Is die cast aluminum safe? It’s a question that pops up quite often, especially among those concerned about health and safety in everyday products. In this article, we’ll dive deep into the world of die cast aluminum, exploring its properties, applications, and safety aspects to give you a well-rounded understanding.

Is Die Cast Aluminum Safe?

Yes, die cast aluminum is safe. It is widely used in various industries due to its strength, lightweight nature, and resistance to corrosion. Regulatory standards and proper manufacturing processes ensure its safety for consumer products, including cookware, electronics, and automotive parts. While some concerns exist, they are effectively managed, making die cast aluminum a reliable and safe material for everyday use.

What is Die Casting?

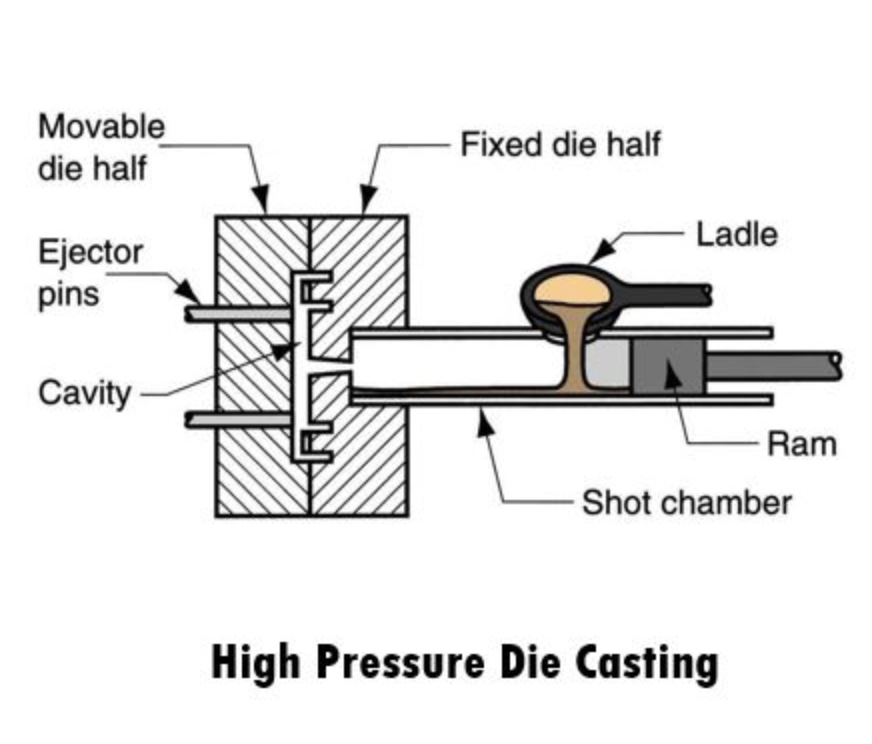

To grasp the safety of die cast aluminum, we first need to understand the die casting process itself.

The Die Casting Process

Die casting is a manufacturing process where molten metal is poured or forced into steel molds. These molds—called dies—are reusable and designed to produce complex shapes with high precision and smooth finishes. The process is quick, efficient, and ideal for mass production.

Common Materials Used

While aluminum is a favorite, other metals like zinc, magnesium, and copper are also used in die casting. Each material offers unique properties, but aluminum stands out due to its versatility and performance.

Why Aluminum is Popular in Die Casting?

Aluminum’s popularity in die casting isn’t random; it’s driven by specific properties that make it an ideal choice.

Aluminum Properties

Aluminum is lightweight, strong, and highly resistant to corrosion. It also has excellent thermal and electrical conductivity, making it perfect for a wide range of applications. Plus, it’s abundant and recyclable, contributing to its widespread use.

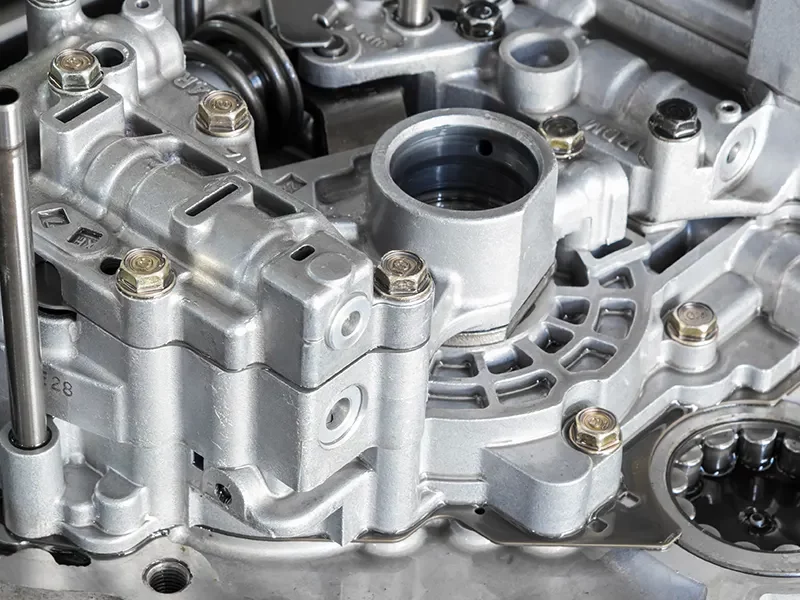

Benefits of Aluminum in Die Casting

The benefits of using aluminum in die casting are numerous. It allows for the creation of intricate designs that are both strong and lightweight. Its natural resistance to rust and corrosion adds to its longevity, and its good thermal properties make it useful in heat dissipation applications.

