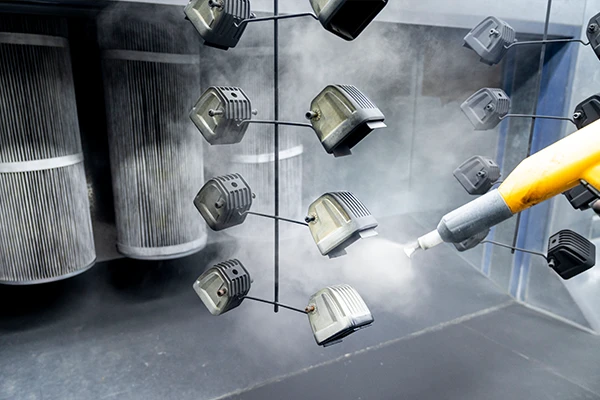

surface finishing service

Polishing

powder coating

lacquer coating

sand blasting

shot blasting

anodizing

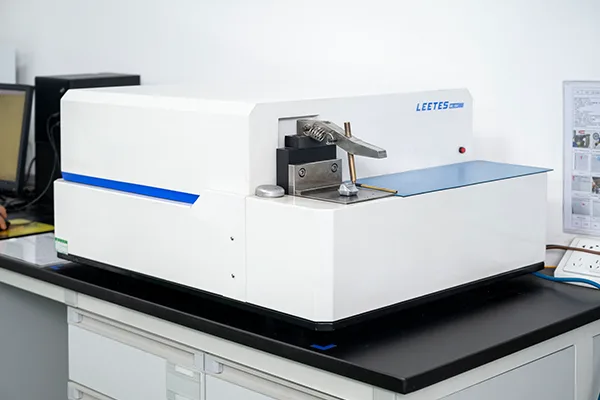

quality control

From die-casting to final inspection, our workshops are equipped with comprehensive sets of facilities. We will conduct a comprehensive range of quality tests to ensure that the die-cast products meet your specific requirements and standards.

Coordinate Measuring Machine (CMM)

Direct Reading Spectrometer

Electronic Density Meter

X-ray Non-Destructive Testing System

Air-Tightness Testing Equipment Vacuum Chamber Helium Leak Detection Device

Cleanliness Scanning Analyzer

Friction and Scratch Tester CS-10F

Maximum Thread Failure Torque Testing

Alcohol & Rubber Friction Testing Machine

Colorimeter

Film Thickness Gauge

Paper Strip Abrasion Tester

2.5D Measurement Instrument

Aluminum Die Casting Services in China

The Bian Diecast Differences

Bian Diecast, an aluminum die casting company, is located in Nanhai District, Foshan City, China. With over a decade of expertise in aluminum die casting, we are committed to providing comprehensive die-casting services for various industries.

Our one-stop advantages include:

- Die casting mold design

- Speciality aluminum die casting

- CNC precision machining

- Surface finishing services

How to Work with Us?

get a quick quote

Upload your file (2D/3D drawing) to us. (NDA signing on your demand.) We'll assist you with free design analysis for your prototypes.

Manufacturing

Once you've confirmed the order, we'll start the manufacturing process. You'll get real-time updates on the production stage.

get custom parts

Get your parts that pass quality inspection safe & sound. You can get custom packaging including packaging materials, logos/label printing.

FAQ

The minimum tolerance requirements depend on the size of the product.

For dimensions up to 200mm, tolerances of ±0.1mm or better are required.

For dimensions up to 300mm, tolerances of ±0.2mm or better are necessary;

and for dimensions up to 500mm, tolerances of ±0.3mm or better are expected.

As for draft angles, a minimum of 1 degree is required, but larger angles are preferred for smoother ejection from the mold.

These tolerance specifications are essential to ensure the precision and quality of die-cast products.

50,000 shots before replacement or refurbishment. If the old die-casting mold reaches the end of its service life, we can replicate a new mold for you

Cold Chamber Die Casting: This method is suitable for materials with higher melting points like aluminum and magnesium. The metal is melted in a separate furnace and then injected into the cold chamber machine. It’s ideal for casting durable and lightweight parts but can be a bit slower due to the need for metal transfer.

Hot Chamber Die Casting: Designed for materials with lower melting points, such as zinc. In this process, the metal remains in a molten state within an integrated furnace connected to the machine. Hot chamber die casting is faster and more efficient for casting smaller, intricate parts, making it cost-effective for high-volume production.

Our mold prices are fair and reasonable, and we don’t aim to profit excessively from our customers on mold costs. Moreover, for customers with large order volumes, in the event that a mold becomes unusable, we offer the option of creating a new mold at no additional cost. Additionally, factors contributing to the pricing of molds include the strength and material selection in the mold design.

Sustainability is a key consideration in our operations. We prioritize sustainable practices by minimizing waste, recycling materials, and implementing energy-efficient processes. Here at Bian, for the sake of material purity, our company utilizes a central melting furnace for the concentrated melting and refining of recycled materials before their reuse. We enforce strict control measures throughout the aluminum die casting process, including incoming raw material inspections, periodic testing of material composition every two hours, and regular third-party testing.

We hold several certifications that attest to our commitment to quality and adherence to industry standards. These certifications include ISO 9001 for quality management, ISO 14001 for environmental management, and IATF 16949, which is specific to the automotive industry. These certifications provide B2B clients with confidence in our processes and our ability to consistently deliver high-quality products.

– High precision and tight tolerances

– Efficient production of complex shapes

– Lightweight and durable

-Excellent heat dissipation

-Cost-effective for large quantities

Yes, our expert team provides Design for Manufacturability (DFM) services to our clients. We collaborate on designs to ensure efficient production, reducing costs and time to market.