In the world of manufacturing and fabrication, CNC routing has revolutionized the way we create intricate and precise designs. With the help of advanced technology, CNC routing machines can cut and shape a wide range of materials with unparalleled accuracy and efficiency. In this article, we will explore the ins and outs of CNC routing, from its basic principles to its applications in various industries.

What Is CNC Routing?

CNC routing stands for Computer Numerical Control routing, which refers to the process of using a computer-controlled machine to cut and shape materials according to a pre-programmed design. This technology allows for precise and consistent results, making it ideal for manufacturing complex parts and components.

What Is a CNC Router Machine

A CNC router machine is a type of CNC routing machine that is specifically designed for cutting and shaping materials such as wood, metal, plastic, and composites. These machines consist of a cutting tool attached to a computer-controlled system that guides the tool along a predetermined path to create the desired shape or design.

How CNC Machines Work?

CNC machines work by interpreting a digital design file and using that information to control the movement of the cutting tool. The operator inputs the design parameters into the computer system, which then translates the instructions into precise movements of the cutting tool. This level of automation allows for increased accuracy and efficiency in the manufacturing process.

Step-by-Step Process of CNC routing

- Inputting the Design: The first step in the operation of a CNC machine involves inputting the design parameters into the computer system. This digital design file serves as the blueprint for the cutting and shaping process.

- Interpreting the Instructions: Once the design file is uploaded, the computer system interprets the instructions and converts them into precise movements of the cutting tool. This translation ensures that the final product matches the design specifications with accuracy.

- Guiding the Tool: The CNC machine guides the cutting tool along the predetermined path outlined in the design file. The tool moves along the x, y, and z axes, following the programmed instructions to create the desired shape or pattern.

- Executing the Cutting Process: As the cutting tool moves across the material, it removes excess material in a series of precise movements. This cutting process is repeated until the final shape or design is achieved, resulting in a finished product that meets the exact requirements of the design.

- Monitoring the Operation: Throughout the cutting process, the CNC machine continuously monitors and adjusts the cutting parameters to ensure consistency and accuracy. This real-time feedback mechanism helps to optimize the cutting operation and maintain quality control.

- Completing the Task: Once the cutting process is complete, the CNC machine stops the operation, and the finished product is ready for further processing or assembly. The efficiency and precision of CNC machines make them indispensable tools in the manufacturing industry.

Types of CNC Routing Machines

There are several types of CNC routing machines available, each with its own unique capabilities and applications.

A. 3-Axis Machines

Starting with the 3-axis CNC routing machines, these systems are equipped with the capability to move the cutting tool along three primary axes – x, y, and z. This fundamental configuration allows for basic cutting and shaping operations, making them versatile and suitable for a broad range of applications. 3-axis machines are commonly used for tasks such as profiling, engraving, and carving on various materials.

B. 4-Axis Machines

Moving on to the 4-axis CNC routing machines, these systems take a step further by incorporating an additional rotary axis into the mix. In addition to the three primary axes, 4-axis machines are able to rotate the cutting tool along a fourth axis, providing enhanced capabilities for creating more complex designs and shapes. With the ability to maneuver around curved surfaces and intricate contours, 4-axis machines are well-suited for applications that require a higher level of precision and detail.

C. 5-Axis Machines

At the forefront of CNC routing technology are the 5-axis machines, renowned for their unparalleled precision and versatility. In addition to the standard three axes, 5-axis machines boast the ability to tilt and rotate the cutting tool along two additional axes. This advanced level of maneuverability allows for the production of highly intricate and detailed designs with ease. 5-axis machines are often used in industries such as aerospace, automotive, and prototyping, where complex geometries and smooth contours are essential.

Advantages and Disadvantages of CNC Routing

Advantages of CNC Routing

- Precision: CNC routing machines offer exceptional accuracy, ensuring that products align precisely with design specifications. This is crucial in industries requiring tight tolerances and intricate details.