Applications of Die Cast Aluminum

You’ll find die cast aluminum in various industries, highlighting its versatility and reliability.

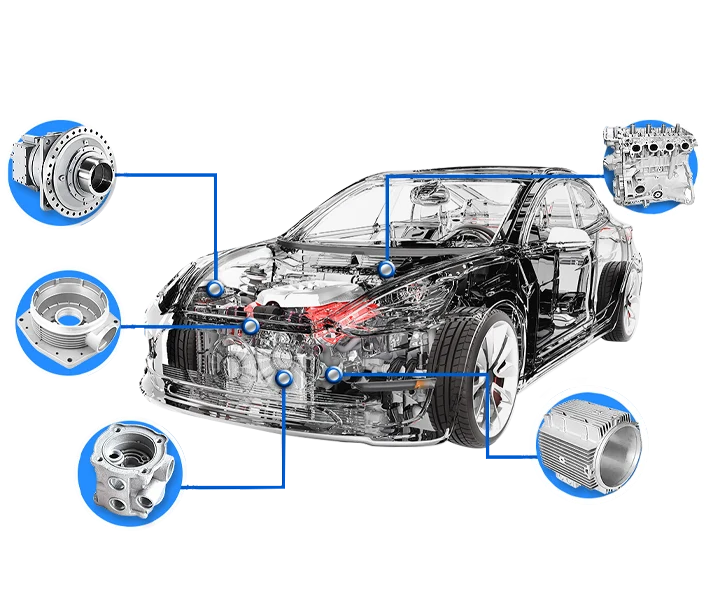

Automotive Industry

In the automotive industry, die cast aluminum is used for engine blocks, transmission housings, and other components. Its lightweight nature helps improve fuel efficiency and overall vehicle performance.

Consumer Electronics

From smartphones to laptops, aluminum die cast parts provides durable and sleek casings for consumer electronics. Its strength and thermal properties are essential for protecting sensitive components and managing heat.

Home Appliances

Many home appliances, like washing machines and refrigerators, incorporate die cast aluminum parts. These components benefit from aluminum’s durability and resistance to wear and tear, ensuring long-lasting performance.

Safety Concerns with Die Cast Aluminum

Despite its many advantages, some safety concerns do exist regarding die cast aluminum.

Potential Health Risks

One major concern is the potential for aluminum exposure to pose health risks. However, scientific studies have shown that aluminum exposure from die cast products is minimal and well within safe limits. The aluminum used in consumer products is alloyed and coated to prevent leaching and corrosion, further mitigating any health risks.

Addressing Environmental Concerns

Environmental safety is another consideration. The die casting process can have environmental impacts, including energy consumption and emissions. However, aluminum’s recyclability helps offset these concerns. Using recycled aluminum requires significantly less energy than producing new aluminum, reducing the overall environmental footprint.

Regulatory Standards and Compliance

To ensure safety, die cast aluminum products must meet specific regulatory standards and guidelines.

Industry Standards

Organizations like the Aluminum Association and the North American Die Casting Association (NADCA) set industry standards for die casting processes and materials. These standards ensure consistent quality and safety across the industry.

Government Regulations

Government agencies, such as the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA), also regulate the use of aluminum in various applications. These regulations are designed to protect both consumers and the environment.

Comparing Die Cast Aluminum to Other Materials

How does die cast aluminum stack up against other die cast metals?

Die Cast Zinc

Zinc is another popular die casting material, known for its strength and ductility. However, it is heavier than aluminum, which can be a disadvantage in applications where weight is a critical factor.

Die Cast Magnesium

Magnesium is even lighter than aluminum and has excellent strength-to-weight ratio. However, it is more expensive and challenging to work with, making aluminum the more practical choice for many applications.

Myths and Misconceptions

Let’s clear up some common myths about die cast aluminum.

Aluminum and Food Safety

One myth is that aluminum is unsafe for food-related uses. In reality, aluminum is widely used in cookware and food packaging. Anodized aluminum, in particular, is highly safe and prevents any aluminum from leaching into food.

Longevity and Durability

Another misconception is that aluminum is not durable. Die cast aluminum is extremely durable and resistant to corrosion, making it a reliable choice for long-lasting products.

Conclusion

So, is die cast aluminum safe? Absolutely. Its properties, regulatory compliance, and widespread use across various industries attest to its safety and reliability. While there are some concerns, proper manufacturing processes and standards ensure that these are effectively managed. Die cast aluminum continues to be a trusted material, offering numerous benefits in everyday applications.

FAQs

Q: Can die cast aluminum leach into food?

A: No, die cast aluminum is often coated or anodized, preventing any leaching into food.

Q: Is aluminum safe for use in electronics?

A: Yes, aluminum’s properties make it ideal for protecting and cooling electronic components.

Q: Does die casting aluminum impact the environment?

A: While the process can be energy-intensive, using recycled aluminum significantly reduces the environmental impact.

Q: How does die cast aluminum compare to stainless steel?

A: Aluminum is lighter and more corrosion-resistant, whereas stainless steel is stronger and more heat-resistant.

Q: Are there any health risks associated with aluminum exposure?

A: Aluminum exposure from consumer products is minimal and well within safe limits set by regulatory agencies.