Casting processes have been vital in the manufacturing industry for centuries, allowing for the creation of complex and intricate metal components. From sand casting to precision casting, there are various methods used to produce high-quality casting parts for a wide range of industries. In this article, we will explore 11 different types of casting processes, providing insights into the advantages and disadvantages of each method.

Table Comparing the 11 Types of Casting Processes

| Casting Process | Production Volume | Material Suitability | Cost |

| Sand Casting | Low to High | Versatile | Low |

| Die Casting | High | Aluminum, Zinc | High |

| Investment Casting | Low to Medium | Steel, Aluminum | High |

| Gravity Die Casting | Medium to High | Aluminum, Copper | Moderate |

| Vacuum Casting | Low to Medium | Intricate Parts | High |

| Continuous Casting | High | Steel, Aluminum | High |

| Shell Molding | Medium to High | Aluminum, Copper | Moderate |

| Lost-Foam Casting | Low to Medium | Aluminum, Iron | Moderate |

| Centrifugal Casting | Low to Medium | Cylindrical Parts | Moderate |

| Permanent Mold Casting | Medium to High | Aluminum, Magnesium | High |

| Squeeze Die Casting | High | Thin-Walled Parts | Moderate |

Sand Casting

What is Sand Casting?

Sand casting is one of the oldest and most widely used casting processes in the industry. It involves creating a mold made of sand, into which molten metal is poured to create the desired shape. Once the metal has solidified, the sand mold is broken apart to reveal the final part.

Pros and Cons of Sand Casting

One of the main advantages of sand casting is its versatility, allowing for the production of large, complex parts with relatively low tooling costs. However, sand casting can be time-consuming and may result in lower dimensional accuracy compared to other casting methods.

Die Casting

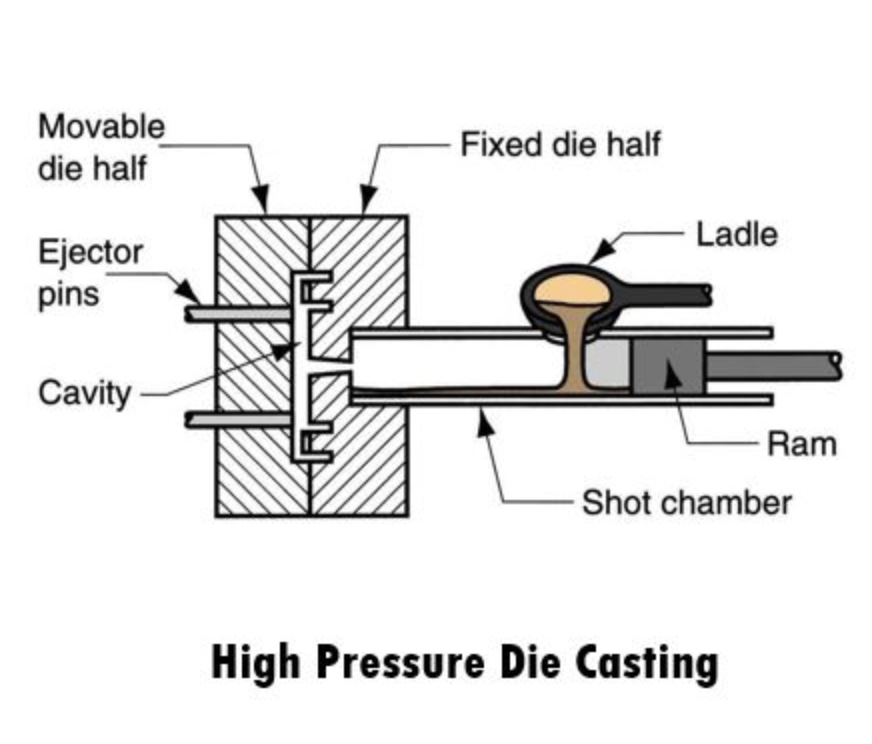

What is Die Casting?

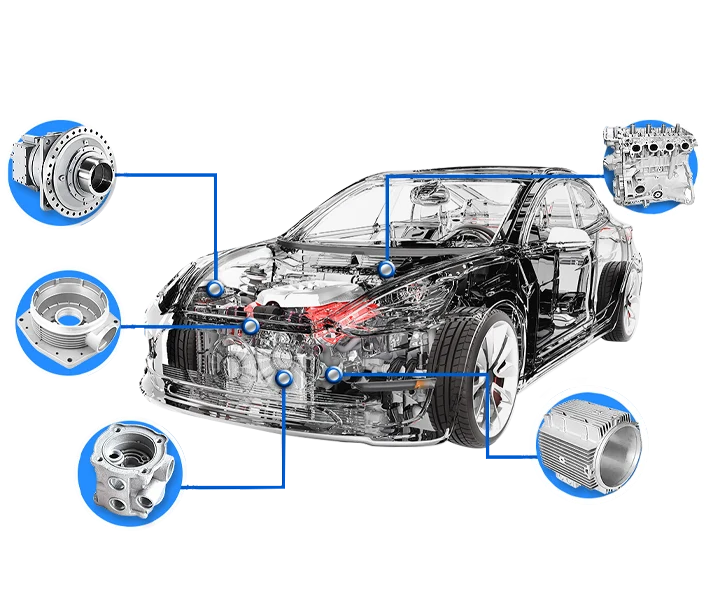

Die casting is a metal casting process that involves injecting molten metal into a steel mold, known as a die. This type of metal casting is widely used for producing high-volume parts with excellent surface finish and dimensional accuracy, such as automatic parts, lighting parts and electronic parts.

