Die casting mold plays a critical role in the manufacturing process of creating precision metal parts. In this article, we will delve into the intricacies of die casting mold, why it is important, the different types of steel materials used for die casting molds, the mold design process, challenges faced in mold manufacturing, and how to select a reliable die casting mold manufacturer.

What is Die Casting Mold?

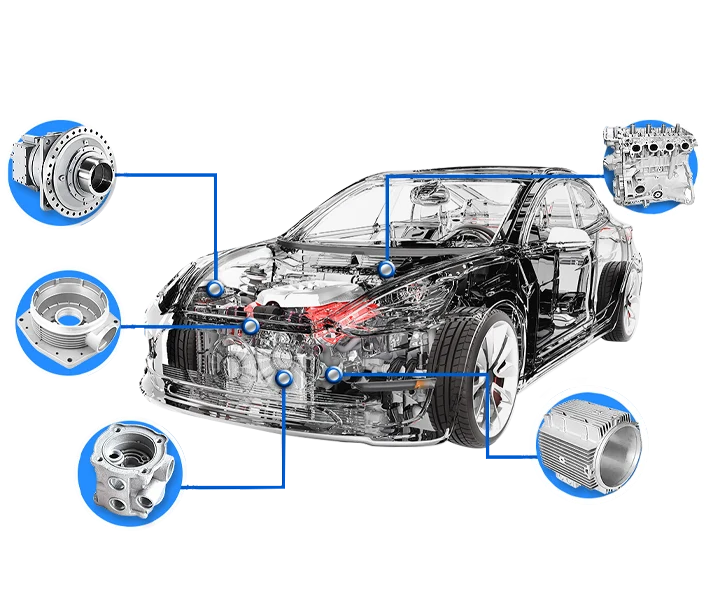

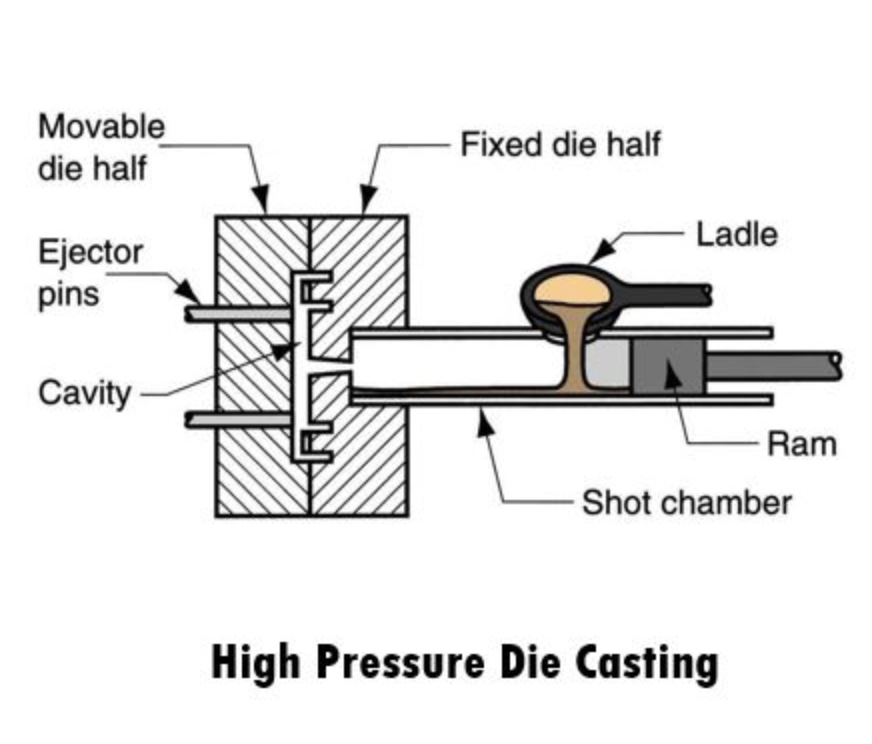

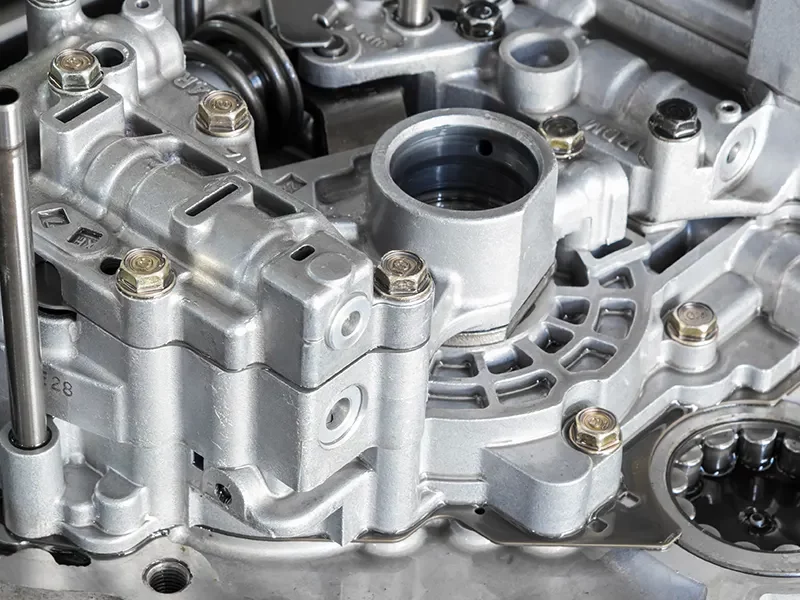

Die casting mold is a permanent mold that is used to shape molten metal into a specific design or shape. It is a crucial component in the die casting process, as it determines the final outcome of the part being manufactured. The mold is typically made from high-quality steel materials to withstand high temperatures and pressure.

Die casting mold consists of two parts: the cavity, which is the negative image of the final part, and the core, which shapes the internal features of the part. The mold is designed to allow molten metal to flow into the cavity under high pressure, solidify, and then be ejected as a finished part.

Why is Mold Important for Die Casting?

The mold is essential for maintaining the dimensional accuracy and surface finish of the final part. It also plays a crucial role in ensuring the structural integrity of the part. Without a properly designed mold, the die casting process would not be able to produce parts with the required precision and quality.

General Steel Materials For Die Casting Molds

Aluminum,zinc and magnesium are three common alloys used for die casting mould design.

Aluminum Alloy Die Casting Mold

Aluminum is a popular choice for die casting molds due to its excellent thermal conductivity and lightweight properties. Aluminum die casting molds are ideal for high-volume production runs and can withstand repeated cycles of heating and cooling without warping or cracking.

Zinc Alloy Die Casting Mold

Zinc alloys are commonly used for die casting molds due to their superior flow properties and high dimensional stability. Zinc molds are durable and resistant to corrosion, making them ideal for producing parts with intricate designs and thin walls.