- Efficiency: CNC routing streamlines production processes, reducing time and labor costs through automation. It boosts productivity while maintaining high-quality output.

- Versatility: Versatile CNC routers can handle various materials like wood, metal, plastic, and composites, catering to a wide range of industries and applications.

- Customization: CNC routing allows for easy creation of customized and intricate designs by programming cutting paths. This flexibility meets specific design requirements efficiently.

- Consistency: CNC routers deliver consistent quality across production runs, ensuring uniformity and meeting high standards in industries like automotive and electronics.

- Cost-Effectiveness: Despite the initial investment, CNC routing provides long-term cost savings through reduced waste, enhanced efficiency, and scalability for adapting to market demands.

Disadvantages of CNC Routing

- Complexity: Operating and programming CNC routing machines require specialized skills and training, which can be a barrier for some businesses without the necessary expertise.

- Cost: The initial investment in CNC routing equipment can be significant, making it a substantial financial commitment for small businesses or those with limited budgets.

- Maintenance: CNC routing machines require regular maintenance and upkeep to ensure optimal performance, which can add to the overall operating costs and downtime.

- Limited Flexibility: While CNC routing machines offer versatility in material cutting, they may have limitations in terms of the size and shape of the workpiece they can handle, restricting some design possibilities.

What Materials Can Be Cut on a CNC Router?

CNC routers can cut a wide range of materials, including wood, metal, plastic, acrylic, and composites. This versatility makes them ideal for a variety of industries, from woodworking to aerospace.

- Woods: CNC routers excel at cutting a variety of wood types, including hardwoods like oak, maple, and walnut, as well as softer woods such as pine and cedar.

- Plastics: CNC routers are also adept at cutting different types of plastics, such as acrylic, PVC, polycarbonate, and nylon.

- Metals: While not all CNC routers are designed to cut metals, some models equipped with the necessary tools and features can handle aluminum, brass, copper, and other soft metals.

- Composites: CNC routers are commonly used for cutting composite materials like fiberglass, carbon fiber, and laminates

- Foam and Foam-like Materials: CNC routers can also cut foam and foam-like materials, such as expanded polystyrene (EPS) and polyurethane foam.

Applications of CNC Routing

The versatility and efficiency of CNC routers make them indispensable tools for a wide range of applications, enabling manufacturers to achieve complex designs, streamline production processes, and enhance product quality.

Woodworking

CNC routing technology has established itself as a cornerstone in the woodworking industry, providing woodworkers with the tools and capabilities needed to create intricate designs, cut complex shapes, and produce custom furniture and cabinetry. From crafting decorative millwork to designing bespoke furniture pieces, CNC routers offer precision cutting and shaping capabilities that elevate woodworking craftsmanship to new heights of creativity and precision.