Pros and Cons of Die Casting

Die casting offers high production rates and tight tolerances, making it ideal for mass production. However, the initial tooling costs can be significant, and die casting may not be suitable for all types of alloys. To learn more, see our guide on die casting.

Investment Casting

What is Investment Casting?

Investment casting, also known as lost-wax casting, is a process that involves creating a wax pattern, coating it with ceramic, and then melting the wax to create a mold. Molten metal is then poured into the ceramic mold to produce the final part.

Pros and Cons of Investment Casting

Investment casting allows for the production of intricate parts with high accuracy and smooth surface finish. However, it can be expensive and time-consuming, making it more suitable for small to medium-sized production runs.

Gravity Die Casting

What is Gravity Die Casting?

Gravity die casting is a time-tested casting of metal process that uses a permanent mold made of metal to produce parts under gravity pressure. This metal casting method is often used for producing large, symmetrical parts with high structural integrity.

Pros and Cons of Gravity Die Casting

Gravity die casting offers excellent dimensional accuracy and mechanical properties, making it suitable for high-strength applications. However, the initial tooling costs can be high, and the process may not be as cost-effective for small production runs.

Vacuum Casting

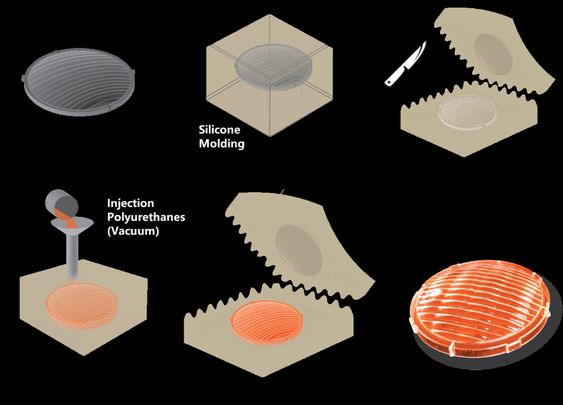

What is Vacuum Casting?

Vacuum casting is a variation of investment casting that involves using a vacuum to draw molten metal into the mold cavity. This method is often used for producing parts with intricate details and thin walls.

Pros and Cons of Vacuum Casting

Vacuum casting offers high precision and surface finish, making it ideal for producing complex parts with tight tolerances. However, the process can be expensive, and the risk of porosity in the final part may be higher compared to other casting methods.

Continuous Casting

What is Continuous Casting?

Continuous casting is a method used for producing long, continuous lengths of metal by pouring molten metal into a water-cooled mold. This process is commonly used for producing steel and aluminum billets, slabs, and rods.

Pros and Cons of Continuous Casting

Continuous casting offers high production rates and improved mechanical properties in the final product. However, the process requires specialized equipment and may not be suitable for all types of metals and alloys.

Shell Molding

What is Shell Molding?

Shell molding, also known as shell casting, is a process that uses a resin-coated sand shell to create the mold cavity. Molten metal is then poured into the mold to produce the final part, with the shell providing excellent surface finish and dimensional accuracy.

Pros and Cons of Shell Molding

Shell molding offers high production rates and can produce parts with complex geometries. However, the process may require additional steps compared to other casting methods, and the tooling costs can be higher.

Lost-Foam Casting

What is Lost-Foam Casting?

Lost-foam casting is a process that uses a foam pattern coated with refractory material to create the mold. When the molten metal is poured into the mold, the foam pattern vaporizes, leaving behind the final part.

Pros and Cons of Lost-Foam Casting

Lost-foam casting allows for the production of complex parts with tight tolerances and minimal machining requirements. However, the process can be expensive and may have limitations in terms of part size and material compatibility.

Centrifugal Casting

What is Centrifugal Casting?

Centrifugal casting is a method used for producing cylindrical parts by pouring molten metal into a rotating mold. The centrifugal force helps to distribute the metal evenly, resulting in parts with high density and excellent mechanical properties.

Pros and Cons of Centrifugal Casting

Centrifugal casting offers high cast metal quality and is well-suited for producing hollow parts with uniform wall thickness. However, the process may be limited to certain part geometries, and the tooling costs can be higher compared to other casting methods.

Permanent Mold Casting

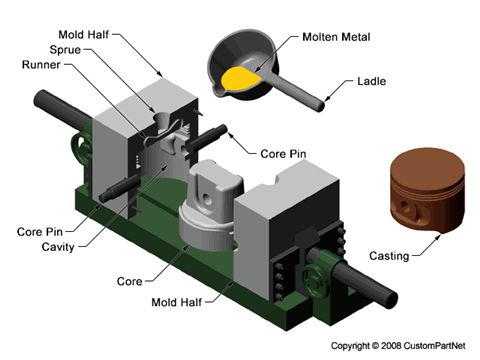

What is Permanent Mold Casting?