Magnesium Alloy Die Casting Mold

Magnesium alloys are lightweight and have excellent strength-to-weight ratio, making them ideal for die casting mold material that require high strength and durability. Magnesium molds can withstand extreme temperatures and provide excellent surface finish.

Mold Design Process for Die Casting

The mold design process for die casting is a critical aspect of the overall die casting process, as it directly impacts the quality, efficiency, and cost-effectiveness of producing die cast parts. Here is an overview of the typical mold design process for die casting:

#1: Define Part Requirements

Begin by understanding the specific requirements of the part to be die cast, including dimensions, features, material properties, and production volume. This information will help guide the mold design process and ensure that the mold meets the desired specifications.

#2: Material Selection

Choose the appropriate material for the die casting mold based on factors such as thermal conductivity, wear resistance, thermal expansion, and cost. Common materials for die casting molds include tool steel, H13, and P20.

#3: Create Initial Design Concepts

Based on the part requirements and material selection, develop initial design concepts for the mold. Consider factors such as parting line location, gating system design, cooling channel placement, ejection methods, and venting options.

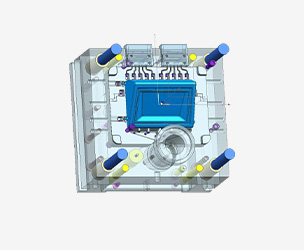

#4: CAD Modeling

Use computer-aided design (CAD) software to create detailed 3D models of the die casting mold components, including the cavity, core, cooling channels, ejector system, and other features. CAD modeling allows for precise and accurate representation of the mold design.

#5: Analyze and Optimize Design

Conduct simulations and analysis using specialized software to evaluate the mold design for factors such as thermal performance, fluid flow, shrinkage and warpage, and mold filling characteristics. This helps optimize the mold design for efficient and effective die casting production.

