Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This process allows for the production of complex shapes with high levels of accuracy and precision. Die casting plays a crucial role in various industries by providing cost-effective solutions for mass production. In this blog, we will delve into its application, benefits, materials used in die casting.

What is Die Casting Used For?

Die casting is commonly used to produce metal parts for a wide range of applications. From automotive die casting parts to electronic devices, die casting is a versatile method that meets the demand for complex and intricately designed die casting products.

Common Die Casting Applications

Die casting is widely used across various industries for producing a diverse range of components. Some of the most common applications include:

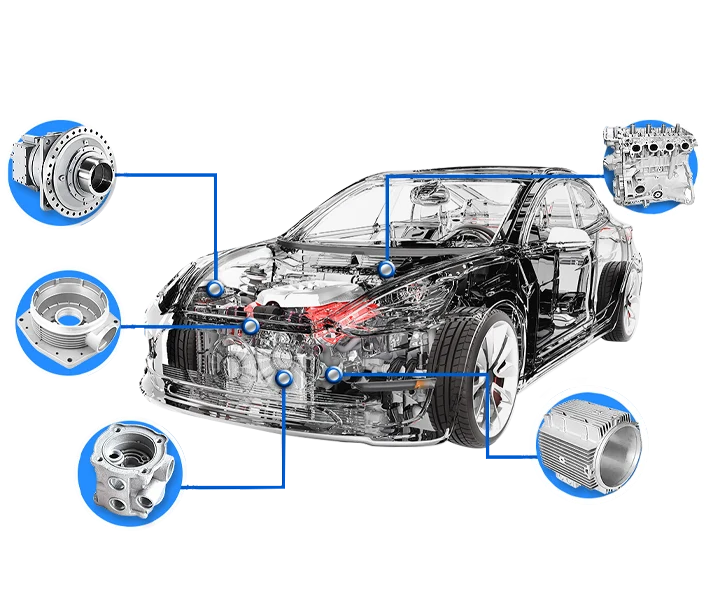

Automotive Industry

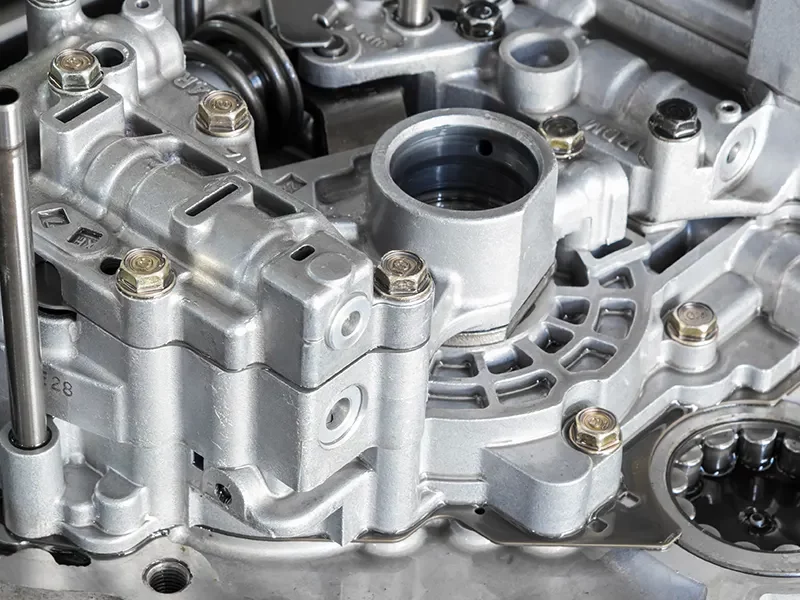

The automotive sector heavily relies on die casting for the fabrication of critical components such as engine parts, transmission components, chassis elements, and more. The high strength-to-weight ratio and dimensional accuracy of die-cast parts make them indispensable in ensuring the safety, performance, and reliability of vehicles on the road. From high-pressure engine components to intricate chassis elements, die casting continues to revolutionize the automotive manufacturing landscape.