Permanent mold casting, also known as gravity die casting, involves using a reusable metal mold to produce parts. The molten metal is poured into the mold cavity, where it solidifies to create the final part.

Pros and Cons of Permanent Mold Casting

Permanent mold casting offers high productivity rates and excellent surface finish, making it ideal for producing high-quality parts with tight tolerances. However, the initial tooling costs can be significant, and the process may not be suitable for all types of alloys.

Squeeze Die Casting

What is Squeeze Die Casting?

Squeeze die casting is a variation of the die casting process that involves applying additional pressure to the molten metal to ensure complete filling of the mold cavity. This method is often used for producing parts with thin walls and intricate details.

Pros and Cons of Squeeze Die Casting

Squeeze die casting offers improved part density and reduced porosity, resulting in parts with higher strength and durability. However, the process may be more expensive and complex compared to traditional die casting methods.

What Is Casting?

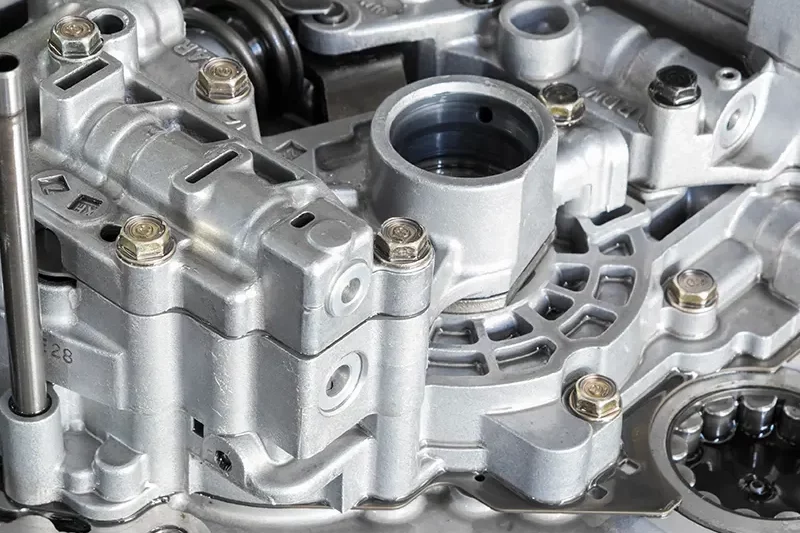

Casting is a manufacturing process that involves pouring molten metal into a mold to create a specific shape or form. This method is widely used in various industries, including automotive, aerospace, and construction, to produce parts with complex geometries and superior mechanical properties.

How Does Casting Work?

Casting works by creating a mold that matches the desired shape of the final part. Molten metal is then poured into the mold cavity, where it solidifies to form the finished part. Once the metal has cooled and hardened, the mold is removed, leaving behind the cast part.

What Are the Materials Used in Casting?

The materials used in casting can vary depending on the specific process and requirements of the part being produced. Common materials used in casting include aluminum, steel, iron, brass, and copper, among others. Each material offers unique properties and advantages for different applications.

How To Choose a Type of Casting Process?

When choosing the right type of casting process among the 11 different types of metal casting options, there are several key factors to consider. Here are some important points to keep in mind:

- Part Complexity: Consider the complexity of the part you need to produce. Some casting processes, such as investment casting and precision casting, are better suited for intricate and detailed parts, while others, like sand casting, may be more appropriate for simpler shapes.

- Production Volume: Think about the volume of parts you need to produce. For high-volume production runs, processes like die casting and permanent mold casting are ideal due to their high production rates and efficiency.

- Material Requirements: Consider the type of metal or alloy you plan to use for your parts. Certain casting processes may be better suited for specific materials. For example, centrifugal casting is often used for producing cylindrical parts from metals like steel and aluminum.

- Cost Constraints: Evaluate the initial tooling costs, production costs, and overall expenses associated with each casting process. Some methods may require higher upfront investments, but offer long-term cost savings in terms of production efficiency and part quality.

- Quality Control: Consider the level of precision and quality control required for your parts. Processes like precision casting and shell molding offer high dimensional accuracy and surface finish, making them suitable for critical applications that demand superior quality standards.

Choosing the Right Casting Manufacturers

Choosing the right casting manufacturer is crucial to ensure the quality and consistency of the final parts. Factors to consider when selecting a reliable casting manufacturer include their experience, capabilities, quality control processes, and ability to meet production deadlines. It is recommended to work closely with a reputable manufacturer who can provide guidance and support throughout the casting process.

Conclusion

In conclusion, there are various types of casting processes available for producing high-quality metal parts with complex geometries and superior mechanical properties. From sand casting to precision casting, each method offers unique advantages and disadvantages that should be carefully evaluated before selecting the most suitable process. By understanding the different casting techniques and considering factors such as part complexity, production volume, and material requirements, manufacturers can choose the right casting process to meet their specific needs and achieve optimal results.