#6: Finalize Mold Design

Based on the analysis results and feedback, refine and finalize the mold design to ensure that it meets all requirements for part quality, production efficiency, and mold longevity. Pay attention to details such as draft angles, fillets, surface finish, and part ejection features.

#7: Create Detailed Drawings

Generate detailed engineering drawings and specifications for the die casting mold components, including dimensions, tolerances, materials, surface treatments, and assembly instructions. These drawings serve as the blueprint for manufacturing the mold.

#8: Manufacture the Mold

Transfer the finalized mold design to a mold manufacturer for fabrication. The manufacturing process may involve various techniques such as CNC machining, EDM (electrical discharge machining), grinding, heat treatment, and polishing to create the mold components.

#9: Test and Validate the Mold

Once the mold is fabricated, conduct testing and validation to ensure that it meets the required specifications and produces high-quality die cast parts. Test the mold for factors such as part dimension accuracy, surface finish, cycle time, and overall performance.

#10: Fine-tune and Refine

Based on the test results and feedback, make any necessary adjustments or refinements to the mold design to optimize performance and address any issues. Iterative improvement is common to achieve the best results in die casting production.

#11: Implement into Production

Once the mold design has been validated and approved, integrate it into the die casting production process for regular use. Monitor the performance of the mold during production runs and conduct regular maintenance to ensure its longevity and reliability.

By following a structured mold design process for die casting, manufacturers can create high-quality molds that meet the specific requirements of the parts to be produced, optimize production efficiency, and ensure consistent and reliable die casting production.

Challenges in Die Casting Mold Manufacturing

Die casting mold manufacturing poses several challenges, such as achieving tight tolerances, controlling porosity, minimizing flash, and preventing warpage.

Relentless Pursuit of Achieving Tight Tolerances

One of the most significant hurdles in die casting mold design is the relentless pursuit of achieving tight tolerances. Ensuring that the dimensions, angles, and specifications of the final part are met with utmost precision demands meticulous attention to detail and technical expertise. Any deviation from the desired tolerances can result in defective parts and production delays, highlighting the criticality of this challenge in the manufacturing process.

Controlling Porosity

Controlling porosity is another vital challenge that die casting mold manufacturers face. Porosity refers to the presence of small voids or holes within the material of the part, which can compromise its structural integrity and aesthetic appeal. Preventing porosity requires a comprehensive understanding of metal alloy properties, optimal casting parameters, and effective mold design to minimize the risk of air entrapment during the casting process.

Minimizing Flash, or Excess Material

Minimizing flash, or excess material that forms along the parting lines of the mold, is a persistent challenge in die casting mold manufacturing. Flash not only detracts from the visual appeal of the final part but can also affect its functional performance. Implementing precise mold designs, maintaining consistent casting conditions, and employing advanced trimming techniques are essential strategies to combat flash and ensure the production of high-quality parts.

Preventing Warpage

Preventing warpage is another common challenge that die casting mold manufacturers encounter. Warpage refers to the distortion or deformation of the part due to uneven cooling rates, internal stresses, or material inconsistencies. Addressing warpage requires a holistic approach that includes optimizing the cooling system design, controlling the casting process parameters, and utilizing stress-relieving techniques to mitigate the risk of distortion in the final product.

Bian Diecast: A Trustworthy Die Casting Mould Manufacturer

When selecting a die casting mold manufacturer, it is essential to consider their experience, expertise, capabilities, and quality control measures. Look for a manufacturer that has a proven track record of delivering high-quality molds on time and within budget.

With a rich history of excellence and expertise in die casting mold manufacturing, Bian Diecast has earned a stellar reputation for delivering top-notch molds that meet the highest industry standards. At Bian Diecast, precision is not just a goal but a guiding principle in every aspect of their mold manufacturing process. Our team of skilled craftsmen and engineers meticulously design and fabricate molds with tight tolerances, ensuring that each part produced meets the exact specifications and requirements of their clients. Partnering with Bian Diecast guarantees a seamless and successful manufacturing process, paving the way for the production of high-quality parts that meet and exceed expectations.

Conclusion

Die casting mold is a critical component in the die casting process, playing a vital role in shaping metal parts with precision and accuracy. Understanding the importance of mold design, materials selection, quality control measures, and overcoming manufacturing challenges is essential for producing high-quality die cast parts. By selecting a reliable and experienced die casting mold manufacturer, companies can ensure the success of their die casting operations.