Aerospace Industry

In the aerospace sector, where precision, reliability, and lightweight properties are paramount, die casting emerges as a vital manufacturing process. The aerospace industry leverages die casting to produce lightweight components that adhere to stringent performance requirements. From aircraft engine parts to structural components, die-cast components play a crucial role in enhancing the efficiency and safety of aerospace systems, contributing to the advancement of air travel technologies.

Electronics Industry

The electronics industry extensively utilizes die casting for the fabrication of housing, heat sinks, and various components for electronic devices. The superior thermal conductivity and dimensional stability offered by die-cast parts make them an ideal choice for maintaining optimal performance, heat dissipation, and reliability in electronic applications. From intricate electronic enclosures to heat management solutions, die casting plays a vital role in ensuring the functionality and longevity of electronic devices we use in our daily lives.

The versatility of die casting extends far beyond these industries, with applications spanning from consumer goods to industrial equipment. As die casting manufacturerscontinue to innovate and refine die casting processes, the potential for new applications and advancements in existing industries remains limitless.

Types of Die Casting Processes

The following are three common types of die casting processes:

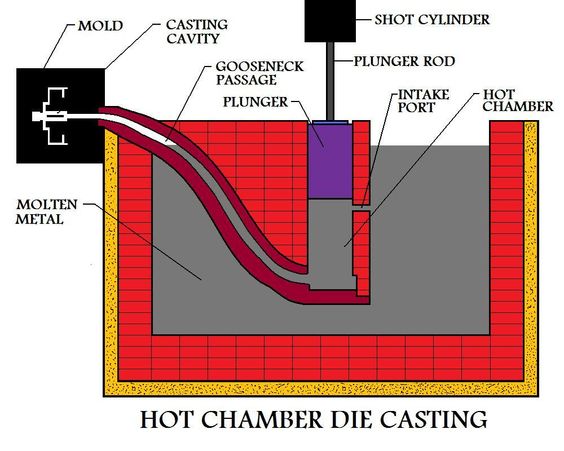

Hot chamber Die Casting

In hot chamber die casting, the injection system is immersed in a pool of molten metal. This process is ideal for metals with low melting points, such as zinc and magnesium. The molten metal is forced into the mold cavity under pressure, resulting in fast cycle times and high productivity.

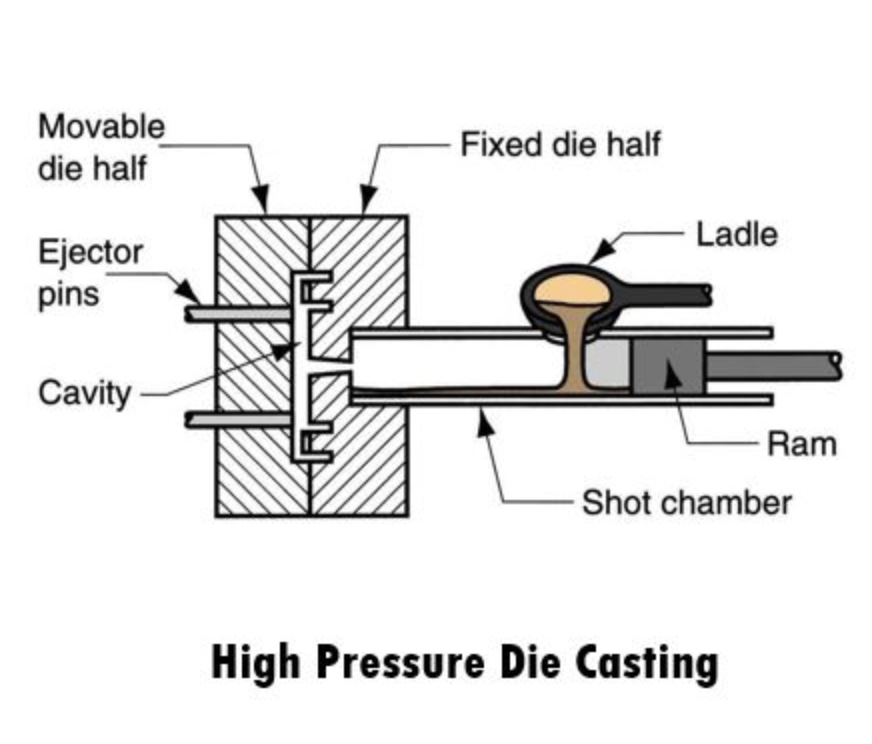

Cold chamber Die Casting

Cold chamber die casting involves melting the metal in a separate furnace before transferring it to the injection system. This process is suitable for metals with high melting points, such as aluminum. Cold chamber die casting allows for the production of more intricate parts with higher strength and durability.