Metal Fabrication

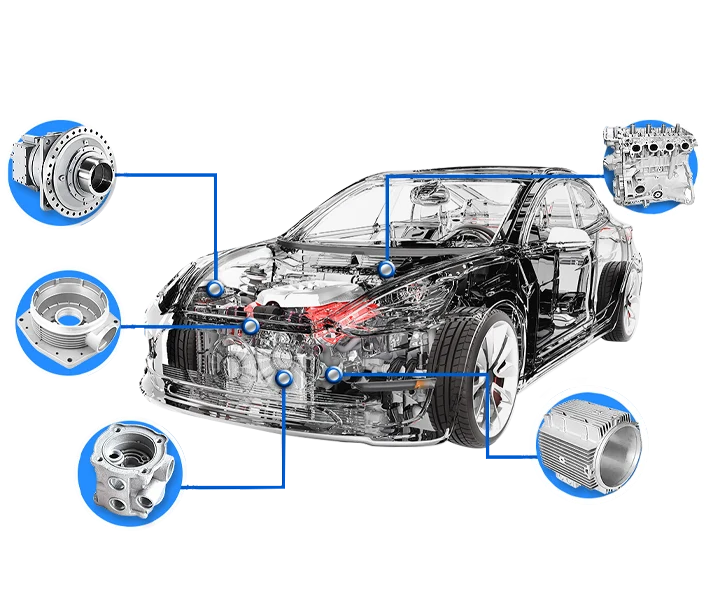

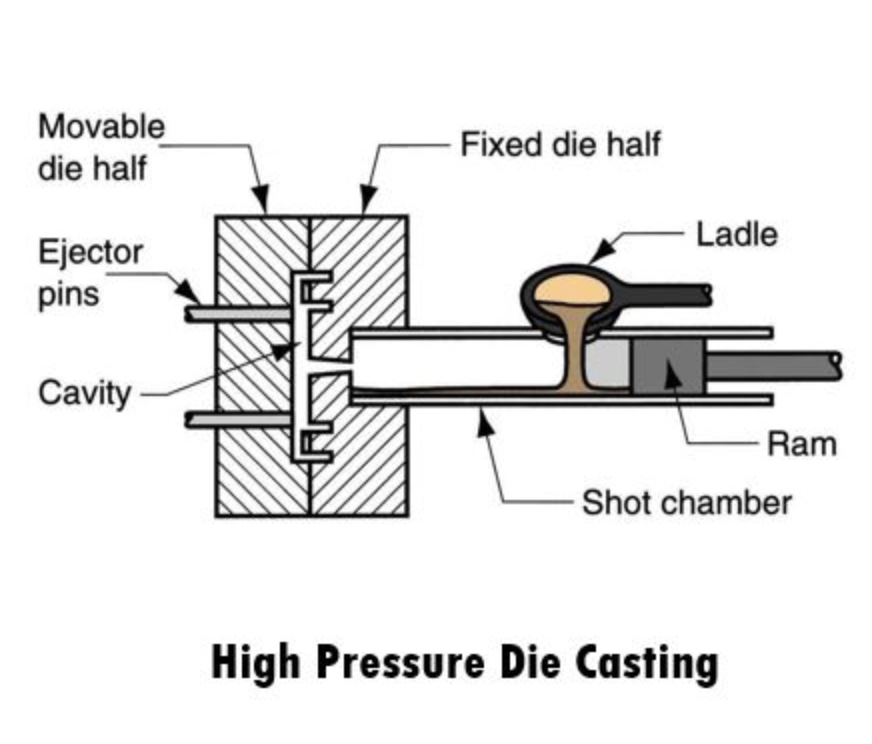

In the realm of metal fabrication, CNC routing technology plays a pivotal role in the production of metal parts with exceptional precision and accuracy. By utilizing CNC routers, metal fabricators can cut and shape metal components, including those used in aluminum die casting, with meticulous detail and consistency. The ability to create intricate designs and precise cuts makes CNC routing an indispensable tool for manufacturing components for diverse industries, from automotive and aerospace to electronics and machinery.

Plastic Fabrication

Similarly, CNC routing technology finds widespread application in the plastic fabrication industry, where it is utilized to cut and shape plastic parts, molds, and prototypes with unparalleled precision and repeatability. From creating custom signage and displays to producing intricate plastic components for various products, CNC routers enable plastic fabricators to achieve high-quality results efficiently and cost-effectively. The versatility of CNC routing in handling different types of plastics makes it a versatile solution for meeting the diverse needs of the plastic fabrication sector.

Collaborate With Bian Die Cast

If you’re looking for a one-stop aluminum die casting manufacturer that offers die casting, CNC machining, and finishing services, look no further than Bian Die Cast. With years of experience and expertise in the industry, Bian Die Cast is committed to providing high-quality products and exceptional customer service.

Conclusion

In conclusion, CNC routing is a powerful technology that has transformed the manufacturing industry by providing unmatched precision, efficiency, and versatility. Whether you’re in woodworking, metal fabrication, or plastic fabrication, CNC routing machines offer a cost-effective solution for producing complex parts and components with ease. Partnering with a trusted manufacturer like Bian Die Cast can help you take your project to the next level and achieve success in your manufacturing endeavors.