Multi-slide Die Casting

Multi-slide die casting uses multiple slides to create intricate shapes and designs. This process is often used for parts with complex geometries or features that require precise detailing. Multi-slide die casting enhances the production capabilities of die casting by allowing for the creation of intricate and detailed parts.

What Are the Advantages of Die Casting?

Die casting offers several advantages that make it a preferred manufacturing method for many industries. Some of the key benefits include:

High Precision and Intricacy

Die casting excels in the production of intricate shapes and components with remarkably tight tolerances. The process allows for the creation of complex geometries and intricate designs with unparalleled precision. This level of accuracy ensures that each part adheres to the required specifications, maintaining consistent quality across production runs.

Cost-Effective Production

One of the primary advantages of die casting lies in its cost-effectiveness for large-volume production. The process is highly efficient, enabling the rapid manufacturing of numerous parts at a lower cost per unit. The high-speed production capabilities of die casting help in minimizing labor costs and reducing material waste, making it a cost-effective solution for mass production scenarios.

Quick Cycle Times

Die casting boasts rapid cycle times, meaning that parts can be produced at a swift pace. The quick turnaround time offered by die casting is instrumental in meeting demanding production schedules, accommodating tight deadlines, and fulfilling urgent orders. The efficiency of die casting in terms of cycle times ensures timely delivery of parts, keeping manufacturing operations running smoothly.

Superior Mechanical Properties

Die-cast parts exhibit excellent mechanical properties, including high tensile strength, durability, and dimensional stability. The metallurgical properties of die-cast components contribute to their superior performance characteristics, making them ideal for applications that require robust and reliable parts. From critical automotive components to intricate electronic devices, the mechanical properties of die-cast parts enhance their functionality and longevity.

Versatility and Design Flexibility

Die casting offers a high degree of versatility and design flexibility, allowing for the creation of complex shapes, thin walls, and intricate details. Manufacturers can achieve unique designs and innovative solutions through die casting, enabling the production of customized parts that meet specific requirements and aesthetic considerations.

Materials Used in Die Casting

Die casting can be performed with a variety of metals, but the most common materials used include:

Aluminum Die Casting

Aluminum is lightweight yet durable, making it an ideal choice for applications that require strength and flexibility. Aluminum die casting is commonly used in the automotive and aerospace industries for producing components that require high strength-to-weight ratios.

Zinc Die Casting

Zinc is a versatile material that offers excellent corrosion resistance and dimensional stability. Zinc die casting is often used for consumer electronics, household appliances, and medical devices due to its low cost and ease of casting.

Magnesium Die Casting

Magnesium is the lightest structural metal available, making it ideal for applications that require lightweight components with high strength and impact resistance. Magnesium die casting is commonly used in the automotive industry for producing parts that require excellent thermal conductivity and strength-to-weight ratios.

Conclusion

Die casting is a versatile and efficient manufacturing process that offers numerous advantages for producing high-quality metal parts. From automotive to aerospace industries, die casting plays a critical role in meeting the demand for complex and intricately designed components. With advancements in technology and materials, the future possibilities in die casting are boundless, paving the way for innovative solutions and enhanced manufacturing capabilities.

Partnering with Bian Diecast: A Reliable Aluminium Die Casting Manufacturers

Bian Diecast has established a strong reputation as a leading aluminium die casting manufacturer, consistently delivering high-quality components that meet the stringent requirements of various industries. With a focus on precision, efficiency, and customer satisfaction, Bian Diecast has become a preferred partner for companies seeking top-tier aluminium die casting solutions. Bian Diecast is the perfect partner to help you achieve your production goals and drive success in your industry.